Thingiverse

K8400 Rods Lengthwise Movement Stopper by Bo_Ris

by Thingiverse

Last crawled date: 4 years, 4 months ago

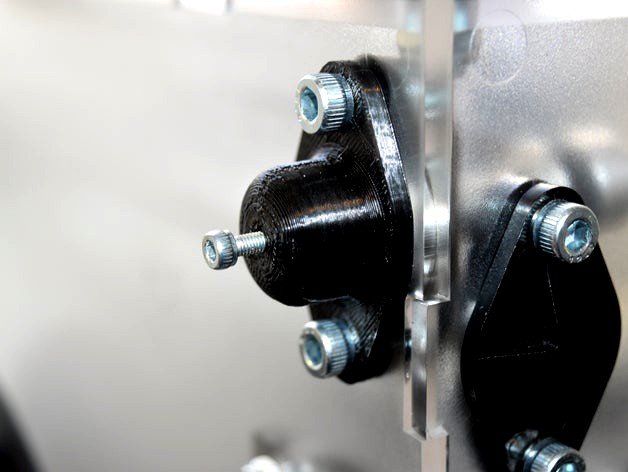

After using Vertex K8400 printer for about 6 months I discovered that rods started to move lengthwise due to worn out plastic end-caps. Several solutions addressing this have been posted here, but I decided to come up with my own that uses steel balls from old 608 bearings. The balls allow to minimize the area of contact with the rod, which reduces friction.

You will need 8 balls in total. One bearing contains 7 balls, so you will need to disassemble 2 bearings.

You will also need four M3x16mm cup-headed bolts and four M3 self-locking nuts.

Print 4 copies of rod_holder.stl. I printed small cylinder with 0.1mm resolution and bigger thing with 0.2mm. No support or brim is required. Infill 20%

Remove 4 end-cups - 2 from the front and 2 from the right side of the printer. Drill a recess in the very center of the end-cups with 3.5mm drill-bit. The depth should be between 1/3 and 1/2 of the ball diameter. Then glue the balls to the centers of end-cups as shown on the images.

Remove the remaining 4 end-cups. We will replace them with rod_holder things.

Place the M3 nut inside the bigger thing and fix it in this position with M3 bolt. Slide in the small cylinder into the bigger thing with cut edge facing the nut. Place the ball inside the small cylinder and mount this assembly to the printer. Make sure the ball does not fall out.

Once the glue dries mount the end-cups to the other ends of the rods. Tighten all end-cup mounting bolts. Finally tighten M3 cup-headed bolts just enough to stop rods' lengthwise movement.

You will need 8 balls in total. One bearing contains 7 balls, so you will need to disassemble 2 bearings.

You will also need four M3x16mm cup-headed bolts and four M3 self-locking nuts.

Print 4 copies of rod_holder.stl. I printed small cylinder with 0.1mm resolution and bigger thing with 0.2mm. No support or brim is required. Infill 20%

Remove 4 end-cups - 2 from the front and 2 from the right side of the printer. Drill a recess in the very center of the end-cups with 3.5mm drill-bit. The depth should be between 1/3 and 1/2 of the ball diameter. Then glue the balls to the centers of end-cups as shown on the images.

Remove the remaining 4 end-cups. We will replace them with rod_holder things.

Place the M3 nut inside the bigger thing and fix it in this position with M3 bolt. Slide in the small cylinder into the bigger thing with cut edge facing the nut. Place the ball inside the small cylinder and mount this assembly to the printer. Make sure the ball does not fall out.

Once the glue dries mount the end-cups to the other ends of the rods. Tighten all end-cup mounting bolts. Finally tighten M3 cup-headed bolts just enough to stop rods' lengthwise movement.