Thingiverse

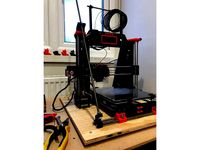

K8200 Z axis rework - cable driven by Brandano

by Thingiverse

Last crawled date: 3 years ago

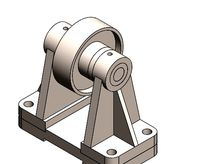

This is an evolution of my Z axis parallel drive, taking advantage of the cable to isolate the oscillations caused by a bent or misaligned threaded rod that normally show up as horizontal ridges in the print.

The Z axis motor is moved to the top of the frame, with the threaded rod placed horizontally and pulling on the cable sideways. To make space for it the top element of the frame is repositioned flush with the top of the columns, which means that two of the metal corner brackets have to be removed. I have added printed brackets that fit on both sides of the frames and also double as supports for the small pulleys, that should restore the lost rigidity.

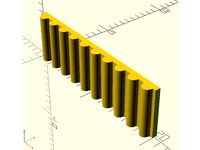

The cable I used is a steel clothesline covered by a 4mm plastic sheath, and the parts are dimensioned to get a good grip on it, but will need to be reworked for a different diameter. The cable also conflicts with the stock bolts that fix the LM10UU bearings to aluminium plate on the left of the carriage, I have replaced mine with flatter ones that barely clear the cable, but it would probably be better to use countersunk bolts.

I have re-designed the pulleys as well to have a reasonable overhang, but am currently using the ones from my earlier mod, so can't guarantee the new ones will work fine. They will probably require some adjustment.

The SCAD file makes use of some features that are only present in the latest development snapshots, specifically the rotation angle in the rotate_extrude() function, so thingiverse will not render it properly in its previews.

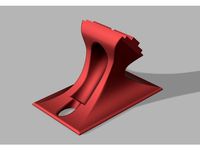

The part that holds the nut is built to house two of them, to handle the twisting load caused by the weight of the z axis. Currently it causes a fair deal of friction, and I had to increase the driver current to the z axis motor. I will probably rework it for a deeper and looser fit over the nut. Nylon M8 nuts would probably work better, I am still experimenting with this.

The Z axis motor is moved to the top of the frame, with the threaded rod placed horizontally and pulling on the cable sideways. To make space for it the top element of the frame is repositioned flush with the top of the columns, which means that two of the metal corner brackets have to be removed. I have added printed brackets that fit on both sides of the frames and also double as supports for the small pulleys, that should restore the lost rigidity.

The cable I used is a steel clothesline covered by a 4mm plastic sheath, and the parts are dimensioned to get a good grip on it, but will need to be reworked for a different diameter. The cable also conflicts with the stock bolts that fix the LM10UU bearings to aluminium plate on the left of the carriage, I have replaced mine with flatter ones that barely clear the cable, but it would probably be better to use countersunk bolts.

I have re-designed the pulleys as well to have a reasonable overhang, but am currently using the ones from my earlier mod, so can't guarantee the new ones will work fine. They will probably require some adjustment.

The SCAD file makes use of some features that are only present in the latest development snapshots, specifically the rotation angle in the rotate_extrude() function, so thingiverse will not render it properly in its previews.

The part that holds the nut is built to house two of them, to handle the twisting load caused by the weight of the z axis. Currently it causes a fair deal of friction, and I had to increase the driver current to the z axis motor. I will probably rework it for a deeper and looser fit over the nut. Nylon M8 nuts would probably work better, I am still experimenting with this.

Similar models

thingiverse

free

Uconduit - Move Z-axis motors and redesign Y-axis pulley mount by RCC1

...unts in the corner (see new red parts in picture).

will publish more pictures when it is completely back together and printing

thingiverse

free

Hictop Frame Reinforcement - Stabilize frame and reduces wobble and vibrations by igortopolski

...t bend that much.

if you like my design make sure you let me know in comments as i'd love to know what people think about it!

thingiverse

free

Delta Counterbalance by BobDavis73

... pulleys are sized for para-cord. if you use the corner tap an m5 thread into the center of the aluminum extrusion for mounting.

thingiverse

free

P3Steel z axis rod top MRZ105Z by galaverse

...05zz inserted in it and then the whole assembly would be inserted in the top hole in the frame, thus keeping the z axis centered.

thingiverse

free

Z Axis Tom Mount by nikolastsr

...ess nut in the upper part of the x-axis mounts.

this also improves the prints.the further away from the stepper motor the better.

thingiverse

free

Z Axis Nut Mount 8mm Traped Nut by Nitrogen777

...uld use stainless steel threaded rod and a steel nut.

this will stop the two binding also the nut will wear not the threaded rod.

thingiverse

free

HIC - Left side Z-X axis (motor side) by RCC1

...ight side, also see:

hic right side z-x axis bracket by rcc1, published may 12, 2018. https://www.thingiverse.com/thing:2907857

thingiverse

free

HIC Right side Z-X axis Bracket by RCC1

...ight side, also see:

hic - left side z-x axis (motor side) by rcc1, created may 28, 2018https://www.thingiverse.com/thing:2935161

thingiverse

free

Ormerod Trapeziodal Z Axis Mod (TR8x2) by MitchOrmerod

...is provided.

the goals of these ormerod designs were to make the ormerod quieter, and more robust to abuse, as it travels a lot.

thingiverse

free

Tronxy x5s single Z motor conversion by napo7

...the threaded rod version, but it can be cheaper and easier to source than leadscrew...

next version to come : with idler pulleys

Brandano

thingiverse

free

GT2 timing belt profile by Brandano

...gt2 timing belt profile by brandano

thingiverse

a couple of openscad functions to generate gt2 profile timing belts.

thingiverse

free

K8200/3Drag Z-axis wobble and backlash reducer by Brandano

...mpt at reducing z-wobble on the k8200. there is more detail about the concept and additional hardware needed in the instructions.

thingiverse

free

Belt holder for GT2 2mm pitch belt by Brandano

... the belt and (within reason) the diameter of the bolt can be adjusted in the scad file to fit other belts of the same thickness.

thingiverse

free

K8200/3DRAG extruder core with flex support and slot mount base by Brandano

...l

updated to easily switch between 3 and 1.75mm paths, and to replace steep overhangs with small bridges on recessed nut sockets.

thingiverse

free

Simple 80mm fan grille by Brandano

...llection the exported file. thanks to xoan for his help in the comments section, sometimes using slic3r is not exactly intuitive.

thingiverse

free

K8200/3DRAG Z axis stepper mount (rework of http://www.thingiverse.com/thing:232446) by Brandano

... easier to print) and with the mounting portion redesigned to fit the extrusion profile for greater rigidity and better alignment

thingiverse

free

3DRAG/K8200 Z axis cable driven parallel drive system by Brandano

...

there's a new, heavily reworked version here that completely rearranges the z axis:https://www.thingiverse.com/thing:1520729

thingiverse

free

K8200/3DRAG CoreXY mod by Brandano

...s are all inverted// compared to the stock drivers)#define invert_x_dir true#define invert_y_dir true#define invert_z_dir true

thingiverse

free

K8200/3Drag Z axis bearing support (rework of http://www.thingiverse.com/thing:175137) by Brandano

... a zip tie vertically around it. i will probably beef this up and maybe work out a way for the zip tie to be a permanent feature.

K8200

thingiverse

free

K8200 Mount

...k8200 mount

thingiverse

universal mounting bracket for velleman k8200 printers.

thingiverse

free

K8200 HANDLE by Zalex60

...k8200 handle by zalex60

thingiverse

handle for k8200 printer

thingiverse

free

k8200 belt tension by wreckless19

...k8200 belt tension by wreckless19

thingiverse

needed for k8200

thingiverse

free

k8200 handle by ralfselfjord

...k8200 handle by ralfselfjord

thingiverse

handle for carrying your k8200. to be mounted on the top rail with 2 bolts.

thingiverse

free

Support tablette K8200 by Zalex60

...support tablette k8200 by zalex60

thingiverse

support pour k8200

thingiverse

free

K8200 Pencil Holder by wallie

...k8200 pencil holder by wallie

thingiverse

k8200 pencil holder

thingiverse

free

vm8201 fixation k8200 by domeniconixavier

...vm8201 fixation k8200 by domeniconixavier

thingiverse

kit for printer screenshot 3d k8200

thingiverse

free

testing velleman K8200 by treblasnirp

...testing velleman k8200 by treblasnirp

thingiverse

velleman k8200 with abs settings in cura.

thingiverse

free

Fan Mount K8200 by telegnom

...fan mount k8200 by telegnom

thingiverse

additional fan mount for the k8200 3d-printer.

thingiverse

free

K8200 LCD-Panel by sharandac

...k8200 lcd-panel by sharandac

thingiverse

lcd-panel with sd-card support for the k8200.

Rework

3d_export

$25

riva aquarama 1970

...visualization, as well as, if desired, it can be reworkd for 3d printing. in the near future, a model...

3d_export

$8

Mosaic 1 3D Model

...outdoor indoor vector ceramic glass mosaic decorative mosaic manually reworkd into a vector. the image is then modified in...

3d_export

$65

sci-fi scene for rendering restyling - tesla

...colors with the name, metal, light metal, dark metal, reworkd renders for preview and processed in photoshop using a...

3d_export

$22

a filter assembly and inspection line

...laser marking station (op40), one packaging station (op50), one rework and pump water detection station (op60), and two assembly...

3d_export

$19

muuto raw chair

...the muuto raw chair.<br>raw chair is a striking functional reworkng of a recognizable everyday object. a part of the...

3d_export

$12

desert rocks stock in blender

...in obj format (non-textured), together with the textures, for reworkng them in other programs.<br>notes: the scene include 12 simple...

3d_export

$10

arclinea principia

...the essence, with the basic principles of the kitchen, reworkd: new steel technology and natural wood cutting. the extraordinary...

thingiverse

free

Doughnut Rework by Johhnny

...doughnut rework by johhnny

thingiverse

i reworked tzani's mobius doughnut for dual extrusion.

thingiverse

free

Beanie the Transformer rework by Whirl55

...beanie the transformer rework by whirl55

thingiverse

found and reworked head pin

and all files

thingiverse

free

AM10 - am8 rework Y

...am10 - am8 rework y

thingiverse

totaly rework to turn your am8 into an am10 with only 2 pieces

Driven

turbosquid

$50

CHAIN DRIVEN CONVEYOR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

driven shaft of the lump crusher

...driven shaft of the lump crusher

3dexport

3d_export

$27

n95 full servo driven mask printer

...n95 full servo driven mask printer

3dexport

n95 full servo driven mask printer

turbosquid

$16

(Project) Food packing helper machine with holding clamp and press table driven by an actuator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$47

the fifth generation of one driven two new mask machine

...ing, lamination, pressing, ear band tapping, ultrasonic, etc. the structure of the model is detailed, including model parameters.

3d_export

$15

industrial belt-driven air cooler

...leaning up necessary, just drop your models into the scene and start rendering/texturing. no special plugin needed to open scene.

3d_export

free

golf cart

...golf cart 3dexport golf cart for golfers to be driven in...

3d_export

$10

design and assembly of pulley

...pulley 3d model which is used for drive and driven ...

archive3d

free

Windmill 3D Model

...windmill 3d model archive3d wind turbine wind-driven powerplant wind-electric set windmill n181208 - 3d model (*.gsm+*.3ds)...

3d_export

$30

Compressed Air Engine 3D Model

...motor flywheel shaft camshaft piston valve block engineering compressed-air driven compressed air engine 3d model zenmunster 92451...

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Cable

3d_export

free

Cables

...cables

3dexport

cables for your purposes

3d_export

free

cable belt for cable organization

...ze your cables in 3d printers. it will bend only to one direction. the area to put the cables per piece is aprox. 1,6cmx2,6cmx1cm

3d_ocean

$16

Ethernet Cable

...ethernet cable

3docean

cable computer electronics ethernet internet network connected

ethernet cable 3d model

3d_export

$65

cable

...cable

3dexport

simple rendering of the scene file

turbosquid

$14

Cable

...l cable for download as ma, max, fbx, 3ds, gltf, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1631358)

3ddd

$1

Cable Cover

...cable cover

3ddd

кабель

vertebra passacavo - cable cover

max + vray 2.20.03

3d_export

$15

Cable reel

...without cable. textures 4k 4096x4096 targa, png, jpeg.<br>number of polygons without cable: 2896<br>with cable: 35328

3d_export

$7

short cable

...short cable

3dexport

rubber cord. very detailed. cable thickness: 2.55 mm total length: 55mm

3d_export

$5

USB CABLE

...usb cable

3dexport

turbosquid

$30

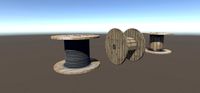

Cable Reels

...osquid

royalty free 3d model cable reels for download as fbx on turbosquid: 3d models for games, architecture, videos. (1439507)

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)