Thingiverse

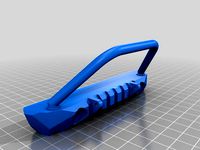

Jeep Crawler Body (SCX10 clone compatible) by WrenchToDrive

by Thingiverse

Last crawled date: 3 years, 4 months ago

Hi guys,

This is a fully 3D printable body shell to go with my earlier project, the Jeep Wrangler roll cage. It's SCX10 clone compatible but you can mod it to work with pretty much any crawler. The wheelbase is 313mm as pictured.

If you already built the roll cage or my 12428 crawler conversion floor boards, there are three small changes. First, the hood frame needs to have the front cross bar trimmed off, or print the file Hood_Frame_Clipped.stl included in this project. Second, this project comes with custom floor boards, but you can use a rotary tool to mod existing front section. Third, I included a round profile foot for the center roll bar which inserts into the hole in the floor boards for this project, but you can drill a hole in your existing one, or the floor boards that came with your crawler (with some planning on your part, of course).

Build video: https://youtu.be/zB_vW6kWlkE

Roll cage: https://www.thingiverse.com/thing:4610573

Bumper mount kit: https://www.thingiverse.com/thing:4617755

Stinger bumper: https://www.thingiverse.com/thing:4588243

Big beefy bumper: https://www.thingiverse.com/thing:4590968

Rear bumper: https://www.thingiverse.com/thing:4622429

Don't like this body? Want to build a 3D printed crawler? Check out my Baja racer project: https://www.thingiverse.com/thing:4597812

Instruction page coming soon. https://wrenchtodrive.blogspot.com/2020/12/jeep-cage-and-body-assembly-guide.html

See the exploded view for a rough guide. It's pretty easy. I used 6 M3x6-8mm screws but you can build the whole thing with hot glue without much trouble. As I show in the video, to make the doors and box easily removable, you will need two screws.

Durability shouldn't be terrible but a roll down a big hill will almost certainly rip off some parts (front fenders, I think for sure). As I've mentioned, the cage is pretty tough if you lay down the parts for printing and so far these parts have all been acceptably strong IMO.

I'm a little less than satisfied with the hood and cowl but I wanted to use the roll cage for this version so that's the best I could come up with and have it easy to take off. I thought the hood hinge would be easy but the cage is in the way, so no hinge for now. A piano hinge would work but it has to be quite large and I didn't like that alternative at all. I'm going to do a no cage version that will be one piece. The downside to that will be lack of durability, without a doubt. If that appeals to you, hold out until around January.

Use at your own risk.

Wrench to drive or drive to wrench?

This is a fully 3D printable body shell to go with my earlier project, the Jeep Wrangler roll cage. It's SCX10 clone compatible but you can mod it to work with pretty much any crawler. The wheelbase is 313mm as pictured.

If you already built the roll cage or my 12428 crawler conversion floor boards, there are three small changes. First, the hood frame needs to have the front cross bar trimmed off, or print the file Hood_Frame_Clipped.stl included in this project. Second, this project comes with custom floor boards, but you can use a rotary tool to mod existing front section. Third, I included a round profile foot for the center roll bar which inserts into the hole in the floor boards for this project, but you can drill a hole in your existing one, or the floor boards that came with your crawler (with some planning on your part, of course).

Build video: https://youtu.be/zB_vW6kWlkE

Roll cage: https://www.thingiverse.com/thing:4610573

Bumper mount kit: https://www.thingiverse.com/thing:4617755

Stinger bumper: https://www.thingiverse.com/thing:4588243

Big beefy bumper: https://www.thingiverse.com/thing:4590968

Rear bumper: https://www.thingiverse.com/thing:4622429

Don't like this body? Want to build a 3D printed crawler? Check out my Baja racer project: https://www.thingiverse.com/thing:4597812

Instruction page coming soon. https://wrenchtodrive.blogspot.com/2020/12/jeep-cage-and-body-assembly-guide.html

See the exploded view for a rough guide. It's pretty easy. I used 6 M3x6-8mm screws but you can build the whole thing with hot glue without much trouble. As I show in the video, to make the doors and box easily removable, you will need two screws.

Durability shouldn't be terrible but a roll down a big hill will almost certainly rip off some parts (front fenders, I think for sure). As I've mentioned, the cage is pretty tough if you lay down the parts for printing and so far these parts have all been acceptably strong IMO.

I'm a little less than satisfied with the hood and cowl but I wanted to use the roll cage for this version so that's the best I could come up with and have it easy to take off. I thought the hood hinge would be easy but the cage is in the way, so no hinge for now. A piano hinge would work but it has to be quite large and I didn't like that alternative at all. I'm going to do a no cage version that will be one piece. The downside to that will be lack of durability, without a doubt. If that appeals to you, hold out until around January.

Use at your own risk.

Wrench to drive or drive to wrench?

Similar models

thingiverse

free

12428 SCX10 Clone Jeep Wrangler Parts by WrenchToDrive

...slands driver i run with this:https://www.thingiverse.com/thing:3533920

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

W2D-VI Bronco Style SCX10 Clone Body by WrenchToDrive

...jeep roll cage. you can use the rear mount similar to the jeep setup (bronco_rear_body_mount_v1) or use the bronco...

thingiverse

free

Redcat Gen 8 Jeep Heavy Duty Bumper (SCX10 Clone Compatible) by WrenchToDrive

...0mm closer together. bmp6_200 is 200mm wide for use with a truck body.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

Redcat Gen 8 Jeep Wrangler Cage (SCX10, TRX4 compatible) by WrenchToDrive

... of the actual size, oops): https://www.thingiverse.com/thing:3533920

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

SCX10 Jeep Bumper by WrenchToDrive

... trx-4 rails are the same as scx10 except that the channels are deeper.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

HCF R/C RockCrawler front grille/bumper - Jeep Style by djtechman

...m body & wanted a precision grille plate for the front.

printed in abs for durability when we're smashing it into things.

thingiverse

free

SCX10 Clone Crawler Stealth(ish) Rear Bumper by WrenchToDrive

... the mount kit for improvements. i expect the bumpers will not change.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

High Clearance Crawler Front Bumper - SCX10, SCX10 II by Robskii

...nce crawler front bumper - scx10, scx10 ii by robskii

thingiverse

direct bolt-on front bumper for either your scx10 or scx10 ii.

thingiverse

free

Scx10 Hood Hinge by mx_rider_250

...scx10 hood hinge by mx_rider_250

thingiverse

not functional, just for looks. designed for a jeep, may work with other bodies

thingiverse

free

WPL C24 Honcho Cage (Fancy)

... this one with brad nails as pins and it seems pretty solid.

as always, use at your own risk.

wrench to drive or drive to wrench?

Wrenchtodrive

thingiverse

free

Kyosho Fazer MK2 Front Bumper by WrenchToDrive

...it works well in tpu but my first version was pla and has held up well.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

Arrma Senton Roof Slider by WrenchToDrive

...;m not so sure about. your mileage may vary.

attach with 2-sided tape.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

Redcat Gen 8 SCX10 Metal Axle Panhard Mount by WrenchToDrive

... hold it in place.

summary and run video: https://youtu.be/zj-lojcs2sw

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

SCX10 Jeep Bumper by WrenchToDrive

... trx-4 rails are the same as scx10 except that the channels are deeper.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

SCX10 Clone Crawler Stealth(ish) Rear Bumper by WrenchToDrive

... the mount kit for improvements. i expect the bumpers will not change.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

Kyosho Fazer MK2 Rear Suspension by WrenchToDrive

... a charger daytona/plymouth super bird front end and wing...

as always, use at your own risk.

drive to wrench or wrench to drive?

thingiverse

free

Generic roof slider (For RC car) by WrenchToDrive

... bit and they are more durable than i expected. your mileage may vary.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

SCX10 Tube Style Bumper by WrenchToDrive

...o, you'll just need to mount the bumper to it with screws and nuts.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

SCX10 (Clone) Tube Front Bumper LED Ready by WrenchToDrive

...k the mount kit for improvements. i expect the bumpers will not change.

use at your own risk.

wrench to drive or drive to wrench?

thingiverse

free

Jeep Front and Rear Inner Fenders by WrenchToDrive

...mment and let me know. i don't consider a little trimming heinous.

use at your own risk.

wrench to drive or drive to wrench?

Scx10

thingiverse

free

wheels for SCX10 by Cnegon

...wheels for scx10 by cnegon

thingiverse

wheels for scx10

thingiverse

free

High Clearance Crawler Front Bumper - SCX10, SCX10 II by Robskii

...nce crawler front bumper - scx10, scx10 ii by robskii

thingiverse

direct bolt-on front bumper for either your scx10 or scx10 ii.

thingiverse

free

SCX10 Türgriff by MonoDani

...scx10 türgriff by monodani

thingiverse

türgriffe für den scx10.

drucken.. bohren.. kleben..

thingiverse

free

Front Bumper SCX10 by Breksys

...front bumper scx10 by breksys

thingiverse

scx10 front bumper

fits on axial scx10 deadbolt. printed and tested.

thingiverse

free

SCX10 / SCX10 II Dual Servo Mount by Robskii

...ervo mount by robskii

thingiverse

cross brace to allow for dual servos to be mounted.

-requires cms

-requires battery relocation

thingiverse

free

Box SCX10 and Other by HappyMaker06

...box scx10 and other by happymaker06

thingiverse

box for scx10 and other...

top, bottom, and cover for battery.

thingiverse

free

axial scx10 bumper by KyleDietrich

...axial scx10 bumper by kyledietrich

thingiverse

fits axial scx10 power wagon, possibly other models

thingiverse

free

Axial SCX10 parts by robertl49

...axial scx10 parts by robertl49

thingiverse

axial scx10 dingo parts

radiator

drivers floor

center console

thingiverse

free

SCX10 Flex and Work Stand by Dungstar

...scx10 flex and work stand by dungstar

thingiverse

scx10 flex and work stand

thingiverse

free

SCX10 hilux truggy grill by imperfect927

...scx10 hilux truggy grill by imperfect927

thingiverse

scx10 hilux truggy grill

Crawler

3d_ocean

$35

Crawler Excavator

...crawler excavator

3docean

944 litronic crawler excavator

3d model of a 944 litronic crawler, excavator

turbosquid

$180

The crawler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$150

crawler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

skull crawler

...quid

royalty free 3d model skull crawler for download as ztl on turbosquid: 3d models for games, architecture, videos. (1253660)

3d_export

$100

crawler excavator

...

3dexport

crawler excavator, yellow colour. available in files formats: obj, sketch up, solidworks, step, , creo, catia v4, iges

3d_export

$5

rock crawler

...rock crawler

3dexport

hello, i put a 3d model created by me, it is a rock crawler car, thank you very much for your attention.

turbosquid

$500

NASA Crawler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$130

crawler-crane

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$48

Crawler Robot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Metalic Crawler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Jeep

3d_export

$5

jeep

...jeep

3dexport

jeep toy

3d_export

$5

jeep

...jeep

3dexport

this is a 3d jeep created in solidworks.

archibase_planet

free

Jeep

...jeep

archibase planet

jeep motor-car car

jeep-wrangler - 3d model for interior 3d visualization.

3d_export

$14

jeep

...jeep

3dexport

turbosquid

$100

Jeep

...ep

turbosquid

royalty free 3d model jeep for download as max on turbosquid: 3d models for games, architecture, videos. (1364849)

turbosquid

$40

jeep

...eep

turbosquid

royalty free 3d model jeep for download as ma on turbosquid: 3d models for games, architecture, videos. (1183919)

turbosquid

$29

Jeep

...eep

turbosquid

royalty free 3d model jeep for download as ma on turbosquid: 3d models for games, architecture, videos. (1377059)

turbosquid

$5

Jeep

...eep

turbosquid

royalty free 3d model jeep for download as ma on turbosquid: 3d models for games, architecture, videos. (1153064)

turbosquid

$5

Jeep

...ep

turbosquid

royalty free 3d model jeep for download as c4d on turbosquid: 3d models for games, architecture, videos. (1391581)

turbosquid

$1

JEEP

...

turbosquid

royalty free 3d model jeep for download as blend on turbosquid: 3d models for games, architecture, videos. (1608181)

Clone

3d_export

$5

Clones great republic

...clones great republic

3dexport

clones great republic.those same clones from the star wars movie universe.4 clones available.

3d_export

$10

Clone 3D Model

...clone 3d model

3dexport

clone woman girl female lady chamber sci fi

clone 3d model calcm1 51695 3dexport

turbosquid

$5

Clone machine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Clone trooper 3D Model

...nd army soldier trooper

clone trooper 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

free

Lego Clone Walker

...ree 3d model lego sw clone walker for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1292252)

turbosquid

$15

Clone trooper helmet

...d model clone trooper helmet for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1199355)

archive3d

free

Clone trooper 3D Model

...and army soldier trooper

clonetrooper 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Clone trooper 3D Model

...and army soldier trooper

clonetrooper 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$35

Surface Clone C4D materials

...+ of the most well made materials for maxon’s cinema 4d; on the internet today. each material is crafted with a specific purpo...

turbosquid

$3

Sci-fi cloning vats

...cloning vats for download as 3ds, obj, wrl, x, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1290168)

Compatible

turbosquid

$3

Genesis 8 Clothing 1 dForce Compatible

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Genesis 8 Clothing Top 1 dForce Compatible

...nesis 8 clothing top 1 dforce compatible (2) for download as on turbosquid: 3d models for games, architecture, videos. (1217671)

turbosquid

$50

Screwdriver Latch Type CSC Torx compatible with Straumann

...sc torx compatible with straumann for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1370064)

3d_export

$9

cad compatible casual woman hand model f1p3d1v1hand

...s: stl, obj, fbx<br>models with quad-topology (1100 quads) are also included (f1p3d1v1hand_quad.obj, f1p3d1v1hand_quad.fbx)

3d_export

$38

uzaki rigify

...uzaki rigify 3dexport compatible-blender ...

3d_export

$5

cloud lowpoly 3d

...cloud lowpoly 3d 3dexport lowpoly 3d format fbx compatible with unreal and...

3d_export

$5

flower lowpoly 3d

...flower lowpoly 3d 3dexport lowpoly 3d format fbx compatible with unreal and...

3d_export

$5

rocks lowpoly 3d

...rocks lowpoly 3d 3dexport lowpoly 3d format fbx compatible with unreal and...

3d_export

$10

pots

...pots

3dexport

pots<br>modeled in blender<br>compatable with evee and cycels

3d_ocean

$95

Mr Techny

...for 3ds max 2010 and later – biped (2010 compatible and cat (2011 compatible) versions incluided. for maya 2012...

Body

3d_ocean

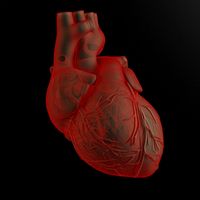

$39

Heart and body

...heart and body

3docean

blood body heart human organ

heart and body highpoly heart inside human body.

turbosquid

free

Body

...lty free 3d model body for download as max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1155461)

3ddd

$1

body

...body

3ddd

маникен

corona mtl

turbosquid

$50

body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$45

Body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

bodies

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

body

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.