Thingiverse

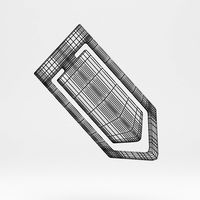

Jeep Comanche Relay cover Clip by MJjeep

by Thingiverse

Last crawled date: 3 years, 1 month ago

THIS DESIGN IS EXPERIMENTAL. Worst case scenario, your clips fail, and your cover is moving around the engine bay (or is lost while driving), and your relays are left exposed. Poor print settings, defects, and/or damage may cause the clip to fail. USE THESE CLIPS/MODELS AT YOUR OWN RISK.

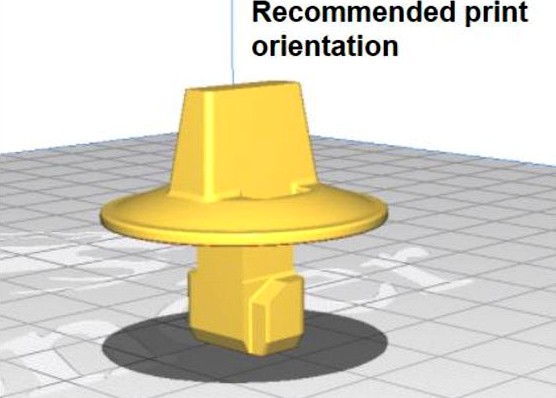

ORIENTATION:

Thumb hold on top- seemed to have less critical layer separation issues transition (see below). If the thumb hold separates, the part can still function. If the stem separates, your relay cover is now unconstrained.

Thumb hold on bottom - aesthetically pleasing surface

PRINT SETTINGS:adjust scales of xyz if annealing

Material: Nylon (dremel)

Nozzle: 260F

Bed: 110F

Layer Height: .1mm

Wall line count: 1

Top/Bottom Layers: 5

Infil: 95%

Triangles

Randomized infill start

Cooling- off

Speed: 60mm/s

Support: (cura experimental tree support)

Adhesion: glue stick on glass bed

I STRUGGLED WITH LAYER SEPARATION:

it usually broke just after it finished printing the head and moved on to either the thumb hold or to the stem that holds the clip/cover in place. The reason for this is because the head of the clip has a large cross sectional area, and the stem and thumb holds have relatively less cross sectional area. I think I solved this by printing 6 at a time, so the previous layers were able to cool uniformly. Ideally, your enclosure is able to hold higher temperatures than mine so that the previous layer is not "cooled". I also played around with adding custom draft guards to try to keep it warmer around the models

INSPECTION:

The head of the clip should flex in order to rotate the clip into place. After rotating into place, pull up on the cover to ensure that there is proper adhesion between the head of the clip and the stem.

PRINTER MODIFICATIONS:

Microswiss hot end (ALL METAL)(recommended but stock does reach 260F)

Enclosure with insulation (I have a giant plastic bin with a blanket over top-might be a fire hazard, don't try this at home) I recommend a heated enclosure.

Stiffer springs (I added washers so the stock spring is compressed more)

Bed insulation (not required)

SOURCE OF DIMENSIONS:

I modeled the design by measuring an original clip. I made some modifications according to my prints/function.

REFLECTIONS AND RECOMMENDATIONS:

I have some clips on my truck, but I haven’t used them enough to say that a 3D printed clip is a good solution. A better enclosure, will create better results. I chose Nylon because of its flexibility (when thin), resistance to cold and heat, and strength. You might be able to print in ABS/PLA with a thicker/rigid head and add a rubber washer (seems like the most robust design). You will probably have to modify the z scale of the print to accommodate for the washer though. I recommend annealing the parts to reduce internal stresses. This will cause your part to drastically change shape , and therefore your final print will be a product of changing the xyz scales by trial and error.

ORIENTATION:

Thumb hold on top- seemed to have less critical layer separation issues transition (see below). If the thumb hold separates, the part can still function. If the stem separates, your relay cover is now unconstrained.

Thumb hold on bottom - aesthetically pleasing surface

PRINT SETTINGS:adjust scales of xyz if annealing

Material: Nylon (dremel)

Nozzle: 260F

Bed: 110F

Layer Height: .1mm

Wall line count: 1

Top/Bottom Layers: 5

Infil: 95%

Triangles

Randomized infill start

Cooling- off

Speed: 60mm/s

Support: (cura experimental tree support)

Adhesion: glue stick on glass bed

I STRUGGLED WITH LAYER SEPARATION:

it usually broke just after it finished printing the head and moved on to either the thumb hold or to the stem that holds the clip/cover in place. The reason for this is because the head of the clip has a large cross sectional area, and the stem and thumb holds have relatively less cross sectional area. I think I solved this by printing 6 at a time, so the previous layers were able to cool uniformly. Ideally, your enclosure is able to hold higher temperatures than mine so that the previous layer is not "cooled". I also played around with adding custom draft guards to try to keep it warmer around the models

INSPECTION:

The head of the clip should flex in order to rotate the clip into place. After rotating into place, pull up on the cover to ensure that there is proper adhesion between the head of the clip and the stem.

PRINTER MODIFICATIONS:

Microswiss hot end (ALL METAL)(recommended but stock does reach 260F)

Enclosure with insulation (I have a giant plastic bin with a blanket over top-might be a fire hazard, don't try this at home) I recommend a heated enclosure.

Stiffer springs (I added washers so the stock spring is compressed more)

Bed insulation (not required)

SOURCE OF DIMENSIONS:

I modeled the design by measuring an original clip. I made some modifications according to my prints/function.

REFLECTIONS AND RECOMMENDATIONS:

I have some clips on my truck, but I haven’t used them enough to say that a 3D printed clip is a good solution. A better enclosure, will create better results. I chose Nylon because of its flexibility (when thin), resistance to cold and heat, and strength. You might be able to print in ABS/PLA with a thicker/rigid head and add a rubber washer (seems like the most robust design). You will probably have to modify the z scale of the print to accommodate for the washer though. I recommend annealing the parts to reduce internal stresses. This will cause your part to drastically change shape , and therefore your final print will be a product of changing the xyz scales by trial and error.

Similar models

thingiverse

free

Clip for PVC tube enclosure - holds multi layer insulation panel by NightOowl

...ngs).

two versions exist: one clip holding insulation material on one side, another clip holding insulation material on two faces

thingiverse

free

Ender 2 Heat Bed Cable Strain Relief by psdesign

...ation. i cannot test others if anyone else wants to give feedback.

if you make one please photograph and post it to this page!!!

thingiverse

free

HypberCube Evolution Heated Bed Thumb Screw by Mach3tte

...d bed thumb screw by mach3tte

thingiverse

thumb screw for heated bed, takes a m3 nut, i recommend to put in a m3 nylon lock nut.

thingiverse

free

AnyCubic Kossel Bed Clips by DaHai8

...0 t-nuts

6x m3x10mm hex head screws

highly recommend printing these in petg as pla will soften and warp from the heat of the bed.

thingiverse

free

Davinci Pro Bed Clip by Sethion

...clip by sethion

thingiverse

clip to hold down the print bed of the xyz davinci pro when the adhesive fails and bed become loose.

thingiverse

free

Boots Industries BI V2.5 Glass Bed Holders by slepp

...ound the entire edge of the plate, instead of at just 2 points.

it also uses a thin set of layers (0.8mm) to hold the plate down.

thingiverse

free

Micromake Kossel Bed Fan Mount (40mm) by Edak

... use together with this, see photos. if you are going to make both, make the clip on one first so you can cool the hot-end fins.

thingiverse

free

Arduino Relay Module Cover by BMaker95

...rint with the enclosure plugin to control the relays for the printer/leds! enjoy!

(note: will update with post-printing pictures)

thingiverse

free

Glass Bed Clip (Screwless) by alexberkowitz

...mm thick but the springy nature of these clips mean they should work for thicker sheets, as well. prints quickly with no support.

thingiverse

free

Bak Industries Roll-X replacement clip by pmidgette

...bed cover on my dodge ram. i thought i would have to print this in nylon, but the pla part seems to be as strong as the original.

Comanche

turbosquid

$15

comanche bike.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$15

RAH-66 Comanche

...66 rah/66 rah66 rotor soar stealth transport

low polygon and well detailed rah -66 comanche. check out my account for more items!

3ddd

$1

Вертолет RAH-66 Comanche

...вертолет rah-66 comanche

3ddd

вертолет

low poly модель американского разведовательно-ударного вертолета rah-66 comanche

3d_export

$20

RAH66 Comanche 3D Model

...pter aircraft rotor attacker transport air soar support hover hovering gun ship

rah66 comanche 3d model heartbreak 55531 3dexport

3d_export

$31

RAH66 Comanche 3D Model

...y military helicopter transport rotor combat drop special ops lift operation

rah66 comanche 3d model martialartist 24707 3dexport

cg_studio

$31

RAH-66 Comanche3d model

...l

cgstudio

.3ds .dxf .lwo .max .obj - rah-66 comanche 3d model, royalty free license available, instant download after purchase.

cg_studio

$15

RAH-66 Comanche3d model

...l

cgstudio

.3ds .max .fbx .dxf .obj - rah-66 comanche 3d model, royalty free license available, instant download after purchase.

3d_ocean

$12

Military helicopter concept

...there are some design elements from apache and from comanche rah-66.model was created with blender3d 2.72,rendering images with blender...

3d_sky

free

Helicopter RAH-66 Comanche

...helicopter rah-66 comanche

3dsky

helicopter

low poly model of american intelligence-attack helicopter rah-66 comanche

thingiverse

free

Carson Comanche axle stub 32408

...carson comanche axle stub 32408

thingiverse

carson comanche axle stub

carson part no. 32408

Relay

turbosquid

$50

Relay Spaceship

... model relay spaceship for download as skp, 3ds, dae, and obj on turbosquid: 3d models for games, architecture, videos. (1655800)

3ddd

$1

Scavolini / Grand Relais

...scavolini / grand relais

3ddd

scavolini

scavolini модель grand relais дизайн gianni pareschi

3ddd

$1

Сантехника Globo Relais

... унитаз , зеркало

сантехника globo relais

умывальник,зеркало,унитаз.

3d_export

$8

relay automatic assembly line

...relay automatic assembly line

3dexport

relay automatic assembly line

3ddd

free

Унитаз и биде Relais

... биде , унитаз

унитаз art.re001 bi и биде art.re009 bi

turbosquid

free

Relay 8 pin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$110

Power relay station3d model

...el

cgstudio

.3ds .fbx .max .obj - power relay station 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Стол обеденный -Scavolini- Grand Relais

...s

3ddd

обеденный , scavolini

обеденный стол scavolini - grand relais, в трёх расцветках.

3d_export

$10

relay jd1912 12v 40a with connector

...lowing bodies: 1. relay jd1912 12v 40a - 1 piece; 2. connector housing - 1 piece; 3. terminal with a part of the wire - 4 pieces.

3ddd

free

Globo Relais furnitures

... , раковина

раковина с консолью st070.ne

зеркалоsp070.bi

стакан re0381x

мыльница re0391x

Jeep

3d_export

$5

jeep

...jeep

3dexport

jeep toy

3d_export

$5

jeep

...jeep

3dexport

this is a 3d jeep created in solidworks.

archibase_planet

free

Jeep

...jeep

archibase planet

jeep motor-car car

jeep-wrangler - 3d model for interior 3d visualization.

3d_export

$14

jeep

...jeep

3dexport

turbosquid

$100

Jeep

...ep

turbosquid

royalty free 3d model jeep for download as max on turbosquid: 3d models for games, architecture, videos. (1364849)

turbosquid

$40

jeep

...eep

turbosquid

royalty free 3d model jeep for download as ma on turbosquid: 3d models for games, architecture, videos. (1183919)

turbosquid

$29

Jeep

...eep

turbosquid

royalty free 3d model jeep for download as ma on turbosquid: 3d models for games, architecture, videos. (1377059)

turbosquid

$5

Jeep

...eep

turbosquid

royalty free 3d model jeep for download as ma on turbosquid: 3d models for games, architecture, videos. (1153064)

turbosquid

$5

Jeep

...ep

turbosquid

royalty free 3d model jeep for download as c4d on turbosquid: 3d models for games, architecture, videos. (1391581)

turbosquid

$1

JEEP

...

turbosquid

royalty free 3d model jeep for download as blend on turbosquid: 3d models for games, architecture, videos. (1608181)

Clip

archibase_planet

free

Clip

...clip

archibase planet

paper-clip clip office equipment

clip band - 3d model for interior 3d visualization.

3d_export

$5

screw clip

...screw clip

3dexport

screw clip

3d_ocean

$4

Butterfly clip

... a butterfly clip, it comes with a ready to render set for out of the box rendering. obj version and max alones version included.

turbosquid

$2

clip

...

royalty free 3d model clip for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1358622)

turbosquid

$5

Clip

...lty free 3d model clip for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1521355)

turbosquid

$19

Clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Clips

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

clips

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Cover

archibase_planet

free

Cover

...cover

archibase planet

cover place setting

cover n170807 - 3d model for interior 3d visualization.

3ddd

$1

cover

...cover

3ddd

ковер , круглый

cover decor

archibase_planet

free

Cover

...cover

archibase planet

cover place setting setting

servis-cafe1930 - 3d model for interior 3d visualization.

turbosquid

free

Coverings

...rings

turbosquid

free 3d model coverings for download as dwg on turbosquid: 3d models for games, architecture, videos. (1279391)

3d_export

$5

plug cover

...plug cover

3dexport

plug cover

turbosquid

$25

Covers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

manhole cover

...manhole cover

3dexport

manhole cover gost, stl, step

turbosquid

$5

Street Gas Cover Manhole Cover

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Bed cover

...bed cover

3ddd

постельное белье

very useful bed cover

3d_export

$5

cpu cover

...cpu cover

3dexport

cpu cover, cpu box, sheet metal container