GrabCAD

Jam Free Parcel Delivery System

by GrabCAD

Last crawled date: 1 year, 10 months ago

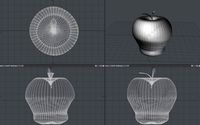

My design for a 'Jam Free Parcel Delivery System' has the following characteristics:

1. A front drawer lip that prevents over-sized items from being forced into the drawer.

This meets directly with the sloped ceiling of each drawer to ensure that no package exceeding the maximum height of the drawer is forced into the compartment.

If the drawer is forced closed with an over-sized parcel, the front lip will act as a scraper bar pushing the parcel back out of the drawer with the sloped inner tray.

2. A glossy finish corrugated (roller-like) sloped drawer ceiling. If a package expands inside the drawer, for instance, a coat, the ceiling acts like a wedge with low friction, sloped towards the front of the drawer to allow opening with minimal force.

The ceiling sits on two fixed pins at the back of the cabinet and two release pins at the front of the cabinet.

3. The shape of the inside of the drawer along with the shape of the ceiling, forms a containment chamber with sloped sides ensuring that the items in the drawer doesn't interfere with the sliding mechanism of the drawer, thus preventing jamming.

4. Each drawer is fitted with high strength ball bearing slides for quiet and for smooth operation. The drawer slides permits minimal sag and is screwed onto the drawer from the inside with special screws to prevent third persons from removing the drawer or gain access to the adjacent (above/below) drawers or the items held in them.

5. Each drawer has a sensory actuator, so named for it's components, mounted on the rear wall behind each drawer. This unit senses the proximity of the drawer once it reaches the fully closed position, then activates the C lock to fully secure the drawer in place.

The locking system of the drawer solution is electronic with the electrical characteristics of 24VDC and maximum 1A. The length of the signal is under 300 ms. Molex Micro Fit 3.0 series connectors are used for connecting the lock.

The unit also has a spring loaded actuator and buffer that gives the drawer the soft close feature, as well as push the drawer out at least 50mm when the signal is given to open the drawer. The unit uses an infrared proximity sensor and receiver to detect the drawer distance for feedback and locking operations.

By packaging all these functionalities into one unit, the cost of production of the system is further reduced, boosts an increase in reliability, and offers ease of maintenance with simply servicing the unit or replacing it.

The unit is sized according to the drawer for scalability and can also be paired to the larger drawers for addition opening force and security.

6. The cabinet is made from laminated chipboard with pre-drilled holes in the sides and back to mount drawer slides, roof mounting pins, and the sensory actuators for the drawers. This mades the cabinet highly configurable to suit any particular need.

7. The upper two compartment both have a door style compartment for easy retrieval of parcel for the customer.

8. The drawer is made up of either sheet metal or plastic. The drawers can withstand up to 10 Kg of weight and can accept bigger parcels because of a larger storage compartment. Weight isn't of problem because each drawer solution is well under 5kg, making the entire system lightweight for easy transportation.

1. A front drawer lip that prevents over-sized items from being forced into the drawer.

This meets directly with the sloped ceiling of each drawer to ensure that no package exceeding the maximum height of the drawer is forced into the compartment.

If the drawer is forced closed with an over-sized parcel, the front lip will act as a scraper bar pushing the parcel back out of the drawer with the sloped inner tray.

2. A glossy finish corrugated (roller-like) sloped drawer ceiling. If a package expands inside the drawer, for instance, a coat, the ceiling acts like a wedge with low friction, sloped towards the front of the drawer to allow opening with minimal force.

The ceiling sits on two fixed pins at the back of the cabinet and two release pins at the front of the cabinet.

3. The shape of the inside of the drawer along with the shape of the ceiling, forms a containment chamber with sloped sides ensuring that the items in the drawer doesn't interfere with the sliding mechanism of the drawer, thus preventing jamming.

4. Each drawer is fitted with high strength ball bearing slides for quiet and for smooth operation. The drawer slides permits minimal sag and is screwed onto the drawer from the inside with special screws to prevent third persons from removing the drawer or gain access to the adjacent (above/below) drawers or the items held in them.

5. Each drawer has a sensory actuator, so named for it's components, mounted on the rear wall behind each drawer. This unit senses the proximity of the drawer once it reaches the fully closed position, then activates the C lock to fully secure the drawer in place.

The locking system of the drawer solution is electronic with the electrical characteristics of 24VDC and maximum 1A. The length of the signal is under 300 ms. Molex Micro Fit 3.0 series connectors are used for connecting the lock.

The unit also has a spring loaded actuator and buffer that gives the drawer the soft close feature, as well as push the drawer out at least 50mm when the signal is given to open the drawer. The unit uses an infrared proximity sensor and receiver to detect the drawer distance for feedback and locking operations.

By packaging all these functionalities into one unit, the cost of production of the system is further reduced, boosts an increase in reliability, and offers ease of maintenance with simply servicing the unit or replacing it.

The unit is sized according to the drawer for scalability and can also be paired to the larger drawers for addition opening force and security.

6. The cabinet is made from laminated chipboard with pre-drilled holes in the sides and back to mount drawer slides, roof mounting pins, and the sensory actuators for the drawers. This mades the cabinet highly configurable to suit any particular need.

7. The upper two compartment both have a door style compartment for easy retrieval of parcel for the customer.

8. The drawer is made up of either sheet metal or plastic. The drawers can withstand up to 10 Kg of weight and can accept bigger parcels because of a larger storage compartment. Weight isn't of problem because each drawer solution is well under 5kg, making the entire system lightweight for easy transportation.

Similar models

grabcad

free

Parcel Delivery System solution

...wer.

on every drawer there is a sloping sheet metal plate that facilitate removing parcels and make the drawers independent.

grabcad

free

The Parcel Delivery System

...the parcel delivery system

grabcad

opens up the drawer by a magnetic lock

grabcad

free

SGCHL CLEVERON Parcel Delivery System

...electronic-locker-systems-with-ce-approved-ma1215l-.html)

3. sheet steel, bolts and nuts

the animation is loaded in mp4 format.

grabcad

free

Anti-stuck and lock solution

... the magnet is removed.

the springs eject drawer front and it opens.

simple and reliable system with no moving locking elements.

grabcad

free

Cleverbox 3

...of the drawer can be reinforced -the drawer is similar to the existing drawers in the cleverbox 2. -it...

grabcad

free

Smart Parcel Delivery System Design

...ecially fragile items), user-friendly (can be used with one hand) and saves a lot of time trying to retrieve an oversized parcel.

grabcad

free

Cleveron Parcel Delivery System Challenge

...me that will slightly compress as well as roll on the parcel.

youtube - https://www.youtube.com/channel/uczfrwbls5z_hmyop_jipkng

grabcad

free

PRE-ASSEMBLED DRAWER UNIT

...ve old 4 drawers and slide the new unit back)

cost effective

not required more additional sensors, motors or electronic elements

grabcad

free

The Ultimate parcels drawer solution

...emove the parcel or to intreduce it.

the slider roof is made of methacrylate ( transparent hard plastic) , with aluminum frame.

grabcad

free

The Parcel Delivery System 2

...the parcel delivery system 2

grabcad

the parcel delivery system 2

Parcel

cg_studio

$32

parcel carrier3d model

...hicle lorries lorry trucks truck

.max - parcel carrier 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

PLANE parcel

...alty free 3d model plane parcel for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1667093)

turbosquid

$9

Parcel 010

...ty free 3d model parcel 010 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1256541)

turbosquid

$20

Wooden Parcel Box

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

cartoon carton parcel

...cartoon carton parcel

3dexport

texture size:512px number of texture:4 texture format: png

3d_export

$19

Parcel wrapped in kraft paper

...; x 7.28" x 7.69"<br>- model parts: 3<br>- material count: 2<br>- xform: yes<br>- boxtrick: yes

3d_export

$30

Cardboard Box 3D Model

...cardboard box 3d model 3dexport cardboard junk parcel paper package packaging crate case box card prop props...

3d_export

$18

Gift boxes 3D Model

...3d model 3dexport gift package present wrapping wrapped box parcel lid ribbon bow birthday christmas xmas paper wrap giftbox...

3d_export

$15

CardBoard Box 3D Model

...cardboard box 3d model 3dexport cardboard junk parcel paper package packaging crate case box card prop props...

3d_export

$24

Cardboard Shipping Carton 3D Model

...shipping corrugated brown closed container fragile freight label mail parcel photoreal detailed textures materials cardboard shipping carton 3d model...

Jam

turbosquid

$39

Jam Bottle

...

royalty free 3d model jam bottle for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1238108)

3d_export

$10

Tostadas and jam

...tostadas and jam

3dexport

turbosquid

$40

Jam Fusion

...lty free 3d model jam fusion for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1472140)

turbosquid

$10

Jam Chairs

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Log Jam

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

pot of jam

...pot of jam

3dexport

subscribe to my youtube channel:

3ddd

$1

Calligaris Jam Stool

... барный

calligaris jam barstool, 3d max file with vray setting, materials included in the scene.

turbosquid

$15

Realistic Jam Tart

...

royalty free 3d model realistic jam tart for download as max on turbosquid: 3d models for games, architecture, videos. (1187021)

3d_ocean

$19

Baked roll with jam

...obj photorealistic roll scanned sweet vray

scanned 3d model of baked roll with jam and white icing. placed on white square plate.

turbosquid

$6

Infographic Traffic Jam

... 3d model infographic traffic jam for download as obj and c4d on turbosquid: 3d models for games, architecture, videos. (1486633)

Delivery

3d_export

$5

Vespa delivery

...vespa delivery

3dexport

vespa delivery model 3d

turbosquid

$60

Delivery Robot

...d model delivery robot for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1582878)

turbosquid

$150

Delivery-Truck

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$100

Delivery Truck

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

Delivery Robot

...del delivery robot for download as ma, c4d, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1705195)

turbosquid

$10

Wagon - Delivery

...- delivery for download as 3ds, lwo, obj, blend, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1217434)

3d_ocean

$5

Wood delivery pallete

...ood delivery pallete with good quality texture map. made in maya rendered with v-ray. texture map 2048*2048 included in .zip file

3d_export

$60

Delivery Van 3D Model

...model

3dexport

car vehicle truck suv minivan transportation delivery catering

delivery van 3d model vanishingpoint 73016 3dexport

cg_studio

$70

Delivery truck3d model

...ruck3d model

cgstudio

.3ds .fbx .max - delivery truck 3d model, royalty free license available, instant download after purchase.

3d_ocean

$89

Volvo Truck 6x2 Delivery

...very detailed detailed fm fm heavy heavy high high truck truck vehicle vehicle volvo volvo

high detailed volvo 6×2 delivery truck

System

archibase_planet

free

System

...m

archibase planet

fire alarm system fire alarm box

security light system - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spider system

...stem spider glass system

spider system to fix glass stefano galli n050912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Euforia System

...euforia system

3ddd

euforia

euforia system

3d_export

$50

Roof system Truss system 3D Model

...oof system truss system 3d model

3dexport

roof system truss truss stage

roof system truss system 3d model aleksbel 38970 3dexport

3ddd

$1

DVD System

...dvd system

3ddd

dvd , schneider

dvd system

design_connected

free

Seating system

...seating system

designconnected

free 3d model of seating system

3d_export

$5

solar system

...solar system

3dexport

solar system in c4d, with 8k nasa textures

3ddd

$1

Quanta System

...quanta system

3ddd

медицина

quanta system.

лазерное оборудование для медицинских центров

3d_export

$15

solar system

...nd the other the sun, the earth and the moon, the latter has an animation with camera movement included, the files are in spanish

3d_export

$14

missile system

...missile system

3dexport

Free

design_connected

$13

Free

...free

designconnected

parri design free armchairs computer generated 3d model. designed by marco maran.

turbosquid

$5

free

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Free

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Free

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

free

Free barstool

...free barstool

designconnected

free 3d model of free barstool by kristalia designed by graffeo, monica.

3d_export

$5

free mixamo

...free mixamo

3dexport

free mixamo

3d_export

free

free rocks

...free rocks

3dexport

free price rock

turbosquid

free

Free Free Standing Punching Bag

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

character free

...urbosquid

free 3d model character free for download as blend on turbosquid: 3d models for games, architecture, videos. (1321193)

turbosquid

free

Hamburger Free

...urbosquid

free 3d model hamburger free for download as blend on turbosquid: 3d models for games, architecture, videos. (1592262)