Thingiverse

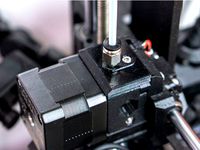

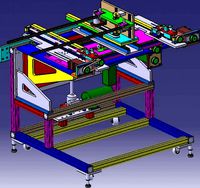

JAFO ROLLER filament dry box and feed system for Prusa i3 MK3 by JAFO01

by Thingiverse

Last crawled date: 3 years, 1 month ago

9/24/2018 edited the z top end bowden connector with 6 m6 threaded holes for bowden connectors. They are also spaced properly and should avoid the z axis carriage part on your printer at max z height.

I spent lots of time looking for what I wanted but never quite found it. So I created a couple things from scratch and then edited the awesome work of a few others. Some of these files are specifically for the i3 mk3 particularly the cover, cover adapter and the reverse bowden endcap. The rest of the files can be used as a standalone drybox for any other 3d printer.

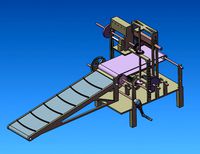

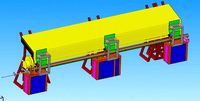

This is a dry box system for using multiple filament types in preparation of the mk3 multi material option I pre-ordered with my Prusa printer. Initially it was going to be a 4 filament unit that since becoming MMU2.0 got upgraded to 5. Well since I dont even have it yet I have held off on expanding my capacity. I really appreciate the bowden concept so I have heavily incorporated it in my design. The ptfe tubing I bought from amazon had both pc4-m10 and pc4-m6 connectors. This is why I use both in my design, I just wanted to use what I had on hand.

I want to thank the individuals who's work allowed and inspired me to create what I have:

https://www.thingiverse.com/thing:2825557 : Prusa i3 Mk3 Z-Tops with Reverse Bowden Mount Option by ctilley79

https://www.thingiverse.com/thing:2929701 : the ultimate spool holder dry box by ritchrock

Sterlite 20qt Gasket Box with latches ($7.99): Target Item Number 002-02-0819

https://www.thingiverse.com/thing:2510947 : Filament Dry Box Tube Feeder by rainreign1

https://www.thingiverse.com/thing:2878333 : Prusa i3 MK3 Bowden tube adapter with spool holder and filament cleaner by 828586

I should also thank all the folks at fusion360 for offering their software for free for us little maker types. I used it for all of my solid editing and creating.

a short list of the required materials:

two 5/16 rods (I used aluminum I had on hand, steel would work, and so would wood dowels I imagine)

608 bearings (4 per spool)

desiccant

m3 screws and nuts (2 per connector on box, think all I could get was 20mm long)

Sterlite 20qt Gasket Box with latches ($7.99): Target Item Number 002-02-0819

I think I got my box for under 8 bucks but at 10 it's still a steal since it does indeed seem very air tight. My system has been working flawlessly for me for about two or three months now. I did use super glue to attach the rods into the rod holders for extra stability. I added length to the legs on the holders so I could just dump the desiccant into the bottom of the box below the rollers. I created the simple spacers to keep the rollers from impinging on each other or the side of the box. Everything that has a bowden thread adapter got the threads added to the model. No force screwing adapters in, they thread in nicely. I printed everything in petg because its mostly what I use. I wouldn't foresee any problems in using different filament types.

I made the JAFO ROLLER tight so I would recommend printing only one at first to test fit with your bearing, you may need to scale up a hair for ease of bearing install.

Enjoy!

I added the cover and cover adapter as well as the back plate for the box connectors. The only editing I did to those files was orient them for better printing.

I spent lots of time looking for what I wanted but never quite found it. So I created a couple things from scratch and then edited the awesome work of a few others. Some of these files are specifically for the i3 mk3 particularly the cover, cover adapter and the reverse bowden endcap. The rest of the files can be used as a standalone drybox for any other 3d printer.

This is a dry box system for using multiple filament types in preparation of the mk3 multi material option I pre-ordered with my Prusa printer. Initially it was going to be a 4 filament unit that since becoming MMU2.0 got upgraded to 5. Well since I dont even have it yet I have held off on expanding my capacity. I really appreciate the bowden concept so I have heavily incorporated it in my design. The ptfe tubing I bought from amazon had both pc4-m10 and pc4-m6 connectors. This is why I use both in my design, I just wanted to use what I had on hand.

I want to thank the individuals who's work allowed and inspired me to create what I have:

https://www.thingiverse.com/thing:2825557 : Prusa i3 Mk3 Z-Tops with Reverse Bowden Mount Option by ctilley79

https://www.thingiverse.com/thing:2929701 : the ultimate spool holder dry box by ritchrock

Sterlite 20qt Gasket Box with latches ($7.99): Target Item Number 002-02-0819

https://www.thingiverse.com/thing:2510947 : Filament Dry Box Tube Feeder by rainreign1

https://www.thingiverse.com/thing:2878333 : Prusa i3 MK3 Bowden tube adapter with spool holder and filament cleaner by 828586

I should also thank all the folks at fusion360 for offering their software for free for us little maker types. I used it for all of my solid editing and creating.

a short list of the required materials:

two 5/16 rods (I used aluminum I had on hand, steel would work, and so would wood dowels I imagine)

608 bearings (4 per spool)

desiccant

m3 screws and nuts (2 per connector on box, think all I could get was 20mm long)

Sterlite 20qt Gasket Box with latches ($7.99): Target Item Number 002-02-0819

I think I got my box for under 8 bucks but at 10 it's still a steal since it does indeed seem very air tight. My system has been working flawlessly for me for about two or three months now. I did use super glue to attach the rods into the rod holders for extra stability. I added length to the legs on the holders so I could just dump the desiccant into the bottom of the box below the rollers. I created the simple spacers to keep the rollers from impinging on each other or the side of the box. Everything that has a bowden thread adapter got the threads added to the model. No force screwing adapters in, they thread in nicely. I printed everything in petg because its mostly what I use. I wouldn't foresee any problems in using different filament types.

I made the JAFO ROLLER tight so I would recommend printing only one at first to test fit with your bearing, you may need to scale up a hair for ease of bearing install.

Enjoy!

I added the cover and cover adapter as well as the back plate for the box connectors. The only editing I did to those files was orient them for better printing.

Similar models

thingiverse

free

Prusa i3 MK3S Bowden Fitting Filament Sensor Cover by Yoonpyo

...k3s that you can screw in a pc4-m5/6/10 fitting. i use this to guide filament from the dry box to the extruder through ptfe tube.

thingiverse

free

fs cover mk3s+ reversed bowden coupler by Pyr0-K4y

...d a little bit of support.

i use this in combination with the spannerhands filament box https://www.thingiverse.com/thing:2119644

thingiverse

free

REMIX: Prusa i3 MK3 Bowden tube adapter with spool holder and filament cleaner by ri3del

...3 mk3 bowden tube adapter with spool holder and filament cleaner by ri3del

thingiverse

i only remixed the arm to pc4-m6 version.

thingiverse

free

Prusa mk3 filament sensor cover with m6 threads for reverse bowden by rrauenza

...:2825557 - i recommend it!!

....print this in black as prusa has stated there are some issues with the sensor with other colors.

thingiverse

free

Sensor Adapter

... visibel on the pictures.https://www.thingiverse.com/thing:4119211

and my filament box: https://www.thingiverse.com/thing:4119344

thingiverse

free

Seals for Sterlite Modular Stacker dry box by bradcfisher

...s:https://www.thingiverse.com/thing:2896607

thermopro tp50 thermometer/hygrometer mount:https://www.thingiverse.com/thing:3168310

thingiverse

free

MK3S Filament Sensor Cover Bowden Adapter (Tested with Mosaic Palette)

...tested with mosaic palette)

thingiverse

this is an edit of the prusa mk3s filament sensor cover to accept a palette bowden tube.

thingiverse

free

MK3 Sensor Cover with threading by OliK

... a 2mm id 4mm od ptfe tube.

original stl from prusa github: https://github.com/prusa3d/original-prusa-i3/tree/mk3/printed-parts

thingiverse

free

Prusa Mk2 Mk3 8 up Dry Box Filament Guide by TheClarkJB

...nage the bowden tubes and filament from a dry box to your mk3. the bowden tube stops in the holder, the filament passes through.

thingiverse

free

Light Bar Bowden Adapter by krazzzyb

...own and .10 layer height and blocked supports in the threads.

it is designed for pc4-m10 adapters and a couple of small zip ties.

Mk3

turbosquid

$50

cention mk3

...ty free 3d model cention mk3 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454148)

turbosquid

$129

MK3 Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$100

Toyota Supra MK3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$44

cention mk3 low poly

...d model cention mk3 low poly for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454666)

turbosquid

$30

Challenger I Mk3 Falcon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

American Frag hand grenade MK3

...free 3d model american frag hand grenade mk3 for download as on turbosquid: 3d models for games, architecture, videos. (1393624)

turbosquid

$20

Mk3 US Navy Combat Knife

...ty free 3d model mk3 us navy combat knife for download as fbx on turbosquid: 3d models for games, architecture, videos. (1172791)

3d_export

$29

Ford Fiesta MK3 Modified 3D Model

...7 tumerfx mtumer mehmet t?mer 1993 1995 1996 wrc special modifed modifiye

ford fiesta mk3 modified 3d model mtumer 30698 3dexport

3d_export

$99

Toyota Supra Mk3 19861993 3D Model

...ort fast coupe japan 1986 1987 1988 1989 1990 1991 1992 1993 tuning turbo

toyota supra mk3 19861993 3d model squir 62530 3dexport

turbosquid

$5

Timothy Oulton Mars Chair MK3

...on mars chair mk3 for download as 3ds, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1209782)

Feed

3d_export

$10

Feed chang

...feed chang

3dexport

turbosquid

$10

Feed-Pump

...lty free 3d model feed-pump for download as 3ds, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1456492)

3d_export

$10

Hydraulic in-feed out-feed support roller

...s at adjustable height, while machining such as cutting, drilling and etc. it is operated by hydraulic and modeled in nx siemens.

turbosquid

$5

Feeding Troughs and Buckets

...free 3d model feeding troughs and buckets for download as fbx on turbosquid: 3d models for games, architecture, videos. (1582798)

3d_export

$180

Boiler Feed Unit 3D Model

...boiler feed unit 3d model

3dexport

boiler feed unit

boiler feed unit 3d model briancrosdale 76895 3dexport

turbosquid

$6

Bird Feed House

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

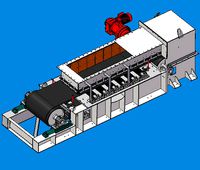

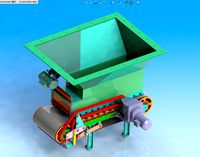

Conveyor belt feeding punching machine

...conveyor belt feeding punching machine

3dexport

conveyor belt feeding punching machine

3d_export

$6

automatic feeding and pipe cutting machine

...automatic feeding and pipe cutting machine

3dexport

automatic feeding and pipe cutting machine

3d_export

$6

ore feeding equipment mining machinery

...ore feeding equipment mining machinery

3dexport

ore feeding equipment mining machinery

3d_export

$5

feed system

...omponent and the executive element constitute the mechanical transmission system, the detection element and the feedback circuit.

Dry

3d_export

$5

hair-dry

...hair-dry

3dexport

hair-dry wahl 5439-024 super dry professional 2000 watts styling hair dryer- black

design_connected

$16

Dry-Dock

...dry-dock

designconnected

restoration hardware dry-dock computer generated 3d model.

archive3d

free

Dry 3D Model

...el

archive3d

drying unit radiator towel dry

towel dry - 3d model for interior 3d visualization.

turbosquid

$9

Dry Sprey

...urbosquid

royalty free 3d model dry sprey for download as ma on turbosquid: 3d models for games, architecture, videos. (1661017)

turbosquid

$1

Dry Persimmon

...quid

royalty free 3d model dry persimmon for download as max on turbosquid: 3d models for games, architecture, videos. (1449030)

turbosquid

$1

Dry Persimmon

...quid

royalty free 3d model dry persimmon for download as max on turbosquid: 3d models for games, architecture, videos. (1448712)

turbosquid

free

drying rack

...osquid

royalty free 3d model drying rack for download as max on turbosquid: 3d models for games, architecture, videos. (1614082)

turbosquid

$7

Dry plant

...

royalty free 3d model dry plant for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1273449)

turbosquid

$37

pineapple dry

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Dry Reed_001

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Roller

turbosquid

$26

Roller A

...urbosquid

royalty free 3d model roller a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1350603)

turbosquid

$3

Roller

...oyalty free 3d model roller for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1460818)

3ddd

$1

edilkamin roller

...edilkamin roller

3ddd

камин

edilkamin roller 360

3ddd

$1

Roller Blinds

...roller blinds

3ddd

рулонная

roller blinds black out finish

turbosquid

$50

Roller

... roller for download as max, max, c4d, max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1700762)

3d_export

$10

rollers

...lers

3dexport

this is low-poly model of rollers.<br>model:<br>- low-poly<br>- textured<br>- uv unwrapped

3d_export

$28

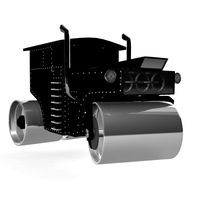

Roller 3D Model

...roller 3d model

3dexport

roller construction boss evil

roller 3d model adagio15740837 50561 3dexport

3d_export

$6

hopper roller conveyor

...hopper roller conveyor

3dexport

hopper roller conveyor

3d_export

$12

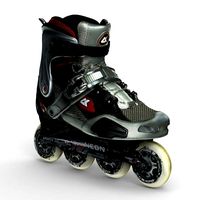

roller skates

...roller skates

3dexport

3d_ocean

$19

roller skate

...can scanned skates skating sport

3d scan of roller skate. the model has been retopologized and made fully compatible with zbrush.

I3

3d_export

$10

suv i3

...suv i3

3dexport

suv i3 2013 series

3d_ocean

$89

BMW i3 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 20143d model

...

cgstudio

.3ds .c4d .fbx .lwo .max .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20123d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2012 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20143d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of BMW i3 2014

...

buy a detailed 3d model of bmw i3 2014 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$40

3D model of Kitchen Set I3

...uy a detailed 3d model of kitchen set i3 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$30

Kitchen set i3

...ensils oven plates shelves sink table ware

kitchen set i3 include 3d models: cooker, oven, sink, cupboards, table, chair, plates.

3d_ocean

$89

BMW i3 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 Concept 20113d model

...i3

.3ds .c4d .fbx .lwo .max .obj - bmw i3 concept 2011 3d model, royalty free license available, instant download after purchase.

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

System

archibase_planet

free

System

...m

archibase planet

fire alarm system fire alarm box

security light system - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spider system

...stem spider glass system

spider system to fix glass stefano galli n050912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Euforia System

...euforia system

3ddd

euforia

euforia system

3d_export

$50

Roof system Truss system 3D Model

...oof system truss system 3d model

3dexport

roof system truss truss stage

roof system truss system 3d model aleksbel 38970 3dexport

3ddd

$1

DVD System

...dvd system

3ddd

dvd , schneider

dvd system

design_connected

free

Seating system

...seating system

designconnected

free 3d model of seating system

3d_export

$5

solar system

...solar system

3dexport

solar system in c4d, with 8k nasa textures

3ddd

$1

Quanta System

...quanta system

3ddd

медицина

quanta system.

лазерное оборудование для медицинских центров

3d_export

$15

solar system

...nd the other the sun, the earth and the moon, the latter has an animation with camera movement included, the files are in spanish

3d_export

$14

missile system

...missile system

3dexport

Box

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box 2 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

carton cardboard box box

box 1 - 3d model (*.3ds) for interior 3d visualization.

3d_export

$6

box

...box

3dexport

box

3d_export

$5

Box

...box

3dexport

box

3d_export

$5

box

...box

3dexport

box

3d_export

$5

box

...box

3dexport

box

archibase_planet

free

Box

...box

archibase planet

box box for paper notebook pencil

box - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box n170111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Box

...box

archibase planet

box carton cardboard box

box n050411 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Boxes

...boxes

archibase planet

boxes box case bin

boxes n281213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.