Thingiverse

IKEA RepRap LINNMON/ADILS by fASE-2

by Thingiverse

Last crawled date: 3 years ago

this design is outdated. for archival purposes only.

FINAL UPDATE March 19th, 2016 ****

i resolved the only major issue (idlers) by removing any printed parts. i used fender washers on top and bottom of 2 bearings on a M3 x 40mm screw drilled into the upper tabletop thereby bracing it at 2 points instead of 1. now that the idlers stay perpendicular, there are no anomalies in the layers, and every line comes out smooth w/o any wobble. i've taken this project as far as its gonna go, and i'm quite satisfied w/ the results. aluminum tubing + PLA makes sense for larger builds based on this project. its not for everyone, but it is a viable alternative in my opinion. the front bearing is slightly loose and makes a bit of noise on fast moves, but the quality of the print is not affected.

here is why you should NEVER BUILD THIS THING:

the 75 x 60cm LINNMON tabletops are no longer available from IKEA, you'd have to go even bigger at 100 x 60cm. that won't affect the movement but it'll be even bigger, and this thing is already pretty ridiculous.

i don't i think posted all the right parts on thingiverse to successfully make this thing. the fact is, i have thousands of designs and can't remember which ones i printed or which ones even worked.

there is little to no maintenance for this printer, but when you DO have to access the XY steppers, it becomes a real hassle and requires a considerable amount of patience.

having said that, i really don't want anyone wasting their time on this thing. it was a proof of concept that has become my main 3D printer. i've disassembled my old printer and have designed a new frameless, smaller, more conventional 3D printer which i will post to thingiverse in the next week or so. that one is designed to be more straight-forward, has both bowden and direct, and uses 8mm shafting + LM8LUU. it uses the same movement for XY but will be much more simplified and accessibility will no longer be an issue. stay tuned, and thanks for checking this thing out.

moved temporary Z-axis to side-to-side instead of front-to-back. got some front bearing noise which i'll address soon, and still having issues on retract and fast move leaving artifacts behind. swapped out 1.7A 0.9degree/step motor for 1.2A 1.8degree/step motor for the extruder. somehow the 0.9 steppers can't keep up w/ the information being sent to them and just panic. i'll look into that too, 'cause ideally i'd want those on XY since they're much smoother. i can always change stepping to 1/8 instead of 1/16 but i'd rather understand why.

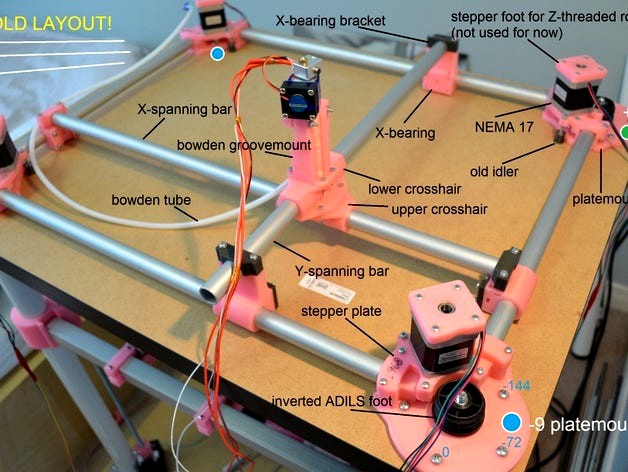

2 IKEA LINNMON tabletops connected by 4 ADILS legs. this is done by inverting the height adjustment feet. i'll explain later and consolidate the other things i uploaded into one. z-axis is temporary as are many other parts. very WIP.

don't attempt to build this thing yet until i publish a BOM.

i have a few ideas for this printer, including floating on just 1 tabletop w/o any legs... maybe even cutting a whole in the top and attempting direct drive instead of bowden. since its rather big, the sky's the limit.

for now i need to modify the platemounts to include a M3 nut the idler pin can screw into so its braced at 2 points in stead of just one (won't be pulled toward the stepper). also i already have a stepper plate w/ endstop holes at either end for endstop mounting for a cleaner design. additionally i have a belt snap in mechanism i'd like to try out in the near future. the Z-axis is very temporary and that has to get redone to use the ADILS legs as smooth rods (if possible--i failed miserably in my previous attempts). cable management, control box, and lighting will be worked on next.

FINAL UPDATE March 19th, 2016 ****

i resolved the only major issue (idlers) by removing any printed parts. i used fender washers on top and bottom of 2 bearings on a M3 x 40mm screw drilled into the upper tabletop thereby bracing it at 2 points instead of 1. now that the idlers stay perpendicular, there are no anomalies in the layers, and every line comes out smooth w/o any wobble. i've taken this project as far as its gonna go, and i'm quite satisfied w/ the results. aluminum tubing + PLA makes sense for larger builds based on this project. its not for everyone, but it is a viable alternative in my opinion. the front bearing is slightly loose and makes a bit of noise on fast moves, but the quality of the print is not affected.

here is why you should NEVER BUILD THIS THING:

the 75 x 60cm LINNMON tabletops are no longer available from IKEA, you'd have to go even bigger at 100 x 60cm. that won't affect the movement but it'll be even bigger, and this thing is already pretty ridiculous.

i don't i think posted all the right parts on thingiverse to successfully make this thing. the fact is, i have thousands of designs and can't remember which ones i printed or which ones even worked.

there is little to no maintenance for this printer, but when you DO have to access the XY steppers, it becomes a real hassle and requires a considerable amount of patience.

having said that, i really don't want anyone wasting their time on this thing. it was a proof of concept that has become my main 3D printer. i've disassembled my old printer and have designed a new frameless, smaller, more conventional 3D printer which i will post to thingiverse in the next week or so. that one is designed to be more straight-forward, has both bowden and direct, and uses 8mm shafting + LM8LUU. it uses the same movement for XY but will be much more simplified and accessibility will no longer be an issue. stay tuned, and thanks for checking this thing out.

moved temporary Z-axis to side-to-side instead of front-to-back. got some front bearing noise which i'll address soon, and still having issues on retract and fast move leaving artifacts behind. swapped out 1.7A 0.9degree/step motor for 1.2A 1.8degree/step motor for the extruder. somehow the 0.9 steppers can't keep up w/ the information being sent to them and just panic. i'll look into that too, 'cause ideally i'd want those on XY since they're much smoother. i can always change stepping to 1/8 instead of 1/16 but i'd rather understand why.

2 IKEA LINNMON tabletops connected by 4 ADILS legs. this is done by inverting the height adjustment feet. i'll explain later and consolidate the other things i uploaded into one. z-axis is temporary as are many other parts. very WIP.

don't attempt to build this thing yet until i publish a BOM.

i have a few ideas for this printer, including floating on just 1 tabletop w/o any legs... maybe even cutting a whole in the top and attempting direct drive instead of bowden. since its rather big, the sky's the limit.

for now i need to modify the platemounts to include a M3 nut the idler pin can screw into so its braced at 2 points in stead of just one (won't be pulled toward the stepper). also i already have a stepper plate w/ endstop holes at either end for endstop mounting for a cleaner design. additionally i have a belt snap in mechanism i'd like to try out in the near future. the Z-axis is very temporary and that has to get redone to use the ADILS legs as smooth rods (if possible--i failed miserably in my previous attempts). cable management, control box, and lighting will be worked on next.

Similar models

3dwarehouse

free

IKEA Table LINNMON 150 x 75 x 3,5cm + ADILS 70 x 4cm

...x 4cm

3dwarehouse

w 150cm x d 75cm x h 74cm white table board, silver legs #adils #ikea #linnmon #table #table_board #table_legs

3dwarehouse

free

Simple table (IKEA reference - linnmon + adils)

...simple table (ikea reference - linnmon + adils)

3dwarehouse

low poly of simple table (ikea reference - linnmon + adils)

3dwarehouse

free

Ikea Linnmon 150x75x34cm

...ikea linnmon 150x75x34cm

3dwarehouse

an ikea linnmon desk, with adils legs, same with my 120x60cm linnmon but bigger.

thingiverse

free

Ikea table lifter for LINNMON / ADILS by EUREKTechnology

...ogy

thingiverse

ikea table lifter for linnmon / adils

designed by: https://eurek.org

donations: http://paypal.me/eurektechnology

3dwarehouse

free

Table - IKEA - LINNMON ADILS

...a - linnmon adils

3dwarehouse

length: 1200 mm width: 1200 mm height: 740 mm ikea linnmon,adils (white) #ikea_linnmon_adils_white

3dwarehouse

free

![IKEA Linnmon Corner Desk WHITE]](/t/6786478.jpg)

IKEA Linnmon Corner Desk WHITE]

...zed the desk itself, then added normal adils legs same with my ikea linnmon normal] you may use this in any way, i don't care

cg_trader

$10

IKEA Linnmon Adils Desk

...ils desk

cg trader

3d model ikea linnmon adils desk ikea desk table, available formats fbx, blend, ready for 3d animation and ot

3dwarehouse

free

ikea linnmon/adils-150x75

...ikea linnmon/adils-150x75

3dwarehouse

bříza

3dbaza

$3

White Table LINNMON / ADILS (IKEA) (132607)

...ble linnmon / adils (ikea) (132607)

3dbaza

ikea linnmon / adils white table 3d model<br>cinema 4d (.c4d), octane rendering

3dwarehouse

free

Ikea LINNMON/ ADILS table white

...assembly. adjustable feet allow the table to stand level on uneven floors. 39 3/8x23 5/8' #adils #ikea #linnmon #table #white

Adils

turbosquid

$9

LINNMON ADILS table

...free 3d model linnmon adils table for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1606861)

turbosquid

$1

ikea linnmon adils table white legs 200cm/60cm

...linnmon-adils table-white-legs-200cm/60cm for download as fbx on turbosquid: 3d models for games, architecture, videos. (1507846)

thingiverse

free

ADILS replacement by taviralber

...adils replacement by taviralber

thingiverse

ikea adil table leg replacement, keeping the same thread.

thingiverse

free

Soporte base mesa ikea ADILS by snoopyteam

...soporte base mesa ikea adils by snoopyteam

thingiverse

ikea adils extender

thingiverse

free

IKEA ADILS leg by amartinsouto

...verse

this is my design to mount a ikea adils leg in a table. the inner hole is only a hole. you have to screw the leg manually.

3dbaza

$4

Adil Vezir Sculptureir Whale Sculpture (160187)

...eir whale sculpture (160187)

3dbaza

adil vezir sculptureir whale sculpture 3d model<br>bronze whale of sculptor adil vezir

thingiverse

free

Headphone holder for IKEA Adils leg by baratiistok3

...headphone holder for ikea adils leg by baratiistok3

thingiverse

headphone holder for adils leg. no tools required.

thingiverse

free

IKEA ADILS snap-on spacer by kjetilv

...thingiverse

this bracket snaps on the bottom of ikea adils desk legs to provide a comfortable space to the wall behind the desk.

thingiverse

free

Ikea Adils Heels by jorgerobles

...e gone short to align up with expedit 2x2 module.

available on https://tinkercad.com/things/9wvf1cwfgkp for your customization.

thingiverse

free

Ikea table lifter for LINNMON / ADILS by EUREKTechnology

...ogy

thingiverse

ikea table lifter for linnmon / adils

designed by: https://eurek.org

donations: http://paypal.me/eurektechnology

Linnmon

turbosquid

$9

LINNMON ADILS table

...free 3d model linnmon adils table for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1606861)

turbosquid

$9

LINNMON OLOV table

... free 3d model linnmon olov table for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1606858)

turbosquid

$9

LINNMON ALEX 2

...alty free 3d model linnmon alex 2 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1606850)

turbosquid

$5

Table Linnmon Aleko

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

IKEA linnmon-lalle

...linnmon-lalle

3ddd

ikea

стол фабрики ikea, модель linnmon-lalle.

длина: 150 см

ширина: 75 см

высота: 74 см

макс нагрузка: 50 кг

turbosquid

$1

IKEA LINNMON table

...kea linnmon table for download as max, 3ds, dwg, stl, and obj on turbosquid: 3d models for games, architecture, videos. (1681423)

turbosquid

$9

LINNMON 2000mm ALEX 2

...ee 3d model linnmon 2000mm alex 2 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1606852)

turbosquid

$5

Ikea LINNMON ALEX table

...del ikea linnmon alex table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1441715)

3d_ocean

$5

Linnmon-Oddvald Ikea Table

...top: top: fiberboard, printed and embossed acrylic paint, . frame: particleboard, abs plastic filling material: paper bottom: ...

turbosquid

$1

ikea linnmon adils table white legs 200cm/60cm

...linnmon-adils table-white-legs-200cm/60cm for download as fbx on turbosquid: 3d models for games, architecture, videos. (1507846)

Fase

archibase_planet

free

Cleaner

...cleaner archibase planet crane lift fase cleaner - 3d model for interior 3d...

archive3d

free

Cleaner 3D Model

...cleaner 3d model archive3d crane lift fase cleaner - 3d model for interior 3d...

turbosquid

$5

Flower Vase Butterfly

...flower vase butterfly turbosquid royalty free 3d model flower fase butterfly for download as ma, max, obj, and fbx...

3d_export

$5

Old Gray Car Coupe From ChemodenStudio Low-poly

...texture size 128x128 (psd,png,jpeg) fbx, stl, blend: verts: 352 fase: 239 tris: 598 ready for...

3d_export

$5

Old Gray Car Minibus From ChemodenStudio Low-poly 3D

...3dexport texture size 128x128 (psd,png,jpeg).fbx, stl, blend: verts: 388 fase: 282 tris: 692 ready for...

3d_export

$5

Valve

...quick import. available formats fbx, obj. vertices - 3,741 fase - 3,697 textures 2048x2048 created in blender...

3d_export

$5

Valve

...quick import. available formats fbx, obj. vertices - 3,841 fase - 3,787 textures 2048x2048 created in blender...

3d_export

$5

Steel valve

...quick import. available formats fbx, obj. vertices - 5,122 fase - 5,186 textures 2048x2048 created in blender...

3d_export

free

Bronze valve

...quick import. available formats fbx, obj. vertices - 1,905 fase - 1,981 textures 2048x2048 created in blender...

3d_export

$5

Valve

...import. available formats fbx, obj, mtl vertices - 3,945 fase - 4,050 textures 2048x2048 texture maps - basecolor, roughness,...

Reprap

turbosquid

$1

Go Pro Balance Hand Wand Reprap

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

Reprap keychain by AndreasD

...reprap keychain by andreasd

thingiverse

a simple reprap logo keychain for the reprap lovers like me!

thingiverse

free

REPRAP CHASSIS by leonk

...reprap chassis by leonk

thingiverse

reprap chassis

thingiverse

free

COUPLER RepRap by leonk

...coupler reprap by leonk

thingiverse

coupler reprap

thingiverse

free

RepRap Switch by n3opl4n

...reprap switch by n3opl4n

thingiverse

switch for reprap prusa i2.

p-space hackerspace logo.

thingiverse

free

Reprap pendulum by mr_seeker

...ap pendulum by mr_seeker

thingiverse

its a pendulum in the shape of the reprap logo. it has a 1mm hole for putting a wire in it.

thingiverse

free

RepRap Ornament by redskinsjbs

...reprap ornament by redskinsjbs

thingiverse

i tried to make a teardrop shape ornament for the holiday season in honor of reprap

thingiverse

free

Spool holder reprap by mdnm

...spool holder reprap by mdnm

thingiverse

this is spool holder for reprap.

thingiverse

free

RepRap logo keyring by mrjohnc

...reprap logo keyring by mrjohnc

thingiverse

reprap logo keyring

thingiverse

free

REPRAP LEON K by leonk

...reprap leon k by leonk

thingiverse

reprap leon k

Ikea

3ddd

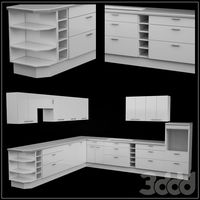

$1

IKEA

...ikea

3ddd

ikea , стеллаж

ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea

кухня ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea

осторожно, тяжелая модель

ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea

5 зеркал от ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea , бойа

ikea светильник потолочный

3ddd

$1

IKEA

...ikea

3ddd

ikea , барный

bar stool ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea , зубная щетка , косметика

ikea

3ddd

free

IKEA

...ikea

3ddd

ikea , трюмо

дамский столик ikea.

3ddd

$1

IKEA

...3ddd

ps , декоративный набор , ikea

ikea decor

3ddd

$1

Ikea

...ikea

3ddd

ikea , lagra

модель лампы от ikea

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$29

Book variation 2 2

...3d model book variation 2 2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1366868)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур