Thingiverse

IKEA Lack Extractor Fan Assembly by DrLeFonque

by Thingiverse

Last crawled date: 3 years, 1 month ago

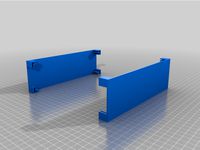

This is my first CAD design, ever. This is an extractor fan assembly designed to be used on an IKEA Lack enclosure setup. The aim was to have an extractor fan (or two) mounted on top of the enclosure to extract heat (for PLA) and fumes (for ABS) from the enclosure when required.

Updates

Update (2018/04/05): I printed out the bottom part of the fan assembly (IKEA_Lack_Extractor_Fan_Assembly_Bottom.stl) and noticed that there was a small 1mm gap between between the inner wall and one side of the fan mount. I've corrected this and uploaded the fixed STL file.

Update (2018/04/05): I printed the top half of the assembly (IKEA_Lack_Extractor_Fan_Assembly_TOP.stl) and found another error I made in the design. Whilst making the slot system so that both halves slot into one another, I forgot that this would take the height (excluding the flared ends) from 50mm to 48mm. Tomorrow I will correct of this and upload the new top half with an extra 2mm added to account for this.

Update (2018/04/06): I have made the 2mm adjustment to the top half of the assembly, the whole assembly should now fit precisely. I am going to reprint the top assembly over the weekend and verify that all the holes line up, then this should be a complete and functional build.

Update (2018/04/06): Added duct mount

Update (2018/04/09): The duct mount was a little too big for the hole it was meant to fit into, I have amended this and uploaded the fixed file. I've also confirmed that all the holes line up, so this is now a complete and functional build.

Parts

For this assembly I've purchased the following parts:

Scythe GlideStream 120mm PWM SC: https://www.amazon.co.uk/gp/product/B01D64OXA4/

The fan comes with a 3 speed controller switch that allows you to increase or decrease RPM's based on your needs. I'm going to be rewiring this to a control panel on the front of my enclosure (still working on this), which will allow me to turn the fans on and off and control the speed as required. There is a hole in the bottom part of the assembly to run the wiring through the enclosure.

Active Carbon Filter (2mm): https://www.amazon.co.uk/gp/product/B06XF5MWWK/

The active carbon filter will (hopefully) neutralise the ABS fumes. If this isn't the case then I'll make another top half with an adaptor where you can attach a duct and pump the ABS fumes out of a window or something.

Flexible Fan Ducting: https://www.amazon.co.uk/White-Flexible-Fan-Ducting-Extractor/dp/B011OOQ9PA/

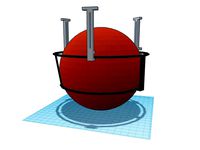

Added a duct mount so you can attach some 100mm (4" in freedom units) flexible fan ducting. I've also added a notch around the mount to secure ducting with a zip tie (less than 5mm thick).

You'll need 4 x M3 screws and nuts to hold the fan and whole assembly together (including duct mount, if using). By my estimates, you'll need 40mm M3 screws (without duct) or 42mm screws (with duct).

Here are the TinkerCAD files, if you want to remix the design: https://www.tinkercad.com/things/25ztyGigLsC#/

As this is my first attempt at making a CAD design for 3D printing, feedback is welcome. Any suggestions on how to optimize the design for 3D printing is also welcome.

Updates

Update (2018/04/05): I printed out the bottom part of the fan assembly (IKEA_Lack_Extractor_Fan_Assembly_Bottom.stl) and noticed that there was a small 1mm gap between between the inner wall and one side of the fan mount. I've corrected this and uploaded the fixed STL file.

Update (2018/04/05): I printed the top half of the assembly (IKEA_Lack_Extractor_Fan_Assembly_TOP.stl) and found another error I made in the design. Whilst making the slot system so that both halves slot into one another, I forgot that this would take the height (excluding the flared ends) from 50mm to 48mm. Tomorrow I will correct of this and upload the new top half with an extra 2mm added to account for this.

Update (2018/04/06): I have made the 2mm adjustment to the top half of the assembly, the whole assembly should now fit precisely. I am going to reprint the top assembly over the weekend and verify that all the holes line up, then this should be a complete and functional build.

Update (2018/04/06): Added duct mount

Update (2018/04/09): The duct mount was a little too big for the hole it was meant to fit into, I have amended this and uploaded the fixed file. I've also confirmed that all the holes line up, so this is now a complete and functional build.

Parts

For this assembly I've purchased the following parts:

Scythe GlideStream 120mm PWM SC: https://www.amazon.co.uk/gp/product/B01D64OXA4/

The fan comes with a 3 speed controller switch that allows you to increase or decrease RPM's based on your needs. I'm going to be rewiring this to a control panel on the front of my enclosure (still working on this), which will allow me to turn the fans on and off and control the speed as required. There is a hole in the bottom part of the assembly to run the wiring through the enclosure.

Active Carbon Filter (2mm): https://www.amazon.co.uk/gp/product/B06XF5MWWK/

The active carbon filter will (hopefully) neutralise the ABS fumes. If this isn't the case then I'll make another top half with an adaptor where you can attach a duct and pump the ABS fumes out of a window or something.

Flexible Fan Ducting: https://www.amazon.co.uk/White-Flexible-Fan-Ducting-Extractor/dp/B011OOQ9PA/

Added a duct mount so you can attach some 100mm (4" in freedom units) flexible fan ducting. I've also added a notch around the mount to secure ducting with a zip tie (less than 5mm thick).

You'll need 4 x M3 screws and nuts to hold the fan and whole assembly together (including duct mount, if using). By my estimates, you'll need 40mm M3 screws (without duct) or 42mm screws (with duct).

Here are the TinkerCAD files, if you want to remix the design: https://www.tinkercad.com/things/25ztyGigLsC#/

As this is my first attempt at making a CAD design for 3D printing, feedback is welcome. Any suggestions on how to optimize the design for 3D printing is also welcome.

Similar models

thingiverse

free

Fume Extractor - 120mm Fan Shroud & Duct Adaptor by Tez_Gelmir

...pter reduces from 120mm to 85mm diameter sleeve to suit the flexible downpipe available from bunnings in australia for $9.90 aud.

thingiverse

free

Fume Extractor 200m Fan by jtranfpv

...

print 2 top-bottom plates

print 2 side plates

print 1 front plates

print 1 back plates

assembly required by fitting in the slots

thingiverse

free

Creality LD-002R Fume Extractor by BostonBowser

...on a cover to that hole in the enclosure.

you will need to power the fan with a 12v power supply or some sort of voltage source.

thingiverse

free

Solder Station Fume Extractor by vo1pwf

...ngiverse

a home made fume extractor made from

80mm pc fan

3d printed enclosure

activated filter

i added a switch for easy on/off

thingiverse

free

![80mm Fans (2) to 4" Dryer Duct [Pairs well with Da Vinci 1.0 Fan Mount for exhaust] by rickschrader](/t/8918295.jpg)

80mm Fans (2) to 4" Dryer Duct [Pairs well with Da Vinci 1.0 Fan Mount for exhaust] by rickschrader

... all of the abs-printing smell (and arguably dangerous fumes) from my area.

i printed with no supports and it turned out great.

thingiverse

free

Remixed 3d fume extractor right side

...o the slot for assembly. i added a channel to the left if the wiring hole that lets the wiring pass in and the fan sit correctly.

thingiverse

free

CR-10 - Ultimate Blow Me Twice by ketchu13

...mount, part cooler by louiscooper" at this stage of progress

thanks to them, take a look at others designs by these authors

thingiverse

free

Soldering Fume Extractor for 120mm Fan by twistedartwork

.... another option would be to connect it to some sort of duct but then you would need to design an adaptor for your specific duct.

thingiverse

free

Cooling Unit for Filastruder Fume Extraction Enclosure by mrflippant

...print without support.

you'll need parts from the fume extraction enclosure that this is remixed from to complete the system.

thingiverse

free

Super Suction Fume Extractor by spectura

... much so that you really hardly have to be close to it for the smoke to get sucked up!

based of the simple solder fume fan by orc

Drlefonque

thingiverse

free

Automatic Fire Extinguisher Mount by DrLeFonque

...n be easily removed.

here are the tinkercad files, if you want to remix the design: https://www.tinkercad.com/things/ic3zwawhxa5

thingiverse

free

D&D Initiative Tracker by DrLeFonque

...y feedback and suggestions on how these trackers can be improved, any good suggestions i get i'll implement into the design.

Extractor

turbosquid

$35

Extractor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

kitchen extractor

...kitchen extractor

3dexport

extractor hood for kitchen in stainless steel with blue tempered glass, very modern.

3ddd

free

Extractor Bosch DWB098E50

...extractor bosch dwb098e50

3ddd

вытяжка , bosch

extractor bosch dwb098e50

3ddd

free

Teka - Extractor hood

...teka - extractor hood

3ddd

teka , вытяжка

teka - extractor hood

turbosquid

$1

Extractor cupboard

...

royalty free 3d model extractor cupboard for download as max on turbosquid: 3d models for games, architecture, videos. (1161308)

turbosquid

$30

Lock extractor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

air extractor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Vehicle Exhaust Extractor

...3d model vehicle exhaust extractor for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1689744)

turbosquid

$29

Liquid Liquid Extractor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Bosch Extractor Modern

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Lack

3d_export

$5

LACK LACK Coffee table white 90x55 cm IKEA

..., white, 90x55 cm ikea<br>https://www.ikea.com/ru/ru/p/lack-lakk-zhurnalnyy-stol-belyy-50449907/?ysclid=l8zshj49w6656165430

turbosquid

$4

Ikea Lack

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

IKEA Lack Coffee Table

... кофейный

ikea lack coffee tablehttp://www.ikea.com/gb/en/catalog/products/00104291

turbosquid

$5

IKEA Lack Table

...ack table for download as blend, blend, unitypackage, and fbx on turbosquid: 3d models for games, architecture, videos. (1623135)

turbosquid

$10

Ikea Lack Set

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

IKEA Lack Library

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

IKEA LACK TABLE

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

IKEA Lack Shelf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Ikea Table 5 Lack

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

IKEA Lack Side Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea , стеллаж

ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea

кухня ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea

осторожно, тяжелая модель

ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea

5 зеркал от ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea , бойа

ikea светильник потолочный

3ddd

$1

IKEA

...ikea

3ddd

ikea , барный

bar stool ikea

3ddd

$1

IKEA

...ikea

3ddd

ikea , зубная щетка , косметика

ikea

3ddd

free

IKEA

...ikea

3ddd

ikea , трюмо

дамский столик ikea.

3ddd

$1

IKEA

...3ddd

ps , декоративный набор , ikea

ikea decor

3ddd

$1

Ikea

...ikea

3ddd

ikea , lagra

модель лампы от ikea

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Assembly

3d_export

$7

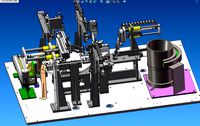

Electronic product assembly machine assembly machine

...electronic product assembly machine assembly machine

3dexport

electronic product assembly machine assembly machine

3d_export

$15

generator assembly line

...ced and assembled in the form of module block. it is a demonstration project of generator assembly. welcome to download and learn

3d_export

$10

elevator traction machine assembly line motor assembly process

... traction machine assembly line motor assembly process

3dexport

elevator traction machine assembly line (motor assembly process)

3d_export

$16

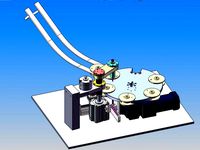

pin assembly machine

...pin assembly machine

3dexport

pin assembly machine

3d_export

$7

tower-crane-assembly

...tower-crane-assembly

3dexport

tower-crane-assembly

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658296)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658291)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658293)

turbosquid

$75

Platform Assembly

...royalty free 3d model platform assembly for download as blend on turbosquid: 3d models for games, architecture, videos. (1472939)

turbosquid

$15

generator assembly

...y free 3d model generator assembly for download as and sldas on turbosquid: 3d models for games, architecture, videos. (1469469)