Thingiverse

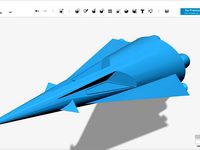

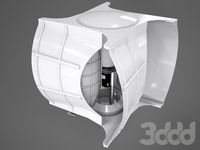

Icarus - A Brushless Micro Offset Quadcopter Frame by Haitchpeasauce

by Thingiverse

Last crawled date: 3 years, 1 month ago

A 3D printed brushless micro FPV quadcopter frame featuring offset motors for smooth flights!

Just wanted to share my first 2-inch frame design. I thought it would be fun to have a crack at designing a 3D printed quadcopter frame.

Here are some cool features of the design:

Flipped top-bottom plates that allow motors to be mounted offset or inverted from each other so that the props ride in clean air.

Flexible build options, allowing 2, 3, perhaps 4 layer stack heights.

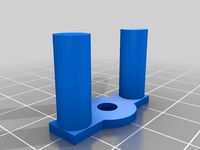

Backpack system allows mounting of a 20x20 VTx or perhaps even a Runcam Split Mini.

Props not in view of the camera.

Can be set up to mount battery top or bottom.

Lightweight yet solid structure.

Easy to print. All parts print quickly and do not require supports.

Plastic frame means screws bite straight into the plastic, no need for nuts when fastening.

Plans to create an HD camera mount, as well as 2.5" and 3" versions.

Total build around 77g dry. This frame performed surprisingly well on its maiden flight, very fast and smooth and easy to handle. There were some minor wobbles when applying high throttle, but with some tuning I think this will become a great little craft. I am very happy with these initial results!

This frame was inspired by the Airblade Dark Knight and the RotorX Switchback. I just love their smooth handling because of the offset motors, and wanted a 3D printable 2" version.

More parts and accessories on the way, as well as an instruction video.

Please post feedback, I'm excited to hear your thoughts!

Hardware required:

4x 18-25mm M2 screws for the stack

10x 6-8mm M2 screws for the camera pod and backpack mount

2x 3mm M2 screws for the camera

20mm M2 standoff, preferably metal

Build Notes:

Select the base plate where the stack screws will go in (top or bottom), and use a 2mm or 2.5mm drill bit to widen the holes so that the stack screws can pass through easily.

The base plate holes are intentionally 2mm diameter so that the stack screws bite into them and hold the completed model together.

Just wanted to share my first 2-inch frame design. I thought it would be fun to have a crack at designing a 3D printed quadcopter frame.

Here are some cool features of the design:

Flipped top-bottom plates that allow motors to be mounted offset or inverted from each other so that the props ride in clean air.

Flexible build options, allowing 2, 3, perhaps 4 layer stack heights.

Backpack system allows mounting of a 20x20 VTx or perhaps even a Runcam Split Mini.

Props not in view of the camera.

Can be set up to mount battery top or bottom.

Lightweight yet solid structure.

Easy to print. All parts print quickly and do not require supports.

Plastic frame means screws bite straight into the plastic, no need for nuts when fastening.

Plans to create an HD camera mount, as well as 2.5" and 3" versions.

Total build around 77g dry. This frame performed surprisingly well on its maiden flight, very fast and smooth and easy to handle. There were some minor wobbles when applying high throttle, but with some tuning I think this will become a great little craft. I am very happy with these initial results!

This frame was inspired by the Airblade Dark Knight and the RotorX Switchback. I just love their smooth handling because of the offset motors, and wanted a 3D printable 2" version.

More parts and accessories on the way, as well as an instruction video.

Please post feedback, I'm excited to hear your thoughts!

Hardware required:

4x 18-25mm M2 screws for the stack

10x 6-8mm M2 screws for the camera pod and backpack mount

2x 3mm M2 screws for the camera

20mm M2 standoff, preferably metal

Build Notes:

Select the base plate where the stack screws will go in (top or bottom), and use a 2mm or 2.5mm drill bit to widen the holes so that the stack screws can pass through easily.

The base plate holes are intentionally 2mm diameter so that the stack screws bite into them and hold the completed model together.

Similar models

thingiverse

free

Joza TX130 quadcopter frame

...are to be threaded m2.

i have had the plates cut out of 3mm carbon fiber plates. 1,5mm for the top plate. stand offs are printed.

thingiverse

free

E-Flight Mini Motor Mount by Shovelhead84

... plate should be large enough to accommodate most 12-20amp escs.

firewall, 3mm

mounting plate, 2mm

sidewalls taper from 2mm - 1mm

thingiverse

free

Brushless Whoop Quadcopter by RalphHilton

...fc and 4 in 1 esc.

i used 4 8mm nylon spacers between the top and bottom sections.

tx01 camera mount. battery housing.

5cm props.

thingiverse

free

EZ-85 85MM brushless frame by Kentuliz

...again in a middle 2mm of flexi, and put flexi again on 90% of progress.

if you printing in abs or other than pla it will be fine.

thingiverse

free

QAV-R 120H - 2.5" Frame by Flowr

...2 and 1304s

designed for 2 - 2.5" props (max 65mm - gemfan flash)

20x20mm fc and escs mount

motor to motor it's +- 120mm

thingiverse

free

Evolution Tube Frame Quad

...pter using 14mm tube arms. print 2 plates and 8 motor mount plates, 4 for top and 4 for bottom. i will upload the arm mount soon.

thingiverse

free

Micro H-Quadcopter FPV Top Plate by FunFlyFPV

...lates are for the spektrum va1100 and the walkera tx5805 micro fpv cameras and attaches to the bottom plate with m2 nylon screws.

thingiverse

free

M2 & M2.5 to M3 Adapters & Soft Mounts (20 x 20 mm Flight Controllers) by Karamvir_Bhagat

... rotate and mount the stack like a tiny whoop with a corner facing forward to in the regular manner by mounting through the arms.

thingiverse

free

TTGT 120mm BETA V4 - 2.5" Freestyle Frame by Flowr

... motors (and some 130x - 1304) and 20x20mm stack, if you want to use 16x16mm stack, please print 16x16mm to 20x20mm fc adapter :)

thingiverse

free

2.5 inch quad H-frame by deaderbug

...0x20 stacks in the middle for the esc and fc and a 20x20 stack in the back for the rx and vtx.

added backpack for miniion antenna

Haitchpeasauce

thingiverse

free

AcroBrat Soft Mount Landing Feet & Arm Protectors by Haitchpeasauce

...uot; version for extra protection

a "light" version for less weight at the extremities

try both and see which you like!

thingiverse

free

TBS Source One v0.11 Motor & Frame Protector by Haitchpeasauce

...**update 23-aug-2018: added a middle hole to allow for use as a soft mount

**update 07-oct-2018: added back versions with no hole

thingiverse

free

AcroBrat Tail Mount Axii, Antenna, Buzzer+LED by Haitchpeasauce

...sion with rx antennas angled in an l shape at 90 degrees for crossfire dipole.

24 apr 2019: added version to fit foxeer lollipop.

thingiverse

free

AcroBrat Bumper Bar Pack by Haitchpeasauce

...sions, making a snug fit. it takes a little more effort to mount the bumper, but the result is better protection and more secure.

Icarus

design_connected

$11

Icarus

...icarus

designconnected

artecnica icarus pendant lights computer generated 3d model. designed by tord boontje.

turbosquid

free

Icarus Lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

SpaceShip Icarus

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

kid icarus

...kid icarus

3dexport

3d printer model kid_icarus

3d_export

$20

Orbital Rocket Icarus 3D Model

...cket icarus 3d model

3dexport

space craft orbital rocket icarus itharus

orbital rocket icarus 3d model janiashvili 30470 3dexport

turbosquid

$3

Wolf Claws (Kid Icarus: Uprising)

...model wolf claws (kid icarus: uprising) for download as blend on turbosquid: 3d models for games, architecture, videos. (1280325)

thingiverse

free

Icarus by GenericStudentJC1

...icarus by genericstudentjc1

thingiverse

icarus from the greek myth icarus and daedalus.

thingiverse

free

icarus by sikander

...icarus by sikander

thingiverse

parts for icarus

thingiverse

free

ANSA Icarus by KineticGothicTank

...odynamic, the lack of landing gear, however means that the icarus command modules have crashed every time they attempted to land.

sketchfab

$20

Icarus - Planet of the Apes

... on the aforementionned planet. - icarus - planet of the apes - buy royalty free 3d model by ralph's workshop (@ralphedenbag)

Brushless

turbosquid

$4

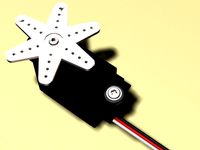

Brushless motor

...r download as 3ds, dxf, obj, xsi, wrl, fbx, dwg, dae, and skp on turbosquid: 3d models for games, architecture, videos. (1366202)

3d_export

$10

wheel and motor for mars rover

...last project: a mars rover concept. complete wheel and brushless electrical motor designed to attach to an atv or...

3d_export

$100

the volt futuristic ev hypercar

...future ! some design aspects : this is in-wheel (brushless hub) motors vehicle, for each motor the core part...

3d_export

$20

si cantik cargo plane for humanity medicine kit

...used for the tailboom. the electronic components used are brushless motor os 1000kv which can produce thrust 3kgas a...

free3d

free

N6375 Brushless Motor

...n6375 brushless motor

free3d

n6375 brushless motor

thingiverse

free

Tyro 79 brushless key

...tyro 79 brushless key

thingiverse

tyro 79 brushless key

thingiverse

free

Propeller antirotation brushless lock

...propeller antirotation brushless lock

thingiverse

propeller antirotation brushless lock

thingiverse

free

Brushless motor holder by NukeCraft

...brushless motor holder by nukecraft

thingiverse

brushless motor holder for bl3650

thingiverse

free

Brushless motor mount by robotbuilders

...brushless motor mount by robotbuilders

thingiverse

replacement mount for brushless motor.

thingiverse

free

Brushless motor mount by TarsVH

...brushless motor mount by tarsvh

thingiverse

a mount for a 2830 size brushless motor

Quadcopter

3d_export

$5

quadcopter

...quadcopter

3dexport

futuristic quadcopter design.<br>original design davidflo 77

turbosquid

$19

quadcopter

...lty free 3d model quadcopter for download as max, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1591426)

turbosquid

$25

QuadCopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Quadcopter 3D Model

...quadcopter 3d model

3dexport

quadcopter studio shaders

quadcopter 3d model vortex333 93968 3dexport

3d_export

$5

Quadcopter 3D Model

...quadcopter 3d model

3dexport

quadcopter aircraft helicopter

quadcopter 3d model greatghost 94019 3dexport

3d_export

$18

passenger quadcopter

... a multicopter is an aircraft built according to a helicopter scheme, with three or more rotors. previews rendered with redshift.

turbosquid

$159

Quadcopter Animated.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Drone Quadcopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Drone Quadcopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$29

Quadcopter

...

questions about the continuation of the collection or the model can be asked here:<br>https://www.artstation.com/evgen_beg

Offset

turbosquid

$20

Armchair Offset

...ee 3d model armchair offset for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1593561)

3ddd

$1

Комод Madia Offset

...комод madia offset

3ddd

oro-milano

комод madia offset. бренд oro-milano

3ddd

$1

Столик Offset (Bonaldo)

...aldo (италия)

артикул: c3596

модель предоставляется в форматах: max(2010), fbx, obj, 3ds, с материалами, текстурами и размерами.

turbosquid

free

Wooden Barrel - Offset

...alty free 3d model wooden barrel - offset for download as fbx on turbosquid: 3d models for games, architecture, videos. (1184305)

turbosquid

$14

Offset Armchair by Menu

...ffset armchair by menu for download as max, 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1681480)

turbosquid

$65

Small Offset Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Offset floor lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Roche Bobois / Offset

...roche bobois / offset

3ddd

стеллаж

линейка мебели offset.roche-bobois.desing sacha lakic.

3d_export

$65

Small Offset Printer 3D Model

...dustrial production equipment tool small offset machine machinery plotter

small offset printer 3d model dropassets 54178 3dexport

turbosquid

$5

MIRROR---Half moon offset

...ror---half moon offset for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1525571)

Micro

3ddd

$1

Micro

...micro

3ddd

автобус

turbosquid

$80

MICRO

...ty free 3d model micro for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1700743)

3ddd

$1

JBL Micro Wireless

... micro , колонка , плеер

jbl micro wireless

turbosquid

$10

Suppressor Micro

...quid

royalty free 3d model suppressor micro for download as on turbosquid: 3d models for games, architecture, videos. (1380433)

turbosquid

$20

Micro Meter

...osquid

royalty free 3d model micro meter for download as fbx on turbosquid: 3d models for games, architecture, videos. (1350448)

turbosquid

$7

NIghtstand Micro

...d

royalty free 3d model nightstand micro for download as max on turbosquid: 3d models for games, architecture, videos. (1248117)

3ddd

$1

Micro wind turbine

...micro wind turbine

3ddd

турбина

micro wind turbine for your green building projects

turbosquid

$29

Micro Speakers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Micro Servo.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Micro cells

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Frame

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n071113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Frame

...frame

3ddd

frame

3ddd

free

Frame

...frame

3ddd

frame

archibase_planet

free

Frame

...frame

archibase planet

frame mirror frame ornament

frame n260113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame photo n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window frame window

frame 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame wall frame decoration

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.