Thingiverse

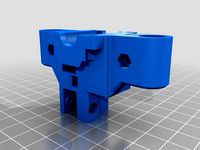

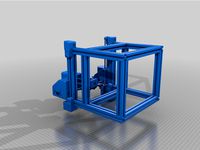

Hypercube evolution 12mm XY modification by sverreb

by Thingiverse

Last crawled date: 3 years ago

Thjis is a modification of the XY-gantry and motor mounts to support 12MM X and Y axis rods. The x-carriage is designed to use IGUS LME12UU compatible bearings as it is assumed that a carbon or aluminum rod will be used for the x-axis.

The Y-axis is designed for LM12LUU bearings but two LM12UUs should also work though not with the security of the circlips.

Use circlips to secure the bearings, tension the clamping bolts so you have no play.

There are three versions of the x-carriage uploaded 00, 02 and 04 The only difference is the OD for the igus bearing carrier. which is designed exact (22mm) in the 00 version, 22.2mm in the 02 and 22.4mm in 04. The reason for this is that 3d printers tend to shrink IDs somewhat the bearing still fits as the outer part of the carrier is flexible, but this has the effect that the bearings are moved slightly outboard which causes binding. So higher number means smaller bearing pitch.

To find which version you need, I suggest starting with the 02 version then assemble the entire x-axis with x-rods and BOTH y-carriages. If the x-carriage experiences increased resistance near the y-carriages you have a binding issue. To find if you need the 04 or 00 try to pinch the xrods a bit while moving the x-carriage, if the carriage moves easier, the x-carriage bearing pitch is too small and are binding on the outside. You should then go to a larger pitch (00). Then spread the rods with your thumb and index finger. If this cause the carriage to move easier your bearing pitch is too large and you should go to 04 OR you can sand the insides of the bearing carrier.

If you have excessive binding or are unable to push the rod through the double bearing the self aligning feature of the carrier does not work. Try to sand a bit off the width of the carrier to avoid having the circlip bind the bearing (The circlips should move freely) Also check the inside for burrs or other unevenness.

I modified the idler corner in order to enable them to be printed in the same orientation as the motor mounts and to allow it to register on the side of the extrusion to help kepping the Y rods square and parallel to avoid calibration issues. Rod holes are oversized by 0.2mm to compensate for the 3d printers tendency to under-size IDs. (So don't dial it out with horizontal size compensation)

Optical endstops are removed and replaced with holders for standard mechanical endstops. Only two are provisioned and they are not adjustable.

The x-carriage extends further down than the original, so some hot-end mounts may need modification. It should work with the e3d volcano but is not yet verified

The design has been proven in use.

By request I have added versions of the x-carriage for the japan dimension bearing (LM12UU compatible) These are just uploaded, not tested.

A new x-carriage have just been uploaded. This adds a 4th bearing to minimize rocking that were affecting mesh bed levelling (It has no apparent effect on print quality). The CAD for this can be found at: https://a360.co/2orpBo4

The Y-axis is designed for LM12LUU bearings but two LM12UUs should also work though not with the security of the circlips.

Use circlips to secure the bearings, tension the clamping bolts so you have no play.

There are three versions of the x-carriage uploaded 00, 02 and 04 The only difference is the OD for the igus bearing carrier. which is designed exact (22mm) in the 00 version, 22.2mm in the 02 and 22.4mm in 04. The reason for this is that 3d printers tend to shrink IDs somewhat the bearing still fits as the outer part of the carrier is flexible, but this has the effect that the bearings are moved slightly outboard which causes binding. So higher number means smaller bearing pitch.

To find which version you need, I suggest starting with the 02 version then assemble the entire x-axis with x-rods and BOTH y-carriages. If the x-carriage experiences increased resistance near the y-carriages you have a binding issue. To find if you need the 04 or 00 try to pinch the xrods a bit while moving the x-carriage, if the carriage moves easier, the x-carriage bearing pitch is too small and are binding on the outside. You should then go to a larger pitch (00). Then spread the rods with your thumb and index finger. If this cause the carriage to move easier your bearing pitch is too large and you should go to 04 OR you can sand the insides of the bearing carrier.

If you have excessive binding or are unable to push the rod through the double bearing the self aligning feature of the carrier does not work. Try to sand a bit off the width of the carrier to avoid having the circlip bind the bearing (The circlips should move freely) Also check the inside for burrs or other unevenness.

I modified the idler corner in order to enable them to be printed in the same orientation as the motor mounts and to allow it to register on the side of the extrusion to help kepping the Y rods square and parallel to avoid calibration issues. Rod holes are oversized by 0.2mm to compensate for the 3d printers tendency to under-size IDs. (So don't dial it out with horizontal size compensation)

Optical endstops are removed and replaced with holders for standard mechanical endstops. Only two are provisioned and they are not adjustable.

The x-carriage extends further down than the original, so some hot-end mounts may need modification. It should work with the e3d volcano but is not yet verified

The design has been proven in use.

By request I have added versions of the x-carriage for the japan dimension bearing (LM12UU compatible) These are just uploaded, not tested.

A new x-carriage have just been uploaded. This adds a 4th bearing to minimize rocking that were affecting mesh bed levelling (It has no apparent effect on print quality). The CAD for this can be found at: https://a360.co/2orpBo4

Similar models

thingiverse

free

LM12UU Y-Carriage for Mendelmax by imrahil

...se.com/thing:80687

be careful with bearings because holders breaks easily (pic 3). but you can use abs glue to fix them (pic 4)

thingiverse

free

Igus 10mm Bushing Holder for LM8LUU by superjamie

...d or tube on the x axis, or just allows to not use a noisy metal linear bearing on a 10mm steel rod.

openscad source is included.

thingiverse

free

IGUS linear bearing hopup for the E3D BigBox by JesperJuul

.../forum.e3d-online.com/index.php?threads/project-whisper-igus-solid-polymer-bearing.1358/

cheers.

p.s. sorry about the orientation

thingiverse

free

igus replacement for Prusa I3 MK2(s) by Knickohr

...s for the mk2, it will work for the mk2s too, but with the old disadvantages.

update :

fixed another belt rubbing at the carriage

thingiverse

free

S.T.E.V.E X Gantry for 10mm rod and IGUS RJZM by Darkorbz

...bigger types:https://www.banggood.com/16t20t-gt2-aluminum-timing-drive-pulley-for-diy-3d-printer-withwithout-tooth-p-1099142.html

thingiverse

free

Laser engraver 12mm rod LM12UU 12mm Linear Ball Bearing, new items. by ezsolt74

... and the gt2 20 tooth pulley was designed for.

the bearings in the pulley 625zz, the front holder 624zz.

40x40mm aluminium frame.

thingiverse

free

Hypercube Evolution Compliant Linear Bearing by Chapelhill

...ndcaps to suit, plain ended variation and screw thread insert version to lock x rods/tube. there is also 12mmdia y end stop flag.

thingiverse

free

Core XY - Sakura Y carriage - lm8uu by Crashoverride

...designed ichibey's sakura x end, 50mm between x axis rods. it should work with standard prusa/mendel x carriage. -=untested=-

thingiverse

free

X carriage for igus pillow block bearings with rear fan mount with rotated extruder mounting by orias

...nut traps so the wade's extruder stepper motor can be angled away from the threaded rod for an extra few mm of x axis travel.

thingiverse

free

Hypercube XY Joiner for 3/8" rods, and IGUS Drylin RJ4JP-01-08 (10mm version also included) by GORILLA_PARTS

...ed in simplify 3d with -.15 mm horizontal size compensation. the bushings should fit absolutely perfectly, so adjust accordingly.

Sverreb

thingiverse

free

lm8uu tensionable self aligning linear bearing carrier by sverreb

...ring to slightly self adjust.

i have included the fusion 360 file so you can customize it

added 18x24mm 4-bolt fastening pattern

thingiverse

free

Hypercube EVO compatible volcano/nimble/bltouch effector by sverreb

...hat this effector does not have endstops as it is designed for use with my x-carriage that have a holder for a mechanical endstop

thingiverse

free

Hypercube Evolution X-Carriage for LM10UU IGUS Bushings by driftology

...bushings by driftology thingiverse this is a mod of sverreb#39;s awesome xcarriage for igus style bushings. this carriage allows...

Hypercube

turbosquid

free

HyperCube

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Hypercube 3D Model

...hypercube 3d model

3dexport

cube hypercube four-dimensional space side geometry edge

hypercube 3d model dmitry87 54991 3dexport

3d_export

$5

tesseract hypercube

...t it. moreover different textures and materials can be added and tesseract can be set in any scene. dimensions: x: 4m y: 4m z: 4m

thingiverse

free

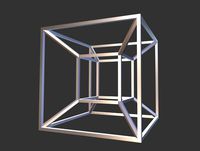

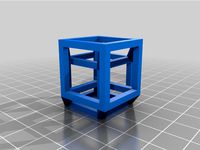

Hypercube

...hypercube

thingiverse

hypercube projected into three dimensional space.

thingiverse

free

Hypercube by alpheccar

...hypercube by alpheccar

thingiverse

projection of an hypercube on an hypersphere.

thingiverse

free

Hypercube by BorisBlavasky

...hypercube by borisblavasky

thingiverse

hypercube. testing the tool.

thingiverse

free

Hypercube by Christian42

...hypercube by christian42

thingiverse

i made a hypercube using rhino3d

thingiverse

free

Hypercube by Christian42

...hypercube by christian42

thingiverse

i made a hypercube using rhino3d

thingiverse

free

HyperCube by wwebber

...hypercube by wwebber

thingiverse

this is the standard perspective projection of the hypercube from 4d to 3d

thingiverse

free

HyperCube scaled by Muzeem

...hypercube scaled by muzeem

thingiverse

customized hypercube

Xy

3ddd

$1

Вешалка напольная XY-027

...а штанги: 171 см

диаметр основания: 38 смhttp://mebelshopos.ru/aksessuary-ofisnye/veshalka-napolnaya-xy-027-detail.html

turbosquid

$9

XY Rectangular Dining Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

holly hunt xy bench

...eight: 17.75 in

width: 45 in, 26 in

depth: 18 in

больше превьюhttps://www.behance.net/gallery/24983999/bench-3d-model?

turbosquid

$8

Xy fine tuning handle adjusts the module

...odule for download as 3ds, max, ige, obj, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1331394)

3ddd

$1

pillows bed 2

...pillows bed 2 3ddd подушка , круглая dimensions: xy ...

3ddd

$1

Honeycomb Floor

...паркет parquet with metalic honeycomb floor demensions 500x500 cm xy multitexture +...

3d_export

$7

positioning screw mechanism

...and lead screw, constitute a double displacement adjustable mechanism, xy axis double position adjustable positioning.<br>**************************************<br>files format contains<br>-solidworks 2017<br>-step<br>-iges<br>- and...

3d_export

$9

positioning mechanism of heavy-duty platform

...activity -- ball mechanism activity ---- drive heavy load xy axis movement -- positioning completed<br>**************************************<br>files format contains<br>-solidworks 2017<br>-step<br>-iges<br>- and...

3d_export

$180

optical fiber laser marking machines assembly

...fiber laser marking machine<br>automatic loading and unloading laser marking machine<br>xy platform adjustable laser marking machine<br>laser marking machine used with...

thingiverse

free

XY ROBOT by ymtlab

...xy robot by ymtlab

thingiverse

xy robot

Evolution

3ddd

$1

Evolution

... evolution , комод

комод из каталога emmemobili модель evolution

design_connected

$18

Evolution

...evolution

designconnected

zanotta evolution computer generated 3d model. designed by ïto, ora.

design_connected

$11

Evolute

...evolute

designconnected

danese evolute computer generated 3d model. designed by crasset, matali.

design_connected

$22

Evolution

...evolution

designconnected

emmemobili evolution shelves and storage computer generated 3d model. designed by ferruccio laviani.

3ddd

$1

Zanotta / EVOLUTION

...zanotta / evolution

3ddd

zanotta

zanotta

884 evolution

3ddd

free

Simas Evolution

...simas evolution

3ddd

simas

раковина simas evolution

3ddd

$1

Lancer Evolution

...lancer evolution

3ddd

автомобиль , машина

lancer evolution viii

3ddd

$1

Zanotta Evolution

...zanotta evolution

3ddd

zanotta

современное кресло evolution фабрики zanotta

turbosquid

$25

Evolution Dragon

...d

royalty free 3d model evolution dragon for download as obj on turbosquid: 3d models for games, architecture, videos. (1212928)

turbosquid

$6

Flowers Evolution

...

royalty free 3d model flowers evolution for download as obj on turbosquid: 3d models for games, architecture, videos. (1214159)

12Mm

turbosquid

$30

Settings 4mm to 12mm

...oyalty free 3d model settings 4mm to 12mm for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1548862)

3d_export

$10

A box of bullets of 12mm caliber

...a box of bullets of 12mm caliber

3dexport

a box of 12mm caliber bullets for hunting small game and poultry.

turbosquid

$7

Straight chisel 12mm

... chisel 12mm for download as max, 3ds, dae, dwg, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1601806)

turbosquid

$7

Straight chisel 12mm

... chisel 12mm for download as max, 3ds, dae, dwg, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1601075)

turbosquid

$1

Linear Bearing 12mm ID

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Rc Paddle Tire 12mm hex

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

fifa world cup qatar 2022

...of the magnet for the stand( diameter 52mm, height 12mm, the magnet in the ground(diameter 30mm, height...

3d_ocean

$8

Roche Bobois - Tenere Coffee Table

...table tenere roche bobois – tenere coffee table – 12mm glued glass top, frame in concrete effect finish, single...

3d_export

$10

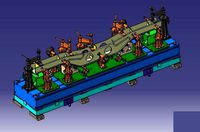

welding fixture for side beam of train bogie

...vertical plate wall thickness is 14mm, the web is 12mm and the middle sections are distributed with 10mm reinforced...

3d_export

$10

bracelet clasp lock12mm x 24mm

...ach others and then enjoy your bracelet. i don't recommend to rescale this model, order to create the lock same as your wish.

Modification

turbosquid

$12

AKMS (AK47 modification)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$79

BusTransForm - Modif Bus Thailand

...d model bustransform - modif bus thailand for download as obj on turbosquid: 3d models for games, architecture, videos. (1383303)

3d_export

$25

mitsubishi evo 9 modification

...mitsubishi evo 9 modification

3dexport

evo 9 has been modified with a nice and elegant look.

3d_ocean

$25

Dart Vader (modificated helm)

...niforms, as well as anatomical model of the character itself. the model is divided into groups for further editing. primarily ...

turbosquid

$15

FN SCAR-H modification low-poly game ready

...fication low-poly game ready for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1386384)

3d_export

$5

sphere light

...sphere light

3dexport

the socket and light are modifables

3d_export

$5

Fabulous chest

...chest 3dexport fabulous chest for your game or further modification ...

3d_export

free

cold coffee

...cold coffee 3dexport cold coffee can. any required modification will be done at...

3d_ocean

$12

Cartoon Dump or Sand Truck

...already rig low poly modifier still in stack for modification unwrap uvw for material and colour...

3d_ocean

$12

Cartoon Cement Mixer Truck

...already rig low poly modifier still in stack for modification unwrap uvw for material and colour...