Thingiverse

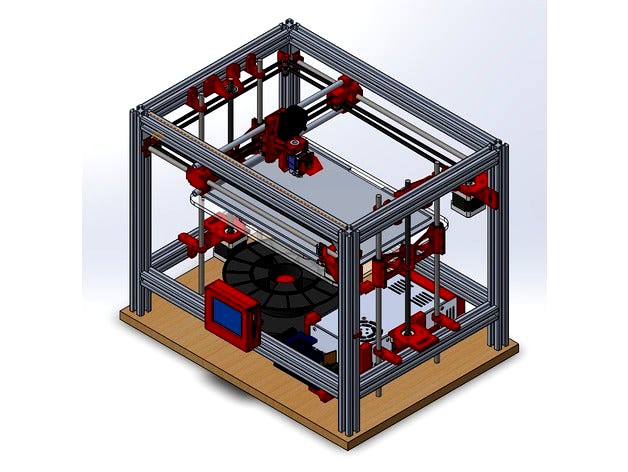

HyperCube 3D printer (2525 Aluminum) by brspartan

by Thingiverse

Last crawled date: 4 years ago

Modified parts from either the Hypercube or Hypercube Evolution for:

-2525 Aluminum Tslot

-3/8 Anodized Aluminum Rod or 8mm steel rods

-Z axis design: Acrylic Base or 2020 Aluminum Tslot

-Dual Z axis motors

-Larger Print Area: 200x300x160mm

-Compact Base Design: Power Supply, Ramps, Bowden Extruder, and Filament all sit below the printer

This printer includes things from:

-Brspartan's Horizontal Spool Mount

-Tom114's E3D fan

-Dintid's MKS TFT28 Case

-Dasaki's Ramps Case

-ProtoBuild's PSU Mounts

This printer modified things from:

-Schlotzz's Bowden Extruder

Change Log:

11.21.18: Uploaded all parts from V1 and V2 of my 2525 Hypercube/Hypercube Evolution. Includes solidworks models and STLs

09.07.18: Uploaded modified 2525 parts from the Hypercube Evolution. I've discovered that some of the original Hypercube parts had design flaws that I wanted to address. This version uses 2020 aluminum Tslot for the base which is much more rigid than my previously used acrylic. This also improved the rigidity of the x axis by switching from the 3/8in aluminum tube to 8mm steel rods. These parts have been modified for 8mm steel rods on all axis and to fit 2525 aluminum Tslot for the printer frame. The z axis base is still 2020.

25.05.17: Added/modified PSUFanDuct QTY1.stl, Tool Holder QTY1.stl, bracket_no_notch_v2 QTY2.stl, and Filament Spool Mount v2 QTY1.stl. The PSU Fan Duct will prevent the air from cooling down your heated bed, the spool mount is now a tighter fit and the spool will no longer be able to slide around, the modified bracket_no_notch_v2 is an option that will drop down the height of the PSU mount and gave me more clearance, tool holder is just for fun!

BOM

Frame:

T-Slot 2525 Aluminium Extrusion Profiles for X200 x Y300 x Z155 print bed area

4 x 340mm (X)

4 x 440mm (Y)

4 x 350mm (Z) (longer if you would like a build height greater than my current 160mm)

Fixings:

100 x M5 x 12mm button head screws (for plastic parts)

50 x M5 x 10mm button head screws (for corner brackets)

2 x 100pcs 2525 T-Slot M5 hammer nuts

3 x 10pcs Aluminium Corner Brackets

CoreXY + Z + Bowden Drive System:

2 x 8mmx440mm Hardened Steel smooth rod (choose 500mm length) for Y axis

4 x 8mmx350mm Hardened Steel smooth rod (choose 350mm length) for Z axis

1 x 3/8"x6' Anodised Aluminium Rod/Tube for X axis

4 x 1pcs Self Lubricating 3/8" ID Bronze Bushing

8 x LM8UU linear bearing for Z axis

4 x LM8UU linear bearing for Y axis

2 x 10pcs F623ZZ Flange Bearing

1 x 5M GT2 Belt and 2 x 20 Tooth Pulleys

1 x Teflon PTFE Tube

1 x MK7 Extruder Gear

1 x Push Fit Connector M5

Fixings:

45 x M3 x 10mm pan head screws

45 x M3 x 20mm pan head screws

2 x M3 x 6mm pan head screws

2 x M3 x 35mm pan head screws

35 x M3 Nyloc nuts

35 x M3 Hex nuts

Motors, Electronics and Accessories:

3 x NEMA17 Stepper Motor

2 x Lead Screw NEMA17 Stepper Motor

1 x 2pcs Endstop Switch

1 x RAMPS 1.4 + MEGA2560 R3 + LCD&SD + A4988 With Heat Sink Kit

1 x 12V DC 50mm Blow Radial Cooling Fan

1 x Heatbed Aluminium MK3 12V 24V

1 x 12V 30A 360W Switching Power Supply

1 x Thermistor 100K With 1M Cable for Heat Bed

1 x DC power wire (choose 14AWG)

1 x 10M Tinned Copper 22AWG 2 Pin Red Black

1 x 5pcs Bed levelling screw/spring/knob

1 x Genuine E3Dv6 or Clone (1.75mm long) with optional Block & Sock v6 Upgrade

1 x Inductive Proximity Sensor - PNP

Print settings:

3 Perimeters

3 top/bottom layers

0.25mm layer height (or better)

50% infill

Print 1 of everything except below:

2 x Bed_Mount_v3

2 x XY_Clamp_v1.1

2 x XY_Joiner_v1.1

2 x XY_Idler

3 x Y_Shaft_Clamp

2 x Dual_Bushing_Holder

Laser Cut:

1 x Acrylic Bed (249mm x 349mm)

Follow Tech2C's build log for detailed instructions on how to build this printer! Be sure to follow them all the way through before you start your build.

-2525 Aluminum Tslot

-3/8 Anodized Aluminum Rod or 8mm steel rods

-Z axis design: Acrylic Base or 2020 Aluminum Tslot

-Dual Z axis motors

-Larger Print Area: 200x300x160mm

-Compact Base Design: Power Supply, Ramps, Bowden Extruder, and Filament all sit below the printer

This printer includes things from:

-Brspartan's Horizontal Spool Mount

-Tom114's E3D fan

-Dintid's MKS TFT28 Case

-Dasaki's Ramps Case

-ProtoBuild's PSU Mounts

This printer modified things from:

-Schlotzz's Bowden Extruder

Change Log:

11.21.18: Uploaded all parts from V1 and V2 of my 2525 Hypercube/Hypercube Evolution. Includes solidworks models and STLs

09.07.18: Uploaded modified 2525 parts from the Hypercube Evolution. I've discovered that some of the original Hypercube parts had design flaws that I wanted to address. This version uses 2020 aluminum Tslot for the base which is much more rigid than my previously used acrylic. This also improved the rigidity of the x axis by switching from the 3/8in aluminum tube to 8mm steel rods. These parts have been modified for 8mm steel rods on all axis and to fit 2525 aluminum Tslot for the printer frame. The z axis base is still 2020.

25.05.17: Added/modified PSUFanDuct QTY1.stl, Tool Holder QTY1.stl, bracket_no_notch_v2 QTY2.stl, and Filament Spool Mount v2 QTY1.stl. The PSU Fan Duct will prevent the air from cooling down your heated bed, the spool mount is now a tighter fit and the spool will no longer be able to slide around, the modified bracket_no_notch_v2 is an option that will drop down the height of the PSU mount and gave me more clearance, tool holder is just for fun!

BOM

Frame:

T-Slot 2525 Aluminium Extrusion Profiles for X200 x Y300 x Z155 print bed area

4 x 340mm (X)

4 x 440mm (Y)

4 x 350mm (Z) (longer if you would like a build height greater than my current 160mm)

Fixings:

100 x M5 x 12mm button head screws (for plastic parts)

50 x M5 x 10mm button head screws (for corner brackets)

2 x 100pcs 2525 T-Slot M5 hammer nuts

3 x 10pcs Aluminium Corner Brackets

CoreXY + Z + Bowden Drive System:

2 x 8mmx440mm Hardened Steel smooth rod (choose 500mm length) for Y axis

4 x 8mmx350mm Hardened Steel smooth rod (choose 350mm length) for Z axis

1 x 3/8"x6' Anodised Aluminium Rod/Tube for X axis

4 x 1pcs Self Lubricating 3/8" ID Bronze Bushing

8 x LM8UU linear bearing for Z axis

4 x LM8UU linear bearing for Y axis

2 x 10pcs F623ZZ Flange Bearing

1 x 5M GT2 Belt and 2 x 20 Tooth Pulleys

1 x Teflon PTFE Tube

1 x MK7 Extruder Gear

1 x Push Fit Connector M5

Fixings:

45 x M3 x 10mm pan head screws

45 x M3 x 20mm pan head screws

2 x M3 x 6mm pan head screws

2 x M3 x 35mm pan head screws

35 x M3 Nyloc nuts

35 x M3 Hex nuts

Motors, Electronics and Accessories:

3 x NEMA17 Stepper Motor

2 x Lead Screw NEMA17 Stepper Motor

1 x 2pcs Endstop Switch

1 x RAMPS 1.4 + MEGA2560 R3 + LCD&SD + A4988 With Heat Sink Kit

1 x 12V DC 50mm Blow Radial Cooling Fan

1 x Heatbed Aluminium MK3 12V 24V

1 x 12V 30A 360W Switching Power Supply

1 x Thermistor 100K With 1M Cable for Heat Bed

1 x DC power wire (choose 14AWG)

1 x 10M Tinned Copper 22AWG 2 Pin Red Black

1 x 5pcs Bed levelling screw/spring/knob

1 x Genuine E3Dv6 or Clone (1.75mm long) with optional Block & Sock v6 Upgrade

1 x Inductive Proximity Sensor - PNP

Print settings:

3 Perimeters

3 top/bottom layers

0.25mm layer height (or better)

50% infill

Print 1 of everything except below:

2 x Bed_Mount_v3

2 x XY_Clamp_v1.1

2 x XY_Joiner_v1.1

2 x XY_Idler

3 x Y_Shaft_Clamp

2 x Dual_Bushing_Holder

Laser Cut:

1 x Acrylic Bed (249mm x 349mm)

Follow Tech2C's build log for detailed instructions on how to build this printer! Be sure to follow them all the way through before you start your build.