Thingiverse

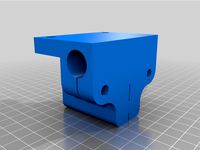

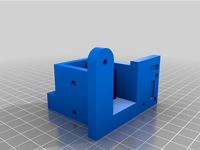

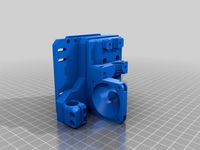

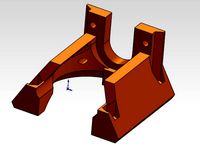

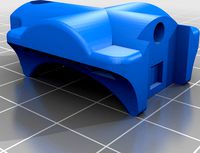

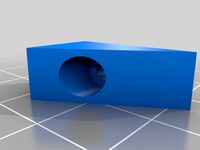

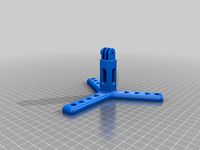

Hotend Mount for Davinci CoreXY by applesan

by Thingiverse

Last crawled date: 3 years, 2 months ago

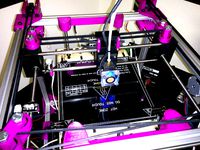

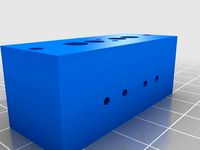

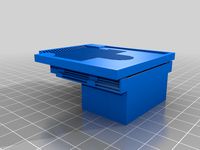

This is a hotend mount for the CoreXY carriage. It was made for ZombiRon's "XYZ DaVinci CoreXY Mod".

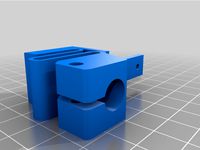

I used m3 and m4 screws from a pack of assorted screws. See below for examples of the parts used for this project. If anyone wants exact measurements of all the screws I used, then let me know. I printed everything on an sla printer because they are the most accurate. I also used long LM8UU bearings for now to ensure alignment. If everything is lined up then I'll switch to the igus bearings. Igus bearings lock/bind up if not perfectly aligned in my experience.

I've Included two different mounting options. One has the BLTouch perpendicular to the hotend and the other one has the BLTouch parallel to the hotend. I originally designed it parallel to the hotend. I then realized I could save some space if I rotated the BLTouch.

The perpendicular mount saves some space but the parallel mount looks nicer because the wires are facing the back of the machine.

This uses TMC sensorless homing for the X and Y. I have mine set to 80 for the X and 85 for the Y. The setting is in Configuration_adv.h

//#define X_STALL_SENSITIVITY 80

//#define Y_STALL_SENSITIVITY 85

I recommend printing the Perpendicular because it saves space.

I've already took out the control board and am using Marlin on an Skr 1.4.

The probe offset for the perpendicular is:

//#define NOZZLE_TO_PROBE_OFFSET {-24, -2.75, -1 } //Please verify this when mounted.

The probe offset for the perpendicular is:

//#define NOZZLE_TO_PROBE_OFFSET {-27, 0, -1 } //Please verify this when mounted.

I also needed a different stepper mount for my Da Vinci Pro. That stepper motor mount is located in on the other page.

I had to invert the X and Y motors. You may not have to because I did a lot of rewiring.

//#define INVERT_X_DIR true

//#define INVERT_Y_DIR true

Here are my settings for the print bed dimensions.

//#define X_HOME_DIR 1

//#define Y_HOME_DIR 1

//#define Z_HOME_DIR -1

// The size of the print bed

//#define X_BED_SIZE 209

//#define Y_BED_SIZE 200

// Travel limits (mm) after homing, corresponding to endstop positions.

//#define X_MIN_POS -57

//#define Y_MIN_POS -2

//#define Z_MIN_POS 0

//#define X_MAX_POS 227

//#define Y_MAX_POS Y_BED_SIZE

//#define Z_MAX_POS 190

For the coreXY Kinematics, all you have to enable is the following:

//#define COREXY

I also made a stepper motor mount for the right side that lets the mod work with my Davinci Pro. Check it out here https://www.thingiverse.com/thing:4789354

Parts used in the build

Assorted screws: https://www.amazon.com/SZHKM-Stainless-Socket-Screws-Assortment/dp/B07M7756TH/ref=sr_1_1_sspa?dchild=1&keywords=m3+m2+m4+screws+assorted&qid=1615340158&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEzSzM4TkYyRDJEVjc2JmVuY3J5cHRlZElkPUEwNTExODY4M0lSMDJGWjVTOEdHNSZlbmNyeXB0ZWRBZElkPUEwODAzMzI1NjNPUERJTjFMUVBGJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

Bearings: https://www.amazon.com/uxcell-Groove-Bearings-Double-Shielded/dp/B08198NQ7Y/ref=sr_1_1?dchild=1&keywords=685ZZ&qid=1615340492&sr=8-1

Extra wide GT2 Idlers: https://www.aliexpress.com/item/4000183519445.html?spm=a2g0s.9042311.0.0.56ee4c4dCSOyuC

Lock Collars: https://www.aliexpress.com/item/32826054805.html?spm=a2g0s.9042311.0.0.27424c4dxCRjsr

Extra stiff GT2 Belt: https://www.amazon.com/gp/product/B07KXRR9T7/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Long LM8UU Bearings: https://www.amazon.com/uxcell-LM8UU-Linear-Bearings-Length/dp/B07H94L2NR/ref=sr_1_13?dchild=1&keywords=lm8uu+bearing&qid=1615340853&s=industrial&sr=1-13

8mm igus bearings: https://www.amazon.com/Igus-RJ4JP-01-08-Printer-Bearing-replacement/dp/B07B3PZ7JH/ref=sr_1_1?dchild=1&keywords=8mm+igus&qid=1615341981&s=industrial&sr=1-1

I used m3 and m4 screws from a pack of assorted screws. See below for examples of the parts used for this project. If anyone wants exact measurements of all the screws I used, then let me know. I printed everything on an sla printer because they are the most accurate. I also used long LM8UU bearings for now to ensure alignment. If everything is lined up then I'll switch to the igus bearings. Igus bearings lock/bind up if not perfectly aligned in my experience.

I've Included two different mounting options. One has the BLTouch perpendicular to the hotend and the other one has the BLTouch parallel to the hotend. I originally designed it parallel to the hotend. I then realized I could save some space if I rotated the BLTouch.

The perpendicular mount saves some space but the parallel mount looks nicer because the wires are facing the back of the machine.

This uses TMC sensorless homing for the X and Y. I have mine set to 80 for the X and 85 for the Y. The setting is in Configuration_adv.h

//#define X_STALL_SENSITIVITY 80

//#define Y_STALL_SENSITIVITY 85

I recommend printing the Perpendicular because it saves space.

I've already took out the control board and am using Marlin on an Skr 1.4.

The probe offset for the perpendicular is:

//#define NOZZLE_TO_PROBE_OFFSET {-24, -2.75, -1 } //Please verify this when mounted.

The probe offset for the perpendicular is:

//#define NOZZLE_TO_PROBE_OFFSET {-27, 0, -1 } //Please verify this when mounted.

I also needed a different stepper mount for my Da Vinci Pro. That stepper motor mount is located in on the other page.

I had to invert the X and Y motors. You may not have to because I did a lot of rewiring.

//#define INVERT_X_DIR true

//#define INVERT_Y_DIR true

Here are my settings for the print bed dimensions.

//#define X_HOME_DIR 1

//#define Y_HOME_DIR 1

//#define Z_HOME_DIR -1

// The size of the print bed

//#define X_BED_SIZE 209

//#define Y_BED_SIZE 200

// Travel limits (mm) after homing, corresponding to endstop positions.

//#define X_MIN_POS -57

//#define Y_MIN_POS -2

//#define Z_MIN_POS 0

//#define X_MAX_POS 227

//#define Y_MAX_POS Y_BED_SIZE

//#define Z_MAX_POS 190

For the coreXY Kinematics, all you have to enable is the following:

//#define COREXY

I also made a stepper motor mount for the right side that lets the mod work with my Davinci Pro. Check it out here https://www.thingiverse.com/thing:4789354

Parts used in the build

Assorted screws: https://www.amazon.com/SZHKM-Stainless-Socket-Screws-Assortment/dp/B07M7756TH/ref=sr_1_1_sspa?dchild=1&keywords=m3+m2+m4+screws+assorted&qid=1615340158&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEzSzM4TkYyRDJEVjc2JmVuY3J5cHRlZElkPUEwNTExODY4M0lSMDJGWjVTOEdHNSZlbmNyeXB0ZWRBZElkPUEwODAzMzI1NjNPUERJTjFMUVBGJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

Bearings: https://www.amazon.com/uxcell-Groove-Bearings-Double-Shielded/dp/B08198NQ7Y/ref=sr_1_1?dchild=1&keywords=685ZZ&qid=1615340492&sr=8-1

Extra wide GT2 Idlers: https://www.aliexpress.com/item/4000183519445.html?spm=a2g0s.9042311.0.0.56ee4c4dCSOyuC

Lock Collars: https://www.aliexpress.com/item/32826054805.html?spm=a2g0s.9042311.0.0.27424c4dxCRjsr

Extra stiff GT2 Belt: https://www.amazon.com/gp/product/B07KXRR9T7/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Long LM8UU Bearings: https://www.amazon.com/uxcell-LM8UU-Linear-Bearings-Length/dp/B07H94L2NR/ref=sr_1_13?dchild=1&keywords=lm8uu+bearing&qid=1615340853&s=industrial&sr=1-13

8mm igus bearings: https://www.amazon.com/Igus-RJ4JP-01-08-Printer-Bearing-replacement/dp/B07B3PZ7JH/ref=sr_1_1?dchild=1&keywords=8mm+igus&qid=1615341981&s=industrial&sr=1-1

Similar models

thingiverse

free

Hotend fan support - LONGER LK4 Pro & Alfawise U30 Pro by MiniMoro

...iga-blower-40x40x10mm-cooling-printer/dp/b08bz6w47m/ref=sr_1_7?dchild=1&keywords=fan+printer+3d&qid=1614643510&sr=8-7

thingiverse

free

mini keg co2 mount by -KT-

...aqax68objr3&dchild=1&keywords=ball+lock+picnic+tap&qid=1602425476&sprefix=ball+lock+picnic%2caps%2c190&sr=8-5

thingiverse

free

Dual belt driven Z-axis for ender 3 pro XL by Fraddle33

...for top of leadscrew.

https://www.amazon.com/gp/product/b07ggvtj6l/ref=ppx_yo_dt_b_asin_title_o03_s00?ie=utf8&psc=1

a. belt

thingiverse

free

Torvol tool organizer by Collinhasasthma

...ver-electronic-short-circuit-available/dp/b088tvvnvm/ref=sr_1_4?dchild=1&keywords=smoke+stopper&qid=1623510410&sr=8-4

thingiverse

free

Pokebank by loneacoustic

...amazon.com/yidimu-falcon-pro-printer-parallel/dp/b0895rrly6/ref=sr_1_3?dchild=1&keywords=yidimu&qid=1609774845&sr=8-3

thingiverse

free

Ardino drone prototype by evan1101

...rqizlbmnyexb0zwrbzelkpuewnzqxmzawrjbwuezgskxhmvnxjndpzgdlde5hbwu9c3bfyxrmjmfjdglvbj1jbglja1jlzglyzwn0jmrvtm90tg9nq2xpy2s9dhj1zq==

thingiverse

free

spool holder and storage by cptgumby2004

...=unxyhj8cuo5g&dchild=1&keywords=skateboard+bearings&qid=1604364780&sprefix=skateboard+bear%2caps%2c263&sr=8-8

thingiverse

free

Flashlight holder/ wall mount by Ifreeee

...f this exact flashlight with different brand names printed on them. they're all the same except for the logo printed on them.

thingiverse

free

Zulay Milk Frother Holder by derekmccurry

...ent-mounting-tape-inches/dp/b00347a8gc/ref=sr_1_13?dchild=1&keywords=3m+double+sided+foam+tape&qid=1609732782&sr=8-13

thingiverse

free

3D Printable 3D Printer by TheJadeRabbit

...r_1_4?ie=utf8&qid=1530916900&sr=8-4&keywords=3d+printer+hotend

code(marlin): https://github.com/marlinfirmware/marlin

Applesan

thingiverse

free

Aesthetic Toilet Seat and Cover Hinge by applesan

...r anyone.

i printed at 100% infill and a higher temp to ensure pla strength but i suspect 20% infill would do just fine as well.

thingiverse

free

DaVinci Pro CoreXY Stepper Motor Mount for right hand side by applesan

...as also made to work with my hotend mount for the corexy mod. check it out at the link: https://www.thingiverse.com/thing:4789349

thingiverse

free

Sprouting Lid Mason Canning Jar - Wide by applesan

...ng beans and go from there.

other:

the scad files are for reference only so if you see any problems and need changes let me know.

thingiverse

free

Z Optical Holder Hustle_Designs's Da Vinci PRO E3D V6 Carriage SingleDual Extrusion by applesan

...8-4c9f-ae7b-9b6f4fda0636-0&btsid=0bb0622d16153286263225332e7bcb&ws_ab_test=searchweb0_0,searchweb201602_,searchweb201603_

Davinci

thingiverse

free

davinci

...davinci

thingiverse

davinci

thingiverse

free

DaVinci DeskTop by jolyon

...davinci desktop by jolyon

thingiverse

davinci desktop by jolyonpc [created on 3dtin]

thingiverse

free

davinci spool filament by asuss

...davinci spool filament by asuss

thingiverse

davinci spool filament (pla )

thingiverse

free

DaVinci Catapult by JackDailey22

...davinci catapult by jackdailey22

thingiverse

thingiverse

free

Playmobil Davinci Man by kike1978

...playmobil davinci man by kike1978

thingiverse

playmobil davinci man, for a keyring or something similar ;)

thingiverse

free

DaVinci Junior Chip by Manrobbie

...s a davinci jr chip which fits inside the spoolholder of the davinci jr.

printed in white pla at 0.2 layer height and 15% infill.

thingiverse

free

DaVinci Code Braille by asespilez

...lle by asespilez

thingiverse

this is a davinci code in braille.

the original project is https://www.thingiverse.com/thing:651654

thingiverse

free

DaVinci Marvin by HephJones

...davinci marvin by hephjones

thingiverse

marvin with base

thingiverse

free

Davinci Y Axis Holder by hugoelec

...davinci y axis holder by hugoelec

thingiverse

davinci y axis holder

thingiverse

free

DaVinci Jr Ventilation Opening by Imura_Industries

...davinci jr ventilation opening by imura_industries

thingiverse

davinci jr ventilation opening

Corexy

thingiverse

free

CoreXY by Kaz_tech

...corexy by kaz_tech

thingiverse

this is the model of corexy platform. i separately put the parts on this place.

thingiverse

free

corexy plotter by tjwan

...corexy plotter by tjwan

thingiverse

parts for corexy mill inspired by http://der-frickler.net/technik/corexyportal

thingiverse

free

ScribbleJ CoreXY Beta by ScribbleJ

...j/corexy-v1https://github.com/scribblej/corexy-v1#corexy-beta

full gallery of development photos here: http://imgur.com/a/donun

thingiverse

free

CoreXY Emblem by emkajot

...by emkajot

thingiverse

an emblem for your corexy printer.

size: 100mm x 38mm x 2mm.

update: added a version with a proper mount.

thingiverse

free

SolidCore CoreXY Carriage by shanehooper

...olidcore 3d printer. this design could be used in other corexy 3d printers.

also see:https://3ddistributed.com/corexy-3d-printer/

thingiverse

free

CoreXY 3D Printer Model by ReginaFabricam

...bricam

thingiverse

this is an original design of a corexy printer.https://www.tinkercad.com/things/jggr9qk4s4p-3d-printer-corexy

thingiverse

free

coreXY Upper structure Left

...corexy upper structure left

thingiverse

my customized corexy 3d printer upper left parts

thingiverse

free

CoreXY by frankie

...ing machines, etc. the design is described in greater detail at http://www.corexy.com . a video is at http://vimeo.com/40914530 .

thingiverse

free

Endstop block for CoreXY carriage by svkeulen

...endstop block for corexy carriage by svkeulen

thingiverse

endstop for corexy carriage

thingiverse

free

X carriage for the CoreXY MGN12 by hackerbijay

...x carriage for the corexy mgn12 by hackerbijay

thingiverse

x carriage for the corexy frame

Hotend

thingiverse

free

hotend by fablab_lueneburg

...hotend by fablab_lueneburg

thingiverse

hotend model

thingiverse

free

Hotend for Graber

...hotend for graber

thingiverse

hotend complement pastes for graber printerhttps://youtu.be/0koxhnsuhdy

thingiverse

free

Hotend adapter by antaviana

...hotend adapter by antaviana

thingiverse

hotend adapter

thingiverse

free

hotend fan by mming1106

...hotend fan by mming1106

thingiverse

hotend fan

thingiverse

free

Hotend schema by ione

...hotend schema by ione

thingiverse

hotend project schema

thingiverse

free

Fabtotum XY Hotend holder for E3D Hotend

...s with integrated supports.

more for the project you can see here: https://kf-designs.com/2019/09/07/fabtotum-printer-conversion/

thingiverse

free

HotEnd Stand by onepointdiy

...tend, when you make your new hotend or repair your j-head or mg-plus hotend.

the hole of 16mm, please adjust using a reamer, etc.

thingiverse

free

fast magnetic hotend changer for Chimera Hotend by Draman

...chimera hotend !

and new basis (the hole from original is to small)

it is a remix form skimmy's fast magnetic hotend changer

thingiverse

free

Hotend Fan Adapter for MicroSwiss All Metal Hotend by jo_schi_man

...

thingiverse

little change for the hotend fan adapter to hold the microswiss all metal hotend (slightly longer and sharp edges).

thingiverse

free

Merlin Hotend by Alejanson

...merlin hotend by alejanson

thingiverse

this is a 1:1 drawing of the classic merlin hotend.

Mount

thingiverse

free

Pen Mount on BLTouch mount by jetspot

...pen mount on bltouch mount by jetspot

thingiverse

pen mount on bltouch mount

thingiverse

free

RAM Mount, Mount by seanmclean

...ram mount, mount by seanmclean

thingiverse

bridging plate to attach ram mount to yamaha 242, for chartplotter placement.

thingiverse

free

Mount for mount for Garmin GPS by GNOBLIN

...you can use this mount for prevent rotation simple mount around hendelbars.

d handelbar 31.8mm

use m3 screw and din 16903 plug.

thingiverse

free

Permanent mount for Modular Mounting System by WIR14

...permanent mount for modular mounting system by wir14

thingiverse

permanent mount for modular mounting system.

thingiverse

free

Gopro Mount and antenna mount by SuperYoyo

...gopro mount and antenna mount by superyoyo

thingiverse

cut the carbon platform to pass the gopro mount and enjoy !

thingiverse

free

Hexagon Mount for 50mm Mount (Sparkcube) by Draman

...for 50mm mount (sparkcube) by draman

thingiverse

hexagon mount remix from skimmys hotend-mount for sparkcube or other 50mm-mount

thingiverse

free

mount by gixster

...mount by gixster

thingiverse

custom mount

thingiverse

free

Mount by Matrxi999

...mount by matrxi999

thingiverse

shelf mount

thingiverse

free

Motor mount

...motor mount

thingiverse

motor mount

thingiverse

free

GoPro Mount

...gopro mount

thingiverse

gopro mount