Thingiverse

Hot Shoe to 1/4-20 Magnetic Quick Release / LumeCube Magnetic Mount

by Thingiverse

Last crawled date: 4 years, 3 months ago

Video:https://www.youtube.com/watch?v=OAIydsQTraw

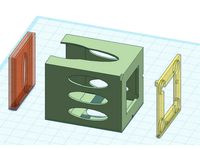

These are some mounts that I developed to use as a magnetic quick-release mount for a LumeCube v2 on my Canon DSLR. One piece of the mount is placed on top of the DSLR camera. The other piece is screwed into the bottom of the LumeCube. Each half has four magnets and when placed together they will be securely connected.

I made two versions of the mount, for 6mm x 3mm and for 10mm x 3mm magnets respectively. The 10mm variant is much stronger (which is both a plus and a minus). The 6mm variant can come loose if the camera is shaken violently.

The base is secured to the camera using a screw and a wedge-shaped plastic piece. Tightening the screw places addition pressure from the wedge onto the camera's hot shoe, and secures the base. You may or may not find this wedge/screw system necessary, the base will kinda stay there on it's own, but the wedge will make it more solid.

In addition to 3D printed parts you will need the following:

Neewer Stainless Steel 1/4" Mounting Screw. This is a 1/4-20 "camera screw". A regular 1/4-20 bolt of the appropriate length will do.

Magnets, either 6mm x 3mm or 10mm x 3mm. Eight magnets total.

M2.5x30 machine screw for the 6mm variant or M2.5x34 machine screw for the 10mm variant. Longer is fine, though it will stick out.

M2.5 heat-set threadsert. You can buy these on ebay. You set them with a soldering iron. An m2.5 nut may also suffice.

The parts are designed to print in the orientation depicted, yes the base is supposed to print vertically like that -- it puts the layer lines in the orientation I wanted them. On the base there will be a small "pillar" across the wedge shot that should snap or cut out cleanly. It's used to support the overhang that prints above it. All of these pieces are intended to be printed without supports.

The magnet packets are designed slightly oversize to allow for some tolerance, be careful you do not set your magnets too deep (if you do, the magnet will usually happily pull back up before your glue sets). Secure the magnets with cyanoacrylate superglue.

I recommend printing the parts in PETG. For the models depicted in the video I used Priline Carbon Fiber PETG. The Carbon Fiber is likely not necessary, but I do recomment PETG or Polycarbonate over PLA. I would be worried about durability of the base if printed in PLA.

I did use raster's "Hot Shoe Mount" (Thing 33823) as a basis for developing the part of the base that interfaces with the camera.

These are some mounts that I developed to use as a magnetic quick-release mount for a LumeCube v2 on my Canon DSLR. One piece of the mount is placed on top of the DSLR camera. The other piece is screwed into the bottom of the LumeCube. Each half has four magnets and when placed together they will be securely connected.

I made two versions of the mount, for 6mm x 3mm and for 10mm x 3mm magnets respectively. The 10mm variant is much stronger (which is both a plus and a minus). The 6mm variant can come loose if the camera is shaken violently.

The base is secured to the camera using a screw and a wedge-shaped plastic piece. Tightening the screw places addition pressure from the wedge onto the camera's hot shoe, and secures the base. You may or may not find this wedge/screw system necessary, the base will kinda stay there on it's own, but the wedge will make it more solid.

In addition to 3D printed parts you will need the following:

Neewer Stainless Steel 1/4" Mounting Screw. This is a 1/4-20 "camera screw". A regular 1/4-20 bolt of the appropriate length will do.

Magnets, either 6mm x 3mm or 10mm x 3mm. Eight magnets total.

M2.5x30 machine screw for the 6mm variant or M2.5x34 machine screw for the 10mm variant. Longer is fine, though it will stick out.

M2.5 heat-set threadsert. You can buy these on ebay. You set them with a soldering iron. An m2.5 nut may also suffice.

The parts are designed to print in the orientation depicted, yes the base is supposed to print vertically like that -- it puts the layer lines in the orientation I wanted them. On the base there will be a small "pillar" across the wedge shot that should snap or cut out cleanly. It's used to support the overhang that prints above it. All of these pieces are intended to be printed without supports.

The magnet packets are designed slightly oversize to allow for some tolerance, be careful you do not set your magnets too deep (if you do, the magnet will usually happily pull back up before your glue sets). Secure the magnets with cyanoacrylate superglue.

I recommend printing the parts in PETG. For the models depicted in the video I used Priline Carbon Fiber PETG. The Carbon Fiber is likely not necessary, but I do recomment PETG or Polycarbonate over PLA. I would be worried about durability of the base if printed in PLA.

I did use raster's "Hot Shoe Mount" (Thing 33823) as a basis for developing the part of the base that interfaces with the camera.

Similar models

thingiverse

free

DSLR Controller - TP Link hot shoe mount by lubosjerabek

...dslr controller - tp link hot shoe mount by lubosjerabek

thingiverse

hot shoe tp-link on dslr camera

thingiverse

free

Roofrack for RC Crawler by Kev_Pe

...screws

glue

happy printing and "makes" would be appreciated. feel free to share feedback and questions in the comments.

thingiverse

free

Raspberry Pi with Sense Hat and Camera combine case by r9kawai

...m2 10mm screw and nut x 4

m2 10mm tapping screw x 2

this model designed with "freecad".

(attached freecad format file)

thingiverse

free

Flash Hot Shoe Adapter 90° Tripod by CaptainRoot

...4 screw hole to hot shoe or cold shoe

i use this for mounting my zoom h1 to my video camera in oder to see the display an the led

thingiverse

free

Camera Hot Shoe Fan Bracket by lenosrep

... by lenosrep

thingiverse

camera hot shoe mounted bracket for usb powered cooling fan. applicable for dslr or mirrorless cameras.

thingiverse

free

Pi Camera Telescope Mount by scottpreston

...ed 2mm screws to mount the camera to the base. i used 6-32 1" standoffs with 6-32 3/8" socket head cap screws to mount.

thingiverse

free

775 DC Motor Mount for DIY Dremel CNC

...nto the lower side of the holder. you need two halves of the shoe. use 4 10mm neodymium magnets to secure the dust shoe in place.

thingiverse

free

Hot-Shoe GoPro Mount by AllCity-Maker

...f the attached device disconnecting.

the holes are designed for an m5 x 20mm bolt and locknut.

print it and go do something cool!

thingiverse

free

Magnet Knob by Tidangerous

...magnetic camera arm build i just finished. after printing use a #8 x 3/4" machine screw to secure the magnetic to the knob.

thingiverse

free

Magnetic Hook by Tidangerous

...magnetic camera arm build i just finished. after printing use a #8 x 3/4" machine screw to secure the magnetic to the hook.

Lumecube

thingiverse

free

HomeMade LumeCube Housing

... the files needed to assemble a housing. the video in which i designed the housing can be found here:https://youtu.be/s1rlheo03zo

thingiverse

free

Yuneec Typhoon H520 Droniq HOD4track and LumeCube Carrier by pose

...ack.

lumecube carrier remixed from https://www.thingiverse.com/thing:4221708. i added the rear carrier for the droniq hod4track.

thingiverse

free

Yuneec Typhoon LumeCube Ring / Carrier

...usion 360 sketch also uploaded.

printed with petg with 4 walls, 10% infill, 0.4mm nozzle and 0.2 mm layerhight

-> weight ~25g:

thingiverse

free

LumeCube housing & magnetic filter plate & holder by Jeyell

...lots, front magnetic plate and frear filter housing to carry a few around. also added a hole for screw-mounting on the underside.

Shoe

3d_ocean

$10

Shoes

...shoes

3docean

adidas colorful shoes nike shoe shoes sports

3d model of sports shoes

3d_ocean

$8

Shoes

...shoes

3docean

cloth shoes

women shoes

archibase_planet

free

Shoes

...shoes

archibase planet

shoes open shoes open toed shoes

shoes n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Shoes

...shoes

archibase planet

shoes open shoes open toed shoes

shoes n120513 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Shoes

...shoes

archibase planet

shoes open shoes open toed shoes

shoes n280614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Shoes

...shoes

archibase planet

court shoes footwear shoes

shoes - 3d model for interior 3d visualization.

archibase_planet

free

Shoes

...base planet

shoes high heels evening shoes high heels shoes

shoes n140713 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Shoes

...chibase planet

shoes open shoes high heels high heels shoes

shoes n231013 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Shoes

...shoes

archibase planet

court shoes patent-leather shoes footwear

black shoes n060707 - 3d model for interior 3d visualization.

3d_export

$7

shoes

...shoes

3dexport

shoes man

Release

turbosquid

$39

Sofa. Updated release

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Film releasing mechanism

...asing mechanism for download as 3ds, ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1227251)

3d_export

$5

shift lock release kia soul

...shift lock release kia soul

3dexport

shift lock release kia soul

turbosquid

$14

Quick release swivel carabiner with ring

...ease swivel carabiner with ring for download as sldpr and stl on turbosquid: 3d models for games, architecture, videos. (1668426)

turbosquid

$60

AUTOMATIC AIR RELEASE VALVE GRP33-07

...odel automatic air release valve grp33-07 for download as ipt on turbosquid: 3d models for games, architecture, videos. (1404884)

3d_export

$10

Kitchen Release Mat

...xture format: .png .jpg<br>resolution: 1024*1024<br>pbr in substance painter<br>formats: .obj .gltf .fbx .blend

3d_export

$5

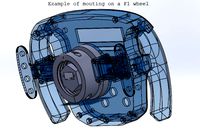

logitech g27-g29 quick release

...r and the other wheel adaptor.<br>files are in stl format, but if you want to edit parts i give you files in sldprt format.

3d_export

$20

mutante veneno

...model created in zbrush 33cm ready for printing, previously release in 6...

3d_export

$5

Drowned Plush Minecraft

...for microsoft windows, macos and linux, and was later re-release for a wide variety of platforms. it is the...

3d_export

$7

Toy drone for kids

...drone for kids. based on only 3 d models. release for toy...

Magnetic

3d_ocean

$2

Magnet

...magnet 3docean 3d 3ds max electric magnet magnetic magnetism max model polygon realistic tesla magnet created in...

turbosquid

$6

Magnet

...

turbosquid

royalty free 3d model magnet for download as obj on turbosquid: 3d models for games, architecture, videos. (1548733)

turbosquid

$6

magnet

...uid

royalty free 3d model magnet for download as 3dm and max on turbosquid: 3d models for games, architecture, videos. (1670606)

turbosquid

$1

Magnet

...y free 3d model magnet for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1215037)

turbosquid

$7

Magnet

...agnet for download as blend, unitypackage, fbx, gltf, and obj on turbosquid: 3d models for games, architecture, videos. (1576588)

3d_export

$5

magnetic knife holder

...magnetic knife holder

3dexport

ordinary magnetic knife holder

archive3d

free

Fridge magnet 3D Model

...3d model archive3d refrigerator magnet fridge magnet magnet toy magnetic s n280712 - 3d model (*.3ds) for interior 3d...

turbosquid

$35

Magnetic butterflies

...alty free 3d model magnetic butterflies for download as blend on turbosquid: 3d models for games, architecture, videos. (1315792)

turbosquid

$2

Magnetic Board

...quid

royalty free 3d model magnetic board for download as ma on turbosquid: 3d models for games, architecture, videos. (1264141)

turbosquid

$977

Magnetic Lego

...oyalty free 3d model magnetic lego for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1142761)

Hot

turbosquid

$1

HOT

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

$9

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

free

hot chili

...hot chili

3dexport

hot chili<br>for fruits and getegables collection

3d_export

$5

hot air balloon

...hot air balloon

3dexport

hot air balloon

3d_export

free

Hot dog shop

...hot dog shop

3dexport

hot dog shop

turbosquid

$90

hot venue

...rbosquid

royalty free 3d model hot venue for download as fbx on turbosquid: 3d models for games, architecture, videos. (1336949)

turbosquid

$20

Hot Rod

...

turbosquid

royalty free 3d model hot rod for download as ma on turbosquid: 3d models for games, architecture, videos. (1351690)

turbosquid

$14

Hot Pepper

...bosquid

royalty free 3d model hot pepper for download as obj on turbosquid: 3d models for games, architecture, videos. (1611643)

turbosquid

$1

Hot dog

...turbosquid

royalty free 3d model hot dog for download as max on turbosquid: 3d models for games, architecture, videos. (1450961)

Quick

3ddd

$1

Quick-Step / Quadra

...quick-step / quadra

3ddd

quick step

ламинат quick-step, серия quadra. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Lagune

...quick-step / lagune

3ddd

quick step

ламинат quick-step, серия lagune. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Classic

...quick-step / classic

3ddd

quick step

ламинат quick-step, серия classic. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Arte

...quick-step / arte

3ddd

quick step

ламинат quick-step, серия arte. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Vogue

...quick-step / vogue

3ddd

quick step

ламинат quick-step, серия vogue. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Rustic

...quick-step / rustic

3ddd

quick step

ламинат quick-step, серия rustic. сайт источник -http://www.quick-step.com

3ddd

$1

Quick-Step / Eligna

...quick-step / eligna

3ddd

quick step

ламинат quick-step, серия eligna. сайт источник -http://www.quick-step.com

turbosquid

$3

Quick Ball

...lty free 3d model quick ball for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1521597)

3ddd

free

Quick-Step / Elite

... ламинат

ламинат quick-step, серия elite. сайт источник -http://www.quick-step.com

turbosquid

$10

Quick Chrome

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

20

3d_export

$15

rocks 20

...rocks 20

3dexport

rocks 3d model 20

3ddd

$1

DECOR MEDIEVO 20*20 MIX

...ллекция: bolonia

фабрика: mainzu

страна: испания

размер: 20x20 см

ссылка:http://www.mainzu.com/bolonia.php#prettyphoto

3d_export

$6

tap-20

...tap-20

3dexport

3ddd

$1

Bed 20

...bed 20

3ddd

постельное белье

bed 20. i hope you like it

software : 3dsmax + md + vray 2.4

turbosquid

$40

20 Shields

...turbosquid

royalty free 3d model 20 shields for download as on turbosquid: 3d models for games, architecture, videos. (1305068)

3d_export

$5

houseberg home 20

...houseberg home 20

3dexport

houseberg home 20

turbosquid

$96

J-20

...20

turbosquid

royalty free 3d model j-20 for download as max on turbosquid: 3d models for games, architecture, videos. (1658873)

turbosquid

$10

Decor 20

...urbosquid

royalty free 3d model decor 20 for download as stl on turbosquid: 3d models for games, architecture, videos. (1677149)

turbosquid

$10

building 20

...osquid

royalty free 3d model building 20 for download as max on turbosquid: 3d models for games, architecture, videos. (1362227)

turbosquid

$6

Bedcloth 20

...osquid

royalty free 3d model bedcloth 20 for download as max on turbosquid: 3d models for games, architecture, videos. (1522681)

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

4

turbosquid

$9

Office Chair 4-4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

doors- 4

...doors- 4

3dexport

doors 4

3d_export

$5

hinge 4

...hinge 4

3dexport

hinge 4

3ddd

$1

Штора №4

...штора №4

3ddd

штора №4

3d_export

free

playstation 4

...playstation 4

3dexport

playstation 4

turbosquid

$1

re 4-4 electric locomotive

... free 3d model re 4 4 electric locomotive for download as obj on turbosquid: 3d models for games, architecture, videos. (1707845)

3ddd

$1

nexus 4

...nexus 4

3ddd

lg , телефон

nexus 4

3ddd

$1

4 Poufs

...4 poufs

3ddd

пуф

4 soft poufs

turbosquid

$12

Calligraphic Digit 4 Number 4

...hic digit 4 number 4 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389332)

3ddd

$1

Dauphin 4+

...dauphin 4+

3ddd

кресло

dauphin 4+ конференц кресло

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)