Thingiverse

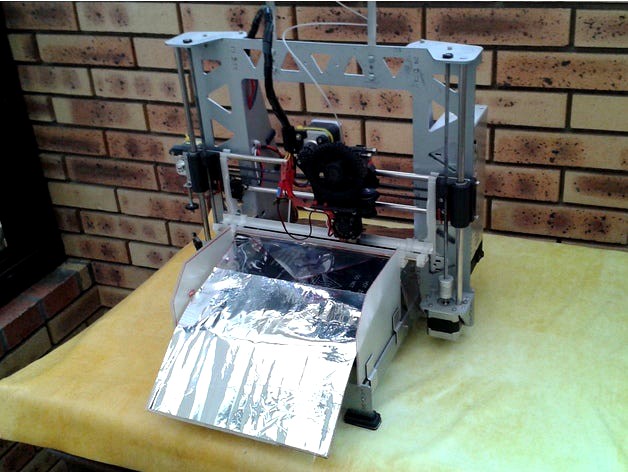

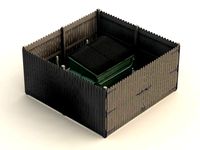

Hot Bed Enclosure V3 by xavan

by Thingiverse

Last crawled date: 3 years ago

Issues of warping and cracking in ABS printing can be solved using a Heated Build Chamber. This kind of chamber is bulky and all the components of the printer (plastics, electronics) undergo a high temperature.

The principle of the proposed solution is to build a heated enclosure around the hot bed, and not as usual around the printer.

The expected advantages are:

Printer parts -electronic components,motors . . .- work at room temperarture,

No need of extra heating,

Less power to heat the bed (up to 50% less).

The enclosure consists of three main parts:

2 insulation sheets that cover the entire hot bed,

2 side plates attached to the printer frame,

and 2 Z shutters which follow the movement of the X axis.

Insulation sheets (upper covers) and shutters of the enclosure are fixed to a support consisting of aluminum angles and plastic parts, itself fixed to the X axis rods.Front and rear covers consist of 3 layers of mylar film, PE foam and aluminized plastic film.

see video: https://youtu.be/211JHkUjk4k

This is an improved version of my previous designs:

www.thingiverse.com/thing:997467

www.thingiverse.com/thing:911708

Additional features are:

Improved insulation,

Simple and easy install/uninstall (nothing to unscrew),

Angle distance adjustment.

The X shutters of the previous designs are suppressed and the distance between the angles is reduced to limit the heat losses.

The principle of the proposed solution is to build a heated enclosure around the hot bed, and not as usual around the printer.

The expected advantages are:

Printer parts -electronic components,motors . . .- work at room temperarture,

No need of extra heating,

Less power to heat the bed (up to 50% less).

The enclosure consists of three main parts:

2 insulation sheets that cover the entire hot bed,

2 side plates attached to the printer frame,

and 2 Z shutters which follow the movement of the X axis.

Insulation sheets (upper covers) and shutters of the enclosure are fixed to a support consisting of aluminum angles and plastic parts, itself fixed to the X axis rods.Front and rear covers consist of 3 layers of mylar film, PE foam and aluminized plastic film.

see video: https://youtu.be/211JHkUjk4k

This is an improved version of my previous designs:

www.thingiverse.com/thing:997467

www.thingiverse.com/thing:911708

Additional features are:

Improved insulation,

Simple and easy install/uninstall (nothing to unscrew),

Angle distance adjustment.

The X shutters of the previous designs are suppressed and the distance between the angles is reduced to limit the heat losses.

Similar models

thingiverse

free

Hot Bed Enclosure v2 by xavan

...ee files), itself fixed to the x axis rods.

upper cover sheets can be lifted or easily detached to give full access to the bed

thingiverse

free

Hot Bed Enclosure by xavan

...sions are for my p3steel printer.

this principle can be adapted to other printers . . .

see video: https://youtu.be/wsdy4zyvi4e

thingiverse

free

BCN3D Sigma enclosure by Jonni

... motors.

with the enclosure i can get the internal air temperature to around 65°c and it also makes the printer a bit more quiet.

grabcad

free

Cetus 3D Printer heated bed electronics enclosure

...s 3d printer. see the link below for more detials.

https://capolight.wordpress.com/2018/08/02/diy-heated-bed-for-cetus-3d-printer

thingiverse

free

Heat cover for QIDITECH X-ONE printer by komadojiro

...olycarbonate cardboard.

cardboard connectors are used for top cover.

and plastic l angle bar has been used for each edge costume.

thingiverse

free

Elegoo Mars heater blower cover

...away from the top of the acrylic printer cover and allows it to heat up the chamber without pinpointing so much heat at one spot.

grabcad

free

PERSPEX ENCLOSURE WITH PLASTIC CORNERS FOR CREALITY PRINTER

...nstant temperature around the 3d printer (creality ender 3) to improve success and quality, specifically when printing abs parts.

thingiverse

free

Z end stop cover with adjusting plate by deskripta

...whole printer skin.

this part is also designed to help adjusting the z axis, especially after mounting glass on aluminum hot bed.

grabcad

free

Hot plate press to melt labels onto flat plastic

...comes dirty by rollers and clamp on top

- solid, simple design without flexing

note: heating elements and electronics not showing

thingiverse

free

Rostock Max v3 Case Enhancements for Enclosure Heating by TimStough

... a raspberry pi on top of my printer and plug it in here.

i will be posting photos later, but i wanted to get the stls up sooner.

Xavan

thingiverse

free

Boxes by xavan

...boxes by xavan

thingiverse

modify the parameters in the scad files to create boxes according to your needs.

thingiverse

free

Extruder cable mount by xavan

...extruder cable mount by xavan

thingiverse

designed for a 9mm spiral binding.

thingiverse

free

Filament guide for P3steel by xavan

...filament guide for p3steel by xavan

thingiverse

filament guide for p3steel (3 mm steel thickness)

thingiverse

free

Lead screw holder for P3steel by xavan

...lead screw holder for p3steel by xavan

thingiverse

lead screw diameter 5 mm

p3steel hole diameter 10 mm

thingiverse

free

Refrigerator door handle by xavan

...tance between the centre of fixing holes is 133 mm. fits also for aeg, zanussi, rosenlew, brandt, frigidaire, arthur martin. . .

thingiverse

free

Retractable handle release for delsey trolley by xavan

...e handle release for delsey trolley by xavan

thingiverse

overall length:123 mm

button size: 13.5x35 mm

adaptable to other models

thingiverse

free

Mouse wheel repair by xavan

...able.

this replacement part is glued to the coding wheel. the dimensions can be adjusted according to your needs (see scad file).

thingiverse

free

Furniture Corner Guards by xavan

...e using a 20 mm double-sided foam tape.

sized to fit most tables, shelving ....

see also http://www.thingiverse.com/thing:2262339

thingiverse

free

P3steel Y belt tensioner by xavan

...gt2 belts

designed in two heights (vs y-carriage):

idle pulley: 11 mm

nema pulley: 16 mm

easy adjustment from the printer front

thingiverse

free

Endoscope camera skids for pipe inspection by xavan

...utilize a rounded shape to better navigate inside the pipes.

designed for a cheap usb endoscope: diam 7.5mm & length 38.5 mm

V3

3d_export

$5

Poison-v3

...poison-v3

3dexport

poison-v3

3ddd

$1

Curtain v3

...curtain v3

3ddd

полупрозрачная штора v3

turbosquid

free

v3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

potato v3

...potato v3

3dexport

turbosquid

$69

Skeletor v3

...royalty free 3d model skeletor v3 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1712713)

turbosquid

$49

Zombie v3

...

royalty free 3d model zombie v3 for download as obj and ztl on turbosquid: 3d models for games, architecture, videos. (1342458)

turbosquid

$2

Bitcoin v3

...

royalty free 3d model bitcoin v3 for download as c4d and prj on turbosquid: 3d models for games, architecture, videos. (1182845)

turbosquid

$29

Turret V3

...alty free 3d model turret v3 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1217498)

turbosquid

$20

Radiators v3

... free 3d model radiators v3 for download as max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1607437)

turbosquid

$10

Wheel V3S

...e 3d model wheel v3s for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1344250)

Enclosure

3d_export

free

electrical enclosure

...l enclosure where electrical devices like (relays, contactors, busbars ) are kept in order to protect from hazardous environment.

turbosquid

$100

GPU Enclosure

...yalty free 3d model gpu enclosure for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1381061)

3d_export

$5

Electrical Enclosure

...ed. also has tower lights attaced on the top.<br>file format that are available:<br>.step<br>.obj<br>.stl

archive3d

free

Enclosure 3D Model

...closure 3d model

archive3d

shower enclosure-acquarius- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-omega- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-vega - 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-zenith - 3d model for interior 3d visualization.

turbosquid

$20

shower enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Dumpster Enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

3d printer enclosure

... model 3d printer enclosure for download as ipt, skp, and fbx on turbosquid: 3d models for games, architecture, videos. (1634310)

Hot

turbosquid

$1

HOT

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

$9

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

free

hot chili

...hot chili

3dexport

hot chili<br>for fruits and getegables collection

3d_export

$5

hot air balloon

...hot air balloon

3dexport

hot air balloon

3d_export

free

Hot dog shop

...hot dog shop

3dexport

hot dog shop

turbosquid

$90

hot venue

...rbosquid

royalty free 3d model hot venue for download as fbx on turbosquid: 3d models for games, architecture, videos. (1336949)

turbosquid

$20

Hot Rod

...

turbosquid

royalty free 3d model hot rod for download as ma on turbosquid: 3d models for games, architecture, videos. (1351690)

turbosquid

$14

Hot Pepper

...bosquid

royalty free 3d model hot pepper for download as obj on turbosquid: 3d models for games, architecture, videos. (1611643)

turbosquid

$1

Hot dog

...turbosquid

royalty free 3d model hot dog for download as max on turbosquid: 3d models for games, architecture, videos. (1450961)

Bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

Bed

...bed

3ddd

bed , постельное белье , постель

bed

3d_export

$7

bed adairs bed

...rs bed

3dexport

bed adairs bed in modern style. if you want a smoother surface, please turn on turbosmooth in the modifier list.