Thingiverse

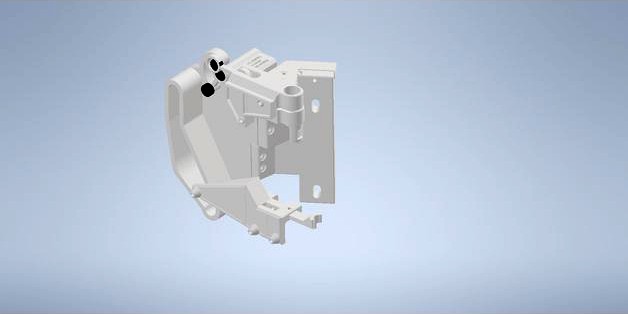

Hornady AP Case Feeder - Bearing Based - V1.0 by Renakx

by Thingiverse

Last crawled date: 3 years, 3 months ago

This is a case feeder for the Hornady Lock and Load AP press, Inspired by the design by Bartje64. While the design was influenced by Barteje64's, all of these components were created new (from scratch) in Autodesk Inventor. This design still utilizes their case selector V5 (https://www.thingiverse.com/thing:3844226/files), so you will need to print theirs to optimize the use of this print, otherwise a tube cut to the desired length could be substituted. You will also need to work out the hardware to mount their component (I used a scrap machine screw with the correct head diameter). A future revision to this design will be to replace their case selector completely, but for now it is functional enough.

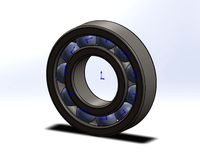

This was designed because I only have a SLA printer (Creality L002R) and the friction between the parts of the available designs was too great for the print to operate. also, this pulls the case slider straight back, rather than from the side of the slider, reducing any lateral torque on the press arm/slide itself. This design relies on 624zz bearings to function and operates with a bell and post style actuator rather than the vertical push-post style found on available designs. I believe this greatly reduces stress and friction applied to the upper components of the assembly.

Another important difference is the geometry of the slider guide. By increasing the retraction angle of the lower slider, its path is much more gradual, which decreases stress on the assembly. Previous versions use the same approach decent path (as does the wire for Hornady's case feeder) but when relying on plastic this is an enhancement in my opinion.

IMPORTANT - This is intended to be available for public use, but not for commercial use. Anyone seeking to print these for profit is requested to contact me before proceeding (the answer will probably be yes, we would just need to agree on a nominal royalty). I can only authorize the creation and sale of my files, no others. This took a quite a bit of trial and error to get this right, so if you'd like to give back you can do so here: https://www.paypal.me/aaronhrenak or via venmo: @aaronhrenak

Build list (Links at bottom of page)

7 Tube Base

7 Tube Bottom

7 Tube Top

REQUIRES - 7 Lee Tubes, 1 M4x25 screw, spring (cut) and washer)

-Tubes press fit (press fit into top first. Once the tubes are press fit into bottom this difficult to remove)

7 tube base requires M4x45mm bolt with M4 nuts to clamp against base of 7 tube base and to connect to Upper Slide Guide.

-M4x25 screw with washer and cut to fit spring hold 7 tube top to 7 tube base. Leave enough room for base to separate from bottom under spring tension.

Bearing Mount Top

REQUIRES - 3 M4x25 screws and 1 624zz bearing.

-Screw secures bearing to part

-2 screws attach part to Upper Slide Guide

Bell and Post Pivot

REQUIRES - 1 624zz bearing and 2 M4x25 screws.

screws secure 1 bearing to part (bearing on outside of bottom hole) and the bearing inserted into Upper Slider to Bell and Post Connector (bearing on outside of upper hole.

this assemble press fits onto bearing attached to Bearing Mount Top

Case Drop Guide

press fits into bottom of Upper Slide Guide

Case Feeder Bracket

REQUIRES - 2 1/4x20mm bolts, 2 1/4" washers.

-use hardware to attach completed assembly to press.

Case Pusher

-Press fits into Lower Slide Roller. A hole is present for a screw if fitment is loose.

Lower Slide Roller

REQUIRES - 6 624zz bearings and 4 M4x25mm screws.

-2 inner pockets both have a bearing held by one screw.

-Lower holes have one bearing each held by one screw respectively (mount from inside).

-Rear of roller has 2 bearings attached using one screw. This is intended to better align the force with the center of the slider, but a single bearing may work as well.

Slide Roller Guide

REQUIRES - 4 M4x25mm screws.

-Slide Roller Guide mounts to back of Case Feeder Bracket

Upper Slide Guide

REQUIRES - 3 M4x25 screws, Spring

One screw secures Upper Slide Guide to back of Case Feeder Bracket

2 screws secure Upper Slide Guide to top of Case Feeder Bracket

Spring goes inside Upper Slide Guide and will be compressed by screw inside of Upper Slide Roller

Upper Slide Roller

Requires - 3 624zz bearings, 3 M4x20mm angle head screws, and 2 M4x25mm screws.

2 bearings mount to inside of slider using M4x20 screws.

1 bearing mounts to bottom of roller using M4x20mm screw (this must be done with Upper slide quide detached from Case Feeder Bracket.

1 M4x25mm screw connects Upper Slider to Bell and Post Connector to rear of Upper Slide Roller

1 M4x25mm screw goes through top of Upper Slide Roller and compresses spring within Upper Slide Guide.

Upper Slide to Bell and Post Connector

Requires - 2 624zz bearings

Bearings press fit into Connector

Parts List

1/4x20mmx3/4"bolts (2)

1/4" washers (2)

1/4"x4.5in (or longer) hex bolt (1)

7/32 x 1-5/8 x 0.015 spring (Picked mine up at lowes)

-I also used a 5/16x1-1/2x0.20 spring around that one but it probably wasn't necessary.

M4x20mm oval head - This style but only (3) needed -https://www.amazon.com/Recessed-Machine-Stainless-Fasteners-ASMM31664/dp/B00BNCRFIE/ref=sr_1_1?dchild=1&keywords=Screws&pd_rd_r=d27f3a9f-a5ee-4ec2-adf5-79e2715a767f&pd_rd_w=YYa16&pd_rd_wg=zDGVJ&pf_rd_p=91473338-a775-4a82-9600-6767cae1f29a&pf_rd_r=1E0J4Q6QT0QYCFYGNRPG&pid=3Hm1qHI&qid=1610417631&refinements=p_n_feature_two_browse-bin%3A2292871011%2Cp_n_feature_twenty-eight_browse-bin%3A19043892011%2Cp_n_feature_five_browse-bin%3A3177285011&s=industrial&sr=1-1

M4x25 screws (19 pan head) -https://www.amazon.com/FixtureDisplays-Socket-M4x25mm-Screws-15168-20PK-NF/dp/B0872NQBS7/ref=sr_1_3?dchild=1&keywords=m4x25mm+screws+20&qid=1610417373&sr=8-3

624zz bearings (13 required) -https://www.amazon.com/XiKe-624ZZ-Pre-Lubricated-Performance-Cost-Effective/dp/B07JHKK44G/ref=sxts_sxwds-bia-wc-nc-drs1_0?cv_ct_cx=624zz&dchild=1&keywords=624zz&pd_rd_i=B07JHKK44G&pd_rd_r=d3d97249-f979-4aab-98cf-8585044e39ff&pd_rd_w=9Ak5F&pd_rd_wg=7uWVB&pf_rd_p=a64002b9-9c26-4361-b8a1-b0f5a4835670&pf_rd_r=XYSSMP2XG2T0EBNMES0D&psc=1&qid=1610414408&s=industrial&sr=1-1-38d0a374-3318-4625-ad92-b6761a63ecf6

Lee tubeshttps://www.amazon.com/LEE-PRECISION-90661-Load-Master-Progressive/dp/B000N8JWEO/ref=sr_1_1?dchild=1&keywords=lee+tubes&qid=1610419915&sr=8-1

This was designed because I only have a SLA printer (Creality L002R) and the friction between the parts of the available designs was too great for the print to operate. also, this pulls the case slider straight back, rather than from the side of the slider, reducing any lateral torque on the press arm/slide itself. This design relies on 624zz bearings to function and operates with a bell and post style actuator rather than the vertical push-post style found on available designs. I believe this greatly reduces stress and friction applied to the upper components of the assembly.

Another important difference is the geometry of the slider guide. By increasing the retraction angle of the lower slider, its path is much more gradual, which decreases stress on the assembly. Previous versions use the same approach decent path (as does the wire for Hornady's case feeder) but when relying on plastic this is an enhancement in my opinion.

IMPORTANT - This is intended to be available for public use, but not for commercial use. Anyone seeking to print these for profit is requested to contact me before proceeding (the answer will probably be yes, we would just need to agree on a nominal royalty). I can only authorize the creation and sale of my files, no others. This took a quite a bit of trial and error to get this right, so if you'd like to give back you can do so here: https://www.paypal.me/aaronhrenak or via venmo: @aaronhrenak

Build list (Links at bottom of page)

7 Tube Base

7 Tube Bottom

7 Tube Top

REQUIRES - 7 Lee Tubes, 1 M4x25 screw, spring (cut) and washer)

-Tubes press fit (press fit into top first. Once the tubes are press fit into bottom this difficult to remove)

7 tube base requires M4x45mm bolt with M4 nuts to clamp against base of 7 tube base and to connect to Upper Slide Guide.

-M4x25 screw with washer and cut to fit spring hold 7 tube top to 7 tube base. Leave enough room for base to separate from bottom under spring tension.

Bearing Mount Top

REQUIRES - 3 M4x25 screws and 1 624zz bearing.

-Screw secures bearing to part

-2 screws attach part to Upper Slide Guide

Bell and Post Pivot

REQUIRES - 1 624zz bearing and 2 M4x25 screws.

screws secure 1 bearing to part (bearing on outside of bottom hole) and the bearing inserted into Upper Slider to Bell and Post Connector (bearing on outside of upper hole.

this assemble press fits onto bearing attached to Bearing Mount Top

Case Drop Guide

press fits into bottom of Upper Slide Guide

Case Feeder Bracket

REQUIRES - 2 1/4x20mm bolts, 2 1/4" washers.

-use hardware to attach completed assembly to press.

Case Pusher

-Press fits into Lower Slide Roller. A hole is present for a screw if fitment is loose.

Lower Slide Roller

REQUIRES - 6 624zz bearings and 4 M4x25mm screws.

-2 inner pockets both have a bearing held by one screw.

-Lower holes have one bearing each held by one screw respectively (mount from inside).

-Rear of roller has 2 bearings attached using one screw. This is intended to better align the force with the center of the slider, but a single bearing may work as well.

Slide Roller Guide

REQUIRES - 4 M4x25mm screws.

-Slide Roller Guide mounts to back of Case Feeder Bracket

Upper Slide Guide

REQUIRES - 3 M4x25 screws, Spring

One screw secures Upper Slide Guide to back of Case Feeder Bracket

2 screws secure Upper Slide Guide to top of Case Feeder Bracket

Spring goes inside Upper Slide Guide and will be compressed by screw inside of Upper Slide Roller

Upper Slide Roller

Requires - 3 624zz bearings, 3 M4x20mm angle head screws, and 2 M4x25mm screws.

2 bearings mount to inside of slider using M4x20 screws.

1 bearing mounts to bottom of roller using M4x20mm screw (this must be done with Upper slide quide detached from Case Feeder Bracket.

1 M4x25mm screw connects Upper Slider to Bell and Post Connector to rear of Upper Slide Roller

1 M4x25mm screw goes through top of Upper Slide Roller and compresses spring within Upper Slide Guide.

Upper Slide to Bell and Post Connector

Requires - 2 624zz bearings

Bearings press fit into Connector

Parts List

1/4x20mmx3/4"bolts (2)

1/4" washers (2)

1/4"x4.5in (or longer) hex bolt (1)

7/32 x 1-5/8 x 0.015 spring (Picked mine up at lowes)

-I also used a 5/16x1-1/2x0.20 spring around that one but it probably wasn't necessary.

M4x20mm oval head - This style but only (3) needed -https://www.amazon.com/Recessed-Machine-Stainless-Fasteners-ASMM31664/dp/B00BNCRFIE/ref=sr_1_1?dchild=1&keywords=Screws&pd_rd_r=d27f3a9f-a5ee-4ec2-adf5-79e2715a767f&pd_rd_w=YYa16&pd_rd_wg=zDGVJ&pf_rd_p=91473338-a775-4a82-9600-6767cae1f29a&pf_rd_r=1E0J4Q6QT0QYCFYGNRPG&pid=3Hm1qHI&qid=1610417631&refinements=p_n_feature_two_browse-bin%3A2292871011%2Cp_n_feature_twenty-eight_browse-bin%3A19043892011%2Cp_n_feature_five_browse-bin%3A3177285011&s=industrial&sr=1-1

M4x25 screws (19 pan head) -https://www.amazon.com/FixtureDisplays-Socket-M4x25mm-Screws-15168-20PK-NF/dp/B0872NQBS7/ref=sr_1_3?dchild=1&keywords=m4x25mm+screws+20&qid=1610417373&sr=8-3

624zz bearings (13 required) -https://www.amazon.com/XiKe-624ZZ-Pre-Lubricated-Performance-Cost-Effective/dp/B07JHKK44G/ref=sxts_sxwds-bia-wc-nc-drs1_0?cv_ct_cx=624zz&dchild=1&keywords=624zz&pd_rd_i=B07JHKK44G&pd_rd_r=d3d97249-f979-4aab-98cf-8585044e39ff&pd_rd_w=9Ak5F&pd_rd_wg=7uWVB&pf_rd_p=a64002b9-9c26-4361-b8a1-b0f5a4835670&pf_rd_r=XYSSMP2XG2T0EBNMES0D&psc=1&qid=1610414408&s=industrial&sr=1-1-38d0a374-3318-4625-ad92-b6761a63ecf6

Lee tubeshttps://www.amazon.com/LEE-PRECISION-90661-Load-Master-Progressive/dp/B000N8JWEO/ref=sr_1_1?dchild=1&keywords=lee+tubes&qid=1610419915&sr=8-1

Similar models

3dwarehouse

free

05 HS2A - Horizontal Slider - 2 Sliding Panels

... your requirements - call for sizes and design information. #10_11_00 #10_11_33 #kpro_specialty_products #visual_display_surfaces

grabcad

free

Feeder and filament guide for Ultimaker 2

....) of the original feeder but requires additional screws, bearings, bolts, and washers (see cad files for information on sizing).

thingiverse

free

Ender 3 Lead Screw Stabaliser - Bolt Free by Jimmyboy161

...4-8724-0f81b51372a6&pf_rd_r=q6gtevtjjm761fx92nrp&psc=1&qid=1607167644&sr=1-1-69f2aa40-4718-4485-ba0d-6c4119696677

thingiverse

free

CR10 v2 Filament guide for top mount spool by Petea4

...2rs-groove-bearing-bearings/dp/b07fdww9d9/ref=sr_1_5?dchild=1&keywords=8mm+x+22mm+x+7mm+bearing&qid=1609328662&sr=8-5

thingiverse

free

CR-10v2 Filament Guide Dual Rollers

... has a roller to help it.

requires 2 608 bearings

small screw/nut to attach to existing hole next to the filament run out sensor.

thingiverse

free

Cetus MK2 Feeder Guide by Giovanni_

...vanni_

thingiverse

new feeder guide for cetus3d mk2

no spring needed, just screw lateral m3 to push bearing towards the filament

thingiverse

free

case feeder tube guide for lee pro 1000 by 86am

...case feeder tube guide for lee pro 1000 by 86am

thingiverse

tube guide for lee pro 1000 case feeder, stops twisting tubes.

thingiverse

free

Kodama Trinus press fit filament tube guide

...e filament entry on the trinus, that's it.

it was made to help guide filament directly into the tube rather than at an angle.

grabcad

free

rolling slider

...ing between the rollers and runway. compare with the case when the rollers arranged in line contact both lower and upper surfaces

thingiverse

free

Bullet Feeder Spring Guide (openSCAD creator) by rkos

...tance from powder measure, more) can be customized by simply changing parameters.

if there are any problems with it let me know.

Hornady

3d_export

$10

17 Hornady Mach 2 Bullet

...best results in blender.<br>no extra plugins are required for this model. lights and cameras are not included in the scene.

thingiverse

free

Hornady Nozzle by Greg198

...hornady nozzle by greg198

thingiverse

thingiverse

free

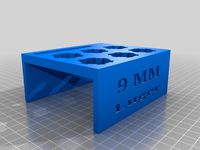

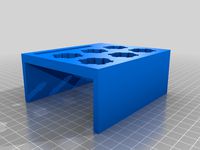

Hornady Die holder 9MM

...hornady die holder 9mm

thingiverse

this will hold 6 reloading dies with the hornady lnl bushing and the shell plate

thingiverse

free

Hornady’s Powder Trickler Funnel by commanderbeatle2

...hornady’s powder trickler funnel by commanderbeatle2

thingiverse

just a funnel for hornady’s powder trickler.

thingiverse

free

Reloading die with Hornady LNL bushing

...reloading die with hornady lnl bushing

thingiverse

for reloading dies with the hornady lnl bushing

thingiverse

free

Die Holder with a Hornady LNL bushing

...die holder with a hornady lnl bushing

thingiverse

holds 6 reloading dies with the hornady lnl bushing and shell plate

thingiverse

free

Wrench for lock ring die Hornady by Dragunov76

...wrench for lock ring die hornady by dragunov76

thingiverse

wrench for lock ring die hornady

thingiverse

free

Hornady deburring tool bit mount by bios86

...hornady deburring tool bit mount by bios86

thingiverse

drill bit mount for hornady deburring tool

thingiverse

free

Hornady die holder

...hornady die holder

thingiverse

this will hold 6 dies with the lnl bushing and the associated shell plate.

thingiverse

free

Hornady Case prep gears by imakershop

...ingiverse

replacement gears for the hornady lock-n-load case prep trio (https://www.midwayusa.com/product/1012733817?pid=245424)

Feeder

3d_export

free

Feeder

...feeder

3dexport

feeder.

3d_ocean

$7

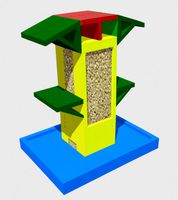

bird feeders

...bird feeders

3docean

bird feeders wood

bird feeders

3d_export

$6

bird feeder

...bird feeder

3dexport

bird feeder

3d_export

free

Bird feeder

...feeder

3dexport

a beautiful, lovely and tranquil bird feeder, which you can use for your amazing games, animations, or pictures.

turbosquid

$59

Hummingbird Feeder

... free 3d model hummingbird feeder for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1444996)

turbosquid

$2

Baby Feeder

...y free 3d model baby feeder for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1488786)

archive3d

free

Bird feeder 3D Model

...r tray feeder

bird feeder n250714 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$18

Pet feeder

...ee 3d model pet feeder for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559898)

turbosquid

$3

dog feeder

... 3d model dog feeder for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1545601)

turbosquid

$29

Chicken Feeder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Ap

design_connected

$11

AP

...ap

designconnected

lapalma ap computer generated 3d model. designed by azumi, shin.

turbosquid

$5

APS

...ty free 3d model aps for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1195340)

turbosquid

$95

aps

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$13

Marylin AP

...marylin ap

designconnected

axo light marylin ap wall lights computer generated 3d model. designed by manuel vivian.

turbosquid

$1

Ape sculpture

...yalty free 3d model ape sculpture for download as max and ztl on turbosquid: 3d models for games, architecture, videos. (1488917)

3ddd

$1

SVEN AP-520

...sven ap-520

3ddd

sven , наушники

наушники sven ap-520

3d_export

$35

APS 3D Model

...techkin semi-automatic weapon оружие пистолет асп стечкин автоматический полуавтоматический

aps 3d model starblaze 70860 3dexport

turbosquid

$39

Ape Beast

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

APS modified

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

AP Pistol

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

V1

turbosquid

$35

v1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

street tree v1

...street tree v1

3dexport

street tree v1

3d_export

$5

potato v1

...potato v1

3dexport

turbosquid

$20

Kitchen V1

...bosquid

royalty free 3d model kitchen v1 for download as max on turbosquid: 3d models for games, architecture, videos. (1153622)

turbosquid

$12

sofa v1

...turbosquid

royalty free 3d model sofa v1 for download as max on turbosquid: 3d models for games, architecture, videos. (1283267)

turbosquid

$3

Chair V1

...urbosquid

royalty free 3d model chair v1 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486093)

turbosquid

$15

Cupboard v1

...royalty free 3d model cupboard v1 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1444568)

3d_export

$5

tram v1

...tram v1

3dexport

3d_export

$8

lumber car v1

...lumber car v1

3dexport

lumber car v1 printable, low poly model.

turbosquid

$20

DELTALIGHT v1

...free 3d model deltalight v1 for download as max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1630928)

Bearing

3d_export

$6

Bear

...bear

3dexport

bear

3d_export

$5

bearing

...bearing

3dexport

bearing

3d_export

$12

bear

...bear

3dexport

bear for 3d printing toy

3d_ocean

$9

Bearing

...ne ball ballbea bearing bearings engine hard industrial machine mechanic metal part piece plastic ring screw sphere steel

bearing

archibase_planet

free

Bear

...bear

archibase planet

statuette bear picturesque element

bear - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

bear

...bear

3dexport

bear have a stl.,3dm files

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear angry n250907- 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear easy n250907 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Teddy bear

...teddy bear

3ddd

teddy bear , медведь

teddy bear :)

3d_ocean

$12

Bear

... formats. created with 3d max 9.0. this file is very useful for learning & rigging. it can be used for any professional work.

0

turbosquid

$12

Calligraphic Digit 0 Number 0

...hic digit 0 number 0 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389318)

3d_export

$6

set-0

...set-0

3dexport

turbosquid

$6

hedge 0

...yalty free 3d model hedge 0 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1450353)

turbosquid

$5

Nuber 0

...oyalty free 3d model nuber 0 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1564674)

turbosquid

$22

0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Steam Locomotive Fowler 4F 0-6-0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Liquid Number 0

... model liquid number 0 for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1689919)

turbosquid

$45

Dragon360_perspShape_tmp.0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Rocks Debris 0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

wood-guardrail-fence 0

...wood-guardrail-fence 0

3dexport

wood-guardrail-fence 0<br>3ds max 2015

Case

3d_export

$1

case

...case

3dexport

case

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case + cakes - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case for chips - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case shelving drawer

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case rack locker

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case drawer kitchen furniture

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case cupboard shelving

glass case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case handbag suitcase

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case suitcase

case 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

locker case dresser

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Based

archibase_planet

free

Base

...base

archibase planet

base column column base

base 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column base column

base 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column base column

base 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

foundation base

column base ionic - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

foundation base

column base tuscan - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$18

Base

...base

designconnected

tom dixon base computer generated 3d model. designed by dixon, tom.