Thingiverse

Hobby Rocket parts by OneOfThree

by Thingiverse

Last crawled date: 4 years, 4 months ago

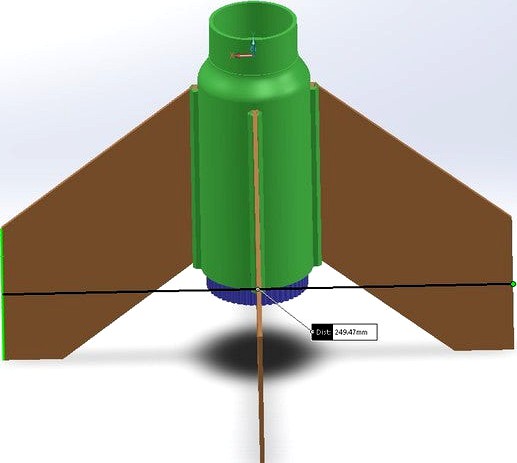

Couple rocket components that are easy to print and are sized so that a paper towel cardboard rube can be used as the rocket core.

Assembled with 2 paper towel tubes this thing is 33 inches tall and weighs in at 190grams w/o recovery system or engine. Will need at least a D12 to get this thing off the pad in this config. Using one tube would help a little.

Working on engine adapters for D and E motors.

-Nose cone is 4 inches tall with .75" engagement into the body tube. and has a connection point for a recovery system.

-The multibody connector is used to connect two sections of tube together w/ .75" engagement on either side.

-Thrust Puck is sized to fit D or E Estes engines in them.

-D and E adapters are sized so that a D is Flush with the start of the nozzle bell, E sticks into the bell 5mm.

-Nozzle Plug will hold everything together. It's a quarter turn release and should pull out easy enough. I had to sand the ID of the Thrust Puck the first time I printed it. I've since clearanced it enough that it should be good.

-Stabilizers are tricky to print.

I printed them laying down with support, that worked well for all but one fin. I think my printer goofed.

I've also printed them with the wider base on the bed, but there was some wavy-ness as it got higher in layers.

Printed on a CR6-SE

Assembled with 2 paper towel tubes this thing is 33 inches tall and weighs in at 190grams w/o recovery system or engine. Will need at least a D12 to get this thing off the pad in this config. Using one tube would help a little.

Working on engine adapters for D and E motors.

-Nose cone is 4 inches tall with .75" engagement into the body tube. and has a connection point for a recovery system.

-The multibody connector is used to connect two sections of tube together w/ .75" engagement on either side.

-Thrust Puck is sized to fit D or E Estes engines in them.

-D and E adapters are sized so that a D is Flush with the start of the nozzle bell, E sticks into the bell 5mm.

-Nozzle Plug will hold everything together. It's a quarter turn release and should pull out easy enough. I had to sand the ID of the Thrust Puck the first time I printed it. I've since clearanced it enough that it should be good.

-Stabilizers are tricky to print.

I printed them laying down with support, that worked well for all but one fin. I think my printer goofed.

I've also printed them with the wider base on the bed, but there was some wavy-ness as it got higher in layers.

Printed on a CR6-SE