Thingiverse

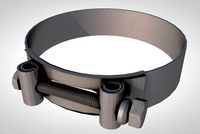

Heavy Duty C Clamp Tripod for Camera and Light

by Thingiverse

Last crawled date: 4 years, 3 months ago

This is an heavy duty c clamp to mount photo gear to an table top or an shelf.

I failed to break the prototype, so I consider it strong enough. Th e secret of its strength will reveal the slicer. So be curios!

It has an 1/4" thread to directly attach a ball head. But the pole gives you more flexibility.

The pole is made for 16mm tubes. You can use cable pipes witch is the cheapest option. The optimal choice would be aluminum, but carbon will also has its appeal ;-)

There are different models for different screw sizes. So you should find the appropriated screws in your stock or at your local hardware store. (Witch wars quite frustrating that's why I added the addition options.)

I have provided two caps for the pole. One for an camera screw and with an spigot for lights. The spigot fits through the clamp, so the pole can be removed from the clamp later.

BOM

1pcs M5x40/50/60 hex bolt (choose according to the clamp body size)

2pcs M5 nuts

1pcs M4x10/12/16 hex bolt (choose the model for the knob according to the size)

1pcs m4 nut

1pcs m3x30 countersink screw (to enforce the spigot)

2pcs 1/4-20 unc 5/8 countersink screw

1pcs anti slip pad with adhesive (non-slip shoe pads, witch are used to make high heels mire secure)

Printing

The body sould be printed wit 0.2mm layer hight, 0.4mm nozzle with and 3 perimeters.

Mounting

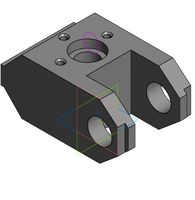

Step: Equip the m5 hex-bolt with the "ClampSpindelKnobLid" and one m5 nut.

step: Insert the prepared m5 Bolt into the body of the clamp. This needs all space from all cavities. Push the nut into its cavity at the bottom and insert a second m5 nut into the cavity at the outside of the clamp screw the bolt down until it engages with the second nut too.

3.Step: Now put the "ClampSpindelKnob" in top of the bolt and press the "ClampSpindelKnobLid" into the "ClampSpindelKnob" from the bottom. This will need a fair amount of force and you will hardly get this apart again.

(not shown:) Screw the 1/4-20 5/8 screw into the upper bracket of the clamp.

Step: Stick an piece of non-slip pad under the upper bracket as shown and trimm of the access with an utility knife.

Step (not shown): Insert the m4 nut into its cavity inside the tunnel at the rear. Fit the knob with the appropriated m4 hex bolt and screw it in from the rear.

Step: Cut the pole from an 16mm tube to the desired length. Equip the "ClampPoleCap" with the second 1/4-20 5/8 screw and glue it in one end of the pole.

The other end is to be equipped with the "ClampSpigot" witch can be enforced with an m3x30 countersink screw.

Please considere leaving me a tip if you like the design.

I failed to break the prototype, so I consider it strong enough. Th e secret of its strength will reveal the slicer. So be curios!

It has an 1/4" thread to directly attach a ball head. But the pole gives you more flexibility.

The pole is made for 16mm tubes. You can use cable pipes witch is the cheapest option. The optimal choice would be aluminum, but carbon will also has its appeal ;-)

There are different models for different screw sizes. So you should find the appropriated screws in your stock or at your local hardware store. (Witch wars quite frustrating that's why I added the addition options.)

I have provided two caps for the pole. One for an camera screw and with an spigot for lights. The spigot fits through the clamp, so the pole can be removed from the clamp later.

BOM

1pcs M5x40/50/60 hex bolt (choose according to the clamp body size)

2pcs M5 nuts

1pcs M4x10/12/16 hex bolt (choose the model for the knob according to the size)

1pcs m4 nut

1pcs m3x30 countersink screw (to enforce the spigot)

2pcs 1/4-20 unc 5/8 countersink screw

1pcs anti slip pad with adhesive (non-slip shoe pads, witch are used to make high heels mire secure)

Printing

The body sould be printed wit 0.2mm layer hight, 0.4mm nozzle with and 3 perimeters.

Mounting

Step: Equip the m5 hex-bolt with the "ClampSpindelKnobLid" and one m5 nut.

step: Insert the prepared m5 Bolt into the body of the clamp. This needs all space from all cavities. Push the nut into its cavity at the bottom and insert a second m5 nut into the cavity at the outside of the clamp screw the bolt down until it engages with the second nut too.

3.Step: Now put the "ClampSpindelKnob" in top of the bolt and press the "ClampSpindelKnobLid" into the "ClampSpindelKnob" from the bottom. This will need a fair amount of force and you will hardly get this apart again.

(not shown:) Screw the 1/4-20 5/8 screw into the upper bracket of the clamp.

Step: Stick an piece of non-slip pad under the upper bracket as shown and trimm of the access with an utility knife.

Step (not shown): Insert the m4 nut into its cavity inside the tunnel at the rear. Fit the knob with the appropriated m4 hex bolt and screw it in from the rear.

Step: Cut the pole from an 16mm tube to the desired length. Equip the "ClampPoleCap" with the second 1/4-20 5/8 screw and glue it in one end of the pole.

The other end is to be equipped with the "ClampSpigot" witch can be enforced with an m3x30 countersink screw.

Please considere leaving me a tip if you like the design.

Similar models

thingiverse

free

Warsley/Ankey rotary tool "clamp" holder by MACPET

...t;screw_feet")

designed for warsley/ankey 480w professional rotary tool

i am going to make more accessories for this holder.

thingiverse

free

Shovel Handle by BoopidooDesigns

...

2pcs 3d-printed handle parts

2pcs countersunk wood screws

1pcs m5x55 screw

1pcs m5 nut

2pcs m5 washers

1pcs 2.5" hose clamp

thingiverse

free

KOSO RX1N 28.6mm fatbar mount by Jebex

...cycle speedometer.

use original mounting dampers.

required screws:

2pcs m5x16 hex head bolt

1pcs m5x20 hex head bolt

3pcs m5 nuts

thingiverse

free

Ender-5 LCD12864 Holder

...eccesary to assemble:

1pc m3x30 screw + m3 nut

1pc m5x20 screw + 2pcs m5 washers + 1pc m5 nut

and stock lcd holder screws.

enjoy!

thingiverse

free

Filament guide for Geeetech A10 + BMG extruder + Runout sensor by Cstom75

... guide with runout sensor for bmg extruder.

bolts:

1pcs m3x10 + nut

1pcs m4x25

2pcs m4 lock nut

2pcs m4 washer

1pcs 688zz bearing

thingiverse

free

Adapter with rotation for Mantis Gripper to EEZYbotARM MK2

..._mount_b

1pcs martins_gripper_claw_3_r

1pcs martins_gripper_claw_3_l

1pcs martins_gripper_gear

2pcs martins_gripper_bearingfix_2x

thingiverse

free

V-slot fan holder (60,80mm) by CaptainDz

... secret screw - 2pc.

m4 nut - 3pc.

for 60mm fan need's:

30mm m4 secret screw - 1pc.

20mm m4 secret screw - 2pc.

m4 nut - 3pc.

thingiverse

free

CR-10 modified spool holder with bearing by szili83

...ols for example: philamentpm

updated, short axes:

"cr_10_tengely_v2_roviditett"

"cr10_tengely_belsoalatet_v3"

thingiverse

free

spool holder for profile delta lightweight by codavr

...crew m4 bolts, thread length 6mm: 4pcs

printed:

rod 1: 2pcs

rod 2: 2pcs

joint 1: 2pcs

joint 2: 1pcs

joint 3: 1pcs

pla amount: 50g

thingiverse

free

turnable base for modular mini tripod by JrGong92

...ead screws

2pcs. m4x16mm lens head screws

3pcs. m4x12mm lens head screws

4pcs. m4 square nuts (low profile)

3pcs. m4 hexagon nuts

Tripod

archibase_planet

free

Tripod

...tripod

archibase planet

tripod staff state stand

tripod - 3d model for interior 3d visualization.

archibase_planet

free

Tripod

...tripod

archibase planet

camera tripod

cam tripod 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Tripod

...tripod

archibase planet

tripod support stand holder

tripod n191213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

design_connected

$13

Tripod

...tripod

designconnected

erickson æsthetics tripod computer generated 3d model. designed by erickson, ben.

design_connected

$13

Tripod

...tripod

designconnected

david weeks studio tripod computer generated 3d model. designed by weeks, david.

3d_ocean

$4

Tripod

...tripod

3docean

3d models coffee table furnishings furniture tripod

3d models,furnishings,furniture

archibase_planet

free

Tripod

...tripod

archibase planet

tv camera equipment

cam tripod - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$4

Tripod

...urbosquid

royalty free 3d model tripod for download as blend on turbosquid: 3d models for games, architecture, videos. (1580064)

turbosquid

$5

Tripod

...uid

royalty free 3d model tripod for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1593078)

turbosquid

$35

Tripod

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Duty

3d_export

$5

call of duty credits emblem

...call of duty credits emblem

3dexport

credits emblem in 3d mode, call of duty coin

turbosquid

$3

Heavy Duty Aircraft

...yalty free 3d model heavy duty aircraft for download as blend on turbosquid: 3d models for games, architecture, videos. (1599053)

3d_ocean

$14

Duty Free Goods

...are a low polygonal models, easy to animate. - poly count: 408 - formats: max /obj /fbx/3ds/dxf - high detail was preserved wi...

turbosquid

$150

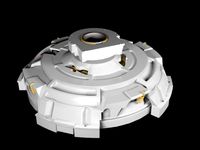

Heavy Duty Drone

... heavy duty drone for download as lwo, obj, fbx, lxo, and dae on turbosquid: 3d models for games, architecture, videos. (1268820)

turbosquid

$120

Heavy Duty Fighter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Heavy duty chain

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Heavy Duty Clutch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Heavy Duty Shelf

...y duty shelf for download as 3ds, obj, wrl, c4d, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1227727)

3d_export

$14

800t heavy duty rubber press

...800t heavy duty rubber press

3dexport

800t heavy duty rubber press

3d_export

$10

Call of Duty personnages 3D Model

...ll of duty character 3ds c4d cinema 4d juggernaut shepherd ghost price

call of duty personnages 3d model arabizzle 66478 3dexport

Heavy

design_connected

$16

Heavy

...heavy

designconnected

decode heavy computer generated 3d model. designed by hubert, benjamin.

turbosquid

$12

Spar TRAIN-Heavy HEAVY-DUTY

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

The Heavy Rabbit

...the heavy rabbit

3ddd

табурет

project: heavy rabbit

designed by bongo design

3d_ocean

$40

Heavy vehicles

...el this model is created with 3ds max 2009 and content .max (3ds max), size: 7,65 mb this model can be used in any scene. enjoy !

3d_export

$8

heavy plastic crusher

...heavy plastic crusher

3dexport

heavy plastic crusher

3d_export

$5

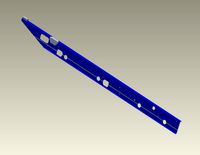

heavy rotation handle

...heavy rotation handle

3dexport

heavy rotation handle

turbosquid

free

heavy sword

...ord

turbosquid

free 3d model heavy sword for download as fbx on turbosquid: 3d models for games, architecture, videos. (1223423)

turbosquid

free

Heavy Shield

...squid

royalty free 3d model heavy shield for download as fbx on turbosquid: 3d models for games, architecture, videos. (1382280)

turbosquid

$42

Heavy Tank

...

royalty free 3d model heavy tank for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1311230)

turbosquid

$3

Heavy Ball

...

royalty free 3d model heavy ball for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1515557)

Clamp

3d_export

$11

clamp

...clamp

3dexport

clamp

3ddd

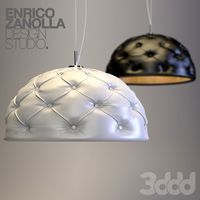

free

Clamp

... enricо zanolla , капитоне

дизайнерenrico zanollмодель clamp

3ddd

$1

Clamp

...ricо zanolla , капитоне

дизайнеры

enrico zanolla

andrea di filippo

модель clamp

dzstudio

3d_export

free

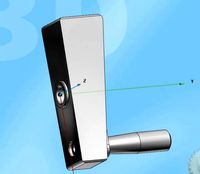

clamp

...clamp

3dexport

simple clamp model, more free 3d models here:

3d_export

$5

clamping handle

...clamping handle

3dexport

clamping handle

3ddd

$1

Clamp / DZstudio

... dzstudio , капитоне

люстра clamp от dzstudio/enrico zanolla(италия).

3ddd

$1

Светильник Clamp

...светильник clamp

3ddd

clamp

стеганый светильник clamp в двух цветах в черном и белом.

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442049)

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442041)

3d_export

$5

Clamp-14

...clamp-14

3dexport

3d model of clamp name 14

C

3ddd

$1

Gustavsberg Skandic 160 c-c

...gustavsberg skandic 160 c-c

3ddd

gustavsberg , смеситель

3dmax 2009

3ddd

$1

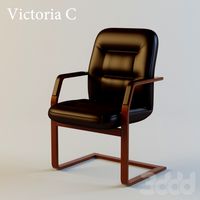

Кресло Victoria C

...кресло victoria c

3ddd

victoria c , стул

victoria c

design_connected

$25

Mobius C

...mobius c

designconnected

zenith mobius c computer generated 3d model. designed by schamburg, marc.

3ddd

$1

Molteni & C

...molteni & c

3ddd

molteni&c

molteni & c

turbosquid

$10

Raids house C&C Tiberian sun

... raids house c&c tiberian sun for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1188376)

turbosquid

$10

Civilian Asylum C&C Tiberian sun

...ilian asylum c&c tiberian sun for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1188365)

3ddd

$1

Molteni & C

...molteni & c

3ddd

molteni&c

стул molteni & c

3ddd

free

kamina&c

...kamina&c

3ddd

kamina-c , табурет барашек

sheep chair by kamina-c

design_connected

$29

Extrasoft C

...extrasoft c

designconnected

living divani extrasoft c computer generated 3d model. designed by lissoni, piero.

design_connected

$4

Mono C

...mono c

designconnected

scp mono c tables computer generated 3d model. designed by konstantin grcic.

Camera

archibase_planet

free

Camera

...base planet

camera surveillance camera video camera

camera surveillance n090211 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...hibase planet

camera security camera video camera

camera security n210515 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Camera

...se planet

camera web camera webcam

camera butterfly usb pc camera n090713 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...mera

archibase planet

surveillance camera video camera camcorder

camera n011211 - 3d model (*.3ds) for exterior 3d visualization.

archibase_planet

free

Camera

...camera

archibase planet

camera digital camera

camera canon digital n041211 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...camera

archibase planet

camera film camera phototechnique

camera n100214 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...amera

archibase planet

camera video camera camcorder

camera video n070315 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...rchibase planet

camera video camera camcorder

camera studio n101213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Camera

...ibase planet

digital camera camera phototechnique

camera canon ixus 400 n310311 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Camera

...ase planet

photocamera video camera camera

camera sony t300 black n291010 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...