Thingiverse

Hammerhead Magnetic Carriage for Delta printers by AdrianW

by Thingiverse

Last crawled date: 4 years, 4 months ago

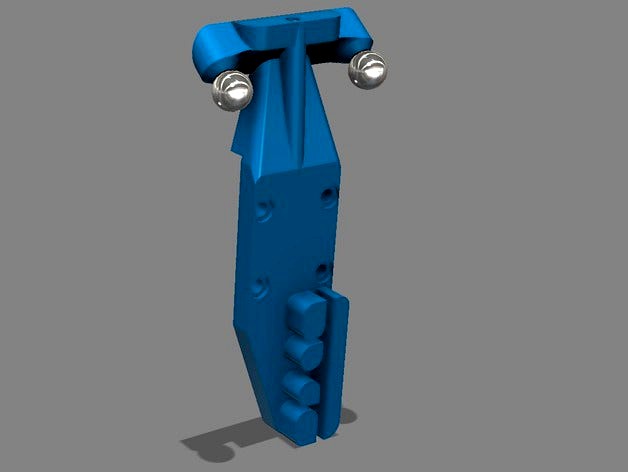

I have designed a new mag-ball carriage. I named them the Hammerhead because they look kinda like the shark... :)

With the old design, i lost 10mm of my build radius. (20mm in both directions) That was too big of a hit on my build plate. These are designed to give that space back; with maximum arm travel.

I printed them out of ABS with a 100% infill and a 2mm wall. They need to be rock solid. Any flex and the prints will come out looking bad.

There are 3 types of STL files attached. One is a complete build. The others fit together with some glue. I used "ABS Juice" as my glue. Make sure they fit together well and hold them tight when you glue them.

I used M3 x 8mm button cap screws for all the mounts. 6 for each carriage. The balls are 9.5mm (3/8th in) ball bearings with an m3 hole drilled and tapped.

The spacing between the balls is 40mm.

I am still working on the effector and arm designs.

Any questions or need some help drop me a line.

Updated 8-26-2017

added 10mm Ball stud ver for 48mm and 50mm Spacing

Updated:8-3-2016

Add 50mm and 48mm ball spacing.

Updated:12-15-2016

Updated the License and added more tags

UPDATED:12-15-2016

Added STEP files and removed duplicate models.

UPDATE: 9-29-2016

Trimmed off one corner of the belt clamp to improve arm reach.

Added a 43mm Ball spacing design

With the old design, i lost 10mm of my build radius. (20mm in both directions) That was too big of a hit on my build plate. These are designed to give that space back; with maximum arm travel.

I printed them out of ABS with a 100% infill and a 2mm wall. They need to be rock solid. Any flex and the prints will come out looking bad.

There are 3 types of STL files attached. One is a complete build. The others fit together with some glue. I used "ABS Juice" as my glue. Make sure they fit together well and hold them tight when you glue them.

I used M3 x 8mm button cap screws for all the mounts. 6 for each carriage. The balls are 9.5mm (3/8th in) ball bearings with an m3 hole drilled and tapped.

The spacing between the balls is 40mm.

I am still working on the effector and arm designs.

Any questions or need some help drop me a line.

Updated 8-26-2017

added 10mm Ball stud ver for 48mm and 50mm Spacing

Updated:8-3-2016

Add 50mm and 48mm ball spacing.

Updated:12-15-2016

Updated the License and added more tags

UPDATED:12-15-2016

Added STEP files and removed duplicate models.

UPDATE: 9-29-2016

Trimmed off one corner of the belt clamp to improve arm reach.

Added a 43mm Ball spacing design