Thingiverse

Halbach Open BLDC Motor First Release by usertogo

by Thingiverse

Last crawled date: 3 years ago

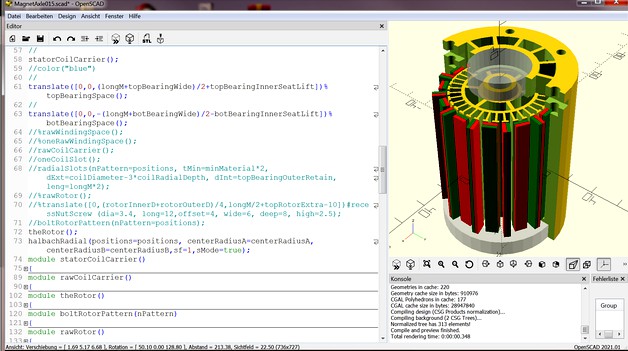

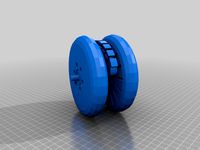

Untested first parametric release of an outrunner BLDC motor

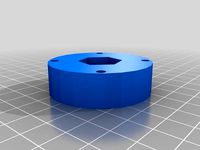

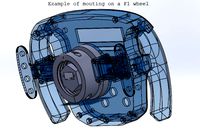

Parametric design can be adjusted for pole pairs (quadruplets because of Halbach setup), magnet sizes and such; however many aspect will have to be manually calibrated... The individual elements have to be accessed for stl exporting by commenting/uncommenting(//) the particular lines. So far there are only 3 printed parts Base, Stator and Rotor. First test print shows that the mating feature between stator and base is too tight to fit and will need some coding...

12xM3x__ Nuts and bolts for base and ?Prop? mount

1x 6807 Bearing (if you buy this from my Ebay Store send me a message and get the 608ZZ Bearing included for free! https://www.ebay.de/itm/184239183693 )

1x 608 Bearing

M8x100 screw or threaded rod plus nuts

24x Magnet 50x5x2.5 mm

winding wire

For general hints on wiring/winding a motor like this refer to the pioneers work: https://www.instructables.com/600-Watt-3d-printed-Halbach-Array-Brushless-DC-Ele/https://www.makesea.com/web/claimer/brushless-motor

looks like my current configuration has not nearly as much space for windings as these samples... However do notice how much my design has been simplified in comparison to the 'inspiration'!

Naturally everything is open to configure in the scad file

Do participate in Open Source developments cause we can not take anything material to the next incarnation...

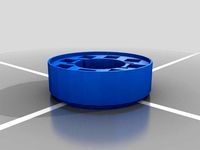

Notice the vented rotor configuration I added, which will result in extra cleanup difficulties, but might help to mitigate a prime concern of these type of experimental motors. The problem is that specifically PLA loses its defined shape already above 50 degrees Celcius and other plastic materials under continued tension and thermal cycling might also only add a few degrees to the operational range. The holes will also help to press out the magnets if that was ever necessay. They should when the motor is spinning accelerate some air outward which will lower the air pressure inside the motor which will help cooling the motor! I might add something similar to the stator from the winding inward - seems like a good idea too!

Parametric design can be adjusted for pole pairs (quadruplets because of Halbach setup), magnet sizes and such; however many aspect will have to be manually calibrated... The individual elements have to be accessed for stl exporting by commenting/uncommenting(//) the particular lines. So far there are only 3 printed parts Base, Stator and Rotor. First test print shows that the mating feature between stator and base is too tight to fit and will need some coding...

12xM3x__ Nuts and bolts for base and ?Prop? mount

1x 6807 Bearing (if you buy this from my Ebay Store send me a message and get the 608ZZ Bearing included for free! https://www.ebay.de/itm/184239183693 )

1x 608 Bearing

M8x100 screw or threaded rod plus nuts

24x Magnet 50x5x2.5 mm

winding wire

For general hints on wiring/winding a motor like this refer to the pioneers work: https://www.instructables.com/600-Watt-3d-printed-Halbach-Array-Brushless-DC-Ele/https://www.makesea.com/web/claimer/brushless-motor

looks like my current configuration has not nearly as much space for windings as these samples... However do notice how much my design has been simplified in comparison to the 'inspiration'!

Naturally everything is open to configure in the scad file

Do participate in Open Source developments cause we can not take anything material to the next incarnation...

Notice the vented rotor configuration I added, which will result in extra cleanup difficulties, but might help to mitigate a prime concern of these type of experimental motors. The problem is that specifically PLA loses its defined shape already above 50 degrees Celcius and other plastic materials under continued tension and thermal cycling might also only add a few degrees to the operational range. The holes will also help to press out the magnets if that was ever necessay. They should when the motor is spinning accelerate some air outward which will lower the air pressure inside the motor which will help cooling the motor! I might add something similar to the stator from the winding inward - seems like a good idea too!

Similar models

grabcad

free

BLDC-Brushless DC motor

...tions of bldc motors are diverse and include industries such as robotics, automation, automotive, aerospace, and medical devices.

thingiverse

free

3D Printed Brushless Motor

...1x 3d printed rotor

1x 3d printed stator

1x 3d printed bearing holder

1x 3d printed base

1x hobbywing skywalker 20a esc

grabcad

free

BLDC Motor Stator

...bldc motor stator

grabcad

bldc motor stator with winding

grabcad

free

BLDC motor stator

...bldc motor stator

grabcad

stator of a brushless dc motor

grabcad

free

Motor BLDC

...motor bldc

grabcad

just a stator and a rotor from a bldc motor.

thingiverse

free

BLDC Permanent magnet

...rushless permanent magnet 3 phase motor dc powered.

wiring configuration

designed in solidworks.

working on releasing

.scad files

thingiverse

free

3-phase brushless motor by DylanMissu

... stator

3x spool

6x m3 hex nut

3x 30mm m3 bolt

1x 25mm m3 threaded rod

2x 8mm dia 3mm bore bearings

4x 6mm dia 4mm length magnets

thingiverse

free

BLDC simple motor by emartinelli

... wiring instruction (find in internet) a phase shown on photo

test of previos verion: https://www.youtube.com/watch?v=r5i5rj5fyzk

thingiverse

free

BLDC motor

...ngs and a 1/4" shaft with a few 1/4" shaft spacers and a locking nut and shaft collar. printed with a longer orange 10.

grabcad

free

Induction motor

... magnetic field of the stator winding.

high level of power

simple structure

brushless motor

we used it for our rfl field! :)))))

Usertogo

thingiverse

free

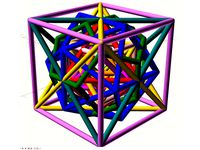

Fractal Tessalation of Platonic Solids by usertogo

...nter. watch this and try and design a similar 'star mother' construction kit: https://www.youtube.com/watch?v=bsd1vo1k6xc

thingiverse

free

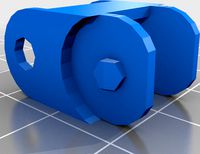

PillowBlock Open SCAD code cleanup... by usertogo

...edo it!

at any rate it is already much better than the original state and should be used as base if sombody wants to expand on it

thingiverse

free

Drone Foot with integrated Propeller Guard Untested by usertogo

... is probably the thing to do - let me know how it goes!

to be continued...

remixed from https://www.thingiverse.com/thing:4441076

thingiverse

free

'Corona Gläubige sind asymptomatisch Intelligent' Funny Parametric Stencil with added Options by usertogo

...

there are obviously further improvements thinkable - for now thanks to the programmer of the original file i edited (remixed)...

thingiverse

free

Cone Foot plus various little Mods Coreless KreQuad Drone by usertogo

...ng remain closed or have adjustable gap width

tripple section of pcb cage support

added a more airodynamic oval prop guard option

thingiverse

free

Code clean up Cable Chain and eliminated zero volume surfaces by usertogo

...int in place straight section only would be beneficial

not print tested by me!

remix of https://www.thingiverse.com/thing:1078216

thingiverse

free

URSA Open Axis Initiative Step1 by usertogo

...t and gear requires some improvements too

ideal would be a fully parametric open source full differential solution in the future

thingiverse

free

Tire Rim Wheel Mockup by usertogo

...r onto the object would take you to the code that caused that element... i shall try to forward that suggestion to the developers

thingiverse

free

Moineau Paste Extruder Nema17 Stepper ZeroSurface cleanup by usertogo

...mote shaft setup, because nema 17 steppers are quite heavy...

to be continued... (by you? please consider open source and share!)

thingiverse

free

Tank Track Print in Place fully Parametric with Motor Gear by usertogo

...s://www.thingiverse.com/janssen86/designs regretably i never been able to get multiple remix inheritance properly ajusted here...

Halbach

thingiverse

free

Halbach array by RoboP

...gnets for amplification of a magnetic field), the magnets i used are 2x5x10mm, totally 20pcs are needed, 5pcs arrangement 5x10x10

thingiverse

free

Halbach Array

...ou rotate the square magnet with n pointing at 12:00 - 3:00 - 6:00 - 9:00 until the holder is full. then glue them all in place.

thingiverse

free

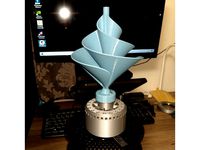

turbine with halbach motor linkage by retiredneedhobbies

...rinted-halbach-array-brushless-dc-ele/

prints fine upright without supports. unlock axis settings and set height at 88% for mk3s.

thingiverse

free

Halbach array holder for NMR spectrometer. by TanyaAkinora

...er.

ndfeb n42 permanent magnet 10x10x25 mm, 0.7tesla, very homogenous field.https://www.indigoinstruments.com/magnets/rare_earth/

thingiverse

free

0.9T Halbach Magnet for NMR by ellie_l

...om/). to be used for testing nmr without requiring a superconducting magnet. hall probe measurements agreed well with simulation.

thingiverse

free

Halbach Array for 16mm Disc Magnets by FadeDude

...nly had a bunch of disc magnets lying around. this array enclosure is nicely marked with + and _ symbols on the enclosure itself.

thingiverse

free

Halbach Disc Motor Electric Scooter

...isc motor electric scooter

thingiverse

electric scooter using a disc motor on the rear axle, with magnets embedded in the wheel.

thingiverse

free

Halbach Array by electromechtro

...printed it on his ultimaker 2 over a year ago, before i had my mk2.

i do know that he was using colorfab xt and a setting of .06.

thingiverse

free

NMR Halbach Mandhala by QuantumEnthusiast

...structed by jeremiah o'mahony with guidance and good-natured mockery from merideth frey, phd, in beautiful yonkers, new york.

thingiverse

free

Halbach Array Linear Direct 3D Printer Extruder Drive by TanyaAkinora

...showed that the drive effort is sufficient to operate as an extruder drive.

this is an experimental device, work on it continues.

Bldc

turbosquid

$1

electric engine BLDC with water cooling for printing 10 000 W stl

...with water cooling for printing 10 000 w stl for download as on turbosquid: 3d models for games, architecture, videos. (1632791)

3d_export

$10

Low noise BLDC remote control fan SMITH-5

...~ 100,000 model parts: 1 texture format: .png .jpg resolution: 1024*1024 pbr in substance painter formats: .obj .gltf .fbx .blend

3d_export

$10

Mega Air Stand Type BLDC Motor Air Circulator

...~ 100,000 model parts: 1 texture format: .png .jpg resolution: 1024*1024 pbr in substance painter formats: .obj .gltf .fbx .blend

3d_export

$10

CX11 BLDC cordless vacuum cleaner

...painter available for all software<br>ue4. ue5. blender. maya. 3d max. unity. c4d.<br>formats: .obj .gltf .fbx .blend

3d_export

$5

Hexacopter

...the hexagonal type dron which has six propalar with bldc motor. its full ready for 3d print. just slice...

thingiverse

free

bldc-turbo-fan

...bldc-turbo-fan

thingiverse

bldc motor fan blades .

thingiverse

free

63100 BLDC by cammas

... by cammas

thingiverse

freerchobby bldc motor, drawn as 8mm shaft, 10mm available. i don't have the motor in hand to verify.

thingiverse

free

BLDC simple motor by emartinelli

... wiring instruction (find in internet) a phase shown on photo

test of previos verion: https://www.youtube.com/watch?v=r5i5rj5fyzk

thingiverse

free

Drive for Maytech BLDC by Schwiedi

...drive for maytech bldc by schwiedi

thingiverse

not tested yet

thingiverse

free

BLDC motor mounting bracket for SunnySky X4108S by antiElectron

...bldc motor mounting bracket for sunnysky x4108s by antielectron

thingiverse

bldc motor mounting bracket for sunnysky x4108s

Release

turbosquid

$39

Sofa. Updated release

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Film releasing mechanism

...asing mechanism for download as 3ds, ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1227251)

3d_export

$5

shift lock release kia soul

...shift lock release kia soul

3dexport

shift lock release kia soul

turbosquid

$14

Quick release swivel carabiner with ring

...ease swivel carabiner with ring for download as sldpr and stl on turbosquid: 3d models for games, architecture, videos. (1668426)

turbosquid

$60

AUTOMATIC AIR RELEASE VALVE GRP33-07

...odel automatic air release valve grp33-07 for download as ipt on turbosquid: 3d models for games, architecture, videos. (1404884)

3d_export

$10

Kitchen Release Mat

...xture format: .png .jpg<br>resolution: 1024*1024<br>pbr in substance painter<br>formats: .obj .gltf .fbx .blend

3d_export

$5

logitech g27-g29 quick release

...r and the other wheel adaptor.<br>files are in stl format, but if you want to edit parts i give you files in sldprt format.

3d_export

$20

mutante veneno

...model created in zbrush 33cm ready for printing, previously release in 6...

3d_export

$5

Drowned Plush Minecraft

...for microsoft windows, macos and linux, and was later re-release for a wide variety of platforms. it is the...

3d_export

$7

Toy drone for kids

...drone for kids. based on only 3 d models. release for toy...

Motor

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$29

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

First

turbosquid

free

First

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Chair First

...chair first

designconnected

magis chair first computer generated 3d model. designed by giovannoni, stefano.

design_connected

$13

Table First

...table first

designconnected

magis table first computer generated 3d model. designed by giovannoni, stefano.

turbosquid

$3

First Character

...squid

royalty free 3d model first character for download as on turbosquid: 3d models for games, architecture, videos. (1498951)

turbosquid

$39

Egg First

...

royalty free 3d model egg first for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1207383)

turbosquid

$20

First Win

...

royalty free 3d model first win for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1440117)

turbosquid

$39

Tour First

...ee 3d model tour first for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1313928)

turbosquid

$3

first aid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

First Aid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

First Aid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Open

3d_export

free

Opener

...r

3dexport

3d model of can opener. its my first work, if u can please show me my mistakes. this 3d model was created in autocad.

3d_export

free

Cap opener

...cap opener

3dexport

handy cap opener, more files/formats here:

3ddd

$1

Кресло, Open Oreon.

...кресло, open oreon.

3ddd

open , oreon

кресло, open oreon.

3d_ocean

$4

Open Book

...r interior max mental model open ray reading shelf text vray

open hardcover book with unique texture map on front and back cover.

turbosquid

$6

Opening Flag

...squid

royalty free 3d model opening flag for download as c4d on turbosquid: 3d models for games, architecture, videos. (1593555)

turbosquid

$10

Open book

...

royalty free 3d model open book for download as skp and obj on turbosquid: 3d models for games, architecture, videos. (1690781)

turbosquid

$2

bottle opener

...lty free 3d model bottle opener for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1621201)

turbosquid

$24

Bottle Opener

...free 3d model bottle opener for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1300948)

turbosquid

$20

Open Box

...yalty free 3d model open box for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1481218)

turbosquid

$10

Wine Opener

...ty free 3d model wine opener for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1240730)