GrabCAD

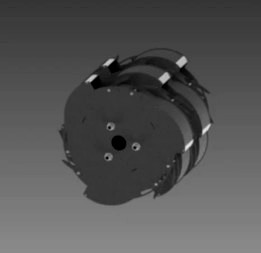

Grate, Rake, and Kevlar Hinge Doors in RASSOR Drum for Improved Efficiency and Performance

by GrabCAD

Last crawled date: 1 year, 10 months ago

NOTES:

- The gif. after the presentation has no thumbnail but it is working, please click on it first to see.

- The doors on the model is simply for illustration purpose, it cannot be simulated because it is fixed in place

- '80%' on the presentation should be '70-80%'

Design Summary:

The design purpose is to met the design requirement from the competition description and the paper that is included on the description. The design goals are as follows:

- Meet the dimension requirement

- Manufacture-able and functional

- Last for at least 5 years

- Prevent icy regolith (equivalent as damped sand on earth) to stuck on the scoop

- Successfully exclude rocks of certain size from entering the bucket

- Maximum weight of 5kg

Based on that, I've created this design. The design is able to:

- prevent rock larger than 1cm in diameter to enter,

- eliminate cohesion of icy regolith prior to entering the scoop,

- able to retain whats inside the bucket when on a trip back to the lander for about 8.5 minutes

- all parts that is expected to wear out will be replaceable

- manufacturing is possible, as explained on the pictures

- assembly is possible, as can be seen on the gif.

- structural integrity

Weight of the bucket in total is about 4.5kg. Dimension of the drum has already fulfilled the dimension requirement, with max. diameter of 450mm with scoop, 340mm without scoop, with length of 360mm, and maximum engaged scoop at any given time 175mm. It will be able to AT LEAST collect 22L of regolith in one mining cycle, with AT LEAST 80% full.

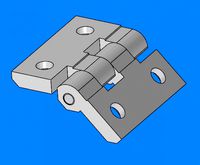

To make it reach at least 80% full I use doors to prevent regolith from falling out, the doors only located in 1 or 2 scoop in each segment. To keep the mining cycle fast, the other scoop that has no doors will have larger outlet, so it catches more regolith as it rotates backward, thus creating faster unloading on that scoop. Will the mining cycle be faster? I don't know, but using this system will allow it to be more effective, as regolith lost is minimal, with still three scoops on each segment, keeping the time of mining fast. It uses marker so the operator can control the position of the bucket for maximum regolith volume retained.

The scoop that has no doors will not be functioning as good as the one with doors when RASSOR is mining. The reason is that when its reaches about 30-40% full, regolith will start to fall into the scoop cavity, so the regolith will not be that much since the way is blocked by the falling regolith from the inside. Thus, to add more regolith when its already 40% full, the scoop with doors will have a more crutial role, as the scoop cavity will not be filled with regolith from the inside, keeping digging capacity for that scoop just like normal, until its about 70-80% full after mining about 10 minutes, beyond that the openings of the door will be limited by the regolith surface, making it less effective.

As an additional information (because its not mentioned on the presentation uploaded):

- the scoop can cut 5cm deep, but cutting it 5cm in one scoop will jam the scoop, as mentioned by Jason Schuler on the competition comments. The design scoop is at least 5cm, therefore able to do the task just like prior design, cutting it only half full about 2.5cm.

- If the grating system got clogged, the main corrective action is to redesign the grate. Maybe enlarge the holes to 2-3cm, or make the holes longer, about 83.5cm while keeping the width 1cm. Also, the vibrating mechanism mentioned on the research article might help.

- Will the centrifugal force hold the door closed? No it won't, centrifugal force at 20RPM is really low compared to weight force of the regolith and the door itself

- To increase the volume, the drum circle line should've been tangent to the scoop curve

- Will the doors got stucked by regolith? No it won't, see my discussion with Sava Savov on the comment section

- After thinking of it for a while, the doors might also have the ability to unload. When its about 60-80% full, the doors won't be fully closed when it rotates backward and reach the surface of the regolith inside, thus some of the regolith will get through the door and will be able to unload through the scoop with doors. But thats not the case when its almost empty, in this case the scoop without doors will unload the regolith

File including:

- STEP and STL file is compiled into one rar.

- STL also available to download in single part

- Renderings

- Explanation pictures

- Animated gif.

- The gif animation in mp4 format

Reference:

- Mueller, R.P., Cox, R.E., Ebert, T., Smith, J.D., Schuler, J.M. & Nick, A.J. 2013. Regolith Advanced Surface Systems Operations Robot (RASSOR). IEEE Aerospace Conference Proceedings. 2013

- Wilkinson, A. & DeGennaro, A. 2006. Digging and pushing lunar regolith: Classical soil mechanics and the forces needed for excavation and traction. Journal of Terramechanics 44 (2007) 133-152

Illustration:

The videos listed below is just to illustrate the reason why I choose the design, all of the videos are not my creation.

- https://www.youtube.com/watch?v=cgI5EzcpK6s&t=456s

- https://www.youtube.com/watch?v=Q675gKNp6zs&t=22s

- https://www.youtube.com/watch?v=C-b-7BYygFs

- The gif. after the presentation has no thumbnail but it is working, please click on it first to see.

- The doors on the model is simply for illustration purpose, it cannot be simulated because it is fixed in place

- '80%' on the presentation should be '70-80%'

Design Summary:

The design purpose is to met the design requirement from the competition description and the paper that is included on the description. The design goals are as follows:

- Meet the dimension requirement

- Manufacture-able and functional

- Last for at least 5 years

- Prevent icy regolith (equivalent as damped sand on earth) to stuck on the scoop

- Successfully exclude rocks of certain size from entering the bucket

- Maximum weight of 5kg

Based on that, I've created this design. The design is able to:

- prevent rock larger than 1cm in diameter to enter,

- eliminate cohesion of icy regolith prior to entering the scoop,

- able to retain whats inside the bucket when on a trip back to the lander for about 8.5 minutes

- all parts that is expected to wear out will be replaceable

- manufacturing is possible, as explained on the pictures

- assembly is possible, as can be seen on the gif.

- structural integrity

Weight of the bucket in total is about 4.5kg. Dimension of the drum has already fulfilled the dimension requirement, with max. diameter of 450mm with scoop, 340mm without scoop, with length of 360mm, and maximum engaged scoop at any given time 175mm. It will be able to AT LEAST collect 22L of regolith in one mining cycle, with AT LEAST 80% full.

To make it reach at least 80% full I use doors to prevent regolith from falling out, the doors only located in 1 or 2 scoop in each segment. To keep the mining cycle fast, the other scoop that has no doors will have larger outlet, so it catches more regolith as it rotates backward, thus creating faster unloading on that scoop. Will the mining cycle be faster? I don't know, but using this system will allow it to be more effective, as regolith lost is minimal, with still three scoops on each segment, keeping the time of mining fast. It uses marker so the operator can control the position of the bucket for maximum regolith volume retained.

The scoop that has no doors will not be functioning as good as the one with doors when RASSOR is mining. The reason is that when its reaches about 30-40% full, regolith will start to fall into the scoop cavity, so the regolith will not be that much since the way is blocked by the falling regolith from the inside. Thus, to add more regolith when its already 40% full, the scoop with doors will have a more crutial role, as the scoop cavity will not be filled with regolith from the inside, keeping digging capacity for that scoop just like normal, until its about 70-80% full after mining about 10 minutes, beyond that the openings of the door will be limited by the regolith surface, making it less effective.

As an additional information (because its not mentioned on the presentation uploaded):

- the scoop can cut 5cm deep, but cutting it 5cm in one scoop will jam the scoop, as mentioned by Jason Schuler on the competition comments. The design scoop is at least 5cm, therefore able to do the task just like prior design, cutting it only half full about 2.5cm.

- If the grating system got clogged, the main corrective action is to redesign the grate. Maybe enlarge the holes to 2-3cm, or make the holes longer, about 83.5cm while keeping the width 1cm. Also, the vibrating mechanism mentioned on the research article might help.

- Will the centrifugal force hold the door closed? No it won't, centrifugal force at 20RPM is really low compared to weight force of the regolith and the door itself

- To increase the volume, the drum circle line should've been tangent to the scoop curve

- Will the doors got stucked by regolith? No it won't, see my discussion with Sava Savov on the comment section

- After thinking of it for a while, the doors might also have the ability to unload. When its about 60-80% full, the doors won't be fully closed when it rotates backward and reach the surface of the regolith inside, thus some of the regolith will get through the door and will be able to unload through the scoop with doors. But thats not the case when its almost empty, in this case the scoop without doors will unload the regolith

File including:

- STEP and STL file is compiled into one rar.

- STL also available to download in single part

- Renderings

- Explanation pictures

- Animated gif.

- The gif animation in mp4 format

Reference:

- Mueller, R.P., Cox, R.E., Ebert, T., Smith, J.D., Schuler, J.M. & Nick, A.J. 2013. Regolith Advanced Surface Systems Operations Robot (RASSOR). IEEE Aerospace Conference Proceedings. 2013

- Wilkinson, A. & DeGennaro, A. 2006. Digging and pushing lunar regolith: Classical soil mechanics and the forces needed for excavation and traction. Journal of Terramechanics 44 (2007) 133-152

Illustration:

The videos listed below is just to illustrate the reason why I choose the design, all of the videos are not my creation.

- https://www.youtube.com/watch?v=cgI5EzcpK6s&t=456s

- https://www.youtube.com/watch?v=Q675gKNp6zs&t=22s

- https://www.youtube.com/watch?v=C-b-7BYygFs

Similar models

grabcad

free

NASA (RASSOR) Bucket Drum Design Challenge with Design VPR 21

...ely for blades and bucket

7. inside section view while filling bucket

8. section view of one from 16 modified 623zz ball bearings

grabcad

free

NASA Bucket Drum Design Challenge V4

...oth mining, discharging and scooping).

the max volume it can collect 15.5 litters

the drum was design so it can be 3d printed.

grabcad

free

NASA Bucket Drum Design Challenge V2

...drum as an exploded view it should be 3d printed (file > nasa bucket drum design challenge v2 drum assm.stl) as a single unit.

grabcad

free

NASA RASSOR BUCKET DRUM

...use four bucket drums of this design as “tires”, similar to the original rassor...

grabcad

free

NASA Bucket Drum Design Challenge

...d. the internal swirl moves the regolith back out through the scoop buckets.

this scooping drum was designed to be 3d printed.

grabcad

free

(RASSOR) Bucket Drum Design Challenge

...et drum design challenge for nasa regolith include step file and gif and realistic photos.

all requirements has been implemented.

grabcad

free

(RASSOR) Bucket Drum Design Challenge

...et drum design challenge for nasa regolith include step file and gif and realistic photos.

all requirements has been implemented.

grabcad

free

Excavator

...ed: 30.88 liters

fill ratio: 80%

the fill ratio of the barrel is estimated, i believe that it should be at least 80% fill ratio.

grabcad

free

NASA Regolith Drum E1

...tries for this challenge:

https://grabcad.com/library/nasa-regolith-drum-e2-1

https://grabcad.com/library/nasa-regolith-drum-e3-1

grabcad

free

NASA's RASSOR 3.0 Bucket Drum

...ience accomplishing this challenge.

thank you all for visiting! :)

Rassor

grabcad

free

RASSOR

...rassor

grabcad

just tried to design rassor

hope you like it :)

grabcad

free

Rassor

...s effesien used for mining in outer space, the system used is the mortar mixing system. this drum rassor uses horizontal rotation

grabcad

free

Rassor

...rassor

grabcad

modeling of rassor drums for the collection of extraterrestrial soil. rhinoceros, file stl and renderings

grabcad

free

Rassor Bucket

...rassor bucket

grabcad

nasa rassor challenge

grabcad

free

RASSOR

... (rassor) with major highlight is the excavation blade is a angle of 30 degree. the software used in particle simulation is edem

grabcad

free

RASSOR

...rassor

grabcad

this is a very simple and innovative plan

grabcad

free

RASSOR Regolith Miner

...rassor regolith miner

grabcad

designed for the nasa rassor bucket challenge

grabcad

free

rassor de Alonso

...rassor de alonso

grabcad

eta es una pala para el sistema rassor

grabcad

free

RASSOR Scoop Drum

...rassor scoop drum

grabcad

stl / jpeg / txt file submission for nasa rassor scoop challenge

grabcad

free

NASA RASSOR BUCKET

... is a design for nasa rassor bucket. the total weight of the bucket is 4.94 kg. for unloading rotate the bucket counterclockwise.

Kevlar

3d_export

$150

army of one girl

...the model is 8,950<br>2. heavy armed version. equipped with kevlar vest, kimber pistol, sordin headgear, and scar rifle. working...

thingiverse

free

Kevlar glove by DrewPetitclerc

...eels like cotton but stops all cutting wounds, will not stop a stab from a really sharp point but i've learned to be careful.

thingiverse

free

drive wheels for kevlar bands by stiganielsen

...teps around a 15mm ø diameter pipe, so if you want to know if it fits your drive wheel, count your kevlar band over something 15ø

thingiverse

free

Microwave Door Handle with Kevlar by CompositesGuy

...itesguy

thingiverse

irreplaceable door handle for my microwave broke off. designed and printed a replacement with the mark one.

thingiverse

free

Kevlar Reinforced Jeep Freedom Top Hooks by CompositesGuy

...eep freedom top hard shell. the core has concentric rings of continuous kevlar printed on the markforged mark one. bulletproof.

thingiverse

free

Dan Topjian's Kevlar® Reinforced Envelope Opener by drewMarkForged

...cause it only takes about 4 hours to print and only uses about 5 cubic centimeters of nylon and 5.7 cubic centimeters of kevlar®.

blendswap

free

kevlar bulletproof vest basic

...you will have 340 vertex but you will have to modify mesh.made in polandbydantelatest change on 2014/02/23, 05:24:34updated files

thingiverse

free

Anycubic I3 Mega E3DV6 by GHIS3D

...mega e3dv6 by ghis3d thingiverse so white and black kevlar ...

thingiverse

free

Box rocket! by MINTEMP_ERRO

...i made. made for 13mm, take some string or kevlar and feed it up through the hole on the...

thingiverse

free

LIGHT iPHONE 8 by GHIS3D

...done, have fun. v.1 standard white light mood v.2 kevlar optimal fatboy light mood & kevlar optimal straight light...

Rake

3d_export

$5

rake

...rake

3dexport

3d rake model

3d_export

$5

rake

...rake

3dexport

3d model of a rake. perfect for games, ads, animations.

3d_export

$5

Rake

...rake

3dexport

rake can be used in video games of different genres for decoration or game mechanics.

turbosquid

$35

Rake

...

royalty free 3d model rake for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1302008)

3d_export

free

garden rake

...garden rake

3dexport

garden rake with a wooden handle.

turbosquid

$8

Rake

...lty free 3d model rake for download as fbx, obj, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1608958)

turbosquid

$29

Rake

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Rake

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

rakes

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Rake

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Grate

archibase_planet

free

Grate

...grate

archibase planet

grate grating lattice

grate n270807 - 3d model for interior 3d visualization.

archibase_planet

free

Grate

...grate

archibase planet

grating grate lattice

grate n140708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Grate

...grate

archibase planet

grating grate lattice

grate n280808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Grate

...grate

archibase planet

grating lattice

grate n220408 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Grate

...grate

archibase planet

picturesque element grate ironwork

grate n190708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$2

grating

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Лампа Grating

...лампа grating

3ddd

лампа grating в двух расцветках

archive3d

free

Grate 3D Model

...d model

archive3d

grate grating lattice

grate n270807 - 3d model for interior 3d visualization.

archive3d

free

Grate 3D Model

...e3d

grating grate lattice

grate n140708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Grate 3D Model

...e3d

grating grate lattice

grate n280808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Drum

3d_export

$5

drums

...drums

3dexport

drums

3d_ocean

$20

Drums

...iled model of drums. charleston,bass drum, tamtam drums, cymbal,etc. available in .blend, .obj, and .lwo format. ready for render

archibase_planet

free

Drum

...hibase planet

drum musical instrument tambour drum kit

drum taiko n091115 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$9

Drum

...drum

designconnected

brent comber drum computer generated 3d model. designed by comber, brent.

turbosquid

$4

Drum 7 Drum 12

... model drum 7 drum 12 for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1641795)

3d_export

$15

Conga Drum

...conga drum

3dexport

conga drums

3d_export

$10

electro drums

...electro drums

3dexport

electro drums

3d_export

$5

electric drums

...electric drums

3dexport

electric drums

turbosquid

$1

Drum

...turbosquid

royalty free 3d model drum for download as blend on turbosquid: 3d models for games, architecture, videos. (1480093)

turbosquid

$1

Drums

...s

turbosquid

royalty free 3d model drums for download as max on turbosquid: 3d models for games, architecture, videos. (1240112)

Efficiency

turbosquid

$50

energy efficiency

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Efficient Dynamic 3D Model

...efficient dynamic 3d model

3dexport

efficient dynamic bmw concept best

efficient dynamic 3d model akila 52142 3dexport

turbosquid

$29

Energy Efficiency 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Energy Efficiency 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Energy Efficiency 1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Energy Efficient Lightbulb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Energy Efficient LightBulb 04

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$19

BMW Efficient Dynamics 3D Model

...port fast tuning 2009 2010 2011 2012 germany cc r-line super power auto car

bmw efficient dynamics 3d model tokeno 29167 3dexport

turbosquid

$30

LEGO HIGH EFFICIENCY SERVO MOTOR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$25

Energy Efficient Light Bulb 3D Model

...ealistic cinema 4d c4d standard green spiral efficient fixture helical

energy efficient light bulb 3d model xellow 58211 3dexport

Hinge

3d_export

$10

hinge and hinge 148 specifications

...hinge and hinge 148 specifications

3dexport

hinge and hinge (148 specifications)

3d_export

free

hinge

...hinge

3dexport

hinge model

3ddd

free

hinges

...hinges

3ddd

крепление

two types of hinge for furniture.

3d_export

$6

Hinge

...hinge

3dexport

hinge assembly render 3d modelling design

turbosquid

$19

Hinges

...

turbosquid

royalty free 3d model hinges for download as max on turbosquid: 3d models for games, architecture, videos. (1453553)

turbosquid

$19

Hinges

...

turbosquid

royalty free 3d model hinges for download as max on turbosquid: 3d models for games, architecture, videos. (1447125)

3d_export

$5

hinge 1

...hinge 1

3dexport

hinge 1

3d_export

$5

hinge 2

...hinge 2

3dexport

hinge 2

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3d_export

$5

hinge 4

...hinge 4

3dexport

hinge 4

Performance

turbosquid

$39

Perform Komers

...osquid

royalty free 3d model perform komers for download as on turbosquid: 3d models for games, architecture, videos. (1144652)

turbosquid

free

Performance Tire

...urbosquid

free 3d model performance tire for download as obj on turbosquid: 3d models for games, architecture, videos. (1485856)

3d_export

$17

F-18 Performance

...f-18 performance

3dexport

f-18 performance

turbosquid

$99

The Performer"s Stage

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$60

Jackson Performer 3D Model

...rformer instrument music musical steelplay band rock heavy metal floyd rose

jackson performer 3d model rendersteel 86884 3dexport

turbosquid

$2

Performance Tyres - set 1

... free 3d model performance tyres - set 1 for download as obj on turbosquid: 3d models for games, architecture, videos. (1691988)

turbosquid

$90

National Centre for the Performing Arts

...tre for the performing arts for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1262784)

turbosquid

$39

Movit Brakes High Performance

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Performance Tire Rim and Brakes

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Adidas performance and originals package 3D Model

...go brand sport store emblem text performance originals

adidas performance and originals package 3d model goyamasta 37255 3dexport

Improved

cg_studio

$49

Robot Z300 (improved version)3d model

...o

.3ds .fbx .max .obj - robot z300 (improved version) 3d model, royalty free license available, instant download after purchase.

3d_export

$39

Robot Z300 improved version 3D Model

...fantasy sci-fi robots bot humanoid droid sci fi materials character

robot z300 improved version 3d model alekrazum 55067 3dexport

3d_export

$75

CV-90 Improved

...nnon. export versions are fitted with hägglunds e-series turrets, armed with either a 30 mm mk44 or a 35 mm bushmaster autocannon

turbosquid

$55

(Important textures coming back soon after improvements)Cuboid gazebo bench area

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

COMPLETE AUDI 80-100 SHIFT LEVER REPAIR KIT WITH IMPROVED BUSHING

...dexport

• sleeve - 1 pc. • elastic band - 1 pc. • hinge - 1 pc. audi 100c3 audi 100 c4 audi 80 b3 (checked) audi 80 b4 (checked)

3d_export

$7

REPAIR KIT FOR GEARSHIFT LEVER AUDI 80-100 IMPROVED

...ar of the gum is excluded. - rusk - 1 pc. - elastic band - 1 pc. audi 100c3 audi 100 c4 audi 80 b3 (checked) audi 80 b4 (checked)

3d_export

$30

cup mask machine front section stereo mask manufacturing machine improved version

...ing rack cad outsourcing list. the drawings are mature drawings that have been produced.<br>drawing version solidworks 2018

3d_export

free

oven - forno

...oven - forno

3dexport

gradually i'm trying to improve my 3d.

3d_export

$75

T-55

...nally, but these improvements made the tank more efficient and lethal. the t-55 was officially adopted by the soviet army in 1958

3d_export

$5

civil registration authorities

...civil registration authorities

3dexport

city wedding square. the model can be used for projects, to improve the project, etc.

Doors

3d_export

$5

door handle of doors

...door handle of doors

3dexport

door handle of doors

3d_ocean

$4

Door

...3docean

architecture door gate gothic door old style door

door, 3d door, gothic door, architecture, old style door, gate, 3d gate

3d_ocean

$10

Door

...door 3docean design door doors home house indoor interior opening doors door...

archibase_planet

free

Door

...r

archibase planet

door sliding door interior door rail door

door n250515 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 900 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 600 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 800 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 800 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 700 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Door

...door

archibase planet

door sash door sash-door interior door

door 600 - 3d model (*.gsm+*.3ds) for interior 3d visualization.