Thingiverse

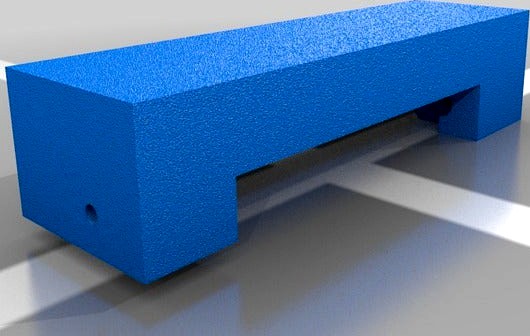

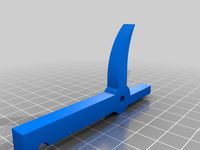

Glock Trigger Housing Adjustable Trigger Drill Jig by ian99rt

by Thingiverse

Last crawled date: 3 years ago

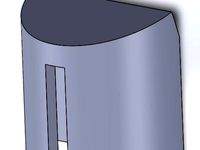

NOTE: These drill jigs are one time use as the holes will open up after drilling and cause you to get too close to the outer surfaces. Also I used variable layer height to tighten around the holes at 0.07mm layer height printing in PLA (PETG doesn't like to print lower than .15mm layer height on my Prusa Mk2s).

UPDATE: R03 has larger hole moved .015" inwards. R02 (.020" offset from R01) worked well but threads almost broke thru on the inside surface. I've used this design on 3 housings and its worked wonderfully.

R01 drill jig was causing the larger drill to be too close to the outer wall of the housing. Not sure exactly why because measurements all lined up but were .020" off when drilled.

Hated the stock trigger on my Gen 3 G34. Zev Spring kit, 25 cent polish job, Zev Pro connector all made it better but the pre-travel and over-travel just stunk.

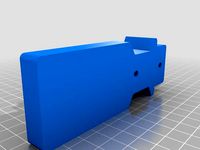

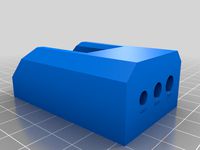

This drill fixture is meant for a #56 (.0465", front end of housing for pre-travel) and #40 (.0980", rear end of housing for over-travel) drill bits for the forward and rear drilling points.

The front end hole is tapped for a M1.6 thread and the rear hole an M3 thread. I used Stainless Flat Face set screws purchased from Mcmaster-Carr.

The trigger housing needs to have the metal ejector component removed. Drilling and tapping the M1.6 thread without the ejector has a benefit of allowing you to adjust the pre-travel then reinsert the ejector which cause an interfence in the thread locking the super tiny set screw in place (you cannot adjust it with the ejector installed in the housing).

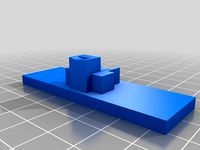

Also to really be able to remove the pre-travel you will need to either shave down or cut off the large "foot" on the back side of the trigger safety. I use a pair of flush cut electronics cutters to simply snip the foot off. This allows you to remove alot of pre-travel and the new ledge created keep the trigger safety functional.

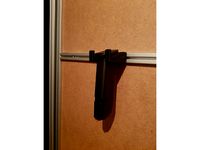

Be sure your printers dimensional accuracy before drilling. Clip is used to simply hold jig in place for drilling.

Also be sure that you do not disable any of the Glocks 3 safety mechanisms. There are multiple youtube videos on the subject and you can print out my Glock Armorer's plate for verifying the drop safety mechanism.

See pictures for final product and trigger safety modification.

UPDATE: R03 has larger hole moved .015" inwards. R02 (.020" offset from R01) worked well but threads almost broke thru on the inside surface. I've used this design on 3 housings and its worked wonderfully.

R01 drill jig was causing the larger drill to be too close to the outer wall of the housing. Not sure exactly why because measurements all lined up but were .020" off when drilled.

Hated the stock trigger on my Gen 3 G34. Zev Spring kit, 25 cent polish job, Zev Pro connector all made it better but the pre-travel and over-travel just stunk.

This drill fixture is meant for a #56 (.0465", front end of housing for pre-travel) and #40 (.0980", rear end of housing for over-travel) drill bits for the forward and rear drilling points.

The front end hole is tapped for a M1.6 thread and the rear hole an M3 thread. I used Stainless Flat Face set screws purchased from Mcmaster-Carr.

The trigger housing needs to have the metal ejector component removed. Drilling and tapping the M1.6 thread without the ejector has a benefit of allowing you to adjust the pre-travel then reinsert the ejector which cause an interfence in the thread locking the super tiny set screw in place (you cannot adjust it with the ejector installed in the housing).

Also to really be able to remove the pre-travel you will need to either shave down or cut off the large "foot" on the back side of the trigger safety. I use a pair of flush cut electronics cutters to simply snip the foot off. This allows you to remove alot of pre-travel and the new ledge created keep the trigger safety functional.

Be sure your printers dimensional accuracy before drilling. Clip is used to simply hold jig in place for drilling.

Also be sure that you do not disable any of the Glocks 3 safety mechanisms. There are multiple youtube videos on the subject and you can print out my Glock Armorer's plate for verifying the drop safety mechanism.

See pictures for final product and trigger safety modification.

Similar models

thingiverse

free

Airsoft Glock 17/19/34 Custom Trigger (Flat w/o Trigger Safety) by MrLongFace

...irsoft pistols (vfc oem). this flat faced trigger is designed to reduce the take up distance and the over travel after the break.

thingiverse

free

AK74 and AKM Rear Trunnion Jig by Crashin_Machines

...trunnion and clamp it with a c-clamp or something similar drill through your receiver so you can then rivet...

thingiverse

free

AR10 80% Jig by neilk

...work in progress since i've only compared the print with a single lower.

edit 1: adjusted the trigger shoe hole size/position

thingiverse

free

Round or Square Stock Drilling Jig by TikiLuke

...center depending on the size of hole you typically drill. if the hole is too small i am sure there is a way to easily enlarge it.

thingiverse

free

80% AR15 lower jig by Hyudryu

...ttom is used as a template to drill out the trigger hole. mark it with a sharpie, and use a drill bit + file to get the job done.

thingiverse

free

Funjet hybrid aluminium motor mount and drill jig

...enter hole and 7mm drill for the vent holes.

use something sharp to score a line around the jig and grind the shape of the mount.

thingiverse

free

Pagoda Jig Ejector by OldHead

...the completed antennas from the jig. the ejector applies pressure evenly across 3 disk of the antenna for safe and easy removal.

thingiverse

free

1 inch tubing pixel jig

...ches. the 12mm holes accomodate a 15/32" drill bit to push your ws2811 pixels into. the holes are spaced at 2" centers.

thingiverse

free

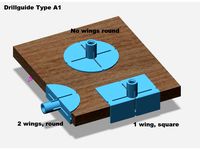

Drillguide for straight/perpendicular holes Type A1, customizable by Coat

...mation about the fantastic and challenging program openscad can be found here: https://en.wikibooks.org/wiki/openscad_user_manual

thingiverse

free

Kreg mini adapter

....

drill a single hole through the most forward hole of the adapter.

the second file is a colette measuring jig for the drill bit.

Ian99Rt

thingiverse

free

Bundled up Bernie by ian99rt

...m to the chair legs be prusaslicer 2.3 with support wasn't attaching the brim to the chair feet and detached during printing.

thingiverse

free

3030 Extrusion End Cap, easy to install / remove by ian99rt

...se

wanted an endcap that had the same radii and profile as the extrusion. wanted it relatively easy to install / remove as well.

thingiverse

free

4 Cube Retraction Calibration by ian99rt

...f retraction and 30mm/sec.

i then iterated until i reached 4.0 mm of retraction and 55 mm/sec and has been working awesome since.

thingiverse

free

Mad Max War Boys Stencil by ian99rt

...nted stencil to hold all the inner pieces in places for painting.

note: stl is in inches, multiply by 25.4 for mm or 2540% scale.

thingiverse

free

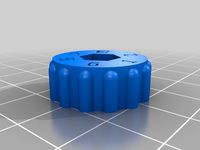

Prusa i3 LCD Open Hardware Gear Knob by ian99rt

... size as r01 felt a little too small.

i printed at 100% size and 98% to find a better fit onto the shaft and 98% was the winner.

thingiverse

free

Deltaprintr Hotend Retainer with wire pass thru by ian99rt

...i had an issue with the retained getting pushed up by the wires so i printed a retaining clip as well (hotend_retainer_clip.stl).

thingiverse

free

Cable Managment for Prusa I3 Haribo 3030 Frame by ian99rt

...qty. 2: ribbon_cable_clips (i had a lot of slack in the ribbon cable so i double folded them over to take up the slack).

thingiverse

free

Deltaprintr Filament Guide for Extended Extruder Arm by ian99rt

...rint with brim as the cylindrical guide's lower surface is very narrow, and support for arch if you have inadequate cooling.

thingiverse

free

OpenWheeler Gen 2 5 Degree Seat Wedge by ian99rt

...er thing required are 2x 8mmx75mm bolts to account for the longer length needed at the front rails-seat frame attachment points.

thingiverse

free

Glock Armorer Inspection Slide Cover Gen 1 thru Gen 4 by ian99rt

...te to view the trigger bar and striker engagement.

printed solid esun petg and worked as intended on a gen 4 g19 and gen 3 g34.

Glock

thingiverse

free

glock v1

...glock v1

thingiverse

first version of glock 17 gen4

thingiverse

free

Glock handle plug for Glock 9mm by jbswaff

...bswaff

thingiverse

this is a plug for the handle of a glock 9mm to keep dirt and debris from becoming trapped inside the handle.

thingiverse

free

MAG INSERT GLOCK

...mag insert glock

thingiverse

magazine insert glock

thingiverse

free

Glock Bottle Opener

...glock bottle opener

thingiverse

glock bottle opener

thingiverse

free

Wall mounted glock

...nted glock

thingiverse

wall mount for kjw glock 17. when printing for cyma glock 18c - 103%. printing with supports. v 2.0. petg

thingiverse

free

Magazine holder Glock

...magazine holder glock

thingiverse

tested with original glock magazine

hole for attachment with an m4 screw

thingiverse

free

Glock Pins by smokeypast

...ngiverse

glock pins

don't know if they work.

slide worked with them installed.

haven't shot my glock with them installed

thingiverse

free

Glock Slide Tool

...glock slide tool

thingiverse

a tool for better slide removal

tested with a glock 17 gen 5

thingiverse

free

Stand for Glock gun by OlegR

...stand for glock gun by olegr

thingiverse

glock gun stand.

thingiverse

free

Glock-19 (PREMIUM EDITION)

...glock-19 (premium edition)

thingiverse

a camouflaged glock 19.

Jig

thingiverse

free

jig by groyer60

...jig by groyer60

thingiverse

jig

thingiverse

free

JIG by spyfeedback

...jig by spyfeedback

thingiverse

jig

thingiverse

free

Jig by _PeskyBee_

...jig by _peskybee_

thingiverse

jig for hole drilling.

thingiverse

free

Trunk Jig

...trunk jig

thingiverse

jig for mustang duck tail cutout

thingiverse

free

Jig stand by cwthoma

... the jigs from touching and a lip for drips. works with 1/32, 1/16, 1/8, and 1/4 oz jig heads. it may work with larger jig heads.

thingiverse

free

Pocket Hole Jig

...pocket hole jig

thingiverse

pocket hole jig

thingiverse

free

Pocket Jig by SgrA8

...pocket jig by sgra8

thingiverse

simple pocket jig.

thingiverse

free

Jig Casing by lm42p

...jig casing by lm42p

thingiverse

this is the jig for drilling the holes in the casing

thingiverse

free

Paracord Jig by Philhawtin

...paracord jig by philhawtin

thingiverse

paracord jig

monkey fist

thingiverse

free

K40 Jig

...g

thingiverse

k40 jig to mark out a line corresponding to the lens focal height for the purpose of mounting a spring loaded bed.

Trigger

thingiverse

free

talon trigger+trigger guide by Muthinor

...de can be printed if wanted to help you placing the trigger in the correct spot.

yellow: trigger

red: guide

blue: rest of the gun

thingiverse

free

trigger

...trigger

thingiverse

watch joker online

thingiverse

free

Novritsch SSG24 Trigger Dust Cover - S-Trigger Trigger by TheBurk

...ory trigger? see my other designs

designs take massive amount of hours, please please donate any amount so i can keep them coming

thingiverse

free

Trigger Button

...trigger button

thingiverse

simple trigger w/ screw hole. fasten with a rubber elastic for snap and better feedback.

thingiverse

free

Intimidator Trigger Guard

... finger trigger in intimidator paintball markers. i plan to upload more items in the future. including a trigger to go with this.

thingiverse

free

clamp trigger by xfred

...clamp trigger by xfred

thingiverse

clamp trigger

thingiverse

free

M4A1 Trigger by uwcrutch

...m4a1 trigger by uwcrutch

thingiverse

m4a1 trigger

thingiverse

free

TRIGGER by mussy

...trigger by mussy

thingiverse

crossbow improved trigger

don't forget to check out my other designs, enjoy ;)

thingiverse

free

Lego Trigger Shoes

...lego trigger shoes

thingiverse

a set of trigger shoes inspired by the famous toys.

can be used in any trigger with 4mm shaft.

thingiverse

free

KoPropo Trigger by Zedpi

...kopropo trigger by zedpi

thingiverse

trigger for kopropo ex1 , ex10

Housing

thingiverse

free

House

...house

thingiverse

generic house

thingiverse

free

house by

...house by

thingiverse

a normal house

thingiverse

free

House

...house

thingiverse

a copy of my house.

thingiverse

free

House

...house

thingiverse

this is a house that has a garage.

thingiverse

free

house by

...house by

thingiverse

just a normal house... or is it?

thingiverse

free

House by

...house by

thingiverse

it's a house

thingiverse

free

House by

...house by

thingiverse

it's a house

thingiverse

free

house by

...house by

thingiverse

a nice house with a driveway and a car

thingiverse

free

house

...house

thingiverse

it is a house with 1 room

i made this for a class project

thingiverse

free

House by aaronalvarez365

... by aaronalvarez365

thingiverse

this house was designed in tinkercad and this house is mainly a house with a porch in the front.

Drill

thingiverse

free

Drill holder

...drill holder

thingiverse

drill holder for metric drills.

thingiverse

free

drill by Syzguru11

...drill by syzguru11

thingiverse

drill

thingiverse

free

drill by Syzguru11

...drill by syzguru11

thingiverse

drill

thingiverse

free

Drill by redkidpavel

...drill by redkidpavel

thingiverse

the drill

thingiverse

free

Handheld Drill

...handheld drill

thingiverse

this handheld drill should fit any normal drill bit.

thingiverse

free

Drill by raikayl

...drill by raikayl

thingiverse

drill model

thingiverse

free

Drills storage

...drills storage

thingiverse

drills storage on the wall.

thingiverse

free

Breaching drill

...breaching drill

thingiverse

hades breaching drill model.

thingiverse

free

Drill Bit Clip for Power Drills by danielferal

...drill bit clip for power drills by danielferal

thingiverse

bit holder that attaches to your drill.

thingiverse

free

Drill Tray

...to allow shaking without dropping drills over edges. also includes a spout for easy placing drills back into original containers.

Adjustable

thingiverse

free

Adjustable Wrench

...adjustable wrench

thingiverse

working adjustable hand wrench.

thingiverse

free

PPG adjustable propellers adjusting device by x3x3x

...ppg) adjustable propellers adjusting device. 95 mm blade width. android phone, apple, symbian os. applications for free download.

thingiverse

free

Adjustable foot

...adjustable foot

thingiverse

just another adjustable foot for m5 screw (better if is self-locking nut).

diameter 20mm

thingiverse

free

Adjustment Handle by adamdthornton

...adjustment handle by adamdthornton

thingiverse

adjustment handle

thingiverse

free

Adjustable foot by denis4

...adjustable foot by denis4

thingiverse

adjustable leg

thingiverse

free

Adjustable Extruded by CruiseLee

...adjustable extruded by cruiselee

thingiverse

adjustable extruded

thingiverse

free

adjustable spanner by stevehaines

...adjustable spanner by stevehaines

thingiverse

adjustable spanner

thingiverse

free

Adjustable Wrench by AdamsLab

...h by adamslab

thingiverse

this is an adjustable wrench.

the top jaws slide into the main body, and you use the nut to adjust it.

thingiverse

free

Lawnmower adjustment handle

...lawnmower adjustment handle

thingiverse

lawnmower adjustment handle

thingiverse

free

Adjustable Frame by Quinventor

...adjustable frame by quinventor

thingiverse

an adjustable picture frame