Thingiverse

Give it a break by technomastermind

by Thingiverse

Last crawled date: 3 years, 1 month ago

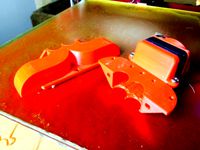

UPDATE 27/04/17 Build photos added.

UPDATE 18/04/17 Build photos added.

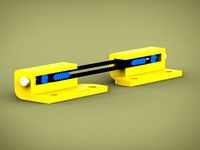

This thing is an offset bracket for mounting a 120mm 230v axial fan to an 80mm aluminium tube.

I have recently brought another small tabletop injection moulding machine,and am having issues with the heat travelling up the melting cylinder and prematurely pre-melting the plastic pellets prior to extrusion.

This results in the cylinder not extruding,and plastic pellets getting lodged in the cylinder.

This is an attempt to decrease to heat build up and prevent the heat travelling into the cold area non melt zone of the barrel.

i have decided to use the items i have got lying around the lab.( give them a go first ) ,-)

I shall eventually mill out a water jacket and use a peltier cooling block with external cooling fans.

Hopefully FOR NOW this forced air cooling will make a worthwhile temporary cooling solution,only my experiments / tests would confirm or dismiss.

The two fan setup will be working in a push/pull arrangement to force to cool air around the barrel and removing the excessive heat buildup

All metal 120mm server fans are to be used,this suits the industrial nature of my machine and are more powerful than their 12v counterparts.(also no psu is required)

I am in the process of printing and waiting for parts to arrive.

Tests will be carried out and photos/video of my finding posted shortly.

This design should help with the many small tabletop machine available today that suffer this particular problem of premature melting prior to extrusion.

On my machine the extrusion barrel measures 38mm,i will be drilling out the hole in the aluminium tube to 40mm to account for heat expansion and to allow for slight barrel movement.

120mm fan grill cover used in the design http://www.thingiverse.com/thing:1595208/#files Thanks Kevin293

Enjoy ,-)

UPDATE 18/04/17 Build photos added.

This thing is an offset bracket for mounting a 120mm 230v axial fan to an 80mm aluminium tube.

I have recently brought another small tabletop injection moulding machine,and am having issues with the heat travelling up the melting cylinder and prematurely pre-melting the plastic pellets prior to extrusion.

This results in the cylinder not extruding,and plastic pellets getting lodged in the cylinder.

This is an attempt to decrease to heat build up and prevent the heat travelling into the cold area non melt zone of the barrel.

i have decided to use the items i have got lying around the lab.( give them a go first ) ,-)

I shall eventually mill out a water jacket and use a peltier cooling block with external cooling fans.

Hopefully FOR NOW this forced air cooling will make a worthwhile temporary cooling solution,only my experiments / tests would confirm or dismiss.

The two fan setup will be working in a push/pull arrangement to force to cool air around the barrel and removing the excessive heat buildup

All metal 120mm server fans are to be used,this suits the industrial nature of my machine and are more powerful than their 12v counterparts.(also no psu is required)

I am in the process of printing and waiting for parts to arrive.

Tests will be carried out and photos/video of my finding posted shortly.

This design should help with the many small tabletop machine available today that suffer this particular problem of premature melting prior to extrusion.

On my machine the extrusion barrel measures 38mm,i will be drilling out the hole in the aluminium tube to 40mm to account for heat expansion and to allow for slight barrel movement.

120mm fan grill cover used in the design http://www.thingiverse.com/thing:1595208/#files Thanks Kevin293

Enjoy ,-)

Similar models

thingiverse

free

Corner 2020 2040 extrusion mount for 120mm PC Fan by jrdiver

...en with just 2 of the extrusion screws in, bit hard to get the other 2 in, but it would be doable with more patience than i have.

thingiverse

free

Aluminium Extrusion Fan Holder by ctheroux

...s holder is design to be mounted on aluminium extrusion. a deflector is also provided to prevent the air to go on the heated bed.

thingiverse

free

Barrel cooling duct for MendelMax 2 & JD Duallie Belt Driven Extruder by JRD

...d other materials where cooling the part would be unwanted. for pla, you need another fan to cool the part after it is laid down.

grabcad

free

120 MM EXTRUDER

...g a system of barrels and cylinders, the machine heats up the product and propels it through the die to create the desired shape.

thingiverse

free

120mm to 75mm x 2 by Esz2fn

...printing in other materials than abs or materials with similar heat...

grabcad

free

Organic fashioned protective grill for a 120mm fan

...l snapshot of the grill instaled over the z axis of the machine. it was made from policarbonate and machined in the same machine.

thingiverse

free

Flashforge dual extrusion air duct by MakerUnit

...ooling fan and remove the one screw that holds the stock air duct. replace the air duct with the new one and reattach the screws.

thingiverse

free

Solidoodle 3 120mm electronics cooling fan by jbolonski

...behind the board and replaces the aluminum stand-offs that come with the printer. ( i got tired of chasing them across the floor)

thingiverse

free

Hanging mount for Ultimaker heatbed fan by hreese

...erse

i'm using a 120mm fan to cool down the heated bed after printing. this suspension holds the fan in an optimal position.

thingiverse

free

fan duct 120mm to 100mm adapter by remcoder

...maller than 120mm so please make sure to scale it to your exact fan size.

i have yet to print it but i will post an update soon.

Technomastermind

thingiverse

free

Matrix soldering magnifier by technomastermind

... by technomastermind

thingiverse

a cheep and simple magnifier for close up or through-hole soldering.

printed on da vinci 1.0

thingiverse

free

DA Vinci Printer grease application tools by technomastermind

...giverse

a set of tools to grease up the 8mm rails in your 3d printer.

also makes a great test print for calibration purposes.

thingiverse

free

mpcnc foot remake 25.4 and 23.45 versions by technomastermind

...ly printed cnc multi tool foot support.

ie 25.4mm and us emt 23.45mm versions.

your feedback and requests are very welcome.

enjoy

thingiverse

free

Totem GT2 belt clip adjuster by technomastermind

...tension the timing belt using an hex socket tool.

you will require m3 nuts and bolts for assembly.

feedback and requests welcome.

thingiverse

free

(Minion) ramps remix XXL lcd by technomastermind

...om/thing:1059189

link to original minion ramps,http://www.thingiverse.com/thing:1029926

feedback and requests very welcome

enjoy

thingiverse

free

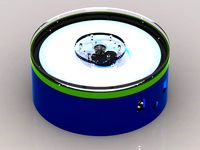

(siois) led turntable by technomastermind

...n 2 rpm which is quite handy for various projects.

build photos and dxf files for laser cutting the acrylic coming shortly.

enjoy

thingiverse

free

minion ramps lcd mounting bracket by technomastermind

...opy (and i know you will) or remix any of my designs please be respectful and give acknowledgement to the original creator.

enjoy

thingiverse

free

Octo-Pi Delta by technomastermind

...nged using a 2mm length of wire inserted through the body,per my other designs.

build photos and assembly list coming soon.

enjoy

thingiverse

free

Da Vinci extruder pcb enclosure by technomastermind

...ck firmware.

printed in abs at 90% solid and 102% scale to compensate for shrinkage,sanded lid rim for a nice snug fitting.

enjoy

Break

3d_ocean

$5

Break Heart

...del is high poly and low poly also included. availabe in various format such .3ds and .obj wich can be used for other 3d program.

turbosquid

$7

Break Table

...osquid

royalty free 3d model break table for download as max on turbosquid: 3d models for games, architecture, videos. (1633932)

3ddd

$1

Break

... печенье , чашка

чашка,блюдце,ложечка и два крэккера.материалы и текстуры прилагаются

turbosquid

$80

Coffee Break

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Coffee break

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Break Heart

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Break Chairs

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

break Barrel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

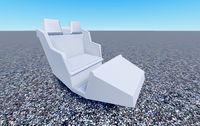

Break Dance Seat

...break dance seat

3dexport

break dance seat ready for 3d printing

turbosquid

$2

Breaking wheel

...eel for download as skp, unitypackage, fbx, 3ds, obj, and dae on turbosquid: 3d models for games, architecture, videos. (1601431)

Give

3d_ocean

$1

Give way sign

...he object is ready to import and render in both formats. the texture comes in .tif format. you can save by buying the road sig...

3d_export

$5

Give way sign 3D Model

...ole vehicle motor way traffic car pedestrian signal circle round stop junction

give way sign 3d model dragosburian 89453 3dexport

turbosquid

$1

Give Way Sign (witout text)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Give me a cucumber please

... огурец

угощайтесь!

polyrate: 34194

в архиве: max2015 (стек открыт), max2012 (стек свернут), fbx и obj.

3d_export

free

the wall and the sidewalk i give it away for free but in return you need a comment whether it was

...dexport

the wall and the sidewalk, i give it away for free, but in return you need a comment whether it was useful to you or not

3d_export

$10

celtic sword

...5th century motif. the celts were the first to give theirry a name. give yours a name...

3d_export

free

new year scene

...new year scene 3dexport give ...

3d_ocean

$3

BlackBerry curve low poly 3D model

...3d model phone blackberry curve low poly. flat colors give model more simplicity and elegance. enjoy .total polys: 12...

3d_export

$5

Fire extinguisher

...fire extinguisher 3dexport fire extinguisher low poly pls give ...

3d_export

$5

happy birthday

...happy birthday 3dexport this is something you can give your son for his...