GrabCAD

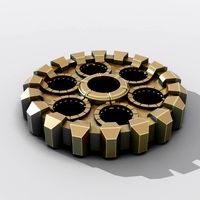

Gear Assembly for a KickScooter with Auxiliary Drive Wheels

by GrabCAD

Last crawled date: 2 years ago

The object of this proposal is a 3D Printable Gear Assembly for a KickScooter with Auxiliary Drive Wheels. It requires four gears in order to transform the impulse of the user on any of the Auxiliary Drive Wheels into a forward movement of the KickScooter.

The Gear Assembly would be attached to the rear of the KickScooter body at the shop, once 3D Printed to fit the specifications of the individual user, while the body itself would be supplied from a centralized manufacturing plant. The original KickScooter with Auxiliary Drive Wheel design has been modified for this challenge, which it has been downsized so its Gear Assembly could fit into the limits of 3D Printing, and now it is designed as a KickScooter for Kids, with their lower size and strength.

To improve its strength and simplify its printing, the Gear Assembly would be produced with only four parts:

The structure of the Gear Assembly

The Rear Wheel, which would include the two attached gears and the axis, it would also include the wheel tire, made in a more flexible material.

The two Auxiliary Wheels, that would include the attached gear and the axis linking them through the structure.

It would require two 3D Printing materials, one for structure the Gears, the axis and wheel bodies, and the second for the wheel tires; the requirements of the tires of the Auxiliary Wheels, in contact with the Kid´s shoes, are different from the ones of the rear Wheel, in contact with the surface of the ground, but to simplify the design for 3D Printing we propose using the same material, with the differences in the design of the tire treads making up for the different requirements, being more flexible tires the ones of the Auxiliary Wheels.

3D Printing would offer three main advantages to the concept of a KickScooter with Auxiliary Drive Wheels.

The first one is a great simplification of the design and a great increase of the strength of the Gear Assembly, as it could be made of only four parts.

The second one is that allows to 3D Print in-shop an almost unlimited range of Gear multiplications and Wheel designs, to fit the exact requirements of every Kid and every location; the main body of the KickScooter, which doesn't require so many modifications, would be produced at central plants to get economies of scale.

The third one is that, as the Kid grows and gets stronger, he can replace the Gear Assembly with one with greater wheel diameters and Gear Multiplications, while keeping the main body of the KickScooter, which is more flexible to the changes in size and strength of the kids.

Kids love KickScooters, and any kid tries to drive a KickScooter when having one closer. As they grow and get stronger, they usually move up to bicycles as they can move faster without getting tired, but in the sitting position of the bicycles they lose freedom of movements compared with the standing position of the scooters, where they can move their whole body to turn faster, and also can hop on and off with ease. They also lose in freedom because there are many places where a group of kids cannot enter with their bikes, as buses, restaurants, houses, elevators, etc.

The main problem with the standard KickScooter is that kid have to hobble in order to kick the ground to be able propel the scooter, moving his body Up and Down the platform: he also have to kick the ground at the speed he wants to move; these two requirements make the use of a KickScooter more tiresome that a bike where there is no Up and Down movement of the body, and the chain system generates a multiplication of the speed so its legs do not have to move at the speed he wants to travel. The proposed solution is to attach a pair of Auxiliary Drive Wheels at the back of the KickScooter, each one linked to the rear wheel by a Gear System, that will generate the desired multiplication of the speed; the Kid would kick the Auxiliary Drive wheel instead the ground, so he doesn´t have to hobble and doesn´t have to kick and the same speed as he wants to move. It gets the advantages of the bicycles while keeping all the benefits of the standard KickScooters.

This project is an adaptation of the main project of “https://grabcad.com/library/kick-and-go-scooter-with-auxiliary-drive-wheel-update-1” by https://grabcad.com/raul.juanatey, looking to adapt it Kids and to 3D Printing. This project recently won the 2013 Altran Foundation Spain Awards, so I will have six months of technical assistance by Altran for its development into a real product. https://grabcad.com/carlos.perez-3 provides to this project his experience on the development of his own https://grabcad.com/library/electric-motorbike-chasis-1, his CAD skills and his rendering talent.

More information about Altran Awards at http://www.altran-foundation.org/2013-award/overview-of-the-2013-award.html

The Gear Assembly would be attached to the rear of the KickScooter body at the shop, once 3D Printed to fit the specifications of the individual user, while the body itself would be supplied from a centralized manufacturing plant. The original KickScooter with Auxiliary Drive Wheel design has been modified for this challenge, which it has been downsized so its Gear Assembly could fit into the limits of 3D Printing, and now it is designed as a KickScooter for Kids, with their lower size and strength.

To improve its strength and simplify its printing, the Gear Assembly would be produced with only four parts:

The structure of the Gear Assembly

The Rear Wheel, which would include the two attached gears and the axis, it would also include the wheel tire, made in a more flexible material.

The two Auxiliary Wheels, that would include the attached gear and the axis linking them through the structure.

It would require two 3D Printing materials, one for structure the Gears, the axis and wheel bodies, and the second for the wheel tires; the requirements of the tires of the Auxiliary Wheels, in contact with the Kid´s shoes, are different from the ones of the rear Wheel, in contact with the surface of the ground, but to simplify the design for 3D Printing we propose using the same material, with the differences in the design of the tire treads making up for the different requirements, being more flexible tires the ones of the Auxiliary Wheels.

3D Printing would offer three main advantages to the concept of a KickScooter with Auxiliary Drive Wheels.

The first one is a great simplification of the design and a great increase of the strength of the Gear Assembly, as it could be made of only four parts.

The second one is that allows to 3D Print in-shop an almost unlimited range of Gear multiplications and Wheel designs, to fit the exact requirements of every Kid and every location; the main body of the KickScooter, which doesn't require so many modifications, would be produced at central plants to get economies of scale.

The third one is that, as the Kid grows and gets stronger, he can replace the Gear Assembly with one with greater wheel diameters and Gear Multiplications, while keeping the main body of the KickScooter, which is more flexible to the changes in size and strength of the kids.

Kids love KickScooters, and any kid tries to drive a KickScooter when having one closer. As they grow and get stronger, they usually move up to bicycles as they can move faster without getting tired, but in the sitting position of the bicycles they lose freedom of movements compared with the standing position of the scooters, where they can move their whole body to turn faster, and also can hop on and off with ease. They also lose in freedom because there are many places where a group of kids cannot enter with their bikes, as buses, restaurants, houses, elevators, etc.

The main problem with the standard KickScooter is that kid have to hobble in order to kick the ground to be able propel the scooter, moving his body Up and Down the platform: he also have to kick the ground at the speed he wants to move; these two requirements make the use of a KickScooter more tiresome that a bike where there is no Up and Down movement of the body, and the chain system generates a multiplication of the speed so its legs do not have to move at the speed he wants to travel. The proposed solution is to attach a pair of Auxiliary Drive Wheels at the back of the KickScooter, each one linked to the rear wheel by a Gear System, that will generate the desired multiplication of the speed; the Kid would kick the Auxiliary Drive wheel instead the ground, so he doesn´t have to hobble and doesn´t have to kick and the same speed as he wants to move. It gets the advantages of the bicycles while keeping all the benefits of the standard KickScooters.

This project is an adaptation of the main project of “https://grabcad.com/library/kick-and-go-scooter-with-auxiliary-drive-wheel-update-1” by https://grabcad.com/raul.juanatey, looking to adapt it Kids and to 3D Printing. This project recently won the 2013 Altran Foundation Spain Awards, so I will have six months of technical assistance by Altran for its development into a real product. https://grabcad.com/carlos.perez-3 provides to this project his experience on the development of his own https://grabcad.com/library/electric-motorbike-chasis-1, his CAD skills and his rendering talent.

More information about Altran Awards at http://www.altran-foundation.org/2013-award/overview-of-the-2013-award.html

Similar models

grabcad

free

KickScooter Driven by an Auxiliary Wheel: Altran Project

...p the concept into a real product.

http://www.altran-foundation.org//2013-award/2013-national-laureates/2013-award-in-spain.html

grabcad

free

Kick and Go Scooter with Auxiliary Drive Wheel: Update

... by miguel angel at www.eicae.es

cad files at https://grabcad.com/library/kick-and-go-scooter-with-twin-auxiliary-drive-wheels-1

grabcad

free

Kick and Go Scooter with Auxiliary Drive Wheel: First Prototype

...ched at each side of the rear wheel, so the user can use both legs and it is possible to have to different multiplication ratios.

grabcad

free

Kick and Go Scooter with Twin Auxiliary Drive Wheels

...scooter by miguel angel at www.eicae.es

original idea at https://grabcad.com/library/kick-scooter-with-an-auxiliary-drive-wheel-1

grabcad

free

Kick and Go Scooter with Auxiliary Drive Wheel

...avoid touching the ground when cornering. a freewheel mechanism, similar to the one used on bicycles, also allows the...

grabcad

free

Car differential

...ent speeds. this would be the front wheels in front-wheel-drive, the rear in rear-wheel drive, and all wheels on all-wheel drive.

grabcad

free

M72 Motorcycle Project Wheel Assembly

...h an external spline attached to the crown wheel in the rear drive hub. a spare wheel was fitted to the rear of the sidecar body.

grabcad

free

Belt Drive Assembly

...reaks, of course the automatic motorbike will not be able to run because there is nothing to transfer engine power to the wheels.

thingiverse

free

dBoots Hoons Felony Rear Wheel Mask by xKmotx

... resized his file so that it would fit the larger rear wheel. the spacer is required to fill the gap around the edge of the tire.

grabcad

free

Differential Gear Box

...ain. the differential gearbox allows the inside wheel to rotate slower than the outside wheel, which prevents binding and damage.

Kickscooter

thingiverse

free

Kickscooter handle end plugs by Skuggan

...kickscooter handle end plugs by skuggan

thingiverse

end plugs for kickscooter handle.

for 19mm inner diameter.

thingiverse

free

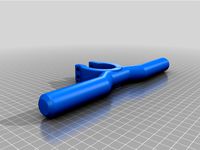

Ninebot Kickscooter ES2/ES1 Hook by Protivizion

...ninebot kickscooter es2/es1 hook by protivizion

thingiverse

remixed ninebot es2/es1 hook. stronger.

thingiverse

free

Ninebot by Segway KickScooter ES2 by ukrutko

...shim 16х10х07 / шайба 16х10х07

anther of shock absorber / пыльник оси амортизатора

sleeve snubber 20mm / втулка амортизатора 20мм

thingiverse

free

Segway Ninebot KickScooter Lock Holder

...rse

2 nos m4 x 15mm and nuts are required, the holder size is 55.6 x 20.8, and upload the solidworks source file also, have fun!

thingiverse

free

Lock holder for Ninebot Kickscooter MAX (G30 + G30D) by RiNax

...older for this kind of lock.

warning!

slide-on design! you have to disassemble your scooters handlebar, reflector and brake line!

thingiverse

free

Additional handles for Ninebot Max/G30/Yokamura i8 by mzeez

...ninebot max/g30/yokamura i8 by mzeez thingiverse additional handles for kickscooter: ninebot max ninebot g30 yokamura i8 need two m5x40...

thingiverse

free

Ninebot ES2 - Handle by manticus

...es2, you can join the group on telegram : https://t.me/kickscooter3dprint ...

thingiverse

free

Ninebot ES2 - Holder by manticus

...es2, you can join the group on telegram : https://t.me/kickscooter3dprint ...

thingiverse

free

Ninebot ES2 - Rubber bushing of folding mechanism by manticus

...es2, you can join the group on telegram : https://t.me/kickscooter3dprint ...

thingiverse

free

GUB Phone holder extender for Segway ES1/ES2 by danbassa

...phone holder" and install it on my segway es2 kickscooter (the original mount was too close to my fingers)...

Auxiliary

turbosquid

$15

Auxiliary burner

...or download as sldpr, max, sldas, 3ds, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1538743)

3ddd

$1

Lola Glamour - Auxiliary cabinet rascacielos

... rascacielos

сервант с 2 дверьми с 3 внутренними полками. коллекция auxiliary.

размеры - ш120 х г40 x в182см.

cg_studio

$15

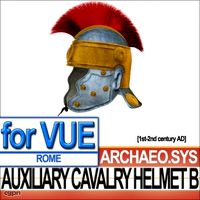

Ancient Rome Auxiliary Cavalry Helmet B3d model

...ds .obj .vue - ancient rome auxiliary cavalry helmet b 3d model, royalty free license available, instant download after purchase.

3d_export

$6

metal auxiliary instrumental table game ready

... table prop.<br>material:<br>-base color<br>- height<br>- roughness<br>- metallic<br>- normal

3d_export

$10

Auxiliary Chair

...painter available for all software<br>ue4. ue5. blender. maya. 3d max. unity. c4d.<br>formats: .obj .gltf .fbx .blend

3d_export

$10

Stool Auxiliary Chair

...painter available for all software<br>ue4. ue5. blender. maya. 3d max. unity. c4d.<br>formats: .obj .gltf .fbx .blend

3d_export

$30

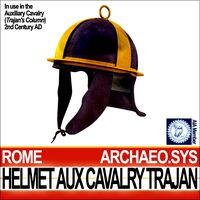

roman auxiliary cavalry helmet trajan

...eries is developing high-fidelity 3d reconstruction of objects, architecture and scenes from classical greek and roman antiquity.

3d_export

$30

roman auxiliary cavalry helmet type e

...eries is developing high-fidelity 3d reconstruction of objects, architecture and scenes from classical greek and roman antiquity.

3d_export

$45

multi-role auxiliary vessel 660

... units. such vessels include: training vessels, target vessels and target boats, boats - target drivers, trial vessels and others

3d_export

$10

Inustool 1 person stool simple auxiliary chair

...painter available for all software<br>ue4. ue5. blender. maya. 3d max. unity. c4d.<br>formats: .obj .gltf .fbx .blend

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Gear

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels

3docean

engine engineering gear gears industry machinery mechanical toothwheel wheel

pair of gear wheels : animated.

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)

Assembly

3d_export

$7

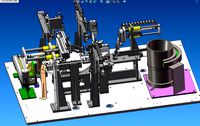

Electronic product assembly machine assembly machine

...electronic product assembly machine assembly machine

3dexport

electronic product assembly machine assembly machine

3d_export

$15

generator assembly line

...ced and assembled in the form of module block. it is a demonstration project of generator assembly. welcome to download and learn

3d_export

$10

elevator traction machine assembly line motor assembly process

... traction machine assembly line motor assembly process

3dexport

elevator traction machine assembly line (motor assembly process)

3d_export

$16

pin assembly machine

...pin assembly machine

3dexport

pin assembly machine

3d_export

$7

tower-crane-assembly

...tower-crane-assembly

3dexport

tower-crane-assembly

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658296)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658291)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658293)

turbosquid

$75

Platform Assembly

...royalty free 3d model platform assembly for download as blend on turbosquid: 3d models for games, architecture, videos. (1472939)

turbosquid

$15

generator assembly

...y free 3d model generator assembly for download as and sldas on turbosquid: 3d models for games, architecture, videos. (1469469)

Wheels

archibase_planet

free

Wheel

...l steering control steering wheel

wheel ship steering wheel n060215 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

3d_ocean

$14

Wheel

...wheel

3docean

car rim car wheel rim wheel

high poly car wheel design. 16,840 polys

3d_export

free

wheel

...wheel

3dexport

wheel

3d_export

free

wheel

...wheel

3dexport

wheel

3d_export

free

Wheel

...wheel

3dexport

wheel

3d_export

$5

wheel

...wheel

3dexport

wheel for car.

3d_export

$5

wheel

...wheel

3dexport

car wheel

3d_export

$5

wheel

...wheel

3dexport

car wheel

3d_export

$5

wheel

...wheel

3dexport

car wheel

3d_export

$5

wheel

...wheel

3dexport

car wheel