Thingiverse

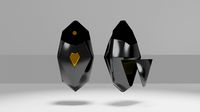

GAUGE POD for BMW 2002 e10 by Gearbox22

by Thingiverse

Last crawled date: 3 years ago

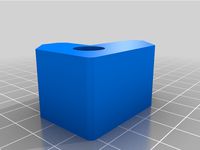

This is my adaptation of the BMW console I made that will fit three 52mm gauges and support a standard period Blaupunkt radio. I also printed the shifter surround but not included in this post as most of you must already have one (I didn't). Important to note is that I have incorporated the OEM ashtray and hazard switch assembly which is necessary for this build. I also 3D printed the rear brace with another part that will hold and support the back of the radio but also did not include it in this post as most of you will already have the rear OEM brace and depending on the radio, the dimensions will be different for the support. But you must make some kind of support as the vibrations of the car and bounces will undoubtedly crack the radio surround. I am sharing these files with the community for individual use but not allowing any commercial use of these files.

With all that being said, the panels are extremely robust but will require time and effort to finish them to OEM standards. I printed the parts using my Makerbot Replicator 2X and ABS filament. The strength will be provided by using 4 shells and this way you can get away with a 15% infill. But it will still take about 23 hours to print with full supports and rafts.

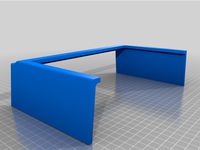

The unit is developed in 2 parts, the upper gauge pod and the lower radio surround as the size for a single complete unit exceeded my print area. I suggest that you get the parts sanded and smooth prior to gluing the two parts together. I used 240 grit sandpaper to knock down all the print lines and then filler primer. You may have to do this procedure a number of times to get a perfect finish. Once you are happy with the result, I used 800-1200 wet sandpaper to polish the primer to uncover any other possible surface defects. Again, you may have to do this a couple of times of re priming and sanding. Any deep marks can be addressed with some automotive bondo. But the better you prepare the surface, the better the part will come out.

Next is to glue the two parts together. The Gel type of crazy glue works great and I have been having some very good results with the "Gorilla" crazy glue, not the standard gorilla glue, that stuff will expand too much. Just test fit the parts and sand so it will have a perfect fit. I also developed the parts so you can use those small spring clamps on the back to hold the parts together while the glue is drying, and it does set quickly, so have everything ready.

Final finishing depends on your objective, pure stock or something different. I elected to make my console to match my Turbo dash pod, so I finished the gauge pod section to a perfectly flat and smooth surface and painted it to match. The radio and shifter surround I used a SEM textured paint and then an interior paint, Landau Black, which if applied correctly, gives you a near OEM look. I developed a bead over the 3 gauges to cover the gap between it and the ashtray panel as these consoles all have some give and take in positioning, so be aware of that. I am also thinking of using some chrome vinyl wrap on just the bead just to make it pop a bit more, especially if you decide to use the chrome bezel gauges which looks very impressive as opposed to the all black VDO gauges which I guess would be more period correct, but hey, do what you like. The screws on the side are number 8 interior screws with the cupped washers you can get from most auto supply houses and "U" speed nuts.

I am happy to share all my files and assist anyone with help with making these parts for for your own cars, but please do not use them commercially. And please let me know how these files worked out for you and hit me up on FB with some pictures of the finished product. Love to see them. The fun just never stops. Cheers Allan

With all that being said, the panels are extremely robust but will require time and effort to finish them to OEM standards. I printed the parts using my Makerbot Replicator 2X and ABS filament. The strength will be provided by using 4 shells and this way you can get away with a 15% infill. But it will still take about 23 hours to print with full supports and rafts.

The unit is developed in 2 parts, the upper gauge pod and the lower radio surround as the size for a single complete unit exceeded my print area. I suggest that you get the parts sanded and smooth prior to gluing the two parts together. I used 240 grit sandpaper to knock down all the print lines and then filler primer. You may have to do this procedure a number of times to get a perfect finish. Once you are happy with the result, I used 800-1200 wet sandpaper to polish the primer to uncover any other possible surface defects. Again, you may have to do this a couple of times of re priming and sanding. Any deep marks can be addressed with some automotive bondo. But the better you prepare the surface, the better the part will come out.

Next is to glue the two parts together. The Gel type of crazy glue works great and I have been having some very good results with the "Gorilla" crazy glue, not the standard gorilla glue, that stuff will expand too much. Just test fit the parts and sand so it will have a perfect fit. I also developed the parts so you can use those small spring clamps on the back to hold the parts together while the glue is drying, and it does set quickly, so have everything ready.

Final finishing depends on your objective, pure stock or something different. I elected to make my console to match my Turbo dash pod, so I finished the gauge pod section to a perfectly flat and smooth surface and painted it to match. The radio and shifter surround I used a SEM textured paint and then an interior paint, Landau Black, which if applied correctly, gives you a near OEM look. I developed a bead over the 3 gauges to cover the gap between it and the ashtray panel as these consoles all have some give and take in positioning, so be aware of that. I am also thinking of using some chrome vinyl wrap on just the bead just to make it pop a bit more, especially if you decide to use the chrome bezel gauges which looks very impressive as opposed to the all black VDO gauges which I guess would be more period correct, but hey, do what you like. The screws on the side are number 8 interior screws with the cupped washers you can get from most auto supply houses and "U" speed nuts.

I am happy to share all my files and assist anyone with help with making these parts for for your own cars, but please do not use them commercially. And please let me know how these files worked out for you and hit me up on FB with some pictures of the finished product. Love to see them. The fun just never stops. Cheers Allan

Similar models

thingiverse

free

Roll Bar Gauge Pod

...print, i got the final finish by putting the parts in a fryer w/ some acetone and "melted" the outer layer of the parts

thingiverse

free

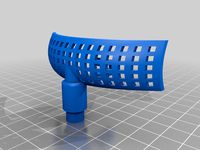

Sanding Tools by 314159

...lender if you need a customised sanding tool for a model. you may also be able to get the concave tool to print out in one piece.

thingiverse

free

Chevy Silverado Gauge Pod by GorillaGizmoz

...gned this for use in a 2003 chevy silverado. its an overhead console gauge pod. it will fit 2" gauge pods.

printed with petg

thingiverse

free

Ghostbusters Radio walkie talkie by daniel_nelms

...ments and perhaps some detailed pictures i could do a better job.

you should be able to print the parts and glue them together.

thingiverse

free

Koto Bridge by ninjafox

...se it to smooth out the bottom part of the bridge. you might have to use a needle file to make the groove for the strings deeper.

thingiverse

free

Volvo 240 Triple Gauge Pod by MesquiteAutomotive

...e revised 240 dash and radio in the lower postilion. you can move the radio to the lower spot on 86-93 240s like i have in my 89.

grabcad

free

Gauge pods

...gauge pods

grabcad

lotus elige gauge pods, central close to shifter. for 3d printing.

thingiverse

free

Fiero Shifter Surround Skeleton by Stricken

...in one piece, so i split it. you may have better luck than me. remove the vinyl from your old skeleton and glue it onto this one.

thingiverse

free

Sanding disk for drill using old orbital sander pads by ldparenteau

...uch at being exactly at right angle with the surface being sanded. cool, i recommend it since it works great, but not essential.

thingiverse

free

Ashtray Cover CAE Short Shifter Aschenbecher Abdeckung for BMW vehicles by zockerbender

...t. just glue it on with some superglue and it should work.

the parts are not rotated properly just print them flat on the bottom.

Gearbox22

thingiverse

free

Megasquirt JimStim Housing by Gearbox22

... removed should you need to add jumpers or re configure the jimstim. good luck with your project and the fun just never stops :d

thingiverse

free

LOTUS EUROPA AND ELAN PLUS 2 STEERING COLUMN SURROUND by Gearbox22

...t smooth as the rafts and supports adds a lot of unwanted artifacts, but it will be unseen and wrapped when finished. good luck.

E10

design_connected

$13

Armchair E10

...armchair e10

designconnected

richard lampert armchair e10 armchairs computer generated 3d model. designed by egon eiermann.

turbosquid

$9

Late WW2 German project E10 anty tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

iriver

...iriver 3ddd плеер , iriver iriver e10 ...

thingiverse

free

E10 by JARLANG

...e10 by jarlang

thingiverse

e10 german - 1:72

3dfindit

free

EASC-E10

...easc-e10

3dfind.it

catalog: festo

3dfindit

free

EASC-E10

...easc-e10

3dfind.it

catalog: festo

3dfindit

free

E10/16

...e10/16

3dfind.it

catalog: te connectivity

thingiverse

free

Radar Extruder Anet E10

...radar extruder anet e10

thingiverse

radar extruder anet e10

thingiverse

free

TABLET WALLMOUNT LENOVO E10

...tablet wallmount lenovo e10

thingiverse

wallmount for lenovo e10 tablet.

3dfindit

free

EAHM-E10-TH

...eahm-e10-th

3dfind.it

catalog: festo

2002

3d_export

$10

spiderman 2002

...spiderman 2002

3dexport

spiderman 2002 3d model high quality for animation

turbosquid

$15

human-2002

...turbosquid

royalty free 3d model human-2002 for download as on turbosquid: 3d models for games, architecture, videos. (1174920)

3d_export

$49

Koenigsegg CC8S 2002 3D Model

...koenigsegg cc8s 2002 3d model

3dexport

koenigsegg cc8s 2002

koenigsegg cc8s 2002 3d model dimary3 72301 3dexport

3d_export

$99

BMW 2002 3D Model

...t

car classic vehicle 3d model 1968 1972 bmw 2002 touring tii old antique coupe sport

bmw 2002 3d model desmonster 98298 3dexport

turbosquid

$75

2002 Nissan Sentra

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$69

2002 Volkswagen Beetle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$29

Ford Expedition 2002 3D Model

... 2002 3d model

3dexport

ford expedition 2000 2001 2002 door utility cars

ford expedition 2002 3d model 3dlogicline 39487 3dexport

3d_export

$99

Citroen C8 2002 3D Model

...port

citroen c8 2002 2010 2011 2012 2013 2014 mpv van minivan bus france french

citroen c8 2002 3d model humster3d 83919 3dexport

3d_export

$99

Ferrari Enzo 2002 3D Model

... 2003 2004 2005 2006 supercar sportcar sport racing car super pininfarina v12

ferrari enzo 2002 3d model humster3d 44650 3dexport

3d_export

$99

Lexus 2054 2002 3D Model

...ort movie steven spielberg 2002 2-door coupe sport luxury japan japanese toyota

lexus 2054 2002 3d model humster3d 83232 3dexport

Bmw

3ddd

$1

BMW

...bmw

3ddd

bmw , машина

высокополигональная модель bmw z4

3ddd

$1

BMW

...bmw

3ddd

bmw

авто бмв

3ddd

$1

bmw

...bmw

3ddd

bmw

3d max 2009,vray 1.5 sp2.fbx

3ddd

$1

Брелок BMW

...брелок bmw

3ddd

брелок , bmw

брелок bmw

3ddd

$1

Диск BMW

...диск bmw

3ddd

bmw , диск

литой диск bmw

3d_ocean

$39

BMW M3

...bmw m3

3docean

3d model bmw m3 car

bmw m3

3ddd

$1

BMW z4

...bmw z4

3ddd

bmw

средне-детализированный bmw z4 coupe.

342500 полигонов

3d_ocean

$49

BMW K1300R

...bmw k1300r

3docean

bike bmw k1300r motorcycle vehicle

3d model of bmw k1300 bike.

3d_ocean

$60

bmw

...bmw

3docean

bmw1 high poly model interior

high poly model of a series 1 bmw with interior and render scene

3ddd

$1

Руль BMW

...руль bmw

3ddd

руль

руль автомобиля bmw.

Pod

design_connected

$13

Pod

...pod

designconnected

niche modern pod computer generated 3d model. designed by pyles, jeremy.

3d_export

$5

engine pod

...engine pod

3dexport

engine pod

turbosquid

$80

POD

...pod

turbosquid

royalty free 3d model pod for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1234976)

3ddd

$1

Pod 325

...pod 325

3ddd

пуф

pod 325

turbosquid

$4

PODS

...oyalty free 3d model pods for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1563118)

3d_export

$5

coworking pods

...coworking pods

3dexport

private pods for workspaces, offices

3ddd

$1

Pod Meeting

...pod meeting

3ddd

pod meeting , martela

146cm x 205cm

design_connected

$16

Pod 325

...pod 325

designconnected

department pod 325 computer generated 3d model.

3d_ocean

$5

Ariel Power Pod

...model ariel power pod ariel power pod, modeled in cinema 4d r14 and all materials are included. if you like it, please rate this

3ddd

$1

POD 325

...pod 325

3ddd

кресло мешок

кресло мешок pod 325, room 21 85x50x100cm.

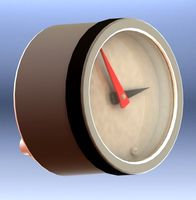

Gauge

3d_ocean

$10

Gauges

...rim to them. each gauge has an xpresso tag to give them an automatic animation without the need for keyframing and can be chan...

3d_export

$5

pressure gauge

...pressure gauge

3dexport

pressure gauge

3d_export

$5

gauge protector

...gauge protector

3dexport

gauge protector

3d_export

$5

Gauge 3D Model

...gauge 3d model

3dexport

gauge pressure gas air liquid

gauge 3d model fau 71180 3dexport

3d_export

$5

protected pressure gauge

...protected pressure gauge

3dexport

protected pressure gauge

3d_export

$5

hard gauge protector

...hard gauge protector

3dexport

hard gauge protector

turbosquid

$29

Screw Gauge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Marking Gauge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Blade Gauge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

12 Gauge 3D Model

...12 gauge 3d model

3dexport

shotgun shell gauge 12

12 gauge 3d model pirog 54511 3dexport