GrabCAD

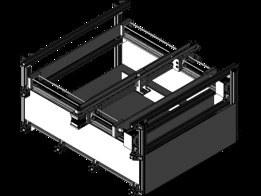

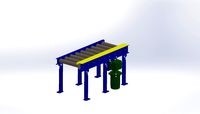

Gantry-Driven HF RFID Product Location Identification System

by GrabCAD

Last crawled date: 1 year, 11 months ago

Gantry-Driven HF RFID Product Location system is the end product of my FYP as Mechatronic Engineering Student. Although it is not physically proved to be functional as a production location identification system, but through simulation and minimum level proof of theory, I obtained an above 90% accuracy through my methodology used in this prototype.

The objective of this prototype is to find an alternative method in product location identification when UHF RFID system is too hard to obtain and the reader itself is too expensive for the application.

Working Theory: -

1. The HF RFID Reader will be scannning through the movable area of the gantry mechanism.

2. The RFID Reader will returned the read data from the tag once tag is detected. At the same time, the step counter will calculate the current step counts of the stepper motor steps for both xy axis gantry movement.

3. The xy axis step counts and also the return datas from the tag is colllected and output into .csv file.

4. The CSV file will be processed to obtain the centroid coordinate of the RFID tag.

Methodology to obtain centroid coordinate of tag similary the product's location is by averaging of x and y data points return to the .csv file.

Pros:

1. Price Effective for RFID System

- Cheaper Price compare to the UHF RFID system

2. Non Complex System

- Easy Calculation to get tag location compared to UHF RFID System that used trionometry method and signal strength for getting the location.

3. Direct Product Location Identification

- The methodology used is straight forward and most importantly accuracy is preserved up to few mm scale if the interval for each horizontal iteration decreased.

Cons:

1. Mechanical Motion

- Energy loss in friction and Material Fatigue

2. Tag Collision

- When tags are closed to each other, the detection rate of the tag will reduce by half. It means with single tag, I can totally get 250 data points for my location. However, when tags are closed to each other, the tag of interest may only have 100 data points due to the interference between electromagnetic wave. Reducing in data points can effect the product location identification algorithm that adapting the averaging method of data points.

3. Non real-time Product Location Identification System

- The system must store the output by a single system and output it to .csv file or equivalent. After completed the scanning, it will only enter data processing stage. But, UHF RFID system can achieved the real time Product Location Identification.

4. Time consuming

- Time is consumed in the scaning. But, the time can be reduced by adding more RFID tag to the system. However, additional controller is needed.

5. XY axis location identification

- Only able to achieve plannar product detection. Meanwhile, UHF RFID system could perform 3 axis location identification by additional of receiving antenna and reader.

6. Bounded Area of Detection

- Bounded by gantry mechanism size.

- Bounded by read range of the RFID Reader.

The objective of this prototype is to find an alternative method in product location identification when UHF RFID system is too hard to obtain and the reader itself is too expensive for the application.

Working Theory: -

1. The HF RFID Reader will be scannning through the movable area of the gantry mechanism.

2. The RFID Reader will returned the read data from the tag once tag is detected. At the same time, the step counter will calculate the current step counts of the stepper motor steps for both xy axis gantry movement.

3. The xy axis step counts and also the return datas from the tag is colllected and output into .csv file.

4. The CSV file will be processed to obtain the centroid coordinate of the RFID tag.

Methodology to obtain centroid coordinate of tag similary the product's location is by averaging of x and y data points return to the .csv file.

Pros:

1. Price Effective for RFID System

- Cheaper Price compare to the UHF RFID system

2. Non Complex System

- Easy Calculation to get tag location compared to UHF RFID System that used trionometry method and signal strength for getting the location.

3. Direct Product Location Identification

- The methodology used is straight forward and most importantly accuracy is preserved up to few mm scale if the interval for each horizontal iteration decreased.

Cons:

1. Mechanical Motion

- Energy loss in friction and Material Fatigue

2. Tag Collision

- When tags are closed to each other, the detection rate of the tag will reduce by half. It means with single tag, I can totally get 250 data points for my location. However, when tags are closed to each other, the tag of interest may only have 100 data points due to the interference between electromagnetic wave. Reducing in data points can effect the product location identification algorithm that adapting the averaging method of data points.

3. Non real-time Product Location Identification System

- The system must store the output by a single system and output it to .csv file or equivalent. After completed the scanning, it will only enter data processing stage. But, UHF RFID system can achieved the real time Product Location Identification.

4. Time consuming

- Time is consumed in the scaning. But, the time can be reduced by adding more RFID tag to the system. However, additional controller is needed.

5. XY axis location identification

- Only able to achieve plannar product detection. Meanwhile, UHF RFID system could perform 3 axis location identification by additional of receiving antenna and reader.

6. Bounded Area of Detection

- Bounded by gantry mechanism size.

- Bounded by read range of the RFID Reader.

Similar models

grabcad

free

UHF Reader

...uhf reader

grabcad

typical chinese rfid reader for uhf

3dwarehouse

free

UHF RFID Tag

...uhf rfid tag

3dwarehouse

generic uhf rfid tag #rfid_tag_uhf

grabcad

free

SparkFun Simultaneous RFID Reader - M6E Nano

... tools or allowing access to the tree house for your secret society meetings, this board may be for you!" - www.sparkfun.com

3dwarehouse

free

Green Tray with UHF RFID Tags

...green tray with uhf rfid tags

3dwarehouse

green tray with uhf rfid tags #tray #green #rfid #tags #greentray

3dwarehouse

free

RFId UHF 4 antennas gate

...rfid uhf 4 antennas gate

3dwarehouse

gate with 4 rfid antennas. #4_antennas #antenna #reader #rfid #rfid_uhf #uhf

grabcad

free

UHF RFID Reader/Writer

...uhf rfid reader/writer

grabcad

basic model

grabcad

free

RFID Reader ID-12LA

...he 2mm pin spacing. power the module, hold up a 125khz card, and get a serial string output containing the unique id of the card.

grabcad

free

VF-747P

...vf-747p

grabcad

uhf rfid fixed reader vf-747p - vanch

grabcad

free

IN Tag RFID UHF

...in tag rfid uhf

grabcad

hid in tag passive contactless rfid

transponders are highly water, chemical

and shock resistant.

3dwarehouse

free

UHF RFID Flat Antenna

...nna

3dwarehouse

this is an antenna to be connected with a uhf reader. the gain of this antenna: 20db #uhf_rfid_antenna #天线 #平板天线

Rfid

turbosquid

$20

RFID Reader

...royalty free 3d model rfid reader for download as obj and 3dm on turbosquid: 3d models for games, architecture, videos. (1450180)

3d_export

$24

Rfid gate 3D Model

... frequency identification gate gates transport logistic tag shipping depot rfdi security

rfid gate 3d model tartino 3854 3dexport

3d_export

$5

rfid door intercom with cam

...ecular<br>**1 material **<br>remember visit my profile for more 3d models and textures<br>thanks for watching!!

thingiverse

free

RFID by MeliMaker3d

...rfid by melimaker3d

thingiverse

diseño del simbolo rfid

thingiverse

free

rfid box by sanyok661

...rfid box by sanyok661

thingiverse

rfid box

thingiverse

free

TAG RFID by lusho01

...tag rfid by lusho01

thingiverse

tag rfid nfc

thingiverse

free

RFID Fob by Schmity47

...verse

this is a rfid keyfob for a .91 inch by .04 inch round rfid chip. not sure if fitment will be perfect, but lmk if its not.

thingiverse

free

RFID-RC522 case

...rfid-rc522 case

thingiverse

two part case or cover for a rfid reader module.

thingiverse

free

RFID Hook by WickertD

...rfid hook by wickertd

thingiverse

hook mounted to a servo motor to pick up the rfid

thingiverse

free

rfid enclosure

...rfid enclosure

thingiverse

really simple project for most

Identification

turbosquid

$25

Automatic Identification System (AIS)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$40

Automatic Identification System (AIS)3d model

....c4d .dxf .obj - automatic identification system (ais) 3d model, royalty free license available, instant download after purchase.

3d_export

$24

Rfid gate 3D Model

...rfid gate 3d model 3dexport rfid radio frequency identification gate gates transport logistic tag shipping depot rfdi security...

3d_export

$59

Falcon 3D Model

...falconidae american kestrel wildlife photography perch pacific northwest falcon identification watching washington falcon 3d model laurenstrimpe 71094...

3d_export

$59

Sperwer 3D Model

...falconidae american kestrel wildlife photography perch pacific northwest falcon identification watching washington sperwer 3d model laurenstrimpe 70677...

3d_export

$8

Wireless alarm beacon 3D Model

...access system home security protection alarm digital door keypad identification equipment wireless alarm beacon 3d model kreatura 92398...

3d_export

$17

Alarm system keypad 3D Model

...access system home security protection alarm digital door keypad identification equipment alarm system keypad 3d model kreatura 92421...

3d_export

$10

Sheriff Badge 3D Model

...3dexport sheriff badge police star authority insignia symbol decoration identification metal patch pinning pin law enforcement security guard tag...

cg_studio

$7

Wireless alarm beacon3d model

...access system home security protection alarm digital door keypad identification equipment .fbx .obj .max .3ds - wireless alarm beacon...

cg_studio

$16

Alarm system keypad low poly3d model

...command level access system home security protection digital door identification equipment 3d vray max .max .obj .fbx - alarm...

Hf

cg_studio

$50

Canon HF S213d model

...era cam digital video handcam lens

.max - canon hf s21 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Aventos HF. Подьемник складной Blum.

...подьемный механизм aventos hf, blum, австрия. 5354 полигонов, текстуры, инструкция.http://www.blum.com/ru/ru/01/10/10/

turbosquid

$100

HF nU gun .blend

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$99

Lancia Stratos HF 3D Model

...ally photorealistic speed people drive championship italy italia italian munari

lancia stratos hf 3d model fabelar 70549 3dexport

cg_studio

$49

Lancia Delta HF integrale3d model

... model

cgstudio

.3ds .max - lancia delta hf integrale 3d model, royalty free license available, instant download after purchase.

turbosquid

$55

Lancia Fulvia HF 4WD concept

...ee 3d model lancia fulvia hf 4wd concept for download as wire on turbosquid: 3d models for games, architecture, videos. (1310343)

3d_export

$129

Lancia Stratos HF 1974 3D Model

...ly sport racing rallye car fast group oldtimer classic retro vintage antique

lancia stratos hf 1974 3d model squir 38155 3dexport

cg_studio

$129

Lancia Stratos HF 19743d model

....3ds .c4d .fbx .lwo .max .obj - lancia stratos hf 1974 3d model, royalty free license available, instant download after purchase.

3d_export

$24

lancia delta hf integrale

...the detail and realism of any of your rendering projects.<br>available 3d file format: max2013, v-ray render, fbx, obj, 3ds

turbosquid

$16

Canon HF-DC2 High-Power

...canon hf-dc2 high-power for download as ma, max, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1202334)

Gantry

turbosquid

$349

Gantry crane

...alty free 3d model gantry crane for download as ige and sldas on turbosquid: 3d models for games, architecture, videos. (1476278)

3d_export

free

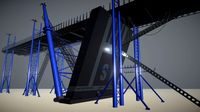

firestone advertising gantry

...rs premises and<br>these advertisement gantries, were very popular in the 30-70's at grand prix races advertising tyres

turbosquid

$30

Derelict Launch Gantry

...alty free 3d model derelict launch gantry for download as fbx on turbosquid: 3d models for games, architecture, videos. (1669952)

turbosquid

$129

Gantry Crane RTG

...e 3d model gantry crane rtg for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1491933)

turbosquid

$120

Gantry stacker Assembly

...try stacker assembly for download as sldas, fbx, 3ds, and ige on turbosquid: 3d models for games, architecture, videos. (1648516)

turbosquid

$19

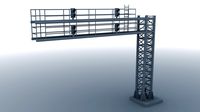

Train Signals Gantry

...l train signals gantry for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1462242)

turbosquid

$5

STS Gantry Crane

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$160

Bulk carrier with gantry crane

...carrier with gantry crane for download as lwo, obj, and blend on turbosquid: 3d models for games, architecture, videos. (1285258)

3d_export

$50

RMG Gantry Crane 3D Model

...t hoist rail rubber tyre tire rtg eot beam portal heigh tonne shipyard port

rmg gantry crane 3d model 5starsmodels 42860 3dexport

3d_export

$29

gantry crane

...istic model that will enhance the detail and realism of any of your rendering projects.<br>file formats: max, obj, fbx, 3ds

Driven

turbosquid

$50

CHAIN DRIVEN CONVEYOR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

driven shaft of the lump crusher

...driven shaft of the lump crusher

3dexport

3d_export

$27

n95 full servo driven mask printer

...n95 full servo driven mask printer

3dexport

n95 full servo driven mask printer

turbosquid

$16

(Project) Food packing helper machine with holding clamp and press table driven by an actuator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$47

the fifth generation of one driven two new mask machine

...ing, lamination, pressing, ear band tapping, ultrasonic, etc. the structure of the model is detailed, including model parameters.

3d_export

$15

industrial belt-driven air cooler

...leaning up necessary, just drop your models into the scene and start rendering/texturing. no special plugin needed to open scene.

3d_export

free

golf cart

...golf cart 3dexport golf cart for golfers to be driven in...

3d_export

$10

design and assembly of pulley

...pulley 3d model which is used for drive and driven ...

archive3d

free

Windmill 3D Model

...windmill 3d model archive3d wind turbine wind-driven powerplant wind-electric set windmill n181208 - 3d model (*.gsm+*.3ds)...

3d_export

$30

Compressed Air Engine 3D Model

...motor flywheel shaft camshaft piston valve block engineering compressed-air driven compressed air engine 3d model zenmunster 92451...

Location

3d_export

$5

location

...location

3dexport

mini-location, tree, house, furniture, etc.

3d_export

free

Location

...location

3dexport

3d_export

free

Location geyser

...location geyser

3dexport

location geyser<br>there was not enough pc power for rendering :)

turbosquid

$46

Sound Locator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Locating conveyor

...veyor for download as 3ds, max, ige, obj, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1257125)

3d_ocean

$25

Sci-Fi Locator

...sci-fi locator

3docean

aerial wire antenna fi future locator sci sci-fi

3d model sci-fi locator by alekrazum vray materials

turbosquid

$30

Well for Medieval Location

... free 3d model well for medieval location for download as fbx on turbosquid: 3d models for games, architecture, videos. (1439306)

turbosquid

$16

Cartoon base location

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$9

location icon logo emblem

...location icon logo emblem

3dexport

location icon logo emblem<br>real texture

3d_export

$15

Laser Target Locator

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

System

archibase_planet

free

System

...m

archibase planet

fire alarm system fire alarm box

security light system - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spider system

...stem spider glass system

spider system to fix glass stefano galli n050912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Euforia System

...euforia system

3ddd

euforia

euforia system

3d_export

$50

Roof system Truss system 3D Model

...oof system truss system 3d model

3dexport

roof system truss truss stage

roof system truss system 3d model aleksbel 38970 3dexport

3ddd

$1

DVD System

...dvd system

3ddd

dvd , schneider

dvd system

design_connected

free

Seating system

...seating system

designconnected

free 3d model of seating system

3d_export

$5

solar system

...solar system

3dexport

solar system in c4d, with 8k nasa textures

3ddd

$1

Quanta System

...quanta system

3ddd

медицина

quanta system.

лазерное оборудование для медицинских центров

3d_export

$15

solar system

...nd the other the sun, the earth and the moon, the latter has an animation with camera movement included, the files are in spanish

3d_export

$14

missile system

...missile system

3dexport

Product

turbosquid

$15

Product

... free 3d model product for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1237814)

turbosquid

$50

Organic Products

...quid

royalty free 3d model organic products for download as on turbosquid: 3d models for games, architecture, videos. (1398510)

turbosquid

$49

Interior for Products

...yalty free 3d model interior for products for download as max on turbosquid: 3d models for games, architecture, videos. (1268700)

turbosquid

$48

Product Stand

...quid

royalty free 3d model product stand for download as max on turbosquid: 3d models for games, architecture, videos. (1483427)

turbosquid

$20

Product Tube

...squid

royalty free 3d model product tube for download as c4d on turbosquid: 3d models for games, architecture, videos. (1294981)

turbosquid

$5

LATHE PRODUCT

...quid

royalty free 3d model lathe product for download as max on turbosquid: 3d models for games, architecture, videos. (1151333)

turbosquid

$4

Product Display

...id

royalty free 3d model product display for download as max on turbosquid: 3d models for games, architecture, videos. (1259446)

turbosquid

$4

Product Display

...id

royalty free 3d model product display for download as max on turbosquid: 3d models for games, architecture, videos. (1259453)

turbosquid

$2

LASER PRODUCT

...id

royalty free 3d model laser product for download as sldas on turbosquid: 3d models for games, architecture, videos. (1363119)

turbosquid

$24

Product Stand

...yalty free 3d model product stand for download as 3ds and c4d on turbosquid: 3d models for games, architecture, videos. (1231329)