Thingiverse

FuseBox 1515 hot end blower nozzle by dgcaste

by Thingiverse

Last crawled date: 4 years, 4 months ago

NOTE: THIS MODEL HAS SOME QUALITY ISSUES THAT I AM ADDRESSING IN A FUTURE UPDATEThe front edge of my prints were popping off prematurely and I suspected it was due to the fan excessively cooling the bed. Ran a SolidWorks flow sim on the part and there it was! http://prntscr.com/b9ldv1 -- I am redesigning the fan to focus air on the top layer of the print and slightly below, assuming you turn on the fan around layer 5 or so which should correspond to about 0.5-1.5mm.

This model will allow you to interface a 15mm thick blower onto the FuseBox 1515 (http://www.thingiverse.com/thing:1047193) carriage. Please note that this will eat up a bit of your maximum Y travel so don't forget to adjust your software endstops.

Additionally featured is a small nozzle to help cool off the extruder's bottom heat sink fins.

As far as printing this, PLA seems to work just fine. Bridging is required for the blower until I can make it nicer. Interface plate needs to be flipped upside down otherwise you'll have a bad time. Solidworks files available for anyone interested, they're not super clean so I haven't uploaded them yet. I can make this work on a 20mm thick blower but it's really too much airflow, 15mm is powerful enough with this nozzle design. This is the fan I modeled this part after: http://www.amazon.com/Connector-Cooling-Blower-50mmx15mm-uxcell/dp/B00MJU6JR2 . I created this model by measuring the fan I linked to, so I can't guarantee it'll fit other fans. Maybe I'll make one with a slot that will fit several angles.

I strongly recommend placing insulation around the nozzle block as the fan is powerful enough to drop the thermistor temperature down and trigger a thermal runaway in the firmware.

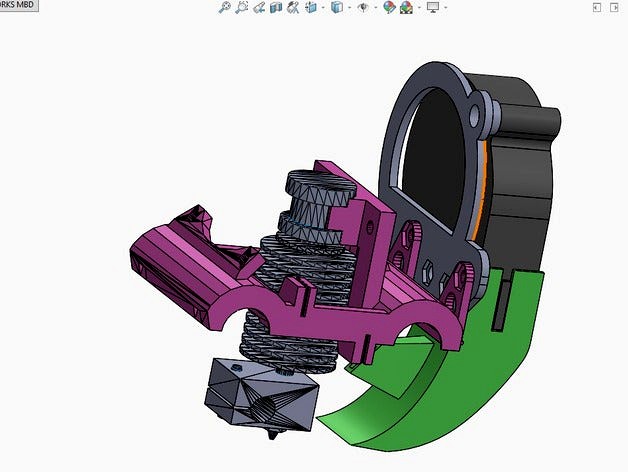

Also included an assembly STL to preview how it goes together.

This model will allow you to interface a 15mm thick blower onto the FuseBox 1515 (http://www.thingiverse.com/thing:1047193) carriage. Please note that this will eat up a bit of your maximum Y travel so don't forget to adjust your software endstops.

Additionally featured is a small nozzle to help cool off the extruder's bottom heat sink fins.

As far as printing this, PLA seems to work just fine. Bridging is required for the blower until I can make it nicer. Interface plate needs to be flipped upside down otherwise you'll have a bad time. Solidworks files available for anyone interested, they're not super clean so I haven't uploaded them yet. I can make this work on a 20mm thick blower but it's really too much airflow, 15mm is powerful enough with this nozzle design. This is the fan I modeled this part after: http://www.amazon.com/Connector-Cooling-Blower-50mmx15mm-uxcell/dp/B00MJU6JR2 . I created this model by measuring the fan I linked to, so I can't guarantee it'll fit other fans. Maybe I'll make one with a slot that will fit several angles.

I strongly recommend placing insulation around the nozzle block as the fan is powerful enough to drop the thermistor temperature down and trigger a thermal runaway in the firmware.

Also included an assembly STL to preview how it goes together.