Thingiverse

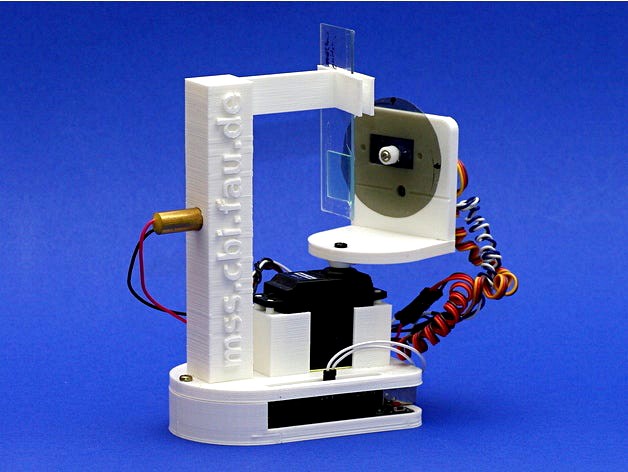

Fully Automated Light Scattering Experiment by cscholz

by Thingiverse

Last crawled date: 3 years ago

A fully automated inexpensive($50) educational lab experiment to measure optical scattering, in particular polarization and angular cross-section.

On a beginner level the setup is suitable to measure scattering of light by optical gratings. In fact scattering from a CD-R surface is used to calibrate the angular servo control using the well-known equation "grating_constant x sine(nth scattering angle) = n x wavelength".

The experiment was developed in our laboratory physics courses to demonstrate Mie-scattering by microscopic colloidal particles. Mie-scattering refers to light scattering by objects that are comparable to the wavelength. This is typically used in expensive laboratory equipment, to determine size-distributions of colloidal suspensions.

The setup is controlled via an Arduino which fits in the bottom of the device. A small amount of soldering or a separate bread-board is required to assemble the device and should be possible on a undergraduate or even school level.

Detailed information, a list of required components, assembly instructions and software (OpenSCAD files; Arduino Firmware; Python & Octave scripts for analysis of measurements - all GPL licensed) can be found on our dedicated website: http://www.mss.cbi.fau.de/Mie-experiment

A live-demonstration of the measurement can be found here: https://www.youtube.com/watch?v=A-WL2huUDuc

The device was featured in the 3/17 German issue of the Make magazine: https://www.heise.de/make/meldung/Guenstig-dank-Maker-Technik-Optik-Experiment-fuer-Schulen-und-Unis-3716721.html

For details on the experiment and explanation of the physics of Mie-scattering we published a scientific paper here:

C. Scholz, A. Sack, M. Heckel and T. Pöschel, Inexpensive Mie scattering experiment for the classroom manufactured by 3D printing, Eur. J. Phys. 37 055305 (2016)http://iopscience.iop.org/article/10.1088/0143-0807/37/5/055305

All parts were printed using an FDM printer (Kühling & Kühling RepRap), PLA or ABS material with 20% filling and 80% for the base. Post-processing involves gluing and screwing together the individual parts and electronic components. Some minor adjustments might be needed to the components (servos, diodes, etc) that are available to you.

On a beginner level the setup is suitable to measure scattering of light by optical gratings. In fact scattering from a CD-R surface is used to calibrate the angular servo control using the well-known equation "grating_constant x sine(nth scattering angle) = n x wavelength".

The experiment was developed in our laboratory physics courses to demonstrate Mie-scattering by microscopic colloidal particles. Mie-scattering refers to light scattering by objects that are comparable to the wavelength. This is typically used in expensive laboratory equipment, to determine size-distributions of colloidal suspensions.

The setup is controlled via an Arduino which fits in the bottom of the device. A small amount of soldering or a separate bread-board is required to assemble the device and should be possible on a undergraduate or even school level.

Detailed information, a list of required components, assembly instructions and software (OpenSCAD files; Arduino Firmware; Python & Octave scripts for analysis of measurements - all GPL licensed) can be found on our dedicated website: http://www.mss.cbi.fau.de/Mie-experiment

A live-demonstration of the measurement can be found here: https://www.youtube.com/watch?v=A-WL2huUDuc

The device was featured in the 3/17 German issue of the Make magazine: https://www.heise.de/make/meldung/Guenstig-dank-Maker-Technik-Optik-Experiment-fuer-Schulen-und-Unis-3716721.html

For details on the experiment and explanation of the physics of Mie-scattering we published a scientific paper here:

C. Scholz, A. Sack, M. Heckel and T. Pöschel, Inexpensive Mie scattering experiment for the classroom manufactured by 3D printing, Eur. J. Phys. 37 055305 (2016)http://iopscience.iop.org/article/10.1088/0143-0807/37/5/055305

All parts were printed using an FDM printer (Kühling & Kühling RepRap), PLA or ABS material with 20% filling and 80% for the base. Post-processing involves gluing and screwing together the individual parts and electronic components. Some minor adjustments might be needed to the components (servos, diodes, etc) that are available to you.

Similar models

3dwarehouse

free

Optical Physics and Engineering Building

...ques and development of microcavity plasma devices and their applications. #engineering #optical #physics #university_of_illinois

thingiverse

free

Automated Glockenspiel With Arduino And Servos by lkiefer

...cad designs

arduino sketches

you can find a complete tutorial, a bom, a video demo and some pictures at https://blog.lkiefer.org/

grabcad

free

Servo Motor

...nes precision, feedback, and controlled motion, playing a pivotal role in the advancement of automation and robotic technologies.

3dwarehouse

free

Water Level Sensor

...water level sensor

3dwarehouse

a simple water level sensor for arduino #arduino #waterlevel #sensor #automation #control

thingiverse

free

Lab-on-an-Arduino Spectral Absorbance Shield aka Optical Density Meter by dusjagr

...rent wavelengths, using 5mm leds. the design fits nicely a til-99 phototransistor.

see details on: http://hackteria.org/?p=2194

grabcad

free

Physical objects of automation systems

...various industries, programming industrial controllers to automate control and gain practical experience in automation of objects

thingiverse

free

Blue Light DNA Transilluminator by gabrielstpierre

...r software programming is needed.

further details can be found at:

https://www.instructables.com/blue-light-dna-transilluminator/

grabcad

free

motion sensor

....

they form a vital component of security, automated lighting control, home control, energy efficiency, and other useful systems.

thingiverse

free

Automated 3d Laser scanner platform by downeym

...ware. this allows me to use the same pc for automation and scanning. this can be downloaded here: http://com0com.sourceforge.net/

thingiverse

free

Servo controlled by a potentiometer - 3DX by mfitchhorn

...servo controlled by a potentiometer - 3dx by mfitchhorn

thingiverse

arduino controlled servo using a potentiometer.

Cscholz

thingiverse

free

My Music Center Case Mod by cscholz

...openscad files, such that you can easily modify the print files, in particular, if you have a slightly different model.

have fun!

thingiverse

free

Roof-Top Tent for Ikea Baby Crib by cscholz

...oler with a custom made fabric roof, but you need someone with sewing skills for this (big thanks to my mother-in-law for that!).

Scattering

3d_ocean

$5

Scattered Papers

...s a low polygonal model, easy to animate. - poly count: 506 - formats: max /obj /fbx/3ds/dxf - high detail was preserved with ...

turbosquid

$3

Scattering Mirrors

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Rock Scatter(1)

...ree 3d model rock scatter for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1610303)

3d_ocean

$29

30 Bush For Scatter

...bj file and fbx file -30 style of bush -low-polygon triangle count 107,820 -high-polygon triangle count 407,780 -tree for scatter

3d_ocean

$39

70 Bush For Scatter

...style of bush -low-polygon triangle count 6,588,337 -high-polygon triangle count 13,178,906 -tree for scatter - 7 high differe...

3d_export

$7

scatter - plant trees

...scatter - plant trees

3dexport

arhive rar 4.01: models. textures: color, normal, opacity<br>3da max 2016

3d_export

$10

grassland1

...corona scatter -corona scatter is not in obj files. only the grasses and flowers - corona scatter settings screen shot in archive

3d_export

$10

grass kit 2

...grass kit 2

3dexport

grass kit 2 with corona scatter setup.

3d_export

$10

grassland2

...in the scene with corona scatter. - corona scatter setting in archive. - only main objects has obj file. (ground has no obj file)

3d_export

$10

auto ivy collections 1

...of the auto ivy collections,<br>idea using corona scatter for scattering object on wall or any surfaces . for this...

Automated

turbosquid

$19

Automation for gates

... model automation for gates for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1600153)

turbosquid

$5

Automated Teller Machine

...tomated teller machine for download as c4d, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1677841)

turbosquid

$30

AUTOMATED GUARD STATION

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$19

Drink Automate New

...w office old red retro rust soda store vending vintage

old rusty drink machine, and new shiny. xsi and lvo exported from blender.

evermotion

$10

home automation system 32 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 35 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 38 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 24 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 30 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 27 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

Experiment

3d_export

$5

Doll for experiments

...doll for experiments

3dexport

this model is suitable for experiments or for the game world as a simple character.

3d_export

free

experiment of shapes

...experiment of shapes

3dexport

simple jar

turbosquid

$1

experiment tube

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$28

experiment tube3d model

...tudio

.3ds .dxf .fbx .lwo .max .obj - experiment tube 3d model, royalty free license available, instant download after purchase.

turbosquid

$29

Half Leaf Experiment

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$37

experiment tube 3D Model

...ab equipment monster doctor surgeon clinic animal creature future prop scene

experiment tube 3d model duchampmodels 7929 3dexport

3ddd

$1

Jacuzzi Virginia Experience

...jacuzzi virginia experience

3ddd

джакузи

оригинал:http://www.azuropool.ru/shop/spa-basseiny-jacuzzi/jexp/virginia.html

turbosquid

$25

icecube physical school experiment

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

INSIDE creative experience - bubble

... - bubble

3ddd

inside

вес модели 14000 полигонов

стек не свернут

сайтhttp://www.inside.it/wp/?page_id=2351⟨=en

turbosquid

$22

Kohler Purist Experience Integrated Bath bathtub Ovale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Fully

turbosquid

$50

Drone fully rigged

...

royalty free 3d model drone fully rigged for download as max on turbosquid: 3d models for games, architecture, videos. (1282280)

turbosquid

$12

FULLY PARAMETRIC CHAIR

...alty free 3d model fully parametric chair for download as rvt on turbosquid: 3d models for games, architecture, videos. (1280209)

turbosquid

$10

firetruck-fully-rigged

...yalty free 3d model firetruck-fully-rigged for download as ma on turbosquid: 3d models for games, architecture, videos. (1653811)

turbosquid

$6

Fully rigged character

...ty free 3d model fully rigged character for download as blend on turbosquid: 3d models for games, architecture, videos. (1486076)

turbosquid

$3

Fully Rigged shark

...ee 3d model fully rigged 3d shark model for download as blend on turbosquid: 3d models for games, architecture, videos. (1517695)

turbosquid

$75

Fully Customizable Hospital

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Fully Rigged Link

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Troy W Fully Covered

...troy w fully covered

designconnected

magis troy w fully covered computer generated 3d model. designed by wanders, marcel.

cg_studio

$99

Pepe fully rigged3d model

...ully rigged3d model

cgstudio

.max - pepe fully rigged 3d model, royalty free license available, instant download after purchase.

3d_export

$60

Ankylosaur 8K - fully animated

...ankylosaur 8k - fully animated

3dexport

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...