Thingiverse

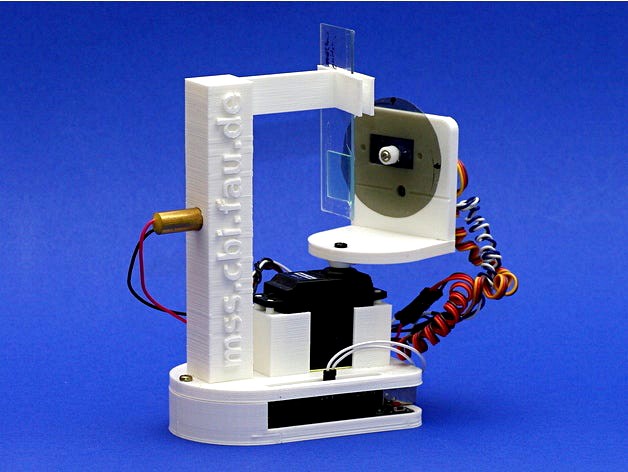

Fully Automated Light Scattering Experiment by cscholz

by Thingiverse

Last crawled date: 4 years, 2 months ago

A fully automated inexpensive($50) educational lab experiment to measure optical scattering, in particular polarization and angular cross-section.

On a beginner level the setup is suitable to measure scattering of light by optical gratings. In fact scattering from a CD-R surface is used to calibrate the angular servo control using the well-known equation "grating_constant x sine(nth scattering angle) = n x wavelength".

The experiment was developed in our laboratory physics courses to demonstrate Mie-scattering by microscopic colloidal particles. Mie-scattering refers to light scattering by objects that are comparable to the wavelength. This is typically used in expensive laboratory equipment, to determine size-distributions of colloidal suspensions.

The setup is controlled via an Arduino which fits in the bottom of the device. A small amount of soldering or a separate bread-board is required to assemble the device and should be possible on a undergraduate or even school level.

Detailed information, a list of required components, assembly instructions and software (OpenSCAD files; Arduino Firmware; Python & Octave scripts for analysis of measurements - all GPL licensed) can be found on our dedicated website: http://www.mss.cbi.fau.de/Mie-experiment

A live-demonstration of the measurement can be found here: https://www.youtube.com/watch?v=A-WL2huUDuc

The device was featured in the 3/17 German issue of the Make magazine: https://www.heise.de/make/meldung/Guenstig-dank-Maker-Technik-Optik-Experiment-fuer-Schulen-und-Unis-3716721.html

For details on the experiment and explanation of the physics of Mie-scattering we published a scientific paper here:

C. Scholz, A. Sack, M. Heckel and T. Pöschel, Inexpensive Mie scattering experiment for the classroom manufactured by 3D printing, Eur. J. Phys. 37 055305 (2016)http://iopscience.iop.org/article/10.1088/0143-0807/37/5/055305

All parts were printed using an FDM printer (Kühling & Kühling RepRap), PLA or ABS material with 20% filling and 80% for the base. Post-processing involves gluing and screwing together the individual parts and electronic components. Some minor adjustments might be needed to the components (servos, diodes, etc) that are available to you.

On a beginner level the setup is suitable to measure scattering of light by optical gratings. In fact scattering from a CD-R surface is used to calibrate the angular servo control using the well-known equation "grating_constant x sine(nth scattering angle) = n x wavelength".

The experiment was developed in our laboratory physics courses to demonstrate Mie-scattering by microscopic colloidal particles. Mie-scattering refers to light scattering by objects that are comparable to the wavelength. This is typically used in expensive laboratory equipment, to determine size-distributions of colloidal suspensions.

The setup is controlled via an Arduino which fits in the bottom of the device. A small amount of soldering or a separate bread-board is required to assemble the device and should be possible on a undergraduate or even school level.

Detailed information, a list of required components, assembly instructions and software (OpenSCAD files; Arduino Firmware; Python & Octave scripts for analysis of measurements - all GPL licensed) can be found on our dedicated website: http://www.mss.cbi.fau.de/Mie-experiment

A live-demonstration of the measurement can be found here: https://www.youtube.com/watch?v=A-WL2huUDuc

The device was featured in the 3/17 German issue of the Make magazine: https://www.heise.de/make/meldung/Guenstig-dank-Maker-Technik-Optik-Experiment-fuer-Schulen-und-Unis-3716721.html

For details on the experiment and explanation of the physics of Mie-scattering we published a scientific paper here:

C. Scholz, A. Sack, M. Heckel and T. Pöschel, Inexpensive Mie scattering experiment for the classroom manufactured by 3D printing, Eur. J. Phys. 37 055305 (2016)http://iopscience.iop.org/article/10.1088/0143-0807/37/5/055305

All parts were printed using an FDM printer (Kühling & Kühling RepRap), PLA or ABS material with 20% filling and 80% for the base. Post-processing involves gluing and screwing together the individual parts and electronic components. Some minor adjustments might be needed to the components (servos, diodes, etc) that are available to you.