Thingiverse

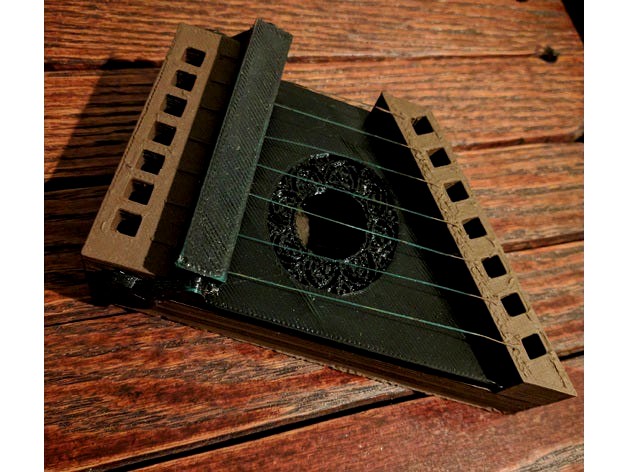

Fully 3D Printed Harp/Zither by MintyFries

by Thingiverse

Last crawled date: 3 years ago

Please consider subscribing to my YouTube page to see cool VR/360 tours of maps from video games: https://youtube.com/mintyfries

DISCLAIMERS!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

-DO NOT expect this to sound good

-This is a proof of concept, not a working instrument

-The strings will break with any rough playing

-I only have a printer with a 5 inch print bed, so I designed it with that in mind. Ideally, it should be re-designed and printed with a larger printer

-The holes are for pins in case you wanted to attach real strings (metal, nylon, gut, etc, not PLA) to the soundboard

-I only know that this works with PLA. I can't speak for ABS or other materials

-This is a WORK IN PROGRESS. I can already think of innumerable improvements to the design (like thinner walls), so hang tight for improvements

This is a 100% 3D printed harp instrument. The main body prints in one piece, strings and all. Then you just have to glue on a soundboard and glue together a crimping mechanism that keeps the strings taut. The crimping mechanism attaches to the body just by pressure, but you need to glue together the two gears and tuning bar. Once that's together, pop on the crimping mechanism and then start strumming (but please strum softly so the strings last longer).

I like to build musical instruments, and thus often find myself testing out the musical properties of various materials. One day I was changing a spool of filament, and my printer started eeking out a ton of thin, stringy PLA. Naturally, I tried stretching some of it across a soundbox (read, a cardboard box). Lo and behold, it actually worked! It could be plucked and made a sound just like any other cheap string material. The string didn't last very long before breaking, but it worked for a brief time.

So I got to work designing and printing small prototype harps and finding out the right dimensions for my printer to print suspended strings across a gap. Since I wanted the strings to print onto the soundbox in one print (without requiring glue), I decided to tune the harp using a crimping mechanism instead of standard tuning pins.

Don't ask me what the tuning for this is because it would be futile to attempt to work out a tuning. The PLA just wouldn't take to being tuned like a more suitable material (like high carbon steel) would. And the stings are so small that the pitch is unpleasantly high and tinny, so tuning doesn't much matter anyway. The crimping mechanism only serves to get the strings taut, not to get them tuned. I wonder if it's possible to print suspended strings and then print a few more layers over them to make the strings thicker, but I doubt it, and I haven't tested it yet.

This is really just a fun proof of concept project, or something to use for decoration, so please don't expect a nice instrument from this print. It would be a far better idea to print a base and then attach real strings to it, rather than using plastic. I just wanted to show that a working harp could be 100% printed from PLA, strings and all.

Please, please, please feel free to take this concept and run with it. I'd love to see what others can make using PLA strings.

DISCLAIMERS!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

-DO NOT expect this to sound good

-This is a proof of concept, not a working instrument

-The strings will break with any rough playing

-I only have a printer with a 5 inch print bed, so I designed it with that in mind. Ideally, it should be re-designed and printed with a larger printer

-The holes are for pins in case you wanted to attach real strings (metal, nylon, gut, etc, not PLA) to the soundboard

-I only know that this works with PLA. I can't speak for ABS or other materials

-This is a WORK IN PROGRESS. I can already think of innumerable improvements to the design (like thinner walls), so hang tight for improvements

This is a 100% 3D printed harp instrument. The main body prints in one piece, strings and all. Then you just have to glue on a soundboard and glue together a crimping mechanism that keeps the strings taut. The crimping mechanism attaches to the body just by pressure, but you need to glue together the two gears and tuning bar. Once that's together, pop on the crimping mechanism and then start strumming (but please strum softly so the strings last longer).

I like to build musical instruments, and thus often find myself testing out the musical properties of various materials. One day I was changing a spool of filament, and my printer started eeking out a ton of thin, stringy PLA. Naturally, I tried stretching some of it across a soundbox (read, a cardboard box). Lo and behold, it actually worked! It could be plucked and made a sound just like any other cheap string material. The string didn't last very long before breaking, but it worked for a brief time.

So I got to work designing and printing small prototype harps and finding out the right dimensions for my printer to print suspended strings across a gap. Since I wanted the strings to print onto the soundbox in one print (without requiring glue), I decided to tune the harp using a crimping mechanism instead of standard tuning pins.

Don't ask me what the tuning for this is because it would be futile to attempt to work out a tuning. The PLA just wouldn't take to being tuned like a more suitable material (like high carbon steel) would. And the stings are so small that the pitch is unpleasantly high and tinny, so tuning doesn't much matter anyway. The crimping mechanism only serves to get the strings taut, not to get them tuned. I wonder if it's possible to print suspended strings and then print a few more layers over them to make the strings thicker, but I doubt it, and I haven't tested it yet.

This is really just a fun proof of concept project, or something to use for decoration, so please don't expect a nice instrument from this print. It would be a far better idea to print a base and then attach real strings to it, rather than using plastic. I just wanted to show that a working harp could be 100% printed from PLA, strings and all.

Please, please, please feel free to take this concept and run with it. I'd love to see what others can make using PLA strings.

Similar models

3dwarehouse

free

WIZ OF OZ GUITAR BY DOITALL

...wiz of oz guitar by doitall

3dwarehouse

please rate #guitar #instrument #play #string #strings #strum #tune

3dwarehouse

free

KONA FLATTOP GUITAR BY DOITALL

...excatly like this one...thought it would be fun to model it...please rate #flattop #guitar #instrument #play #string #strum #tune

cg_trader

$5

Harp Studio Max

...d strings. harp strings can be made of nylon (sometimes wound around copper), gut (more commonly used than nylon), wire, or silk.

thingiverse

free

A fretless dulcimer strum stick

...hould do it.

feel free to experiment with how you want to tune it. i've tuned it to dad and it sounds great and easy to play.

grabcad

free

Baby Harp 11 Strings Woodworking Project Kids Harp

...ar. unfortunately i don't remember what key i tuned mine to so you're gonna have to experiment. plans are also available.

3d_export

$39

Harp 3D Model

...oard 3ds max maya lxo c4d xsi fbx

harp 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl digitallab3d 106798 3dexport

cg_studio

$39

Harp3d model

...

.c4d .3ds .xsi .x .obj .max .ma .lxo .lwo .fbx - harp 3d model, royalty free license available, instant download after purchase.

grabcad

free

Harp Music instrument

...rough improvements in their design and construction through the beginning of the 20th century.

http://en.wikipedia.org/wiki/harp

grabcad

free

Rubber Band Harp

...ent! this harp has a full octave and can even be tuned. just print and add eight rubber bands, then you can start making music!

3dwarehouse

free

Harp concept

...harp concept

3dwarehouse

reduced concert harp, double stringing, impulse/toggle pedals, - tones without re-tuning #harp #reduced

Zither

3d_export

$28

Zither 3D Model

...g musical stinged old wood music play hobby hobbies yafaray 3ds blend obj realistic

zither 3d model energyoverflow 63988 3dexport

thingiverse

free

Scherrzither (German kind of a Drone Zither) by StreetPiet

....org/wiki/scheitholthttps://de.wikipedia.org/wiki/scherrzither

..or my uncle playing: https://www.youtube.com/watch?v=fdnnuv8cnwm

thingiverse

free

Tuning peg cap by rdrink

...for this tuning peg http://www.pinpegpickups.com/category-s/1824.htm for guitars, ukes, banjos, zither, ...

cg_trader

$2

zither

...zither

cg trader

3d model vr / ar ready zither zither guitar, available formats 3ds, fbx, blend, ready for 3d animation and ot

cg_trader

$26

Zither

...zither

cg trader

detailed model of an old style zither. ready for quality renders and close ups.

cg_trader

$19

Chinese zither stand

...ither stand

cg trader

3d model chinese zither stand zither stand, available formats max, obj, fbx, ready for 3d animation and ot

cg_trader

$29

Zither Chinese musical instrument

...nstrument

cg trader

3d model zither chinese musical instrument zither, formats max, obj, fbx, mdl, ready for 3d animation and ot

cg_trader

$3

Gu Qin Zither 3D Model

...er 3d model

cg trader

gu qin zither 3d model guqin chinese zither musical instrument, formats obj, ready for 3d animation and ot

cg_trader

$19

3D Zither Musical Instrument model

...ry plectrum pick resonating chamber sound box music song vintage old antique guitar medieval german lowpoly stl electronics other

Mintyfries

thingiverse

free

Sonic.EXE by MintyFries

...nic.exe made for the youtuber angry sonic.

here's a video about my sonic prints: https://www.youtube.com/watch?v=4pfmvfauude

thingiverse

free

Bee by MintyFries

...e approximations of a bee. this isn't exactly anatomically correct, but it's the best i could come up with in tinkercad.

thingiverse

free

Adventure Time Spinner by MintyFries

...please consider subscribing to my youtube page to see cool vr/360 tours of maps from video games: https://youtube.com/mintyfries

thingiverse

free

Mario Odyssey Spinner by MintyFries

...please consider subscribing to my youtube page to see cool vr/360 tours of maps from video games: https://youtube.com/mintyfries

thingiverse

free

Rocko's Modern Life Spinner by MintyFries

...please consider subscribing to my youtube page to see cool vr/360 tours of maps from video games: https://youtube.com/mintyfries

thingiverse

free

Hey Arnold! Spinner by MintyFries

...ey arnold! spinner by mintyfries

thingiverse

here's a video detailing how i made this spinner: https://youtu.be/6l295h6tlgs

thingiverse

free

Ocarina of Time Logo Paperweight by MintyFries

...

please consider subscribing to my youtube page to see cool vr/360 tours of maps from video games: https://youtube.com/mintyfries

thingiverse

free

Zelda Twilight Princess Spinner by MintyFries

...please consider subscribing to my youtube page to see cool vr/360 tours of maps from video games: https://youtube.com/mintyfries

thingiverse

free

Pokemon Cards Spinner by MintyFries

...d a video on my channel that shows how i modeled, printed, and painted this spinner: https://www.youtube.com/watch?v=2o6t0nd0dvs

thingiverse

free

(Slightly) Low Poly Charmander by MintyFries

...

please consider subscribing to my youtube page to see cool vr/360 tours of maps from video games: https://youtube.com/mintyfries

Harp

archibase_planet

free

Harp

...harp

archibase planet

harp musical instrument

harp n281213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

design_connected

$16

Harp

...harp

designconnected

jørgen christensens snedkeri harp computer generated 3d model. designed by høvelskov, jørgen.

turbosquid

$18

Harp

...rp

turbosquid

royalty free 3d model harp for download as c4d on turbosquid: 3d models for games, architecture, videos. (1458753)

turbosquid

$14

Harp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Roda / HARP 359

...roda / harp 359

3ddd

roda

roda harp 359 armchair

3d_export

$15

Harp 3D Model

...er pedal medieval musician celtic folk orchestra band musical classical classic chordophones

harp 3d model firdz3d 75447 3dexport

archive3d

free

Harp 3D Model

...harp 3d model

archive3d

harp - 3d model for interior 3d visualization.

3d_export

free

Harp

... 4096 -available formats: 3d s max _v ray blender obj -suitable for close-ups animation game interior design architectural object

turbosquid

free

Celtic Harp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Jew's harp

...#39;s harp for download as 3ds, obj, fbx, blend, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1394285)

Fully

turbosquid

$50

Drone fully rigged

...

royalty free 3d model drone fully rigged for download as max on turbosquid: 3d models for games, architecture, videos. (1282280)

turbosquid

$12

FULLY PARAMETRIC CHAIR

...alty free 3d model fully parametric chair for download as rvt on turbosquid: 3d models for games, architecture, videos. (1280209)

turbosquid

$10

firetruck-fully-rigged

...yalty free 3d model firetruck-fully-rigged for download as ma on turbosquid: 3d models for games, architecture, videos. (1653811)

turbosquid

$6

Fully rigged character

...ty free 3d model fully rigged character for download as blend on turbosquid: 3d models for games, architecture, videos. (1486076)

turbosquid

$3

Fully Rigged shark

...ee 3d model fully rigged 3d shark model for download as blend on turbosquid: 3d models for games, architecture, videos. (1517695)

turbosquid

$75

Fully Customizable Hospital

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Fully Rigged Link

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Troy W Fully Covered

...troy w fully covered

designconnected

magis troy w fully covered computer generated 3d model. designed by wanders, marcel.

cg_studio

$99

Pepe fully rigged3d model

...ully rigged3d model

cgstudio

.max - pepe fully rigged 3d model, royalty free license available, instant download after purchase.

3d_export

$60

Ankylosaur 8K - fully animated

...ankylosaur 8k - fully animated

3dexport

Printed

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints