Thingiverse

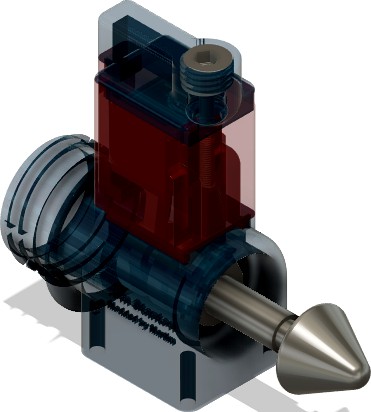

Fully 3D Printed Air Engine

by Thingiverse

Last crawled date: 5 years, 10 months ago

I decided to edit Tom Stanton's air engine and make it fully 3D Printable

(remove the need for screws, bearing, etc) here is the result

I went to 70PSI, but i cannot guarantee that it will work with you!

you can download the fusion 360 file is air-engine.f3d and edit if you want

https://www.youtube.com/watch?v=3OBtR_EZo9E

https://www.youtube.com/watch?v=YLPY8CY5Fm4&t=657s

for now just follow tom stanton's tutorial, the only major thing that changes is that the connecting rod is pressure fitted , and you use superglue to connect the cylinderhead

bearing is on the file 608, choose the one best fitted for your printer, I used 608_tight

Print settings:

Nozzle diameter - 0.2mm

Print width - 0.25mm

Layer height - 0.1mm

Top/Bottom layers - 6

Outer walls - 6

Infill - 50%

Infill type - Rectilinear

Material - PLA

Print speed - 50mm/s

Nozzle Temperature - 220c

Bed temperature - 40c

*These settings are required for this print. The other settings can be changed depending on your printer/filament.

Hardware required:

1pc Plastic bottle cap

1pc Presta valve (for tubeless tyres)

1pc Propeller (at least 8 inch in diameter)

1pc Rubber O-ring OD 8mm Cross section 2mm

Bike pump or compressor

fusion file is attached

(remove the need for screws, bearing, etc) here is the result

I went to 70PSI, but i cannot guarantee that it will work with you!

you can download the fusion 360 file is air-engine.f3d and edit if you want

https://www.youtube.com/watch?v=3OBtR_EZo9E

https://www.youtube.com/watch?v=YLPY8CY5Fm4&t=657s

for now just follow tom stanton's tutorial, the only major thing that changes is that the connecting rod is pressure fitted , and you use superglue to connect the cylinderhead

bearing is on the file 608, choose the one best fitted for your printer, I used 608_tight

Print settings:

Nozzle diameter - 0.2mm

Print width - 0.25mm

Layer height - 0.1mm

Top/Bottom layers - 6

Outer walls - 6

Infill - 50%

Infill type - Rectilinear

Material - PLA

Print speed - 50mm/s

Nozzle Temperature - 220c

Bed temperature - 40c

*These settings are required for this print. The other settings can be changed depending on your printer/filament.

Hardware required:

1pc Plastic bottle cap

1pc Presta valve (for tubeless tyres)

1pc Propeller (at least 8 inch in diameter)

1pc Rubber O-ring OD 8mm Cross section 2mm

Bike pump or compressor

fusion file is attached