Thingiverse

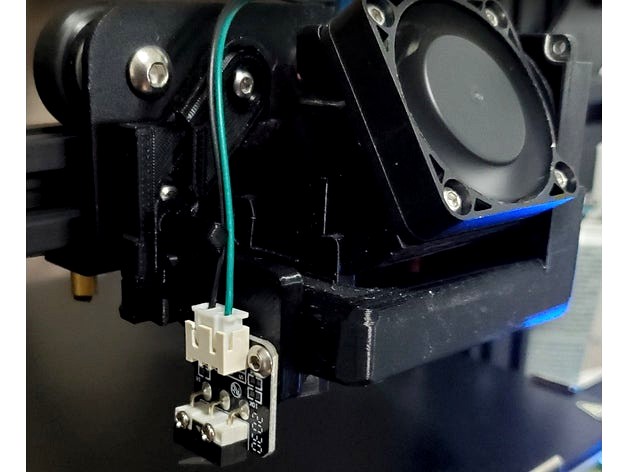

FreeABL V2 a major redesign for accuracy and convenience by urmamasllama

by Thingiverse

Last crawled date: 3 years, 1 month ago

This object was made in Tinkercad. Edit it online https://www.tinkercad.com/things/7d5wh50wxaE

Update V2.5 Made changes to the deploy bar assembly to tighten tolerances and give better coverage of the slideclip this is likely to be the last update for a while as I'm fairly happy with the current design I will update with a way to deal with the filament problem but that will likely be an existing solution elsewhere. I do hope to have a tutorial out soon to cover the full process.

Update V2.4 Tightened tolerances on the slideclip and changed the handle piece to work better with the deploy bar.

Update V2.3 Huge update.

Automatic deployment is now released! we have achieved full ABL on the cheap

Added a new stowage bar that requires not additional hardware

Made the slideclip easier to print and tightened up some tolerances in the slidelock

Demo of stowage and deployment https://www.youtube.com/watch?v=zn5f2ia9Gtk

Update V2.2 minor adjustment to the stowage bar and gcode

Update V2.1: Automated probe stowage.

A few small tweaks and a stick is all it took to automate stowing the probe for printing. I plan for deployment as well but I need to take some time planning it out. Files updated to make the change are indicated in their name. Instructions for implementing this will follow in the setup section here is a video to demo how it works https://www.youtube.com/watch?v=D1w-PWs0ABs.

To keep in the spirit of the original model I have designed this remix to only require stock parts and an extension of the Z-probe wire so that it can be run in the loom. To make that happen I had to make some precise pressure fit pieces. As such before attempting this design you will need to have a decent calibration of your printer. For that I recommend the teaching tech calibration guide https://teachingtechyt.github.io/calibration.html#intro

At minimum you should have your E-steps and flow rate tuned in, However I also strongly recommend having Linear advance enabled if possible. As long as you don't have a creality silent mainboard you should be able to do so. Additionally I strongly recommend printing on a raft. This is to counteract elephants foot to improve accuracy further and reduce the post processing needed on the prints

This project is still evolving and I have some amazing additions coming so keep an eye out.

Update V2.5 Made changes to the deploy bar assembly to tighten tolerances and give better coverage of the slideclip this is likely to be the last update for a while as I'm fairly happy with the current design I will update with a way to deal with the filament problem but that will likely be an existing solution elsewhere. I do hope to have a tutorial out soon to cover the full process.

Update V2.4 Tightened tolerances on the slideclip and changed the handle piece to work better with the deploy bar.

Update V2.3 Huge update.

Automatic deployment is now released! we have achieved full ABL on the cheap

Added a new stowage bar that requires not additional hardware

Made the slideclip easier to print and tightened up some tolerances in the slidelock

Demo of stowage and deployment https://www.youtube.com/watch?v=zn5f2ia9Gtk

Update V2.2 minor adjustment to the stowage bar and gcode

Update V2.1: Automated probe stowage.

A few small tweaks and a stick is all it took to automate stowing the probe for printing. I plan for deployment as well but I need to take some time planning it out. Files updated to make the change are indicated in their name. Instructions for implementing this will follow in the setup section here is a video to demo how it works https://www.youtube.com/watch?v=D1w-PWs0ABs.

To keep in the spirit of the original model I have designed this remix to only require stock parts and an extension of the Z-probe wire so that it can be run in the loom. To make that happen I had to make some precise pressure fit pieces. As such before attempting this design you will need to have a decent calibration of your printer. For that I recommend the teaching tech calibration guide https://teachingtechyt.github.io/calibration.html#intro

At minimum you should have your E-steps and flow rate tuned in, However I also strongly recommend having Linear advance enabled if possible. As long as you don't have a creality silent mainboard you should be able to do so. Additionally I strongly recommend printing on a raft. This is to counteract elephants foot to improve accuracy further and reduce the post processing needed on the prints

This project is still evolving and I have some amazing additions coming so keep an eye out.

Similar models

thingiverse

free

Kossel Mini z-probe deployment by jones66

...nd the right position for deployment when you move your z-probe manual to the new deployment position an hit m114 in pronterface)

thingiverse

free

Kossel Clear auto calibration probe deployment post by barneyj

... used to retract the probe. the bolt is covered with some heat shrink tubing.

see it in use here: http://youtu.be/ft3f_rupb9k

thingiverse

free

Ultimaker Retracting Z-Probe by destroyer2012

...again!

video here http://www.youtube.com/watch?v=a-a90wp4wus

or maybe do because this thing doesn't work perfectly. wip!

thingiverse

free

Printer Calibration Block by Zmotive

...it better and corrected the stl so it is in the correct orientation and scale for printing. so it is a simple download and print.

thingiverse

free

Extruder Calibration Test Rectangle by v3ctors

...n. https://www.youtube.com/watch?v=89bhs9hfsuk

next, i would calibrate your extruder. https://www.youtube.com/watch?v=yupfbjz3i6y

grabcad

free

Self-Deploying Heliostat System based on a Spring made out of Shape Memory Polymers

...eployable concept idea

https://www.youtube.com/watch?v=fgwnqu0t2ou

locking mechanism

https://www.youtube.com/watch?v=vlcqlceecb8

thingiverse

free

SCTouch DIY BLTouch Z Probe by chanders

...ere is interest i’ll update with a non-manual solution.

https://www.facebook.com/shivanand.chanderbally/videos/10155084090041863/

thingiverse

free

1-100 truck pack by SnowLeopard101

... of them so that it will have stowage space. to view my other designs go here:

https://www.thingiverse.com/snowleopard101/designs

thingiverse

free

20mm XYZ Calibration Cube by sjdennis

...ignment, so you can make minor adjustments to achieve more accurate dimensions in your parts.

hope you enjoy, and happy printing.

thingiverse

free

3 piece puzzle by OpenScadDad

...e sanding and smoothing.

you will need to print this 3 times to make all of the pieces. i have not printed this out to check it.

Freeabl

thingiverse

free

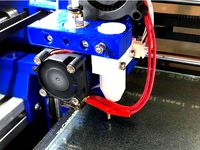

FreeABL Mount With Stowing Socket

... does not cover the side vents of the stock hotend shroud. requires the z-stop clip from the original freeabl source, obviously.

thingiverse

free

Z-19 FreeABL mount

...z-19 freeabl mount

thingiverse

this is a remix of another mount, slightly beefed up, untested. print at your own risk.

thingiverse

free

Bullseye RHS mount for FreeABL switch by FeNi64

...ese seem to work (the switch is 50mm to the right, 10mm in front and 4mm below the nozzle)

nozzle_to_probe_offset { 50, -10, -4 }

thingiverse

free

Bullseye LHS mount for FreeABL switch by FeNi64

...e found that the z-offset needs to be adjusted when you change the nozzle. enable babystep_zprobe_offset to have it on the menu.

thingiverse

free

FreeABL - Left Hand Version for Hero Mero V3 and Direct Drive Mod by AppleAssassin

...eabl allen key mod because my direct drive mod was in the way.

works well with the direct drive mod and herome v3 mods installed.

thingiverse

free

FreeABL Mount for Z-19 UNTESTED

...runs really low, so you might have to adjust your firmware min z probe offset, and height after homing.

if it works, let me know.

thingiverse

free

Allen Key ABL - FreeABL - For Hero Me Remix by xchgre

...ge endstop:https://www.myminifactory.com/es/object/3d-print-ender-3-x-axis-stepper-motor-damper-mount-for-press-fit-pulleys-89997

thingiverse

free

Hero Me Gen 5 FreeABL Mount by p047

...r stl file if you need a place to put the endstop when it's finished probing. you will need to print it with support however.

thingiverse

free

FreeABL - the ultra cheap (free) ABL for Ender 3 Optimized by Sebastiandruckt

...ve sensor. however i managed to print petg with this abl without additional adhesion stuff and it helped me a lot for some weeks.

Accuracy

turbosquid

$15

Accuracy International Weapon

...ee 3d model accuracy international weapon for download as obj on turbosquid: 3d models for games, architecture, videos. (1217320)

turbosquid

$5

Accuracy International AWM

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Accuracy International L96A1 / Arctic Warfare

...роизводства: середина 1980-х. масса, кг: 6,8 (без оптического прицела) длина, мм: 1124—1194. длина ствола, мм:. 22" (655 мм)

humster3d

$75

3D model of Accuracy International AS50

... 3d model of accuracy international as50 in various file formats. all our 3d models were created maximally close to the original.

3d_export

$99

Accuracy International Arctic Warfare L96A1 3D Model

...ctic warfare british weapon gun l96a1 rifle sniper

accuracy international arctic warfare l96a1 3d model humster3d 101360 3dexport

turbosquid

$10

Kitchen Set - High Accuracy 3D model

...set - high accuracy 3d model for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1537682)

turbosquid

$1

Accuracy International AWM sniper rifle with scope

...m sniper rifle with scope for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1386281)

humster3d

$75

3D model of Accuracy International Arctic Warfare (L96A1)

...acy international arctic warfare (l96a1) in various file formats. all our 3d models were created maximally close to the original.

cg_studio

$99

Accuracy International Arctic Warfare (L96A1)3d model

...d .3ds - accuracy international arctic warfare (l96a1) 3d model, royalty free license available, instant download after purchase.

3d_export

$5

apple emblem

...emblem 3dexport the apple logo in 3d model, high accuracy & nice curves, the only model in the world...

Major

design_connected

$16

Major majbi-a

...major majbi-a

designconnected

sitia major majbi-a computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majai-a

...major majai-a

designconnected

sitia major majai-a computer generated 3d model. designed by dorigo, florenzo.

3d_ocean

$16

Marshall Headphones Major

...marshall headphones major

3docean

headphones major marshall

marshall headphones major

turbosquid

$25

Major balustrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Major majbi-h

...major majbi-h

designconnected

sitia major majbi-h computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majai-h

...major majai-h

designconnected

sitia major majai-h computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majai-d

...major majai-d

designconnected

sitia major majai-d computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majai-c

...major majai-c

designconnected

sitia major majai-c computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majbi-b

...major majbi-b

designconnected

sitia major majbi-b computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majbi-c

...major majbi-c

designconnected

sitia major majbi-c computer generated 3d model. designed by dorigo, florenzo.

Redesign

3d_ocean

$45

Hyundai SUV vehicle redesigned

...was redesigned by me. 3d model was created in blender3d.preview images were rendered with realistic plugin yafaray.side view o...

turbosquid

$25

Pagani Huayra Redesign

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Colt M16 (Redesign)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

3D for Pose Scarlet Witch redesign\para Posar redesign Feiticeira Escarlate

... imprimir redesign feiticeira escarlate for download as blend on turbosquid: 3d models for games, architecture, videos. (1700850)

3d_export

$5

Gaz 21 redesign 3D Model

...gaz 21 redesign 3d model

3dexport

gaz 21 volga

gaz 21 redesign 3d model rossergorp 71511 3dexport

turbosquid

$55

Porsche Cayman 2015 redesign

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$55

Gallardo superleggera redesign

...model was made with blender3d 2.62.preview images were rendered with blender3d and yafaray 0.1.2 realistic rendering engine.ob...

3d_ocean

$55

Chevy Stingray 2013 redesign

...car.i gave my best to create accurate model,but without top view image it wasn’t possible for me.so when i lost a lots of nerv...

turbosquid

$30

Redesign Crash Bandicoot (c4d,obj,max,zpr)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Tango Floor Lamp

...3ddd andrey kole , tango , castlewerks andrey kole redesign tango floor lamp by castlewerks. 3dsmax2012 - corona...

Convenience

3d_export

$30

convenience

...convenience

3dexport

convenience

turbosquid

$50

Desert Convenience Store

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

convenience store

... materials. features: uv unfolded. udim texturing. all materials, textures are included. no special plug-in needed to open scene.

3d_export

$101

convenience store 0001

...s, v-ray 3.4 material for 3ds max 2016 compatible guaranteed. for any questions, please contact us and we'll respond quickly.

turbosquid

$20

JAPANESE CONVENIENCE STORE 23-417 N-HO-OO GAUGE SCENERY

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$12

Chair

...chair 3docean chair convenience sit chair,sit,convenience ...

3d_export

free

exhibition item

...exhibition item

3dexport

convenient for interior design

3d_export

$5

desktop

...desktop

3dexport

desktop with shelving. very convenient and practical find.

3d_export

$40

Store Spaces 034 3D Model

...spaces 034 3d model 3dexport merchandise store general convenient convenience food merch candy chips junk coffee shelves shelving display...

3d_export

$40

Store Spaces 007 3D Model

...spaces 007 3d model 3dexport merchandise store general convenient convenience food merch candy chips junk coffee shelves shelving display...

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

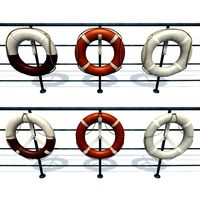

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)