GrabCAD

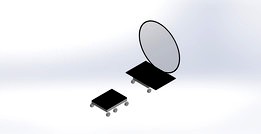

FNL Gradient Index Flexible Film Lens Inflatable to Rigid Frame Heliostat

by GrabCAD

Last crawled date: 2 years, 7 months ago

Gradient Index Flexible Film Lens Inflatable to Rigid Frame Heliostat

Est. Weight of Lens System: 21.36 kilograms

Est. Volume of Lens System: 0.012 m^3

Area of Lens (or less desirable Metalized Film): 12.6 m^2

Please Click On Show More for Additional Details and Fabrication Notes

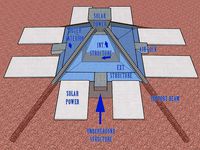

The exterior construction is of a layered composition over wrapping an interior pressure bladder or inner tube. The layering is such as the exterior layer is for restricting the expansion of the inner tube as well as providing for encapsulating the assembly in an air tight manner, the intermediate layer is a prepreg carbon fiber composition, and the interior pressure tube. To deploy the interior tube is inflated from either an onboard tank of a gas generator or a high pressure gas. The tank should designed such upon deployment it can either double as a sample storage container or the container itself should also house low packing density sub-components of the rover with appropriate bulkheads. Such that a portion of the rover could even be designed as a monocoque hull to provide for the pressure vessel and housing of components etc. The pressure of the inner tube against the exterior layer in addition to the high temperature during the lunar day and the intentional black body form of the expanding frame should provide sufficient heat but not sufficient for curing as the Tg to maintain structural stability needs to be higher than the lunar day temperature, such that with an added flexible heat tape running in the tube or on the exterior additional heat is provided merely for the initial cure, provides for the curing of the prepreg carbon form such that pressure need not be maintained longer than the duration of curing for structural stability. In that the prepreg epoxy is chosen such that its curing temperature is chosen to maintain a Tg higher than that of the lunar day temperature high structural integrity will be maintained during normal lunar day temperatures. It should be noted that additional layered tubes could be provided for further structural support as required or to provide for structural framework etc.

The web of this version is comprised of a gradient index flexible thin film. The film could be provided with thin exterior films to minimize damage and extend life against UV exposure. The gradient index film could be fabricated using either partial polymerization or direct laser writing methods of manufacturing. If partial polymerization is utilized it is suggested that a UV laser source is used in a cnc system to provide a highly tuned fabrication process for the variation of the refractive index.

To keep the film as thin as possible it is likely best to have one solid surface area with a plurality of gradient index lenses formed in the thin film as the total film area increases. Or if optic considerations allow a single lens may suffice depending on focal lengths and desired surface area etc. That is, it should be noted, that there are slight tradeoffs in the simplicity/complexity of the lens fabrication, thickness, focal length, and total desired area. As the area increases over the proposed 12 m^2 the complexity of fabrication increases etc. Although the focal length is generally understood to be considerable a plurality of lens portions within the singular film should not be required and a single film could be used to simplify mfg.

Another method of fabrication for the gradient index film, as to the best of my knowledge, untested by conventional standards is the use of 3D printing whereby the stock material itself could be augmented as deposited onto a thin film as the substrate. This could further produce a novel structure for a gradient index thin film fresnel lens to further lightweight the film and total system weight. Here it should be noted that whereas such a method would likely be insufficient for optical systems it should far outperform mirror surface types of power transmission due to the inherent fact that it is not only the flatness of the surface it is also the combined directional accuracy of multi part arrays that must be addressed as any deviation between the plates would compromise the output. Herein the proposed concept a monolithic lens would far out perform other systems.

Further should the thickness of the gradient index lens need increased flexibility could be maintained through the use of stacked thin sheets for the web with the appropriate gradient index applied to each sheet. This would allow and maintain for flexible and pliable storage while greatly increasing the level of convergence versus a single monolithic lens in thickness which would be inflexible etc. Here as the intention is to focus for power transmittance approaching the level of optics is not necessarily required allowing for slight misalignment between layers while still outperforming the mirror alternative in performance and weight etc. Such a construction method would also negate such a need for a near perfectly flat surface although the proposed structure once cured should sufficiently meet the flat surface requirement nonetheless.

(While the gradient index should be sufficient for focusing the solar power other implementations could be employed such as having a layered film composite whereby an intermediate layer could be constructed in a traditional manner of a Fresnel lens utilizing a tilting axis cnc laser system. Although this would be less preferred regarding manufacturing and performance.)

The lens could be operated such as to provide for parallel ray illumination or could be turned 180 to allow converging rays for specific targeting of solar arrays on opposing rover(s) for rapid recharging.

The prepreg thickness may need adjusted dependent on expected loading requirements due to rover motion and required rates of adjustment of the lens position.

Alternate Mirror Film Heliostat

The web of this version is fabricated from a thin metalized film. The structural prepreg members could be further augmented such as to provide a frame for a parabolic or other shaped mirror form for focusing.

Solar Panels

Solar panels are kept on the rover in a conventional manner as the clear gradient index Fresnel lens will not impact the loads severely. In addition adding the weight of the solar panel to the heliostat would increase the size and power requirements of actuators. For the mirror metalized film the solar panel could be added to the system merely by having the inflatable prepreg carbon structure account for mounting of the panel and increasing the overall size to account for the decreased surface area of the metalized film.

Operation

The subsystems of conventional design such as solar intensity sensors, antenna, and 2 axis tracking motors are not shown. Conventional systems are sufficient for panning however the one alteration for the tilt is to use two scissor screw type jack actuators at the base with rotating connecting points such as to minimize the size of the alternate components due to the torque load required for quick alterations to tilt. Simple “boots” or covers are provided at these locations to mitigate concerns regarding lunar dust. Another beneficial component to reduce weight is to have motors operating in pairs and located by components requiring heating for operation, instead of adding a separate heat source the motors in pairs could be actuated in opposition producing no motion of the system but to produce heat for those required components a simple temperature sensor could ensure that the loads on the motors do not exceed their capacity.

During Transit

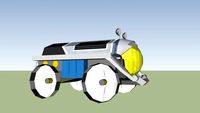

During travel the lens system merely tilts to parallel with the top surface of the rover to lower the center of gravity etc. Other supports for the lens could be provided in a manner similar to motorized artillery vehicles where the barrel is supported such as to further provide support to the lens during travel.

Technical Details as Shown

Approximate Weight of Lens: 21.36 kilograms

This weight could vary depending on the required thickness of the gradient index film for the required focal lengths. As well for the metalized mirror web if additional structural prepreg tubes are required the weight would increase accordingly.

Approximate Volume of Lens: 0.012 m3

Packaging or cube is enhanced due to the overall flexibility of the system such that it could be fitted into crevices so long as testing indicates free form removal upon actuation of the gas generating chemical combination or from a high pressure gas. As shown the lens is merely folded in a flat rectangular form.

Est. Weight of Lens System: 21.36 kilograms

Est. Volume of Lens System: 0.012 m^3

Area of Lens (or less desirable Metalized Film): 12.6 m^2

Please Click On Show More for Additional Details and Fabrication Notes

The exterior construction is of a layered composition over wrapping an interior pressure bladder or inner tube. The layering is such as the exterior layer is for restricting the expansion of the inner tube as well as providing for encapsulating the assembly in an air tight manner, the intermediate layer is a prepreg carbon fiber composition, and the interior pressure tube. To deploy the interior tube is inflated from either an onboard tank of a gas generator or a high pressure gas. The tank should designed such upon deployment it can either double as a sample storage container or the container itself should also house low packing density sub-components of the rover with appropriate bulkheads. Such that a portion of the rover could even be designed as a monocoque hull to provide for the pressure vessel and housing of components etc. The pressure of the inner tube against the exterior layer in addition to the high temperature during the lunar day and the intentional black body form of the expanding frame should provide sufficient heat but not sufficient for curing as the Tg to maintain structural stability needs to be higher than the lunar day temperature, such that with an added flexible heat tape running in the tube or on the exterior additional heat is provided merely for the initial cure, provides for the curing of the prepreg carbon form such that pressure need not be maintained longer than the duration of curing for structural stability. In that the prepreg epoxy is chosen such that its curing temperature is chosen to maintain a Tg higher than that of the lunar day temperature high structural integrity will be maintained during normal lunar day temperatures. It should be noted that additional layered tubes could be provided for further structural support as required or to provide for structural framework etc.

The web of this version is comprised of a gradient index flexible thin film. The film could be provided with thin exterior films to minimize damage and extend life against UV exposure. The gradient index film could be fabricated using either partial polymerization or direct laser writing methods of manufacturing. If partial polymerization is utilized it is suggested that a UV laser source is used in a cnc system to provide a highly tuned fabrication process for the variation of the refractive index.

To keep the film as thin as possible it is likely best to have one solid surface area with a plurality of gradient index lenses formed in the thin film as the total film area increases. Or if optic considerations allow a single lens may suffice depending on focal lengths and desired surface area etc. That is, it should be noted, that there are slight tradeoffs in the simplicity/complexity of the lens fabrication, thickness, focal length, and total desired area. As the area increases over the proposed 12 m^2 the complexity of fabrication increases etc. Although the focal length is generally understood to be considerable a plurality of lens portions within the singular film should not be required and a single film could be used to simplify mfg.

Another method of fabrication for the gradient index film, as to the best of my knowledge, untested by conventional standards is the use of 3D printing whereby the stock material itself could be augmented as deposited onto a thin film as the substrate. This could further produce a novel structure for a gradient index thin film fresnel lens to further lightweight the film and total system weight. Here it should be noted that whereas such a method would likely be insufficient for optical systems it should far outperform mirror surface types of power transmission due to the inherent fact that it is not only the flatness of the surface it is also the combined directional accuracy of multi part arrays that must be addressed as any deviation between the plates would compromise the output. Herein the proposed concept a monolithic lens would far out perform other systems.

Further should the thickness of the gradient index lens need increased flexibility could be maintained through the use of stacked thin sheets for the web with the appropriate gradient index applied to each sheet. This would allow and maintain for flexible and pliable storage while greatly increasing the level of convergence versus a single monolithic lens in thickness which would be inflexible etc. Here as the intention is to focus for power transmittance approaching the level of optics is not necessarily required allowing for slight misalignment between layers while still outperforming the mirror alternative in performance and weight etc. Such a construction method would also negate such a need for a near perfectly flat surface although the proposed structure once cured should sufficiently meet the flat surface requirement nonetheless.

(While the gradient index should be sufficient for focusing the solar power other implementations could be employed such as having a layered film composite whereby an intermediate layer could be constructed in a traditional manner of a Fresnel lens utilizing a tilting axis cnc laser system. Although this would be less preferred regarding manufacturing and performance.)

The lens could be operated such as to provide for parallel ray illumination or could be turned 180 to allow converging rays for specific targeting of solar arrays on opposing rover(s) for rapid recharging.

The prepreg thickness may need adjusted dependent on expected loading requirements due to rover motion and required rates of adjustment of the lens position.

Alternate Mirror Film Heliostat

The web of this version is fabricated from a thin metalized film. The structural prepreg members could be further augmented such as to provide a frame for a parabolic or other shaped mirror form for focusing.

Solar Panels

Solar panels are kept on the rover in a conventional manner as the clear gradient index Fresnel lens will not impact the loads severely. In addition adding the weight of the solar panel to the heliostat would increase the size and power requirements of actuators. For the mirror metalized film the solar panel could be added to the system merely by having the inflatable prepreg carbon structure account for mounting of the panel and increasing the overall size to account for the decreased surface area of the metalized film.

Operation

The subsystems of conventional design such as solar intensity sensors, antenna, and 2 axis tracking motors are not shown. Conventional systems are sufficient for panning however the one alteration for the tilt is to use two scissor screw type jack actuators at the base with rotating connecting points such as to minimize the size of the alternate components due to the torque load required for quick alterations to tilt. Simple “boots” or covers are provided at these locations to mitigate concerns regarding lunar dust. Another beneficial component to reduce weight is to have motors operating in pairs and located by components requiring heating for operation, instead of adding a separate heat source the motors in pairs could be actuated in opposition producing no motion of the system but to produce heat for those required components a simple temperature sensor could ensure that the loads on the motors do not exceed their capacity.

During Transit

During travel the lens system merely tilts to parallel with the top surface of the rover to lower the center of gravity etc. Other supports for the lens could be provided in a manner similar to motorized artillery vehicles where the barrel is supported such as to further provide support to the lens during travel.

Technical Details as Shown

Approximate Weight of Lens: 21.36 kilograms

This weight could vary depending on the required thickness of the gradient index film for the required focal lengths. As well for the metalized mirror web if additional structural prepreg tubes are required the weight would increase accordingly.

Approximate Volume of Lens: 0.012 m3

Packaging or cube is enhanced due to the overall flexibility of the system such that it could be fitted into crevices so long as testing indicates free form removal upon actuation of the gas generating chemical combination or from a high pressure gas. As shown the lens is merely folded in a flat rectangular form.

Similar models

grabcad

free

Gradient Index Flexible Film Lens Inflatable to Rigid Frame Heliostat

...e gas generating chemical combination or from a high pressure gas. as shown the lens is merely folded in a flat rectangular form.

grabcad

free

Gradient Index Flexible Fresnel Lens Inflatable to Rigid Frame Heliostat

...e gas generating chemical combination or from a high pressure gas. as shown the lens is merely folded in a flat rectangular form.

grabcad

free

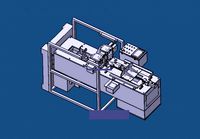

PenTRAY

...m proximity.

the model has greater flexibility and solar panels which will give the heliostat to work under difficult conditions.

grabcad

free

Lunar heliostat

...all motor inside every central tube is used for reeling tape while stowing heliostat. the structure is easily scalable in height.

grabcad

free

Solar tube lunar torch

...ces where heliostat can't redirect sunlight. the size of the tube is 29 inches so it is almost equal to the normal heliostat.

grabcad

free

ALLGO crane (An Advanced Lightweight Lunar gantry for Operations)

... cover system. the load force is borne by this structure, but the tube is responsible for keeping the structure open and opening.

grabcad

free

Lunar inflated structure heliostat

...which air will be pumped into supporting structure and controls the orientation of inflated structure which has reflector surface

grabcad

free

Lunar Torch

...that provides power for onboard electronics. heliostat is folded similar to simple hand fan and deployed using spring loaded...

3dwarehouse

free

Lunox Pressurized Lunar Rover

...uld house all four astronauts in an emergency as a safeguard against catastrophic failure. #lunar_rover #lunox #pressurized_rover

grabcad

free

Mobile Lunar Heliostat

...s the capsulation process very easy. the weight of the rover is about one ton, which makes it carryable with the regular rockets.

Fnl

grabcad

free

Platform scale load cell 350kg 200kg 100kg 60kg

...400x400mm,load capacities available in 60kg 100kg 200kg 350kg.loadcell model fnl ...

grabcad

free

Platform scale load cell 350kg 200kg 100kg 60kg weight sensor

...400x400mm,load capacities available in 60kg 100kg 200kg 350kg.weight transducer fnl ...

3dwarehouse

free

mn fnl

...mn fnl

3dwarehouse

3dwarehouse

free

casa fnl

...casa fnl

3dwarehouse

sketchup

3dwarehouse

free

Logo FC Baikal Irkutsk

...founded in 2009. it was relegated from the second-tier fnl back to pfl at the end of the 2015–16...

Heliostat

3d_export

$199

Solar Power Plant 3D Model

...plant 3d model 3dexport solar power plant industrial helios heliostat modern energy station tower sun panel farm solar power...

thingiverse

free

Heliostat by DamianPaton

...cale from the heliostat by arisolar (all right reserved). this model shows the new 2 axis motion system (spinning and elevation).

thingiverse

free

Conie the Heliostat by Cod

...e it is rain protected.

stepper motore i've used 42byghw208. for use with inductive limit switches(lj12a3-4-z/by)

have fun!

thingiverse

free

Heliostat Solar Sensor support structure by Daedelus

...nting at the brightest spot.

the two parts are superglued together so that the smaller part functions as an attachment bracket.

thingiverse

free

Pan Tilt Mechanism for 28BYJ-48 Motors by zimirken

...towards an ideal design for a heliostat. speaking of heliostat, included is a mounting bracket for a mirror or...

thingiverse

free

solar sensor one axis by arduinomastercomau

...upload another design that is more suitable for a heliostat ...

free3d

$30

TURBOSPAIN SOLAR PLANT

...it uses an array of flat, movable mirrors (called heliostat) to focus the sun's rays upon a collector tower...

thingiverse

free

Mars Habitat Concept by sjwaldron

...dual solar collection system, both solar power tower with heliostat and photovoltaic type devices would be...

grabcad

free

lunar heliostat

...lunar heliostat

grabcad

lunar heliostat

cg_trader

$33

AT heliostat

...g formula’s. see the 'purchasing_the_models' link at appropedia's at_cad_team for additional information on the model

Gradient

turbosquid

$5

Gradient Teapot

... 3d model gradient teapot for download as obj, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1439831)

turbosquid

$20

CURTAINS GRADIENT

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Gradient Art Pack

...

royalty free 3d model gradient art pack for download as max on turbosquid: 3d models for games, architecture, videos. (1578564)

3ddd

$1

Журнальный столик от Gradient Matter

... стол , gradient matter

журнальный столик от gradient matter

3d_export

$5

Steep gradient sign 3D Model

...hicle motor way traffic car pedestrian signal circle round stop junction

steep gradient sign 3d model dragosburian 89427 3dexport

3d_ocean

$1

Steep gradient sign

... the object is ready to import and render in both formats. the model has been built to be able to subdivide flawlessly for a s...

turbosquid

$1

energy saving table lamp modern nickel-matt with orange gradient

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

table lamp modern nickel-matt with orange-yellow gradient opaque

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

womens shoes

...womens shoes 3dexport women's shoes. high heel. gradient ...

3ddd

free

Arteriors lamp

...arteriors lamp 3ddd arteriors , gradient , ocean настольная ласпа arteriors в морском...

Inflatable

3d_ocean

$25

Inflatable boat

...inflatable boat

3docean

boat boat egine inflatable boat water

high poly inflatable boat 33.352 polys

3d_ocean

$25

Inflatable Tent Exterior

...table tent

promotional inflatable tent exterior look. it comes with flags. and an inflatable arc. surrounded with metalic fences.

3d_export

$5

shock absorber inflator

...shock absorber inflator

3dexport

shock absorber inflator

3d_export

$13

inflatable castle

... castles have been suggested as having some therapeutic value for children with certain sensory impairments, similar to ball pits

3d_export

$5

inflatable pool toys

...inflatable pool toys

3dexport

inflatable pool toys with mapping

turbosquid

$6

Inflatable Climbing

...d

royalty free 3d model inflatable climbing for download as on turbosquid: 3d models for games, architecture, videos. (1298328)

turbosquid

$129

inflatable pool

...id

royalty free 3d model inflatable pool for download as max on turbosquid: 3d models for games, architecture, videos. (1650023)

turbosquid

$25

Inflatable boat

...

royalty free 3d model inflatable boat for download as blend on turbosquid: 3d models for games, architecture, videos. (1586932)

turbosquid

$5

Inflatable tent

...id

royalty free 3d model inflatable tent for download as c4d on turbosquid: 3d models for games, architecture, videos. (1622474)

3d_export

$5

boat inflatable

...boat inflatable

3dexport

Index

turbosquid

$15

Hand index

...bosquid

royalty free 3d model hand index for download as ige on turbosquid: 3d models for games, architecture, videos. (1338657)

3d_export

$5

Hanger Kare Coat Rack Index 78232 3D Model

...ndex hanger

hanger kare coat rack index 78232 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl alt.s 109750 3dexport

3ddd

$1

Вешалка Kare Coat Rack Index,78232

...азмеры-210/660/55

ссылка на оригиналhttp://www.kare-design.com/ru/shop28085/products/catalog/product_detail/78232/37/4/

turbosquid

$1

RGD-5 (a hand grenade, remote, GRAU index - 57-D-717)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$39

valve index vr headset with controllers and sensors - full kit

...is available in 3ds max for vray next gpu render. please use your own hdri map.<br>sincerely yours, motionblur studios team

3ddd

$1

На перезаливку

...перезаливку 3ddd тумба , комод , постельное белье , index living mall , missouri фабрика index living mall (таиланд)...

3ddd

free

Кровать MISSOURI

...кровать missouri 3ddd кровать , тумба , комод , index living mall , missouri , постельное белье фабрика index...

3ddd

free

MARCO POLO

...комод бельевой marco polo spa-mp-05 зеркало настенное marco polo spa-mp-09http://www.olimar.ru/item.asp?index3283 http://www.olimar.ru/item.asp?index=3287 ...

3ddd

free

Дикарт Дюна

...дикарт дюна 3ddd дикарт , панель стеновая панель дикарт дюнаhttp://www.dikart.ru/indexpanel/duna/ ...

3ddd

free

MOBILIDEA ATHENA VETRINA - DISPLAY CABINET

...athena vetrina - display cabinet 3ddd витрина , mobilidea http://www.medea.it/it/products/mobilidea/day/indexamp;nbsp; ...

Rigid

turbosquid

$15

Rigid Bag Filter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Rigid body Cube

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

Semi Rigid Rubberduck 3D Model

... tender yacht marine boat rigid bottom inflatable dinghy run-around 38m

semi rigid rubberduck 3d model southdesign 32727 3dexport

turbosquid

$35

Among Us Rigid Character

...among us rigid character for download as blend, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1637362)

3d_export

$15

Rigid Bag Filter 3D Model

...rigid bag filter 3d model

3dexport

filter bag clean air ahu conditioning

rigid bag filter 3d model matvic 85845 3dexport

3d_export

$60

Rabbit Rigid 3D Model

...oe hare burrow long ears pet 3d realistic rigged white brown fur small cute mammal

rabbit rigid 3d model scorpio47 78247 3dexport

cg_studio

$119

Mercedes Antos rigid truck3d model

... .fbx .lwo .max .obj .xsi - mercedes antos rigid truck 3d model, royalty free license available, instant download after purchase.

3d_export

$119

Mercedes Antos rigid truck 3D Model

...os actros van boxtruck trailer heavy daimler german european rigid

mercedes antos rigid truck 3d model fisherman3d 66670 3dexport

3d_export

$50

of a hydrofoil board with a rigid wing sail

...model is made in the form of: hull parts, sail parts, as well as a ballast centerboard and keel.<br>all peace and goodness.

turbosquid

$12

Device for loading and unloading of non-rigid CME roller tracks

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Lens

3d_ocean

$16

Lens

...lens

3docean

camera film lens video widescreen

a standard camera lens with reflections.

3d_export

$15

Lens optical lens 3D Model

...odel

3dexport

lens optical accessories for the tablet accessories electronics

lens optical lens 3d model sergio108 76763 3dexport

turbosquid

$1

Lens

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Massive / Len

...massive / len

3ddd

massive , встроенный

светильник потолочный massive len

3d_ocean

$9

50mm Canon lens

...50mm canon lens

3docean

50mm canon foto lens photo

canon lens 50mm 1.8 the most practical affordable lens to start with

turbosquid

$20

Camera Lens

...osquid

royalty free 3d model camera lens for download as c4d on turbosquid: 3d models for games, architecture, videos. (1414988)

turbosquid

$2

Axicon Lens

...osquid

royalty free 3d model axicon lens for download as max on turbosquid: 3d models for games, architecture, videos. (1169215)

turbosquid

free

Camera Lens

...quid

royalty free 3d model camera lens for download as blend on turbosquid: 3d models for games, architecture, videos. (1546983)

turbosquid

$2

MAGNIFYING LENS

...y free 3d model magnifying lens for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1633553)

turbosquid

$1

MAGNIFYING LENS

...y free 3d model magnifying lens for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1633707)

Flexible

turbosquid

$5

Flexible Pencils

...id

royalty free 3d model flexible pencils for download as ma on turbosquid: 3d models for games, architecture, videos. (1572382)

turbosquid

$5

Flexible Building

...el flexible building for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1394743)

turbosquid

$15

DODGE FLEXIBLE COUPLING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

flexible pipe manometer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Flexible Desk Lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$9

Flexible Desk Lamp 3D Model

...scritorio lamp lampara house casa accesories accesorios iluminacion ilumination

flexible desk lamp 3d model jff111 45153 3dexport

turbosquid

$15

FLEXIBLE EXHAUST PIPE(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$8

Flexible Modern Faucet

...4 and rendered with mental ray. all materials are included in file. included in the zip file: 3ds max (2012-2014), 3ds, dxf, f...

3d_export

$7

flexible escalator

...is done with 3ds max 2015 version with v-ray sharers. please visit my other projects. if you like this product - rate it! thanks!

turbosquid

$20

Flexible Camera Tripod Low Poly

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Frame

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n071113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Frame

...frame

3ddd

frame

3ddd

free

Frame

...frame

3ddd

frame

archibase_planet

free

Frame

...frame

archibase planet

frame mirror frame ornament

frame n260113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame photo n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window frame window

frame 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame wall frame decoration

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Film

3d_export

$65

filming

...filming

3dexport

simple rendering of the scene file

design_connected

$16

Oka Film

...oka film

designconnected

nkuku oka film computer generated 3d model.

turbosquid

$80

Film Actress2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Film Reel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Film Projector

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Film Strip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Film clapper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$8

Photographic Film

...n texture

- realistic highly detailed and animation ready photographic film - adjustable photographic tape (by curve) - textured

turbosquid

$4

film reel

...rbosquid

royalty free 3d model film reel for download as c4d on turbosquid: 3d models for games, architecture, videos. (1212542)

3d_export

$65

film base

...film base

3dexport

simple rendering of the scene file