GrabCAD

Fluid Pressure Assisted Single Point Incremental Forming(SPIF)

by GrabCAD

Last crawled date: 1 year, 11 months ago

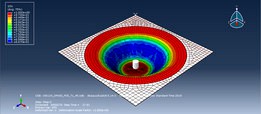

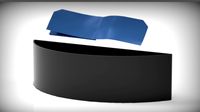

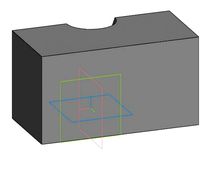

Single Point Incremental Forming (SPIF) method is a process of shaping sheet material using a spherical tipped tool. Machining time is considerably higher than production by a sheet metal die. However, since it is not necessary to use a die, it is generally suitable for use in prototype or a small number of parts production. In this study, the formability of Al6061 Aluminum alloy by spif method was analyzed. Forming analyzes of 1mm and 1.5 mm thick aluminum sheet materials were made at 30°, 45°, and 60° angles. In addition, the effect of the fluid pressure applied on the bottom of the sheet material was investigated. Abaqus software was used for analyzes. As a result of the study, the changes in the wall thickness at a certain cross-section were compared. It was found that Fluid pressure assisted SPIF process improves the forming properties of the material.

Single point Incremental Forming method which allows better formability properties of a sheet metal part without using forming die.

Analysis of Single Point Incremental Forming Method(SPİF) were done by using Abaqus FEA Solver Software. In this work Analyzes were done with fluid assisted for improve forming specifications. Fluid pressure had applied to bottom surface of sheet fixed on to fixture. The coordinates that used for movement of tool generated by Mastercam and Siemens NX CAM software.

Single point Incremental Forming method which allows better formability properties of a sheet metal part without using forming die.

Analysis of Single Point Incremental Forming Method(SPİF) were done by using Abaqus FEA Solver Software. In this work Analyzes were done with fluid assisted for improve forming specifications. Fluid pressure had applied to bottom surface of sheet fixed on to fixture. The coordinates that used for movement of tool generated by Mastercam and Siemens NX CAM software.

Similar models

grabcad

free

Roll Forming U-shaped channel

...grabcad

laminated composite roll forming sheet

simulation and analysis of roll forming process by abaqus finite element software

grabcad

free

Die forming

...die forming

grabcad

forming aluminum sheet with impact press

grabcad

free

Die forming

...die forming

grabcad

forming aluminum sheet with impact press

grabcad

free

A flow simulation study on a prototype pipe

...hot fluid with high pressure points and the outlet i wanted to be a mixed fluid with cold and hot fluid with low pressure point.

grabcad

free

Die Cutting Process

...die cutting process

grabcad

an animation of a die cutting process done by solidworks motion study.

grabcad

free

SHEET METAL PROCESS IN ANSYS EXPLICIT DYNAMIC ANALYSIS

...unch forms the bend so that the distance between the punch and the side wall of the v is greater than the material thickness (t).

grabcad

free

Stress analysis of a pump impeller using Abaqus

...e elements and stress distribution is obtained using abaqus. an uniform pressure is applied over the inner surface of each blade.

grabcad

free

CGP process

...cgp process

grabcad

simulation of cgp process in abaqus software

grabcad

free

Matricaria

...deposited into the die in the process. depending on the material being punched this slug may be recycled and reused or discarded.

grabcad

free

Punching tool - alat za izvlačenje

...es can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

Spif

thingiverse

free

Hinged Chest with Working Lock and Wood Texture by DrLex

...it is trivial, but it is functional. i also spifed up the overall looks of the chest with extra...

3dwarehouse

free

SPIF Chicken in Mbombela Rural, South Africa

...spif chicken in mbombela rural, south africa

3dwarehouse

modeled with building maker #south_africa

3dwarehouse

free

Quadro BOSS - Galeria9, por Rafael Spif

...e, através da decoração. arte de verdade, descomplicada e acessível. #arte #decor #quadro #retratos #streetart skuart13910-25312]

3dwarehouse

free

Quadro AFROPAINTING1 - Galeria9, por Rafael Spif

...o. arte de verdade, descomplicada e acessível. #arte #decor #quadro #colagem #retratos #streetart #surrealista skuart13910-23911]

3dwarehouse

free

Quadro AFROPAINTING 8 - Galeria9, por Rafael Spif

...rte, através da decoração. arte de verdade, descomplicada e acessível. #arte #decor #quadro #colagem #retratos skuart13910-28006]

3dwarehouse

free

Quadro AFROPAINTING 9 - Galeria9, por Rafael Spif

...rte, através da decoração. arte de verdade, descomplicada e acessível. #arte #decor #quadro #colagem #retratos skuart13910-28739]

3dwarehouse

free

Quadro URBAN CHARLIE - Galeria9, por Rafael Spif

...através da decoração. arte de verdade, descomplicada e acessível. #arte #decor #quadro #colagem #filmeseséries skuart13910-26181]

3dwarehouse

free

Quadro EQUAÇÃO ABSTRATA - Galeria9, por Rafael Spif

...a decoração. arte de verdade, descomplicada e acessível. #arte #decor #quadro #colagem #streetart #surrealista skuart13910-25693]

3dwarehouse

free

Quadro AFROPAINTING 7 - Galeria9, por Rafael Spif

...rte, através da decoração. arte de verdade, descomplicada e acessível. #arte #decor #quadro #colagem #retratos skuart13910-25505]

Incremental

3d_export

$5

electro-glass lifts plug e30

...electro-glass lifts plug e30

3dexport

plug electro-glass lifts. i did it from the original, printed in 0.2 abs increment

3d_ocean

$6

Generic Volleyball

...meball generic plain play sport volley volleyball

a nicely detailed volleyball that you can use and increment into your projects!

3d_ocean

$2

Casino Dice

... like casino dice bearing the original red color with accurate orientation of dots to use and increment into your projects.enjoy!

3d_export

$5

rattan stool

... separate folder for your viewing convenience.<br>i have included three increments of detail on this model.<br>enjoy.

3dfindit

free

SX80 / incremental

...sx80 / incremental

3dfind.it

catalog: waycon

3dfindit

free

SX120 / incremental

...sx120 / incremental

3dfind.it

catalog: waycon

3dfindit

free

Linear Measurement - incremental

...linear measurement - incremental

3dfind.it

catalog: elgo-electric

thingiverse

free

Incremental Encoder Button by Pinaut

...ncremental encoder or potentiometer with 6mm hole.

i'm totally new to 3d printing and modeling. but this thing works perfect.

thingiverse

free

Angle Measuring Tool with Increments by ya_nervous

...rinted it myself yet but the increments are only .5mm gaps to bridge so should turn out just fine printed with ruler facing down.

3dfindit

free

Battery-Powered Position Indicators - incremental

...battery-powered position indicators - incremental

3dfind.it

catalog: elgo-electric

Fluid

turbosquid

free

Fluid(Fluid/Flow)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

fluid

... вода , раковина , унитаз

сантехника_fluid

turbosquid

$3

correction fluid

...d

royalty free 3d model correction fluid for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1148772)

turbosquid

$25

Fluid-sofa

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Fluid Tank

...odel fluid tank for download as obj, fbx, blend, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1335082)

3ddd

$1

Softline Fluid 274

...e , fluid

высота (см) - 65

высота седалища (см) - 30

глубина (см) - 105

длина (см) - 160

turbosquid

$5

Mana Potion Fluid

...

royalty free 3d model mana potion fluid for download as c4d on turbosquid: 3d models for games, architecture, videos. (1366155)

3d_export

$20

fluid crystal

...fluid crystal

3dexport

it is a one-man electric car, part of its components are made of glass

turbosquid

$40

SUN with fluid anim

... free 3d model sun with fluid anim for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1480698)

3d_ocean

$4

Detail Fluid Splash

...id liquid miscelaneus splash

high quality liquid splash generated with realflow and sculpted zbrush. comes in 3ds and obj models.

Assisted

turbosquid

$120

Robot Assistant

...id

royalty free 3d model robot assistant for download as max on turbosquid: 3d models for games, architecture, videos. (1381212)

3d_export

$5

painting assistant

...painting assistant

3dexport

draw samples

3d_export

$5

assistive cane

...assistive cane

3dexport

aristocratic cane for characters

3d_export

$10

Assist bike 3D Model

...assist bike 3d model

3dexport

assist bike

assist bike 3d model modelix 59218 3dexport

turbosquid

$69

computer assistant character

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Robot Assistant

...d

royalty free 3d model 3d robot human for download as blend on turbosquid: 3d models for games, architecture, videos. (1599434)

turbosquid

$30

Galaxy Assistant's Stool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

Prototype version of the robot assistant

...ersion of the robot assistant, designed to help a person in a variety of tasks, both in helping in the garden and in armed escort

turbosquid

$69

Droid Assistant

... robot guard for download as blend, dae, fbx, obj, stl, and x on turbosquid: 3d models for games, architecture, videos. (1624852)

turbosquid

free

Free Realistic Grass Assistant

...3d model free realistic grass assistant for download as blend on turbosquid: 3d models for games, architecture, videos. (1454100)

Pressure

3d_export

$5

pressure gauge

...pressure gauge

3dexport

pressure gauge

3d_export

$40

Pressure Vessel

...pressure vessel

3dexport

pressure vessel assembly render 3d modelling design

3d_export

$5

Pressure cooker

...pressure cooker

3dexport

simple low-poly pressure cooker model. not removable parts.

3d_export

$5

protected pressure gauge

...protected pressure gauge

3dexport

protected pressure gauge

turbosquid

$25

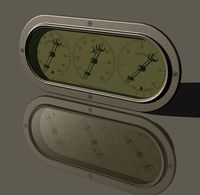

Vintage US Gauge Co Cluster, Pressure, Oil Pressure & Vacuum Fuel Pressure

...re for download as 3ds, dxf, obj, c4d, fbx, 3dm, dwg, and stl on turbosquid: 3d models for games, architecture, videos. (1367117)

turbosquid

$20

PRESSURIZATION FAN

...

royalty free 3d model pressurization fan for download as max on turbosquid: 3d models for games, architecture, videos. (1269534)

turbosquid

$20

Pressurization Pumps

...oyalty free 3d model pressurization pumps for download as max on turbosquid: 3d models for games, architecture, videos. (1270559)

turbosquid

$23

Pressure cooker

...ee 3d model pressure cooker for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1440991)

turbosquid

$25

pressure cooker

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Pressure Controller

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Point

3ddd

$1

Point

...nt , садовая мебель

кресло tahiti ref. 72096 (74x95x93)

пуф tahiti ref. 72052 (54x71x46)

3ddd

free

Point

...f. 71541 (220x100x83)

столики combi ref. 74470 (50x50x59) и ref. 74471 (50x50x79)

стол журнальный diabolo ref. 74151 (130x130x35)

3ddd

$1

Point armchair

... ротанг

сайт производителяhttp://www.point1920.com/archivos/varios/point-feelings/

turbosquid

$21

Loft Point

...turbosquid

royalty free 3d model loft point for download as on turbosquid: 3d models for games, architecture, videos. (1446385)

turbosquid

$20

Point Of Sale

...id

royalty free 3d model point of sale for download as blend on turbosquid: 3d models for games, architecture, videos. (1661269)

turbosquid

$8

Sale Points

...y free 3d model sale points for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1301072)

turbosquid

$3

Point Of Sale

...free 3d model point of sale for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1301061)

turbosquid

$250

Crown Point

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Flash point

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Ball-Point

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Forming

3d_export

$5

Forms

...forms

3dexport

very gooooooooood forms)

design_connected

$13

Form

...form

designconnected

kartell form computer generated 3d model. designed by lissoni, piero.

3d_ocean

$3

Form

...reen screenshot texture ui wallppaper

form poly count:168 texture :1024×768 tga + alpha hope someone will find it useful .enjoy !

design_connected

$16

Form Pendants

...form pendants

designconnected

design house stockholm form pendants computer generated 3d model. designed by form us with love.

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

Single

3d_export

$5

single sofa single chair

...single sofa single chair

3dexport

single sofa single chair 3d model

3d_export

$5

single sofa single chair

...single sofa single chair

3dexport

single sofa single chair 3d model

3d_export

$5

single fastener

...single fastener

3dexport

single fastener

3ddd

$1

Single FLOU

... sofa , трансформер

диван-трансформер single от итальянского производителя flou

3ddd

$1

bed single

...bed single

3ddd

постельное белье

bed single 190cm*90cm

3ddd

$1

Single Flou

...single flou

3ddd

качественная моделька дивана-трансформера single flou.

3d_ocean

$9

Single sofa

...le sofa

3docean

modern sofa single sofa sofa white sofa.comfortable sofa

single sofa,sofa,modern sofa,white sofa.comfortable sofa

3d_export

free

Single Knife

...single knife

3dexport

a single knife, presumably it was used as one of the throwing knives.

3d_export

free

couch - single

...couch - single

3dexport

low poly single couch with .psd file for personal customization

3d_ocean

$5

Single Sofa

...single sofa

3docean

single sofa made by fabric , wood frame & ss leg