Thingiverse

Flex Filament Pulley Guide for Lulzbot Taz 5 by billyd

by Thingiverse

Last crawled date: 3 years, 2 months ago

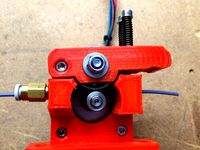

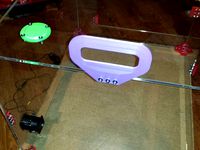

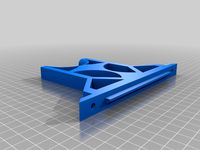

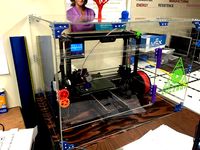

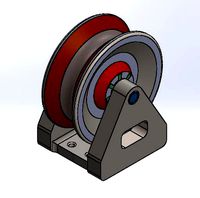

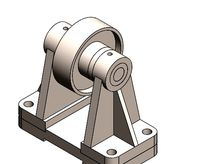

This is a flexible filament guide for a Taz printer (mine is a Taz 5) using pulleys instead of the typical guide tube. I have found the tube creates too much friction with some soft filaments and this can lead to under extrusion. The pulleys have ball bearings installed and are very low friction. Also this guide will not interfere (see pictures above) with the normal guide tube when using regular hard filaments. This pulley guide system is NOT appropriate for any other filament types. For the hard filaments use the stock tube setup.

You will need the following hardware:

Qty 2: 5mm x 25mm long hex socket screw (or longer)

Qty 4: 4mm x 30mm long hex socket screw (or longer)

Qty 2: 5mm hex nut

Qty 4: 4mm hex nut

Qty 2: 5mm Heat set insert 6.7mm long

Qty 4: 4mm Heat set insert 7.9mm long

Qty 2: 5mm x 15mm long hex socket screw (or 16mm long)

Qty 2: 5mm x 10mm long hex socket screw (These are on hand with a Taz 5 printer)

Qty 4: 5mm washers (2 are already with the Taz 5 frame)

Qty 2: 5mm slide nut for Taz frame

Qty 2: 10mm od x 5mm id x 4mm thick ball bearings

Qty 8: 3mm x 5mm long hex socket screw

Qty 8: 3mm hex nut

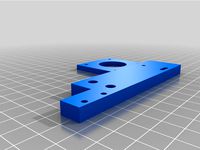

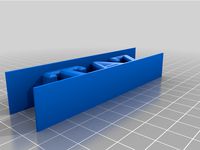

Print one of each bracket, 4 idlers, and 2 pulley tops, and 2 pulley bottoms.

Mount the shorter bracket at the right rear most top two 5mm screws on the frame. (see pictures for reference. Use the 5x16mm screws here with washers. Take the existing 5mm screws from this spot and the other two washers for the other bracket. The other bracket mounts on the top rear transverse frame piece such that the filament drops vertically when your extruder is at the center of travel.

The 4 and 5mm nuts are used at the pulley and idler locations at the back of the brackets to cinch up against their respective heat set inserts to give the bolts rigidity to hold the pulleys and idlers firmly in place.

The bearings are sandwiched between the two pulley halves and captured by the 4x 3mmx5 screws and 3mm nuts.

If your idlers are creating too much friction reheat the 4mm heat set inserts and alter them from the 90 degree angle such that the idler creates a bigger gap at the pulley. But not so much that the filament can pull through.

This is for 2.85mm or 3mm filament.

You will need the following hardware:

Qty 2: 5mm x 25mm long hex socket screw (or longer)

Qty 4: 4mm x 30mm long hex socket screw (or longer)

Qty 2: 5mm hex nut

Qty 4: 4mm hex nut

Qty 2: 5mm Heat set insert 6.7mm long

Qty 4: 4mm Heat set insert 7.9mm long

Qty 2: 5mm x 15mm long hex socket screw (or 16mm long)

Qty 2: 5mm x 10mm long hex socket screw (These are on hand with a Taz 5 printer)

Qty 4: 5mm washers (2 are already with the Taz 5 frame)

Qty 2: 5mm slide nut for Taz frame

Qty 2: 10mm od x 5mm id x 4mm thick ball bearings

Qty 8: 3mm x 5mm long hex socket screw

Qty 8: 3mm hex nut

Print one of each bracket, 4 idlers, and 2 pulley tops, and 2 pulley bottoms.

Mount the shorter bracket at the right rear most top two 5mm screws on the frame. (see pictures for reference. Use the 5x16mm screws here with washers. Take the existing 5mm screws from this spot and the other two washers for the other bracket. The other bracket mounts on the top rear transverse frame piece such that the filament drops vertically when your extruder is at the center of travel.

The 4 and 5mm nuts are used at the pulley and idler locations at the back of the brackets to cinch up against their respective heat set inserts to give the bolts rigidity to hold the pulleys and idlers firmly in place.

The bearings are sandwiched between the two pulley halves and captured by the 4x 3mmx5 screws and 3mm nuts.

If your idlers are creating too much friction reheat the 4mm heat set inserts and alter them from the 90 degree angle such that the idler creates a bigger gap at the pulley. But not so much that the filament can pull through.

This is for 2.85mm or 3mm filament.

Similar models

thingiverse

free

Flashlight Holder Bracket by mikeymakesit

... washers to fit m5

1 qty. m5 metal washer

1 qty. m5 butterfly nut

1 qty. replacement screw for taz 6 frame corner mount - m5 10mm

thingiverse

free

Filament Guide With Pulley by Anakel

... extruder

1 608 bearing

2 half pulley

1 bracket

2 bearing covers

1 bearing screw

1 nut

1 whasher

printed with dagoma discoeasy200

thingiverse

free

Quick Release Filament Holder by dfrechette

...ing feet. (optional)

note: the hub design was inspired by the spool holder with bearings http://www.thingiverse.com/thing:467008

thingiverse

free

CR10 Frame Brace by z4gunn

...(for top brackets)qty 4 m5 hammer nuts (for top brackets)qty 2 m8 x 1m threaded rodsqty 8 m8 nylock hex nutsqty 8 m8 flat washers

thingiverse

free

Voxelab Aquila Dual Extruder Mods - Mounting Plate, Filament Guide, & Spool Holder by Jameswis

...:

-608zz bearing

-1 5mm x 15mm screw (or longer)

-1 5mm nut for screw

-2 3mm x 10mm screws for mounting

-2 3mm nuts for mounting.

thingiverse

free

Elbow belt tensioner suitable for 2020 frame

...allbearing x 2

5mm id 20 tooth gt2 idler pulley

feature:

easy to print,easy to adjust,fit for various system,fit for closed belt.

thingiverse

free

Mini Kossel 1.75mm extruder by wallie

...et head cap screw

2x spring

1x m5 pneumatic straight threaded-to-tube adapter, push in 4 mm 4mm male

tools

m5 manual screw tap

thingiverse

free

Filament Tube Guide Holder by Swilli38

...ube and takes the filament from the middle of the spool.

single hex nut and bolt/washer into existing hole in the back of my ctc.

thingiverse

free

Palatis FricEx (belt driven friction extruder cold-end) (1.75mm filament) by palatis

...1.8deg) * 16 (microstepping) / (16 (teeth) * 2 (gt2 2mm))

= 100 steps / mm

however, always calibrate e-steps/mm for your printer.

thingiverse

free

Taz 6 style Externally Accessable Y axis belt tensioner by piercet

... an adjusted endplate that will clear the tensioner bolt and washer. if you are using a more stock taz you do not need that part.

Billyd

thingiverse

free

Golf Box by billyd

...plify printing.

the lid should be dropped about 1mm into the bed before slicing. the lid will need supports around the perimeter.

thingiverse

free

Nerdcam3D MK2 Mount by billyd

... camera and tricopter!

enjoy

update added file nerdcam3d-mk2_cover_mobius which is a cover with a mount for the mobius hd camera.

thingiverse

free

Filament Saver by billyd

... when not in use. it saves filament because the device does not damage or require bending the filament to keep it from unspooling

thingiverse

free

Facehugger by billyd

...actice with my scanner, i am learning quite a bit. so i've just uploaded a much better quality scan of the facehugger. enjoy!

thingiverse

free

Christmas Tree Star Topper by billyd

...revised it so it could be printed in two halves and glued together to make a whole. note this is a small tree topper. 118mm wide.

thingiverse

free

Exhaust Fitting, Wall Mount by billyd

...t is meant as a means to mount the exhaust tube to a dryer vent or similar on a wall, to carry the printed exhaust fumes outside.

thingiverse

free

Earring Stand by billyd

...would advise using pla or petg for this print.

i also supply the stand with just holes instead of slots for stud earrings.

enjoy!

thingiverse

free

Nerdcam3D Mount for Cinetank MK2 by billyd

...locations on the forward top of the cinetank mk2 upper plate. nerdcam3d with cinetank mk2 frame is an amazing experience. enjoy!!

thingiverse

free

Handle for Lulzbot Taz 4 or 5 enclosure by billyd

...h side of my lulzbot enclosure for taz 4 or 5 (found here: http://www.thingiverse.com/thing:746922 ) for easy lifting and moving.

thingiverse

free

Hero2 mount for the Firefly 6 by billyd

...pt a single "one-wrap" style velcro tie 8x1/2". you can typically find them in retail stores in the craft section.

Taz

3d_ocean

$19

TAZ RIGGED

...ax version only texture is used only for wb logo, taz dont need texture no special render engine needed, just unzip and render...

3d_export

$5

Taz character 3D Model

...taz character 3d model

3dexport

taz toon character cartoon

taz character 3d model supercigale 22095 3dexport

cg_studio

$10

Taz 3D3d model

...taz 3d3d model

cgstudio

.3ds .max - taz 3d 3d model, royalty free license available, instant download after purchase.

cg_studio

$15

Taz Rigged3d model

...ged3d model

cgstudio

.3ds .fbx .max .obj - taz rigged 3d model, royalty free license available, instant download after purchase.

3d_export

$10

Taz Toy Calendar 3D Model

... 3d model

3dexport

taz toy calendar day month year looney tunes cartoon kid child

taz toy calendar 3d model nkfrds 49687 3dexport

3d_export

$10

Taz Tasmanian Devil RIGGED 3D Model

...y tunes anime bunny rigged material fantasy creature diable dessin

taz tasmanian devil rigged 3d model supercigale 28390 3dexport

3d_export

$19

Thylacine 3D Model

...animalia chordata mammalia marsupial dog extinct animals tiger tassie taz thylacine 3d model poly3dmodels 90790...

3d_export

$12

Bowl Decorated 3D Model

...bowl decorated 3d model 3dexport bowl tazn elements ceramics kitchen plastic cup container decorative cake biscuits...

3ddd

$1

Crate & Barrel Serveware

...crate & barrel поднос -http://www.crateandbarrel.com/feast-platter/s186961 набор ножей для сыра -http://www.crateandbarrel.com/tazcheese-knife-3-piece-set/s681377 бокал...

thingiverse

free

TAZ by Taz8373

...taz by taz8373

thingiverse

my 1st print

Lulzbot

thingiverse

free

LulzBot Rocktomek by LulzBot

...lulzbot rocktomek by lulzbot

thingiverse

https://download.lulzbot.com/3d_models/rocktomek/

thingiverse

free

THE Lulzbot spool holder

...the lulzbot spool holder

thingiverse

stl and ipt topmount spool holder for lulzbot

thingiverse

free

Lulzbot logo by Halg199703

...lulzbot logo by halg199703

thingiverse

this is the lulzbot logo. i also have a file for dual extruder.

thingiverse

free

LulzBot Bio printer Model

...lulzbot bio printer model

thingiverse

this is a model of the lulzbot bioprinter

thingiverse

free

Lulzbot Taz Enclosure by MrMcGuire

...lulzbot taz enclosure by mrmcguire

thingiverse

parts for an enclosure for lulzbot taz

thingiverse

free

Lulzbot Spool Holder by MAKE

...lulzbot spool holder by make

thingiverse

a spool holder for your lulzbot.

thingiverse

free

Lulzbot mini spool holder by chewie80524

...lulzbot mini spool holder by chewie80524

thingiverse

this part holds the spool on a lulzbot mini. this design came from lulzbot.

thingiverse

free

Lulzbot Claystruder by 102drewt

...r for the lulzbot taz 4. every thing is snap together, and it only requires a threaded rod, a nut to fit it, and a stepper motor.

thingiverse

free

Lulzbot Mini Enclosure brackets by chewie80524

...lulzbot mini enclosure brackets by chewie80524

thingiverse

lulzbot taz/mini enclosure brackets.

thingiverse

free

Lulzbot mini toolbox by nicsna

...t mini using cura scale down to 0.97.

hope you like it and make sure to leave some feedback or suggestions for my next design. :)

Pulley

3d_export

$1

pulley

...pulley

3dexport

3d_export

$30

Pulley export

...pulley export

3dexport

pulley export design render 3d modelling

3d_export

free

Pulley

...ort

this is a pulley<br>formats: ".3ds", ".fbx", ".obj", ".stl", "blend"

3d_export

$6

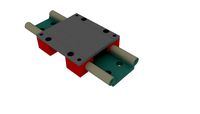

roller pulley

...r pulley

3dexport

this is the roller pulley 3d model its used for 3d printers and some other uses for toys and usefull things .

turbosquid

$2

aluminum pulley

...

royalty free 3d model aluminum pulley for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1671716)

turbosquid

$29

pulley wheel

...d model pulley wheel for download as obj, wrl, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1319384)

turbosquid

free

Pulley.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

design and assembly of pulley

...design and assembly of pulley

3dexport

design and assembly of pulley 3d model which is used for drive and driven

3d_export

$10

Pulley 3D Model

...y sewing sewingmachine c4d fbx metal

pulley 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl dixiony 107270 3dexport

3d_export

$10

Pulley 3D Model

...trial machine c4d fbx cinema4d metal

pulley 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl dixiony 107271 3dexport

Flex

3ddd

$1

Flex

...flex

3ddd

flex , конференц-зал

кресло для переговоров

3ddd

$1

Flex — I Laccati

... i laccati

3ddd

flex , дверь

двери межкомнатные, окрашенные. flex, коллекция «i laccati»

3ddd

free

Flex Seating 6032

... конференц-зал , flex

кресло модульное, модель flex seating 6032

3ddd

free

TechnoGym Flex Posterior

... flex , тренажер

3ds max 2012 (v-ray) + fbx

technogym flex posterior

3ddd

$1

Банкетка Flex Team

... , flex team

http://www.abitant.com/products/banketka-flex-team-2014-kilt-pouf

3ddd

free

FLEX , I Laccati

...cati

3ddd

flex , i laccati

flex , i laccati

модель p 14 q stucco fiorentino decoro gigli

3ddd

$1

Metal lux / FLEX

...metal lux / flex

3ddd

metal lux

люстра metal lux flex.

turbosquid

$11

Stool Flex

...ty free 3d model stool flex for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1673813)

3ddd

$1

Flex by Skandiform

...flex by skandiform

3ddd

skandiform , стул

enjoy

turbosquid

$7

Flex Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Guide

turbosquid

$15

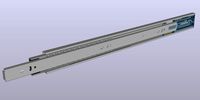

Guide drawer

...squid

royalty free 3d model guide drawer for download as dwg on turbosquid: 3d models for games, architecture, videos. (1261387)

turbosquid

$1

Road Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Guide-board 3D Model

...ion sign guide sign

guide-board n170112 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

turbosquid

$2

soap cutter guide

...

royalty free 3d model soap cutter guide for download as stl on turbosquid: 3d models for games, architecture, videos. (1694030)

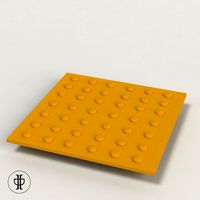

turbosquid

$15

Blind Guiding tiles

...free 3d model blind guiding tiles for download as 3dm and dae on turbosquid: 3d models for games, architecture, videos. (1156598)

turbosquid

$69

Japanese Tour Guide

...d model japanese tour guide for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1614288)

turbosquid

$10

CNC Linear Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Tank Model Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Road Guide 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$9

Guide Books 3

...sformed separately and each have unique texture map on front and back cover. to make your work easier this model comes in thre...

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

5

turbosquid

$6

Rock 5-5

...urbosquid

royalty free 3d model rock 5-5 for download as obj on turbosquid: 3d models for games, architecture, videos. (1639063)

3d_export

$5

hinge 5

...hinge 5

3dexport

hinge 5

turbosquid

$10

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Calligraphic Digit 5 Number 5

...hic digit 5 number 5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389333)

3ddd

$1

5 роз

...5 роз

3ddd

5 роз в стеклянной вазе

design_connected

$11

iPhone 5

...iphone 5

designconnected

apple iphone 5 computer generated 3d model.

3ddd

$1

Lola 5

...lola 5

3ddd

miniforms

lola 5 miniforms 300*65*134

3ddd

$1

Nexus 5

...dd

nexus , phone , телефон

google nexus 5 phone

3d_ocean

$15

iPhone 5

...iphone 5

3docean

3d 4d apple cinema iphone model modeling phone screen texture

iphone 5 3d model and texture realistic iphone 5.