Thingiverse

FlashForge New Creator Pro - Bed Extender - Sized for 8 x 10 Plexiglass by Timetoprint00

by Thingiverse

Last crawled date: 3 years, 1 month ago

I find that on the FlashForge NEW Creator Pro (received November-2016) that parts with large surface areas are difficult to remove from the bed plate. For example the first time I printed out the orange bird house (thingi1351023), I did so on a glass plate, that I clipped to the FlashForge Bed. Because this bird house has such a large contact surface area to the bed, I found it to be very difficult to remove. In the end the glass plate shattered, and in fear of cutting my fingers from the shards of glass, I simply threw the bird house into the garbage.

To remedy, I decided to use plexi-glass, so that I could flex the plate to create a separation between it and the 3d printed object. Locally (at HD) thin plexi-glass can be purchased in 8” x 10” sheets for approximately $4 USD. These sheet are approximately 2mm thick. Then to avoid having to cut the plexi-glass to size, I designed the bed extensions to accommodate the 8 x 10 plexi-glass sheet.

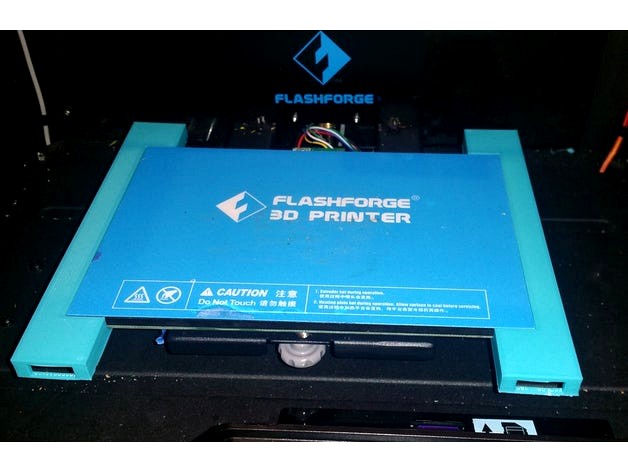

The Bed extensions are small enough to be able to be printed out on top of the original FlashForge Bed. They Bed Extentions are secured into place by using 3mm Wing-Nuts, one for each corner, so a total of 4. From the picture you can see I have the "NEW" Creator Pro Logo is silver/chrome. Therefore this is the 2016 "NEW" Creator Pro. The Bed Extenders accommodate the position of the corner bolts for this model. I do not know, but I would expect that the bed bolt positions are the same for the previous Creator Pro.

To help hold the plexi-glass in position on the bed when printing, small clips are used for clamping. There are 5 slots on each bed extender. The wire clips in the picture are from Dollar Tree; you can purchase a pack of 6 of them for $1. When clamped in place the clips remain outside where the nozzle moves; there is about 10mm clearance. Note: I use Simply3D to slice the parts I print. Therefore starting position of the nozzle is at the front right-hand corner of the bed. If you are using Slic3r or ReplicatorG, the nozzle’s starting position is at the front Left-Hand corner; In this case the wire clip may interfere with the starting position of the nozzle (depending where you place it), you may need to put the clip into a different slot.

As a result I can now print out much larger objects. When I originally printed out the bird house with a glass plate (that shattered), I had scaled it down to 90%, because it came so close to the edge of the FlashForge bed, and I wanted a rim printed. However, with the plexi-glass bed, I was able to print it full size with no worries of hitting the wire clips. It is so nice to be able to print larger objects.

Two other quick notes, I use blue painters tape on the top surface of the plexi-glass, and then liberally apply glue stick to the top of the blue tape. Parts, especially PLA, adhere very well.

Enjoy!

To remedy, I decided to use plexi-glass, so that I could flex the plate to create a separation between it and the 3d printed object. Locally (at HD) thin plexi-glass can be purchased in 8” x 10” sheets for approximately $4 USD. These sheet are approximately 2mm thick. Then to avoid having to cut the plexi-glass to size, I designed the bed extensions to accommodate the 8 x 10 plexi-glass sheet.

The Bed extensions are small enough to be able to be printed out on top of the original FlashForge Bed. They Bed Extentions are secured into place by using 3mm Wing-Nuts, one for each corner, so a total of 4. From the picture you can see I have the "NEW" Creator Pro Logo is silver/chrome. Therefore this is the 2016 "NEW" Creator Pro. The Bed Extenders accommodate the position of the corner bolts for this model. I do not know, but I would expect that the bed bolt positions are the same for the previous Creator Pro.

To help hold the plexi-glass in position on the bed when printing, small clips are used for clamping. There are 5 slots on each bed extender. The wire clips in the picture are from Dollar Tree; you can purchase a pack of 6 of them for $1. When clamped in place the clips remain outside where the nozzle moves; there is about 10mm clearance. Note: I use Simply3D to slice the parts I print. Therefore starting position of the nozzle is at the front right-hand corner of the bed. If you are using Slic3r or ReplicatorG, the nozzle’s starting position is at the front Left-Hand corner; In this case the wire clip may interfere with the starting position of the nozzle (depending where you place it), you may need to put the clip into a different slot.

As a result I can now print out much larger objects. When I originally printed out the bird house with a glass plate (that shattered), I had scaled it down to 90%, because it came so close to the edge of the FlashForge bed, and I wanted a rim printed. However, with the plexi-glass bed, I was able to print it full size with no worries of hitting the wire clips. It is so nice to be able to print larger objects.

Two other quick notes, I use blue painters tape on the top surface of the plexi-glass, and then liberally apply glue stick to the top of the blue tape. Parts, especially PLA, adhere very well.

Enjoy!

Similar models

thingiverse

free

FlashForge Creator Pro by Rafatpanah

... out a new glass plate on top of the printing bed so i made some easily removable clips. you can use 2 or 4 to secure your plate.

thingiverse

free

FlashForge Creator Pro - Corner Glass Clips +3mm by thelab_ms

...r the original corner clips to get a good grip on the glass.

we extended the part of the clip that holds that glass by about 3mm.

thingiverse

free

FlashForge Creator Pro - Corner Glass clips by jherridge

...ip by harlique:http://www.thingiverse.com/thing:537595

wing nut cover by legreatmagnet:http://www.thingiverse.com/thing:604579

thingiverse

free

Flashforge Creator Pro Glass Bed Corner That works by Tjp2579

...ed every corner file on here and thy did not work for one reason or the other so i made one. increase size 3% if printing in abs.

thingiverse

free

Flashforge Creator Pro 180x240 glass holder by helste

...s where they don't get hit by the nozzle.

the 3rd foto shows a setup, where i do not have problems with nozzle hitting clips.

thingiverse

free

Micro Binder clip 16mm for FlashForge Creator Pro 2016 by LaurentRueil

....thingiverse.com/thing:2070108

the micro binder clip 16mm was too small to be used, so i created that to use them.

printer in abs

thingiverse

free

Flashforge Creator Pro - Bed Clip for Zebra Plate by FunFunBoy

...lashforge creator pro heated bed but it's suitable for any system with 12.5 mm whole plate thickness.

print set of 4 clips.

thingiverse

free

FlashForge Creator Pro Glass Clips by jherridge

.... i made my clips with abs filament. i wanted an alternative to steel binder clips that were easier to put on and remove. enjoy!

thingiverse

free

FlashForge Creator Pro - Corner Glass clips

... to hold it in place. i also used the spare thumb nut that came with the printer for the front corner for easy glass bed removal.

thingiverse

free

Extended Glass Mount for Flashforge Creator Pro by Bassna

..., be careful.

shoutout to maker111 for the original model, and eagleseven for doing the measurements for the larger glass plate.

Timetoprint00

thingiverse

free

Elephant Magnet - w reinforced trunk by Timetoprint00

...ut in half and added a magnet. sized for a cheap 20mm magnet. same magnet style as sold at hobby lobby, comes in a 50 piece pack.

thingiverse

free

Elephant - Reinforced Trunk by Timetoprint00

...so i reinforce it by placing a half circle within it. i did so using tinkercad. it so sooooo much stronger and still looks good.

thingiverse

free

Bird Magnet Matthew 6:26 by Timetoprint00

... to children that god cares for the birds, and yet god values people more than them. i handed these out for jr. church on sunday.

thingiverse

free

Apple Android Refrigerator Magnet by Timetoprint00

... speed; hasn't been a problem yet).

altered design using tinkercad.

gorilla glue to attach magnet

this is a remix of 1290514

thingiverse

free

Oculus Quest Vive Adapter DAS by Timetoprint00

... thinner if petg were used for the material. however, petg clogs my nozzels after each print, so i don't use petg very often.

thingiverse

free

Jellyfish Mod Resized for ease of Assembly by Timetoprint00

...ei cut to size and glued down to the original bed. it becomes tacky as the bed heats up, and pla and petg sticky very well to it.

thingiverse

free

UDI Holystone U818A Cover with Camera Stand and storage for separate battery pack by Timetoprint00

...e lower section of a motor is simply an extended antenna. this did not seem to help the distance for control that much if at all.

thingiverse

free

WinBook TW700 Tablet Cooling Stand by Timetoprint00

...uld be diminished.

monoprice tablet 12 x 9: http://www.monoprice.com/product?p_id=6815 (an excellent tablet for just under $100).

thingiverse

free

UDI U818A - Stand Alone - Camera Mount & Battery Storage by Timetoprint00

... housing, then see my alternate design of a dome with camera mount .... thingi 2816084.

https://www.thingiverse.com/thing:2816084

Plexiglass

turbosquid

free

Plexiglass Lamp

...turbosquid

free 3d model plexiglass lamp for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1144847)

turbosquid

$35

plexiglass chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

eiffel tower

...eiffel tower 3dexport eiffel tower interior design<br>plexiglass ...

3d_export

$5

Type chair Philippe Starck 3D Model

...type chair philippe starck 3d model 3dexport plexiglass chair philippe starck type chair philippe starck 3d model...

3d_export

$10

Glass Table 09 3D Model

...3d model 3dexport glass table contemporary modern furniture materials plexiglass detailed photoreal vray glass table 09 3d model alekrazum...

3d_export

$10

Glass Table 05 3D Model

...3d model 3dexport glass table contemporary modern furniture materials plexiglass detailed photoreal vray glass table 05 3d model alekrazum...

3d_export

$10

Glass Table 08 3D Model

...3d model 3dexport glass table contemporary modern furniture materials plexiglass detailed photoreal vray glass table 08 3d model alekrazum...

3d_export

$10

Glass Table 07 3D Model

...3d model 3dexport glass table contemporary modern furniture materials plexiglass detailed photoreal vray glass table 07 3d model alekrazum...

3d_export

$10

Glass Table 06 3D Model

...3d model 3dexport glass table contemporary modern furniture materials plexiglass detailed photoreal vray glass table 06 3d model alekrazum...

3d_export

$10

Glass Table 03 3D Model

...3d model 3dexport glass table contemporary modern furniture materials plexiglass detailed photoreal vray glass table 03 3d model alekrazum...

Flashforge

thingiverse

free

Flashforge Logo

...flashforge logo

thingiverse

flashforge logo

thingiverse

free

flashforge logo by morive3d

...flashforge logo by morive3d

thingiverse

this is a flashforge stamphttps://www.youtube.com/channel/ucu6ge9qrju9cpgg6wrlxkqw

thingiverse

free

Flashforge Glass Bed by olo2000pm

...flashforge glass bed by olo2000pm

thingiverse

flashforge glass bed

thingiverse

free

Toolbox for FlashForge Finder by Gringo1970

...toolbox for flashforge finder by gringo1970

thingiverse

smal toolbox for flashforge finder

thingiverse

free

Flashforge / Dremel lid by Disco_Rob

...flashforge / dremel lid by disco_rob

thingiverse

lid extension for the flashforge dreamer

thingiverse

free

Flashforge Dreamer Filamentguide by PeterS1

...de for flashforge dreamer / dremel idea. you need also flashforge dreamer lid spacer (http://www.thingiverse.com/thing:1219953)

thingiverse

free

Flashforge creator legs by cybadigitals

...flashforge creator legs by cybadigitals

thingiverse

these legs gives a clearance of 25mm for flashforge creator series

thingiverse

free

Flashforge Inventor/Dreamer by Iprintr7

...orge inventor/dreamer by iprintr7

thingiverse

this is my first thingiverse project and is a model of the flashforge 3d printer

thingiverse

free

Flashforge Filiment Guide by russellscanlan

...flashforge filiment guide by russellscanlan

thingiverse

my design to feed filament through the door on a flashforge adventure 3

thingiverse

free

Flashforge Winder Adapter by newky2k

...winder adapter by newky2k

thingiverse

adapters for the flashforge 0.5 kg spools to the for the filament spool winder by ssinnott

Creator

3ddd

$1

CREATOR

... молдавия

круглая кровать молдавской мастерской creator.диаметр спального места - 1900мм,материалы настроены.

turbosquid

$75

Creators Realm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

LEGO Creator Part 2

...

lego , конструктор , машина

lego creator №6753

turbosquid

free

Game Creator Pack

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

LEGO Creator №6753 Part 3

...

lego , конструктор , машина

lego creator №6753

3ddd

$1

LEGO Creator №6753 Part 1

...

lego , конструктор , машина

lego creator №6753

turbosquid

$29

Train Track Creator Pro

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$39

Train Track Creator Pro

...n tracks, for video game or rendering in a matter of minutes. all the models in this pack are low poly with high resolution te...

turbosquid

$7

FPS Creator Reloaded Rock Pack 1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Декоративные элементы BV Decor CREATOR III часть

...ментов и декорирования стен.

множество вариантов для вашей фантазии.https://bvdecor.com/es/category/list/cat/creator-es

Extender

turbosquid

$39

Extending table

...id

royalty free 3d model extending table for download as max on turbosquid: 3d models for games, architecture, videos. (1290552)

turbosquid

$5

Extend Table

...squid

royalty free 3d model extend table for download as skp on turbosquid: 3d models for games, architecture, videos. (1372508)

turbosquid

$40

Engine Extended

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Triple extender

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$99

Monica (Extended Pack)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Berlino Extendable Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Extendable Modern Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$32

KC10 Extender 3D Model

...c 10 aircraft jet fighter bomber close support interceptor spy attacker plane

kc10 extender 3d model martialartist 24527 3dexport

3d_export

$50

Extended Range Trailer 3D Model

...railer 3d model

3dexport

extended range trailer military patrol equipment

extended range trailer 3d model dougmavs 75684 3dexport

design_connected

$13

Big Dining Tables Extended

...ining tables extended

designconnected

bonaldo big dining tables extended computer generated 3d model. designed by gilles, alain.

Pro

turbosquid

$29

Pro

...ree 3d model mac pro for download as obj, c4d, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1505782)

turbosquid

$15

Apple Mac Pro and Pro Display

...ee 3d model apple mac pro and pro display for download as max on turbosquid: 3d models for games, architecture, videos. (1417078)

3d_export

$5

iphone 13 pro max and pro

...3 pro max and 13 pro the model is made in four colors (graphite, gold, silver, and blue), all of which are attached in the files.

3d_export

free

sapphire pro

...sapphire pro

3dexport

sapphire pro 3d printer head mask

3d_export

$4

macbook pro

...macbook pro

3dexport

macbook pro 13" inch 2020 years model

3ddd

free

GentleLase Pro

... syneron , candela

gentlelase pro аппарат для лазерной эпиляции

turbosquid

$25

PRO frame

...rbosquid

royalty free 3d model pro frame for download as max on turbosquid: 3d models for games, architecture, videos. (1148329)

turbosquid

$5

Alien pro

...osquid

royalty free 3d model alien pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1678446)

turbosquid

$5

iphone11 pro

...uid

royalty free 3d model iphone11 pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1562707)

3ddd

$1

Mac Pro (appel)

...mac pro (appel)

3ddd

компьютер , apple

mac pro

Bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

Bed

...bed

3ddd

bed , постельное белье , постель

bed

3d_export

$7

bed adairs bed

...rs bed

3dexport

bed adairs bed in modern style. if you want a smoother surface, please turn on turbosmooth in the modifier list.

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

turbosquid

$24

Chandelier MD 89310-10+10 Osgona

... chandelier md 89310-10+10 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218762)

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.

8

turbosquid

$6

Rock 8-8

...urbosquid

royalty free 3d model rock 8-8 for download as obj on turbosquid: 3d models for games, architecture, videos. (1659393)

3ddd

$1

Italamp 387/8+8

...italamp 387/8+8

3ddd

italamp

люстра italamp 387/8+8

размеры 92x71h

3ddd

$1

8 марта

...8 марта

3ddd

8 марта

кресло 8 марта

design_connected

$16

No 8

...nected

photo-realistic 3d models of the sibast no 8 armchair from sibast for 3d architectural and interior design presentations.

3d_export

$5

hinge 8

...hinge 8

3dexport

hinge 8

3d_export

$5

iphone 8

...iphone 8

3dexport

iphone 8

turbosquid

$69

iPhone 8 and iPhone 8 Plus

... free 3d model iphone 8 and iphone 8 plus for download as max on turbosquid: 3d models for games, architecture, videos. (1202442)

turbosquid

$12

Calligraphic Digit 8 Number 8

...hic digit 8 number 8 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389341)

3ddd

free

PLANTS 8

...plants 8

3ddd

цветок , горшок

plant 8,,, hope u all like it

3ddd

$1

8 Марта / Amadey

...8 марта / amadey

3ddd

8 марта

8 marta amadey

New

turbosquid

$119

New New Beetle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

New-feather

...new-feather

3dexport

new-feather

3d_export

$6

new style

...new style

3dexport

new style room

3ddd

free

New Items

...ew items

3ddd

new items , барный

барный стул от китайского производителя фирмы new items

3d_export

$6

Logo new

...logo new

3dexport

new american style logo

3d_export

$10

New jersey

...new jersey

3dexport

new jersey stp and stl format

design_connected

$20

New Deal

...new deal

designconnected

new deal computer generated 3d model.

3d_ocean

$15

New bed

... for this bed all this file format include in zip file 3ds,obj,max,zip file change material and re-size very easy very for render

3ddd

free

Sofa-New Classic

...sofa-new classic

3ddd

new classic

sofa,new classic

design_connected

$13

New Antiques

...new antiques

designconnected

cappellini new antiques computer generated 3d model. designed by wanders, marcel.

Sized

3d_export

$7

shoes size from 5 inch size to 11 inch

...shoes size from 5 inch size to 11 inch

3dexport

shoes design women model sizing from 5 inch to 11 inch

turbosquid

$15

Closet-small size

...

royalty free 3d model closet-small size for download as max on turbosquid: 3d models for games, architecture, videos. (1186088)

turbosquid

$5

Full size Futon

...id

royalty free 3d model full size futon for download as max on turbosquid: 3d models for games, architecture, videos. (1339638)

turbosquid

$4

mid size sword

...d

royalty free 3d model mid size sword for download as blend on turbosquid: 3d models for games, architecture, videos. (1160246)

turbosquid

$3

Mid size hammer

...

royalty free 3d model mid size hammer for download as blend on turbosquid: 3d models for games, architecture, videos. (1160647)

turbosquid

$19

Beaker 3 Sizes

...yalty free 3d model beaker 3 sizes for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1645955)

turbosquid

$20

Full Sized Bed

...d model full sized bed for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1547542)

turbosquid

$45

King Size Bed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Queen size bed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Bed - Full Size

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.