Thingiverse

Flashforge FFC Pro Vent Kit by ragingrivers

by Thingiverse

Last crawled date: 3 years ago

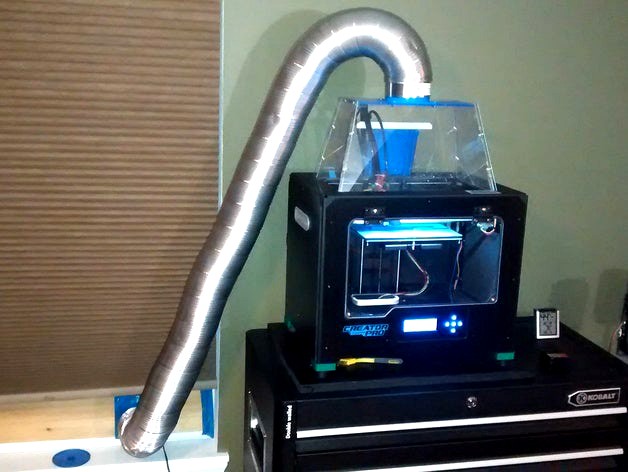

Latest UPDATE 8/14/16 Added a Straight Coupling Adapter for the clear hose listed, see pictures, works with all existing parts but now allows easy plug and unpluging of the hose and I use the Vent plug when ventilation system is not in use.

This is meant to be a full ventilation kit for a Flashforge Creator Pro.

You will need to print:

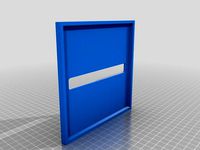

-Top Replacement pieces for FFC Pro: FFC PRO Vent Top Left and Right (2 pieces total)

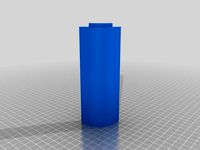

-Duct to mount to top of new FFC Pro Top: 4in Vent adapter from ffcp01 file duct.mount (1)

-A 120mm Fan to 4in Vent Hose adapter (1)

Recommended to print but not needed:

-120mm exhaust cap (designed for smooth exhaust directed downward with blocked line of sight, preventing most drafts and rain)

-FFC PRO Hood Plug Remix (Trapping additional heat inside for printing ABS)

-Some form of side plugs, many available on thingiverse (to trap heat)

-4in Vent Plug (for when not in use in an air conditioned home, I originally intended for this to be wrapped in a compliant tape like electrical tape but this is not sealing as well as I'd want, and will likely make another version in the future)

You will need to buy:

-1x 120mm fan (you can use more, or use a different fan setup with a different adapter), I used a Corsair SP https://www.amazon.com/Corsair-SP120-High-Performance-Twin/dp/B007RESFYK

-1x 4in Duct hose, I originally purchased https://www.amazon.com/gp/product/B003CLL9V8/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1 and the fittings are currently setup to take both hoses as pictured, but I prefer this: https://www.amazon.com/gp/product/B000DZFTEO/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 which is more flexible.

-1x 12 volt power supply, anything will do to power one fan, I used: https://www.amazon.com/gp/product/B000MGG6SC/ref=oh_aui_search_detailpage?ie=UTF8&psc=1 (it really can only power two fans and there is a good speed drop)

-4x #8 or #6 screws, depending on how accurate your hole drilling is :) 2.5 to 3in long, and nuts

4x #8 or #6 screws, depending on how accurate your printing is :) 1in long and nuts

-1x piece of 1inx6inxwidth of your window, I used cedar which is recommended, or you will need a painted board or weather resistant material if you want it exposed

Nice to haves:

-Foam and tape to seal the window sash where open above, and stick on foam around the board, mine is sealed pretty tight.

-A way to make this work between my fan and the outside http://www.thingiverse.com/thing:529661 I haven't tried yet but would be a nice solution, short of that there will be a sliding door eventually, for now the plug.

With everything above I am able to print abs without warping, and without any hint of fumes. Note the Exhaust port pictured, that was printed with this setup, without it installed.

I still recommend running a in room hepa filter for any leftover fumes, but at least I don't mind staying in the room while its printing.

There were some great files I remixed from, thanks to BrookTrout, ffcp01, and ADN_NMX for having your good ideas posted for sharing.

Let me know if you have better ideas, and suggestions. This is version 1, will likely be improved, and have an adapter for the rostock max.

UPDATE: 8/8/16 -> Received the clear hose today from amazon (pictured), much easier to work with (if a danger to easy puncture, avoid animals). The fit is a bit off on my current setup of adapters, I may have to remix the linked 4in outlet and the 120 to 4, but it works pretty well. I would recommend getting the clear hose if you don't have a danger of tearing the plastic (there is a pic of both to help you choose, both are $10).

UPDATE 8/14/16 Added a Straight Coupling Adapter for the clear hose listed, see pictures, works with all existing parts but now allows easy plug and unpluging of the hose and I use the Vent plug when ventilation system is not in use.

This is meant to be a full ventilation kit for a Flashforge Creator Pro.

You will need to print:

-Top Replacement pieces for FFC Pro: FFC PRO Vent Top Left and Right (2 pieces total)

-Duct to mount to top of new FFC Pro Top: 4in Vent adapter from ffcp01 file duct.mount (1)

-A 120mm Fan to 4in Vent Hose adapter (1)

Recommended to print but not needed:

-120mm exhaust cap (designed for smooth exhaust directed downward with blocked line of sight, preventing most drafts and rain)

-FFC PRO Hood Plug Remix (Trapping additional heat inside for printing ABS)

-Some form of side plugs, many available on thingiverse (to trap heat)

-4in Vent Plug (for when not in use in an air conditioned home, I originally intended for this to be wrapped in a compliant tape like electrical tape but this is not sealing as well as I'd want, and will likely make another version in the future)

You will need to buy:

-1x 120mm fan (you can use more, or use a different fan setup with a different adapter), I used a Corsair SP https://www.amazon.com/Corsair-SP120-High-Performance-Twin/dp/B007RESFYK

-1x 4in Duct hose, I originally purchased https://www.amazon.com/gp/product/B003CLL9V8/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1 and the fittings are currently setup to take both hoses as pictured, but I prefer this: https://www.amazon.com/gp/product/B000DZFTEO/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 which is more flexible.

-1x 12 volt power supply, anything will do to power one fan, I used: https://www.amazon.com/gp/product/B000MGG6SC/ref=oh_aui_search_detailpage?ie=UTF8&psc=1 (it really can only power two fans and there is a good speed drop)

-4x #8 or #6 screws, depending on how accurate your hole drilling is :) 2.5 to 3in long, and nuts

4x #8 or #6 screws, depending on how accurate your printing is :) 1in long and nuts

-1x piece of 1inx6inxwidth of your window, I used cedar which is recommended, or you will need a painted board or weather resistant material if you want it exposed

Nice to haves:

-Foam and tape to seal the window sash where open above, and stick on foam around the board, mine is sealed pretty tight.

-A way to make this work between my fan and the outside http://www.thingiverse.com/thing:529661 I haven't tried yet but would be a nice solution, short of that there will be a sliding door eventually, for now the plug.

With everything above I am able to print abs without warping, and without any hint of fumes. Note the Exhaust port pictured, that was printed with this setup, without it installed.

I still recommend running a in room hepa filter for any leftover fumes, but at least I don't mind staying in the room while its printing.

There were some great files I remixed from, thanks to BrookTrout, ffcp01, and ADN_NMX for having your good ideas posted for sharing.

Let me know if you have better ideas, and suggestions. This is version 1, will likely be improved, and have an adapter for the rostock max.

UPDATE: 8/8/16 -> Received the clear hose today from amazon (pictured), much easier to work with (if a danger to easy puncture, avoid animals). The fit is a bit off on my current setup of adapters, I may have to remix the linked 4in outlet and the 120 to 4, but it works pretty well. I would recommend getting the clear hose if you don't have a danger of tearing the plastic (there is a pic of both to help you choose, both are $10).

UPDATE 8/14/16 Added a Straight Coupling Adapter for the clear hose listed, see pictures, works with all existing parts but now allows easy plug and unpluging of the hose and I use the Vent plug when ventilation system is not in use.

Similar models

thingiverse

free

Ikea lack enclosure

...04_s00?ie=utf8&psc=1

magnetshttps://www.amazon.com/gp/product/b07wj6l7w3/ref=ppx_yo_dt_b_asin_title_o06_s00?ie=utf8&psc=1

thingiverse

free

120mm Fan to 4in Vent Hose Adapter (Female) by ragingrivers

... this works well, just an annoying aluminum dentable hose.

full kit: http://www.thingiverse.com/thing:1708681

thanks to wdsparrow

thingiverse

free

Garage door enclosure duct adapter.

...arage door. it does leave a small gap under the door which you might want to cover somehow but it successfully vents those fumes.

thingiverse

free

3D Printer Fume Fan / Duct Coupler 120mm fan to 4-inch duct by addennis

...8&psc=1

use a zip tie or hose clamp to attach the duct; it's a pretty tight fit but will fall off if tugged.

works great!

thingiverse

free

Air Filter

...00?ie=utf8&psc=1

all that is needed extra are bolts to hold the duct to the fan. i just used old bolts i found in the garage.

thingiverse

free

Nema 17 Heatsink and Fan mount by chakkuchan

...1

i'll be adding a second remix of this for the nema 14 on the back of my biqu h2 extruder but with a 40mm fan still i think.

thingiverse

free

Fan mount for FatShark Transformer FPV Goggles by DavidCanfield

...00?ie=utf8&psc=1

wire connector

https://www.amazon.com/gp/product/b01ddhutfm/ref=oh_aui_detailpage_o00_s00?ie=utf8&psc=1

thingiverse

free

K40 Laser, Air Vent, 4in Hose Adapter by wleigh

...following 4in blower:https://tinyurl.com/y7kxsv4t -and used a 4in vinyl hose similar to the...

thingiverse

free

Rotating Modular Hydroponics garden by MuchWick3D

...e_o06_s00?ie=utf8&psc=1

pumphttps://www.amazon.com/gp/product/b08cy28xkw/ref=ppx_yo_dt_b_asin_title_o09_s00?ie=utf8&psc=1

thingiverse

free

Desk Fan by NebNorse

...lpages04?ie=utf8&psc=1

motor control: https://www.amazon.com/gp/product/b01cnl6imc/ref=od_aui_detailpages04?ie=utf8&psc=1

Ragingrivers

thingiverse

free

Ballot Box by ragingrivers

...ballot box by ragingrivers

thingiverse

a simple ballot box.

thingiverse

free

Heart Vase by ragingrivers

...u put a plant in it, and want to water it, make sure to go heavy on the top layers if you are not going to seal it, 4 layers min.

thingiverse

free

Power and Air Tool Hangar by ragingrivers

...power and air tool hangar by ragingrivers

thingiverse

a hangar for my air powered nail guns to hang on a wire rack.

thingiverse

free

Bliss Light Indoor Mount V3 by ragingrivers

...ht indoor mount v3 by ragingrivers

thingiverse

modified for improved robustness and appearance, as well as ease of installation.

thingiverse

free

Dyson Heater Replacement Base by ragingrivers

...ven knows where the original is. print with supports, tear them out, should fit on loose, rotate to snug just like the original.

thingiverse

free

80mm Fan Cabinent Mount by ragingrivers

...ed an extra for my audio video cabinet). i used orings for damping, and a random 80mm fan grill from this site for the backside.

thingiverse

free

Wire Shelf Corner Cap by ragingrivers

...block stops the support bracket from wagging. free cad file attached if you want it more robust or have non standard wire gauge.

thingiverse

free

Flexible Toy Truck Replacement Tires (EN40) by ragingrivers

...ugh, and low and behold some tires were missing. didn't i just get some of that new en40 flexible filaments from makergeeks?

thingiverse

free

Audio Video Cabinent Vent 50mm by ragingrivers

... air flow. this is the first of many mods, and passes the wife test of "must look purchased." free cad file uploaded.

thingiverse

free

Air Tool Inlet Cap (Flexible) by ragingrivers

...to print a nice cap. note this ninja flex stuff sticks ridiculously well to the bed. reheat bed (40c for me) to aid in removal.

Ffc

3d_export

$10

ffc soft flat wire punching machine and ccd visual inspection equipment

...on equipment

3dexport

mobile phone ffc blanking machine, ffc soft flat wire punching machine and ccd visual inspection equipment

3d_export

$20

wire laser cutting peeling cutting machine ffc cutting machine

...and receiving machine, with the structure of this drawing, you don't need to draw by yourself, welcome to collect, thank you.

3dfindit

free

FFC Accessories

...ffc accessories

3dfind.it

catalog: te connectivity

3dfindit

free

FFC Connectors

...ffc connectors

3dfind.it

catalog: te connectivity

3dfindit

free

FFC Contacts

...ffc contacts

3dfind.it

catalog: te connectivity

thingiverse

free

Cable Clip for FFC Cables by nad_22

...cable clip for ffc cables by nad_22

thingiverse

this is a simple clip for mounting ffc cables to what ever ;-)

thingiverse

free

FFC to FFC adapter extension clamp for Geeetech A10 by Deejayshag

... effectively for other ffc cables as well, as long as they have less than 40 pins (think raspberry pi camera, which has 15 pins).

thingiverse

free

V Slot FFC Cable Clamp by firepower9966

...usion.

need this to keep my geeetech lcd interface tidy and safe.

print two stand upright to go on either side of ffc to hold it.

thingiverse

free

Quanum V2 FFC Mount by hpz937

...ount for the crazepony 700tvl fpv camera. mount was then hot glued to quanum v2 monitor.

camera dimensions 12.5mm x 12.5mm x 6mm

thingiverse

free

BCN3D+ cable chain + ffc cable by AlexQuad

...er, solution for cables cuts in the extruder.

the chain is from http://www.thingiverse.com/thing:11978http://youtu.be/ymd8anl5bni

Flashforge

thingiverse

free

Flashforge Logo

...flashforge logo

thingiverse

flashforge logo

thingiverse

free

flashforge logo by morive3d

...flashforge logo by morive3d

thingiverse

this is a flashforge stamphttps://www.youtube.com/channel/ucu6ge9qrju9cpgg6wrlxkqw

thingiverse

free

Flashforge Glass Bed by olo2000pm

...flashforge glass bed by olo2000pm

thingiverse

flashforge glass bed

thingiverse

free

Toolbox for FlashForge Finder by Gringo1970

...toolbox for flashforge finder by gringo1970

thingiverse

smal toolbox for flashforge finder

thingiverse

free

Flashforge / Dremel lid by Disco_Rob

...flashforge / dremel lid by disco_rob

thingiverse

lid extension for the flashforge dreamer

thingiverse

free

Flashforge Dreamer Filamentguide by PeterS1

...de for flashforge dreamer / dremel idea. you need also flashforge dreamer lid spacer (http://www.thingiverse.com/thing:1219953)

thingiverse

free

Flashforge creator legs by cybadigitals

...flashforge creator legs by cybadigitals

thingiverse

these legs gives a clearance of 25mm for flashforge creator series

thingiverse

free

Flashforge Inventor/Dreamer by Iprintr7

...orge inventor/dreamer by iprintr7

thingiverse

this is my first thingiverse project and is a model of the flashforge 3d printer

thingiverse

free

Flashforge Filiment Guide by russellscanlan

...flashforge filiment guide by russellscanlan

thingiverse

my design to feed filament through the door on a flashforge adventure 3

thingiverse

free

Flashforge Winder Adapter by newky2k

...winder adapter by newky2k

thingiverse

adapters for the flashforge 0.5 kg spools to the for the filament spool winder by ssinnott

Vent

archibase_planet

free

Vent

...vent

archibase planet

aeration venting home equipment

diffuser vent - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent atlantica - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent half frame - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood kitchen equipment

vent - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

damper diffuser air gate

vent grate n100807 - 3d model for interior 3d visualization.

archibase_planet

free

Vent

...vent

archibase planet

cooker hood cooking hood

vent - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$10

Vent

...nt

turbosquid

royalty free 3d model vent for download as fbx on turbosquid: 3d models for games, architecture, videos. (1143454)

turbosquid

$2

Vent

...nt

turbosquid

royalty free 3d model vent for download as obj on turbosquid: 3d models for games, architecture, videos. (1323956)

Kit

turbosquid

$3

Bathroom Kit Baño kit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Kit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

Drift Kit

...drift kit

3dexport

turbosquid

$40

BitCoin Kit

...urbosquid

royalty free 3d model bitcoin kit for download as on turbosquid: 3d models for games, architecture, videos. (1519068)

turbosquid

$9

Industrial kit

...osquid

royalty free 3d model industrial kit for download as on turbosquid: 3d models for games, architecture, videos. (1144117)

turbosquid

$6

Kit Vases

...

turbosquid

royalty free 3d model kit vases for download as on turbosquid: 3d models for games, architecture, videos. (1285114)

turbosquid

free

Survival Kit

...rbosquid

royalty free 3d model survival kit for download as on turbosquid: 3d models for games, architecture, videos. (1637721)

turbosquid

$50

Ninja Kit

...rbosquid

royalty free 3d model ninja kit for download as fbx on turbosquid: 3d models for games, architecture, videos. (1672364)

turbosquid

$35

Brushes Kit

...osquid

royalty free 3d model brushes kit for download as max on turbosquid: 3d models for games, architecture, videos. (1216721)

turbosquid

$19

Medical kit

...osquid

royalty free 3d model medical kit for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486089)

Pro

turbosquid

$29

Pro

...ree 3d model mac pro for download as obj, c4d, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1505782)

turbosquid

$15

Apple Mac Pro and Pro Display

...ee 3d model apple mac pro and pro display for download as max on turbosquid: 3d models for games, architecture, videos. (1417078)

3d_export

$5

iphone 13 pro max and pro

...3 pro max and 13 pro the model is made in four colors (graphite, gold, silver, and blue), all of which are attached in the files.

3d_export

free

sapphire pro

...sapphire pro

3dexport

sapphire pro 3d printer head mask

3d_export

$4

macbook pro

...macbook pro

3dexport

macbook pro 13" inch 2020 years model

3ddd

free

GentleLase Pro

... syneron , candela

gentlelase pro аппарат для лазерной эпиляции

turbosquid

$25

PRO frame

...rbosquid

royalty free 3d model pro frame for download as max on turbosquid: 3d models for games, architecture, videos. (1148329)

turbosquid

$5

Alien pro

...osquid

royalty free 3d model alien pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1678446)

turbosquid

$5

iphone11 pro

...uid

royalty free 3d model iphone11 pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1562707)

3ddd

$1

Mac Pro (appel)

...mac pro (appel)

3ddd

компьютер , apple

mac pro