Thingiverse

Filament Server System Mark II by JuliaTruchsess

by Thingiverse

Last crawled date: 3 years ago

Since publishing the Filament Server System in 2013, I've sought an improved system requiring less printing, fewer loose parts, less assembly, and easier spool changeovers. When I created the pipe-based, wall-mounted Spool Storage Rack last year, I became intrigued by the idea of feeding directly from spools sitting on pipes, but the friction of the spool edges on iron pipes is too great.

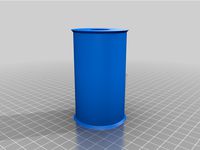

As it turns out, the black drainage pipe sold in Home Depot and Lowe's, from "Charlotte Pipe" is made from a very "slippery" material that allows most (but not all) filament spools to turn freely. Normal PVC plumbing pipe will not work, it has too much friction. For spools that don't turn freely on the Charlotte pipe (cardboard, for one), or for situations requiring absolute minimal pulling force, I designed a snap-on axle support, two of which can support a piece of 2"/50mm OD plastic pipe acting as an axle. The scheme can be seen in action here: https://youtu.be/O7FAWeHpkeU

The plastic pipe slides over 3/4" (23.4mm OD) electrical conduit, which is cheaper, lighter, cleaner, and easier to cut than iron pipe, and has no threaded ends needing to be concealed. I'm not sure what the nominal size of the Charlotte pipe is, but its OD is about 1.25" or 30mm.

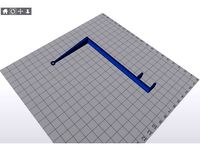

This system also addresses a need I had for a free-standing rack not requiring wall-mounting. The vertical members are 1-1/4" perforated square "Boltmaster" tubing from SteelWorks, available from Amazon and elsewhere. In my setup these uprights are bolted to a butcher block workbench with the help of some bracketry. The "mid" and "top" rail guides are a tight friction fit into the square tubing and might require a whack or two with a mallet. The conduit snaps smartly into the rail guides, as do the filament guides and axle supports into the plastic pipe.

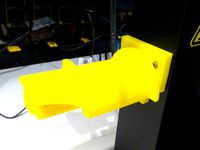

The system can feed from spools at a significant lateral distance from the printer, but if not prevented from doing so, the spool will creep sideways and run into other spools, increasing friction. To prevent this, and to provide a smooth, low-friction path for the filament regardless of feed angle, snap-on multifunction guides are provided. Spools can simply sit between them, or the spool edge can be placed in the "groove" provided. There's also a notch-y thing at the front of each guide where a loose filament end can be secured.

IMPORTANT: When feeding from a spool resting on the pipe rails, it is imperative that the filament feed from "under" the spool, between the rails. If you feed from "over the top" of the spool, the spool will get pulled off the rails and topple over (don't ask me how I know). Spools using the axle holder can feed either way.

As it turns out, the black drainage pipe sold in Home Depot and Lowe's, from "Charlotte Pipe" is made from a very "slippery" material that allows most (but not all) filament spools to turn freely. Normal PVC plumbing pipe will not work, it has too much friction. For spools that don't turn freely on the Charlotte pipe (cardboard, for one), or for situations requiring absolute minimal pulling force, I designed a snap-on axle support, two of which can support a piece of 2"/50mm OD plastic pipe acting as an axle. The scheme can be seen in action here: https://youtu.be/O7FAWeHpkeU

The plastic pipe slides over 3/4" (23.4mm OD) electrical conduit, which is cheaper, lighter, cleaner, and easier to cut than iron pipe, and has no threaded ends needing to be concealed. I'm not sure what the nominal size of the Charlotte pipe is, but its OD is about 1.25" or 30mm.

This system also addresses a need I had for a free-standing rack not requiring wall-mounting. The vertical members are 1-1/4" perforated square "Boltmaster" tubing from SteelWorks, available from Amazon and elsewhere. In my setup these uprights are bolted to a butcher block workbench with the help of some bracketry. The "mid" and "top" rail guides are a tight friction fit into the square tubing and might require a whack or two with a mallet. The conduit snaps smartly into the rail guides, as do the filament guides and axle supports into the plastic pipe.

The system can feed from spools at a significant lateral distance from the printer, but if not prevented from doing so, the spool will creep sideways and run into other spools, increasing friction. To prevent this, and to provide a smooth, low-friction path for the filament regardless of feed angle, snap-on multifunction guides are provided. Spools can simply sit between them, or the spool edge can be placed in the "groove" provided. There's also a notch-y thing at the front of each guide where a loose filament end can be secured.

IMPORTANT: When feeding from a spool resting on the pipe rails, it is imperative that the filament feed from "under" the spool, between the rails. If you feed from "over the top" of the spool, the spool will get pulled off the rails and topple over (don't ask me how I know). Spools using the axle holder can feed either way.

Similar models

thingiverse

free

Filament Spool Holder and Guides for Anycubic I3 Mega

...guide upper" just makes it a bit neater; make sure you install it high enough lest it cause problems for your taller prints.

thingiverse

free

Radial filament guide for cabinet mount by wavexx

...ariant) sitting on top of the cabinet, combined with these hooks https://www.thingiverse.com/thing:2923602 for the display panel.

thingiverse

free

1Kg Spool to CD Spindle guide by MasonStonehenge

...d. just ensure that the 1st couple of layers stick properly to the bed because they have very little surface area (low friction).

thingiverse

free

PrintrBot 2pc Basic Spool Holder by Cmerritt_319

...l so that the filament is "retained" in the area between the spool of filament and the filament retainer bar.

yer done!

grabcad

free

Micro M3D External Filament Guide

...t is a snap fit over the plastic body of the printer.

i've included solidworks (2015), parasolids and stl file formats here

thingiverse

free

Filament Guide by bbtinkerer

...ide keeps the filament centered on the spool preventing filament from running out on the sides and getting caught up on the axle.

thingiverse

free

TEVO Black Widow - Filament Holder - 20x80 Spool Holder by Liam_Miller

...um extrusion and does not require any fastening. filament spool turns freely on the holder and feeds into the extruder from above

thingiverse

free

Filament spool holder (25mm conduit) for the ORIGINAL PRUSA I3 MK2 by mickgalt

...m id of the pvc pipe and modified the 2 arms for the 25mm od.

this design is a big improvement over the original i3 spool holder!

thingiverse

free

Hictop Prusa I3 Filament Feed Guide by odonnellp24

...ps filament from de-spooling and tangling while printing. simply snap it into place and feed the filament through the guide hole.

thingiverse

free

Prusa i3 filament spool axle holder by LeifA

...hat will provide a smooth surface for the filament to glide on. print two short ones, or one long, and snap them to the axle rod.

Juliatruchsess

thingiverse

free

Racquetball Racquet Keyfob by JuliaTruchsess

...fy yourself as one of the elite humans who loves the ultimate sport! "if it's too fast, there's always tennis."

thingiverse

free

Empyreal Chess by JuliaTruchsess

...s can be glued (i used lead rod) and recesses for stick-on felt pads.

the board is here: http://www.thingiverse.com/thing:1441258

thingiverse

free

Napkin Holder by JuliaTruchsess

...ned with tinkercad. the base is a tight squeeze on the m200 platform but it does fit if you rotate it 34.7 degrees in the z axis.

thingiverse

free

Tripod by JuliaTruchsess

...y be trimmed to fit on the afinia if needed.

the source files can be found and edited at https://tinkercad.com/things/dg7uzmdpezh

thingiverse

free

Badass Stanford Armadillo by JuliaTruchsess

...ted the stanford scans to obj, and i converted that to stl.

both sites grant non-commercial license provided attribution is made.

thingiverse

free

Shifter Bezel for 2011 Jeep JK by JuliaTruchsess

...r, your outfit, your nails, your mood...

editable on tinkercad at

https://tinkercad.com/things/aiuckhef9m6-jeep-shifter-bezel

thingiverse

free

Spoonriders by JuliaTruchsess

...te thingiverse heroes are here, or at least most of mine, anyway. chow down with cthulu, slurp soup with gorn, gorge with ganesh!

thingiverse

free

Viking Helmet Extruder Cover for Zortrax M200 by JuliaTruchsess

... because i can.

https://www.youtube.com/watch?v=lff9qxdmkhu

fits and installs just like the oem cover; has clearance for z-temp™.

thingiverse

free

FonaSmoka by JuliaTruchsess

...he buttons are very fragile - don't push them if the phone's not in the case! once the phone is inside, they're fine.

thingiverse

free

MakerBot Spool Adapter for Up! Octave Spool Holder by JuliaTruchsess

... octave spool holder for up! and accommodates makerbot spools with their larger hub openings and one-side-recessed configuration.

Server

archibase_planet

free

Server

...

archibase planet

server pc workstation it equipment

server it-pc n270815 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Server

...server

3dexport

3d_export

$10

Server cabinet

...server cabinet

3dexport

server cabinet built on solidworks software.

turbosquid

$50

Server

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$36

Server

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Server A

... model server a for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1694729)

turbosquid

$2

Server

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

server

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

SERVER

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

server a

...ance painter 2017 and rendered in bledner using eevee. model has two sets of uvs: one for texturing and one for lightmap backing.

Mark

3ddd

$1

MARK - Ribbon

...mark - ribbon

3ddd

mark , ribbon

mark - ribbon

turbosquid

$20

mark

...squid

royalty free 3d model mark for download as 3ds and stl on turbosquid: 3d models for games, architecture, videos. (1445786)

3d_export

$5

road markings

...road markings

3dexport

construction of road markings

turbosquid

$99

Mark

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кресло Mark

...кресло mark

3ddd

mark , david casadesus

760x850x800

david casadesus · 2008

3d_export

$5

check mark and cross mark

...max 2015,cinema4d obj fbx stl dwg dxf warning:dont forget to active turbosmooth after final modeling. enjoy 3d modeling good luck

3ddd

free

Mark Albrecht Chair

...mark albrecht chair

3ddd

mark albrecht

mark albrecht chair

design_connected

$16

Question Mark

...question mark

designconnected

tonon question mark chairs computer generated 3d model. designed by stefan heiliger.

turbosquid

$20

Bed Mark

...d

royalty free 3d model bed mark for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1565907)

turbosquid

$60

Mark IV

...oyalty free 3d model mark iv for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1515462)

Ii

3d_ocean

$5

inoplanet II

...inoplanet ii

3docean

3ds arman3dg games ii inoplanet low max poly trees

inoplanet ii

3ddd

$1

Novecento II

...novecento ii

3ddd

консоль

консоль: ii novecento

дизайнер: elia monterosso

3ddd

$1

Спальня VENERO II

...d

venero ii , venero , hulsta

спальня venero ii

3ddd

$1

PROPORTION II

...proportion ii

3ddd

malabar emotional

консоль proportion ii

malabar emotional design

коллекция euphoria

3ddd

$1

Regina II

...ltrona frau , капитоне

this is a custom version of the poltrona frau regina ii armchair.

3d_export

$119

cinderella ii

...cinderella ii

3dexport

3d_export

$119

lara ii

...lara ii

3dexport

3d_export

$119

doris ii

...doris ii

3dexport

3ddd

$1

Heracleum II

...s endless technical possibilities,

making this new version much more efficient while providing unique and sparkling illumination.

3ddd

$1

Towel Collection II

...towel collection ii

3ddd

полотенце

towel collection ii

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

System

archibase_planet

free

System

...m

archibase planet

fire alarm system fire alarm box

security light system - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spider system

...stem spider glass system

spider system to fix glass stefano galli n050912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Euforia System

...euforia system

3ddd

euforia

euforia system

3d_export

$50

Roof system Truss system 3D Model

...oof system truss system 3d model

3dexport

roof system truss truss stage

roof system truss system 3d model aleksbel 38970 3dexport

3ddd

$1

DVD System

...dvd system

3ddd

dvd , schneider

dvd system

design_connected

free

Seating system

...seating system

designconnected

free 3d model of seating system

3d_export

$5

solar system

...solar system

3dexport

solar system in c4d, with 8k nasa textures

3ddd

$1

Quanta System

...quanta system

3ddd

медицина

quanta system.

лазерное оборудование для медицинских центров

3d_export

$15

solar system

...nd the other the sun, the earth and the moon, the latter has an animation with camera movement included, the files are in spanish

3d_export

$14

missile system

...missile system

3dexport