Thingiverse

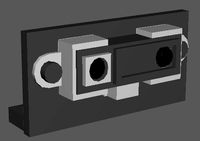

Filament Sensor Mount for CR-10 by psdesign

by Thingiverse

Last crawled date: 3 years ago

This is an improved filament runout sensor mount for the CR-10.

Revision June 1, 2018: I have just modified and uploaded a new revision *- which has a thicker base plate for more resistance to long term strain from filament tension.

I have constrained the filament path to the minimal it needs right up to cutaway for the lever of the switch to move. I have created a path that should lead right into your extruder at the right height and position. I have specifically designed it to work with the EXR Struder by SeeMeCNC, but it seems to align well with stock and aluminum versions.

Be sure when screwing it to the 2 screws which mount your bearing on the Z rods, that you dont tighten the screws too much this may constrain the bearing from moving into the most comfortable position for it to allow for free movement.

Also look at my tape fix for the metal switch lever, this is probably the main reason every one has problems inserting filament.

I did make it to mount a PFTE tube at the entrance, I find this helps filament to bend and align with new path to extruder from the reel without allowing the filament to wear down the sensor mount.

print with no supports. both parts laying on their flat backs and open clam shell upward.

I print at 0.1 layer height and slow 35mm/s to get all of the detail sharp.

You will need 2 socket head or button head M3 x 10mm and 3 countersunk M3 x 10mm

I like to keep assortments such as:http://a.co/8sZ7tY4

or full assortment:http://a.co/1QCcfcb

and 3 countersunk M3 x 10:http://a.co/h1ciAqL

1 30mm length of PFTE tubing, cut with sharp razor (not scissors), flair exposed end a bit with a Phillips screw driver

If you make one please post your 'make' photos.

••••Update March 2 files filambox5 have been updated with a slightly adjusted height to better align path to extruder, have repaired some internal issues. Have opened the rear screw mount so you can leave the brass bearing connected with one screw, just raised, slip it on, then screw in second.

Updates on Base6 made opening at higher angle to ease mounting without removing rear screw, still to be tested.

*** Update March 4, following a few user tests and comments I have made version 7.

the screw holes have been made longer and countersinks wider to accommodate standard screws from stock filament holder. I have also made oval openings for screw mounts to allow more flexibility in mounting and less stress on bearing position. For this reason I was also forced to remove the open ended top screw.

thanks!

Revision June 1, 2018: I have just modified and uploaded a new revision *- which has a thicker base plate for more resistance to long term strain from filament tension.

I have constrained the filament path to the minimal it needs right up to cutaway for the lever of the switch to move. I have created a path that should lead right into your extruder at the right height and position. I have specifically designed it to work with the EXR Struder by SeeMeCNC, but it seems to align well with stock and aluminum versions.

Be sure when screwing it to the 2 screws which mount your bearing on the Z rods, that you dont tighten the screws too much this may constrain the bearing from moving into the most comfortable position for it to allow for free movement.

Also look at my tape fix for the metal switch lever, this is probably the main reason every one has problems inserting filament.

I did make it to mount a PFTE tube at the entrance, I find this helps filament to bend and align with new path to extruder from the reel without allowing the filament to wear down the sensor mount.

print with no supports. both parts laying on their flat backs and open clam shell upward.

I print at 0.1 layer height and slow 35mm/s to get all of the detail sharp.

You will need 2 socket head or button head M3 x 10mm and 3 countersunk M3 x 10mm

I like to keep assortments such as:http://a.co/8sZ7tY4

or full assortment:http://a.co/1QCcfcb

and 3 countersunk M3 x 10:http://a.co/h1ciAqL

1 30mm length of PFTE tubing, cut with sharp razor (not scissors), flair exposed end a bit with a Phillips screw driver

If you make one please post your 'make' photos.

••••Update March 2 files filambox5 have been updated with a slightly adjusted height to better align path to extruder, have repaired some internal issues. Have opened the rear screw mount so you can leave the brass bearing connected with one screw, just raised, slip it on, then screw in second.

Updates on Base6 made opening at higher angle to ease mounting without removing rear screw, still to be tested.

*** Update March 4, following a few user tests and comments I have made version 7.

the screw holes have been made longer and countersinks wider to accommodate standard screws from stock filament holder. I have also made oval openings for screw mounts to allow more flexibility in mounting and less stress on bearing position. For this reason I was also forced to remove the open ended top screw.

thanks!

Similar models

thingiverse

free

Creality CR-6 SE PFTE Cable Guide for Filament Sensor by michaelbourque

...

use this with m3 x 25mm screws to attach to top of cr-6 se filament sensor. screw in a pfte tube coupler and a short pfte tube.

thingiverse

free

CR-10 Rotating Filament Sensor by youngjc

...essed fit into the mount and plate, might require some sanding.

requires

(1) m4 screws & t-nut

(4) m3 screws

(1) 608 bearing

thingiverse

free

CR-10 Titan Extruder Filament Sensor by jnsanders1983

...its lever and the lead screw. i created this sensor holder to take advantage of the ability to insert a pfte tube into the lever.

thingiverse

free

CR-10s filament sensor frame mount by timreeves

...w you to use the cr-10s filament sensor mounted to the frame, i use it on mine at the top as i have changed to a direct extruder.

thingiverse

free

CR-6SE BALL BEARING PULLEY FILAMENT GUIDE by HAAUK

...m3 x 20mm++ screws to mount the plate and pulley

it is designed for a 1608 ball bearing because i have many of those lying around

thingiverse

free

CR-200B extruder and filament sensor relocation braces by pienjo

...ing holes for the stepper motor and the extruder.

this requires extending the cables for the stepper motor and filament detector.

thingiverse

free

Creality CR-6 SE filament sensor riser plate for WINSIN dual gear extruder by MrSovieticus

...ual gear extruder.

the stock screws are too short, you will need to use 2x m3 25mm or longer screws to hold the mount the sensor.

thingiverse

free

CR6 SE Filament Sensor lift block by agent9

...is.

i used the old dual gear extruder from my cr10s pro but any of the ones from amazon for creality printers should fit as well.

thingiverse

free

Filament guide/run-out sensor relocation (Creality CR-10S PRO V2) by AtoMic09

...n tube.

you will need:

1x 608rs bearing

4x m3 8mm countersunk flat head screws

4x m3 20mm countersunk flat head screws

4x hex nut

thingiverse

free

CR-10 X Dual Damper with filament sensor holder by jnsanders1983

...d tolerance for limit switch and changed mounting postion.

update: fix model error in filament sensor cap with the hole placement

Psdesign

thingiverse

free

Batman Toy by psdesign

...r kids.

made this one with holes for small magnets, but left them out of the file so you can drill to your magnet size.

have fun.

thingiverse

free

50mm Fan Guard by psdesign

...n ingress.

this is for a 50 square fan, i will upload other sizes on request.

if you print and like them please post your photos!

thingiverse

free

Jack O Lantern Stencils by psdesign

...s for halloween pumpkins, eyes, noses, mouthes.

have fun!

scale to your needs

if you print and like them please post your photos!

thingiverse

free

tri-spinner by psdesign

...mp;psc=1

and 22mm bearings like these:https://www.amazon.com/gp/product/b01c9xdpvq/ref=oh_aui_search_detailpage?ie=utf8&psc=1

thingiverse

free

Spacer for Reel Holder for CR-10 by psdesign

...fore and after your filament reel on the cr-10 standard reel holder.

if you like this please post photos of your print in action!

thingiverse

free

Extruder Knob by psdesign

...rrectly, with this one you have much more visibility

if you print this please post your photos

print flat side down, no supports.

thingiverse

free

Glasses Clip for M2 MakerGear by psdesign

...ou get to the machine. i made a glasses clip to attach to the m2, i secured it with a bit of two sided tape, and it works great.

thingiverse

free

sword through body by psdesign

...ut in half, insert each end with a bit of super glue, and you are good to go!

if you print and like them please post your photos!

thingiverse

free

fidget spinner circular by psdesign

...mp;psc=1

and 22mm bearings like these:https://www.amazon.com/gp/product/b01c9xdpvq/ref=oh_aui_search_detailpage?ie=utf8&psc=1

thingiverse

free

Filament Roll Clip by psdesign

...to have them around!

think its perfect now!

let me know how it works for you!

if you print and like them please post your photos!

Cr

turbosquid

$15

Creazioni CR-673 CR-4461

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Ravak CR 055.00

...ravak cr 055.00

3ddd

ravak , смеситель

ravak cr 055.00

turbosquid

$100

CR-002

...

turbosquid

royalty free 3d model cr-002 for download as stl on turbosquid: 3d models for games, architecture, videos. (1686037)

3ddd

$1

Ravak CR 012.00

...ravak cr 012.00

3ddd

ravak , смеситель

смеситель ravak cr 012.00

3ddd

free

Консоль CR Currin

...ь , cr currin

консоль cr currin

ширина - 1675 мм

глубина - 510 мм

общая высота - 810 мм

3ddd

$1

CR 39444

...0

диаметр: 100

тип патрона: gu5,3 gu10

количество ламп: 1

мощность: 35w

цвет: золото хрусталь

материал: металл хрусталь exclusive

3d_ocean

$89

Honda CR-Z

...www.youtube.com/watch?v=rrbb4d4lypk ` he honda cr-z‘s exterior styling is formed around a “one-motion wedge” concept with a lo...

3ddd

$1

Creazoni / STEFY CR-8901

...creazoni / stefy cr-8901

3ddd

creazoni

creazioni stefy cr-8901

turbosquid

$60

Chain-CR-001

...squid

royalty free 3d model chain-cr-001 for download as stl on turbosquid: 3d models for games, architecture, videos. (1680536)

turbosquid

$99

Honda CR-Z

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

turbosquid

$26

Wind sensor C

...free 3d model wind sensor c for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328943)

turbosquid

$26

Wind sensor B

...free 3d model wind sensor b for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328168)

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

turbosquid

$52

Wind sensor A B C

...

royalty free 3d model wind sensor a b c for download as fbx on turbosquid: 3d models for games, architecture, videos. (1408406)

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

turbosquid

$24

Chandelier MD 89310-10+10 Osgona

... chandelier md 89310-10+10 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218762)

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)