Thingiverse

Filament runout sensor for Tevo Tarantula (and others) by corruptfile

by Thingiverse

Last crawled date: 3 years, 1 month ago

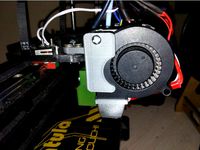

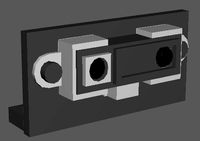

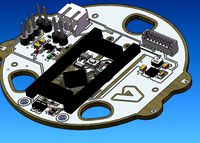

Quick and dirty filament runout sensor. I will be leveraging a RPi3 for this, but there are tutorials on how to wire a runout sensor to the MKS board. This is for 1.75mm filaments only.

For this, you will need:

Raspberry Pi running Octoprint

I am running Marlin 1.1.5. YMMV if you are running something else...

2x M4x10 socket head cap screws

2 M4 T-nuts (like the ones the printer came with) -OR-

2 M4 threaded inserts (I used McMaster-Carr P/N 94510A040

A microswitch. I used an OMRON SS-5GL2T (https://www.amazon.com/ELECTRONIC-COMPONENTS-SS-5GL2T-MICROSWITCH-ROLLER/dp/B011N9VGV8)

2 pieces of 1.75mm filament cut to ~20mm

2 conductor cable

Heatshrink

Female jumper or some other connector to hook up to the GPIO pins

(optional) 2 t-nuts to direct mount this to the frame if desired.

(optional) some sort of connectors for quick disconnection of the cable.

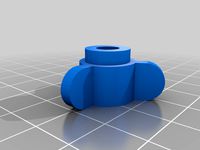

The physical assembly should be straight forward for the assembly. If you are not using the press inserts, you just drop the tnuts in the back of the rear clamshell and tighten up. Might be a good idea to do this before mounting to the printer to allow you to tighten the nut in and have it swage into the plastic. I never used that method so I'm not sure!

Solder one conductor of your cable to the relay COM/GND. The other should be soldered to the NO terminal (you can use the NC terminal too, and just change it in Octoprint). Use heatshrink to protect your connections and offer some strain relief. Place the switch in the housing and use the 2 pieces of filament to secure the switch. Depending on your printer performance, you may need to drill (use a 5/64" bit) it out a tad.

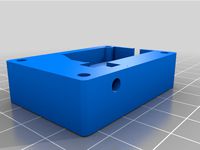

After the assembly is done, you will need to wire it to your RPi. I am using the RPi for remote on/off as well, so I opted to build an enclosure for the relay to live. Also, I used a breadboard with a GPIO extension board for ease of wiring. This is totally optional and you can get away with wiring directly to the GPIO header on the RPi. Connect one conductor (doesn't matter which) to your switching pin (I used Pin 24 (BCM8/CE0) for signal) and the other to a ground pin (pin 20 or 25, for example). Congrats, now you are wired.

In Octoprint, download and install the "Filament Sensor Reloaded" plugin. After it is installed, change the pin to 24 (or whatever one you used), leave debounce at 250ms, leave switch type to Normally Open (unless you wired your switch NC!), select board mode, and deselect "Pause print when out of filament". In custom g-code, add the following:

M600 X0 Y0 Z5

This will start the filament change process (M600) and send the print head to home. Follow the prompts on your LCD to complete the filament change.

No more partial rolls!

For this, you will need:

Raspberry Pi running Octoprint

I am running Marlin 1.1.5. YMMV if you are running something else...

2x M4x10 socket head cap screws

2 M4 T-nuts (like the ones the printer came with) -OR-

2 M4 threaded inserts (I used McMaster-Carr P/N 94510A040

A microswitch. I used an OMRON SS-5GL2T (https://www.amazon.com/ELECTRONIC-COMPONENTS-SS-5GL2T-MICROSWITCH-ROLLER/dp/B011N9VGV8)

2 pieces of 1.75mm filament cut to ~20mm

2 conductor cable

Heatshrink

Female jumper or some other connector to hook up to the GPIO pins

(optional) 2 t-nuts to direct mount this to the frame if desired.

(optional) some sort of connectors for quick disconnection of the cable.

The physical assembly should be straight forward for the assembly. If you are not using the press inserts, you just drop the tnuts in the back of the rear clamshell and tighten up. Might be a good idea to do this before mounting to the printer to allow you to tighten the nut in and have it swage into the plastic. I never used that method so I'm not sure!

Solder one conductor of your cable to the relay COM/GND. The other should be soldered to the NO terminal (you can use the NC terminal too, and just change it in Octoprint). Use heatshrink to protect your connections and offer some strain relief. Place the switch in the housing and use the 2 pieces of filament to secure the switch. Depending on your printer performance, you may need to drill (use a 5/64" bit) it out a tad.

After the assembly is done, you will need to wire it to your RPi. I am using the RPi for remote on/off as well, so I opted to build an enclosure for the relay to live. Also, I used a breadboard with a GPIO extension board for ease of wiring. This is totally optional and you can get away with wiring directly to the GPIO header on the RPi. Connect one conductor (doesn't matter which) to your switching pin (I used Pin 24 (BCM8/CE0) for signal) and the other to a ground pin (pin 20 or 25, for example). Congrats, now you are wired.

In Octoprint, download and install the "Filament Sensor Reloaded" plugin. After it is installed, change the pin to 24 (or whatever one you used), leave debounce at 250ms, leave switch type to Normally Open (unless you wired your switch NC!), select board mode, and deselect "Pause print when out of filament". In custom g-code, add the following:

M600 X0 Y0 Z5

This will start the filament change process (M600) and send the print head to home. Follow the prompts on your LCD to complete the filament change.

No more partial rolls!

Similar models

thingiverse

free

Filament runout sensor for UP Plus 2 by BogdanKecman

...up provided auto bed leveling sensor this part will don't work for you (the actual piece holding microswitch will be missing)

thingiverse

free

Filament Sensor optical sensor Runout Sensor by nosbiker

...up for the plugin.

works with all 1.75 mm filament (you should be able to drill it up to work with 3mm), except transparent ones.

thingiverse

free

Sigma3d Extruder With Filament Runout Sensor by serkanc

...pin

19 for z max pin

in configuration.h enable the filament_runout_sensor, uncomment the first line,

fil_runout_inverting = false

thingiverse

free

Fillament run out sensor by fragmen52

...wden(1.75mm filament) and m3 nut and bolts

using this plugin for octoprint https://github.com/kontakt/octoprint-filament-reloaded

thingiverse

free

Filament runout housing by didymus

...sed with the filament sensor reloaded plugin for octoprint available here: https://github.com/kontakt/octoprint-filament-reloaded

thingiverse

free

Filament runout sensor for CR-10 by HobbitBen

...round to pin 9

octoprint setup

install plug-in "filament sensor reloaded"

set up the plug-in as per the attached image.

thingiverse

free

1.75mm filament runuot switch holder by ffejrxx

...h with arm and no roller

wire switch, print 2 halves, adjust arm to sense filament and smash together around switch

may need glue

thingiverse

free

Filament run out sensor manual switch octoprint plugin filter by brotherchris

...: http://plugins.octoprint.org/plugins/filament_sensor/

new plugin:http://plugins.octoprint.org/plugins/filament_sensor_reloaded/

thingiverse

free

Ender 2 Filament Runout Sensor by DataMouse

...nder 2 with original-board.

the sensor is connected on pin 29 (marlin 1.1.9) which is on the board labled with "check".

thingiverse

free

Direct Drive DIY Filament Runout Sensor (Ender 3 / 3 Pro) by YorkieOl

... sensor' for information on your paticular board..

anyway, i hope this is helpful for otheres and so share it with you here..

Corruptfile

thingiverse

free

Hanging Spool Holder by corruptfile

...thingiverse

print 2 of these to make a hanging spool holder. made for 3/4" pvc pipe (or a ~27mm dia shaft of your choosing.

thingiverse

free

Tevo Tarantula Titan Extruder Riser by corruptfile

...this will bed them in the plastic, securing them). next attach the riser to your frame. lastly, attach the extruder to the riser.

Runout

3d_export

$6

clamping mechanism of heavy workpiece

...load<br>the inertia force at the maximum acceleration of horizontal runout is less than the retraction side thrust of cylinder.<br>selection...

thingiverse

free

Filament runout sensor by TA1AUB

...filament runout sensor by ta1aub

thingiverse

filament runout sensor

thingiverse

free

Runout filament sensor by davidix68

...runout filament sensor by davidix68

thingiverse

ender 3 runout sensor microswitch case

thingiverse

free

runout sensor -bowden by chroja

...runout sensor -bowden by chroja

thingiverse

runout sensor -bowden

v5 optimalize design

thingiverse

free

Filament runout sensor by jos

.../webshop/cartesio-shop/electronics/filament-runout-sensor

for assembly :http://mauk.cc/mediawiki/index.php/filament_runout_sensor

thingiverse

free

Filament runout by pochetto

...y pochetto

thingiverse

easy filament runout.

1 endstop

1 led

nel firmware attivare la funzione di fine filo e assegnare un pin.

thingiverse

free

Filament runout sensor support by 100s99s

...filament runout sensor support by 100s99s

thingiverse

support for filament runout sensor of direct drive.

thingiverse

free

Swivel mount runout sensor by notnyt

...swivel mount runout sensor by notnyt

thingiverse

608 bearing mounted filament runout sensor

thingiverse

free

Filament runout sensor fastener by Cherepok

...filament runout sensor fastener by cherepok

thingiverse

movable adjustable mount for bigtreetech filament runout sensor.

thingiverse

free

Runout gauge for pulley by tom4cad

...runout gauge for pulley by tom4cad

thingiverse

20t pulley with 5 mm bore. measured runout 0,07 mm

edit

tool with 8mm hole added

Tarantula

turbosquid

$5

tarantula

...rbosquid

royalty free 3d model tarantula for download as c4d on turbosquid: 3d models for games, architecture, videos. (1690032)

3d_ocean

$8

Tarantula

...rantula 3d model. perfect for animations or still image. textures psd and jpeg files included. modelled using autodesk maya 2011.

turbosquid

$50

tarantula

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$45

Tarantula

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Spider black widow tarantula tarantula Insects

... black widow tarantula tarantula insects for download as max on turbosquid: 3d models for games, architecture, videos. (1582101)

3ddd

$1

Журнальный столик - tarantula

... бионика , tarantula

журнальный столик tarantula

h=600

d=2000

3d_export

$35

Tarantula

...: zbrush 3ds max ztool obj fbx dae 3ds stl properties : 20*20*8 production time : 23 hours 328 gram models are drawn with zbrush.

3d_ocean

$20

Tarantula spider

...igged, animated, uv textured. particle system for the fur. very easy to animate. a 250 frames animation is available in the pack.

turbosquid

$45

Tarantula Spider

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

spider tarantula

...spider tarantula

3dexport

3d model of a steppe spider for your ideas and projects.

Tevo

thingiverse

free

TEVO Logo by limwenyao

...verse

tevo logo - for customizing your builds to look cooler with the tevo logo! pdf version is editable with adobe illustrator.

thingiverse

free

Tevo Tornado e3d Tevo Flash Style fan Mount by DemolitionX

...an mount by demolitionx

thingiverse

just messing around and made a tevo flash style fan mount for the e3d v6 on the tevo tornado

thingiverse

free

BODEN TUBE CLAMP FOR TEVO TARANTULA PRO AND TEVO TORNADO

... and tevo tornado

thingiverse

bodwen tube clamp. printable adjustable tension clamp for tevo tarantula pro and tornado extruder.

thingiverse

free

TEVO Tornado Model by JMDesigns

...tevo tornado model by jmdesigns

thingiverse

tevo tornado model

thingiverse

free

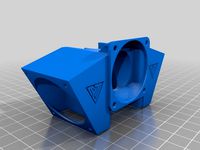

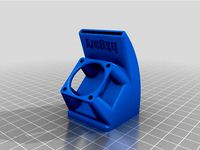

Tevo Tarantula FanDuct by hkgary_g

...tevo tarantula fanduct by hkgary_g

thingiverse

fanduct for tevo tarantula

thingiverse

free

FAN TEVO TARANTULA by llprokall

...fan tevo tarantula by llprokall

thingiverse

fan tevo tarantula

thingiverse

free

Tevo Tarantula filament by Xbertus

...tevo tarantula filament by xbertus

thingiverse

suport for filamente tevo tarantula

thingiverse

free

TEVO Top Brackets by _Godoy_

...tevo top brackets by _godoy_

thingiverse

top brackets for tevo tarantula

thingiverse

free

Tevo Tarantula Spool Holder

...tevo tarantula spool holder

thingiverse

strong spool holder for tevo tarantula

thingiverse

free

tevo tarantula spacer by poundskinnyboy

...tevo tarantula spacer by poundskinnyboy

thingiverse

it's a tevo tarantula spacer

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

turbosquid

$26

Wind sensor C

...free 3d model wind sensor c for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328943)

turbosquid

$26

Wind sensor B

...free 3d model wind sensor b for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328168)

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

turbosquid

$52

Wind sensor A B C

...

royalty free 3d model wind sensor a b c for download as fbx on turbosquid: 3d models for games, architecture, videos. (1408406)

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

Others

design_connected

$16

ST12 Other

...signconnected

photo-realistic 3d models of the st12 other stool from e15 for 3d architectural and interior design presentations.

turbosquid

$26

Oar and Other

...quid

royalty free 3d model oar and other for download as fbx on turbosquid: 3d models for games, architecture, videos. (1473409)

turbosquid

$5

chair with other

...id

royalty free 3d model chair with other for download as ma on turbosquid: 3d models for games, architecture, videos. (1171468)

3ddd

$1

parfume and other

...parfume and other

3ddd

тумбочка

create by sametyuzer

turbosquid

$79

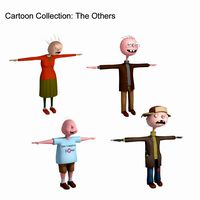

The Others Collection

...others collection for download as 3ds, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1480228)

turbosquid

$25

Other Man

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

other car.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Other Mothers Hand

... 3d model other mothers hand for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1663825)

turbosquid

$8

other sport wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

pool and other elements

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.