Thingiverse

Feeder Clamp with Conical filament driver by fns720

by Thingiverse

Last crawled date: 4 years, 7 months ago

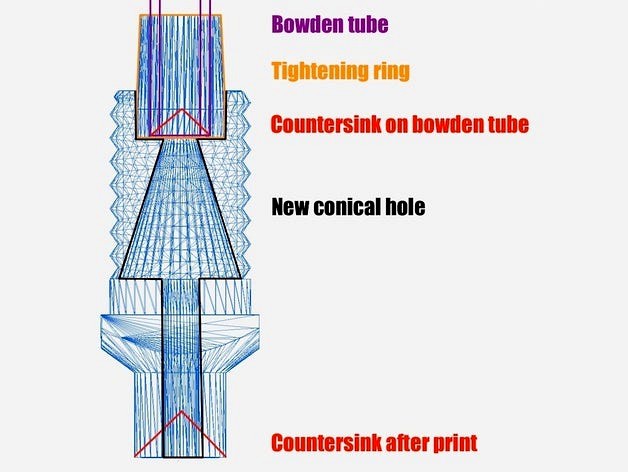

I printed pit3k's bowden clamp and I experienced some difficulties to pass the filament through the riser. I made a subtle change on the riser hole which guides the filament through on the nut part. Now the nut has a conical hole and just 5 mm before the top it extends to fit the tightening ring into it.

I also made a countersink on the bottom on the riser after the print by using a countersink tool (I tried to create this countersink directly in the model but it fails to print on a heated bed, even when raft was switched on).

I also recommend to do another countersink on you bowden tube too.

Finally, I printed chopmeister's great H3 feeder unit and tried to install this bowden clamp in it. It was OK, except that the riser was a bit loose so I made a small tightening nut too to fix this.

Modified OpenSCAD source attached.

I also made a countersink on the bottom on the riser after the print by using a countersink tool (I tried to create this countersink directly in the model but it fails to print on a heated bed, even when raft was switched on).

I also recommend to do another countersink on you bowden tube too.

Finally, I printed chopmeister's great H3 feeder unit and tried to install this bowden clamp in it. It was OK, except that the riser was a bit loose so I made a small tightening nut too to fix this.

Modified OpenSCAD source attached.