Thingiverse

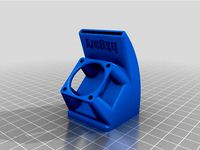

Fanduct Delta Printer by Junior_Designs

by Thingiverse

Last crawled date: 3 years, 1 month ago

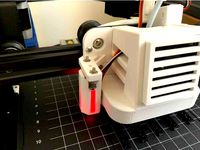

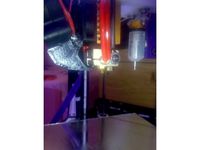

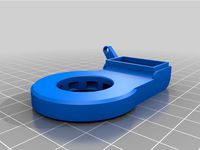

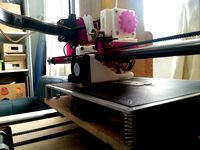

This is a fanduct for Delta Printers, it is compact yet still gets enough airflow to the printing area. All of the designs are for the volcano hotend. As I bought alu parts for my printer to convert all plastic molded parts I came to a hold when I didn't find a compact fanduct that would be easy to mount on the alu parts without getting in the way of the travelling area. I still wanted or atleast was trying to find a fanduct that would blow air around 360° so I came up with my own design. As I use a BLTouch I made a copy with the appropriate mount for it as wel. (One that can be adjusted and one that can't)

There are 3 designs :

-360° fanduct with regular 404010mm fan

-360° fanduct with 404010mm turbo fan

-Fang fanduct with 404010mm turbo fan

Best use Noctua Fans for the regular fanducts, for the turbo fan I used is this one : https://www.aliexpress.com/item/Gdstime-40mm-x-40mm-x-10mm-4cm-DC-12V-2Pin-Brushless-Turbo-Blower-Fan-For-3D/32800602260.html?spm=2114.01010208.3.84.0m912B&ws_ab_test=searchweb0_0,searchweb201602_5_10152_10065_10151_10068_436_10136_10137_10157_10060_10138_10155_10062_10156_10154_10056_10055_10054_10059_10099_10103_10102_10096_10147_10052_10053_10142_10107_10050_10051_10084_10083_10080_10082_10081_10177_10110_10111_10112_10113_10114_10181_10183_10182_10185_10078_10079_10073_10070_10123,searchweb201603_2,ppcSwitch_5&btsid=c33daa72-ec75-4b4a-b957-a20736f3d14f&algo_expid=91aec55e-e0d7-4015-ad02-891773214216-11&algo_pvid=91aec55e-e0d7-4015-ad02-891773214216

The bridges of the part will need supports, however DO NOT USE supports inside the fanduct. You won't be able to get them cleaned up and the fanduct won't be effective anymore then.

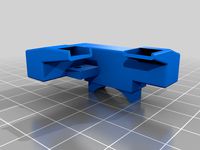

The Adjustable BLTouch Mounts work with springs, for the Turbofan I used one big spring and a long M3 Bolt. The M3 Bolt head goes in the slot between the pillars for the BLTouch mount with the threads facing up, the spring goes on the M3 Bolt. Then slide the mount on the bolt and put a nut on top to keep it in place and to adjust height. Pictures on how it's assembled will follow shortly once I have mine all set up.

Little sidenote : I suggest you slow down your printing speed and make sure to either lower extruding temperature a bit or decent part cooling. The fanduct has small surfaces to print in it and not having any cooling, printing to fast or extruding temperature to hot might result in the small surfaces not sticking well and they will end up draging around with the hotend instead of actually sticking together. (This was a lesson I learned after trying a few times)

The Fan Intake is mainly used to create more air suction for the turbo fan. As I noticed it increases a lot of the air comming out of the fanduct compared to without the fan intake.

I print all my printer parts with 40% infill because my printed is in a heated enclosure, therefore I want as much strenght in my parts as possible. But I tested it with 10% and it works just fine to.

There are 3 designs :

-360° fanduct with regular 404010mm fan

-360° fanduct with 404010mm turbo fan

-Fang fanduct with 404010mm turbo fan

Best use Noctua Fans for the regular fanducts, for the turbo fan I used is this one : https://www.aliexpress.com/item/Gdstime-40mm-x-40mm-x-10mm-4cm-DC-12V-2Pin-Brushless-Turbo-Blower-Fan-For-3D/32800602260.html?spm=2114.01010208.3.84.0m912B&ws_ab_test=searchweb0_0,searchweb201602_5_10152_10065_10151_10068_436_10136_10137_10157_10060_10138_10155_10062_10156_10154_10056_10055_10054_10059_10099_10103_10102_10096_10147_10052_10053_10142_10107_10050_10051_10084_10083_10080_10082_10081_10177_10110_10111_10112_10113_10114_10181_10183_10182_10185_10078_10079_10073_10070_10123,searchweb201603_2,ppcSwitch_5&btsid=c33daa72-ec75-4b4a-b957-a20736f3d14f&algo_expid=91aec55e-e0d7-4015-ad02-891773214216-11&algo_pvid=91aec55e-e0d7-4015-ad02-891773214216

The bridges of the part will need supports, however DO NOT USE supports inside the fanduct. You won't be able to get them cleaned up and the fanduct won't be effective anymore then.

The Adjustable BLTouch Mounts work with springs, for the Turbofan I used one big spring and a long M3 Bolt. The M3 Bolt head goes in the slot between the pillars for the BLTouch mount with the threads facing up, the spring goes on the M3 Bolt. Then slide the mount on the bolt and put a nut on top to keep it in place and to adjust height. Pictures on how it's assembled will follow shortly once I have mine all set up.

Little sidenote : I suggest you slow down your printing speed and make sure to either lower extruding temperature a bit or decent part cooling. The fanduct has small surfaces to print in it and not having any cooling, printing to fast or extruding temperature to hot might result in the small surfaces not sticking well and they will end up draging around with the hotend instead of actually sticking together. (This was a lesson I learned after trying a few times)

The Fan Intake is mainly used to create more air suction for the turbo fan. As I noticed it increases a lot of the air comming out of the fanduct compared to without the fan intake.

I print all my printer parts with 40% infill because my printed is in a heated enclosure, therefore I want as much strenght in my parts as possible. But I tested it with 10% and it works just fine to.

Similar models

thingiverse

free

E3D v6 fanduct with 40x40 hotend fan by vdwel

...t for the bltouch sensor.

the x carriage in this design is for the tevo tarantula, but the fanduct is universal for all printers.

thingiverse

free

Titan Extruder mount for V-Slot mini Gantry by ssombra

...crews to attach the fan mount and the extruder lid (m3 35mm). regarding the bltouch mount, i used m3 screws and m3 brass inserts.

thingiverse

free

Delta dual extruder mount and platform by Bigfella

...ve it fully functional on my printer. i will be making some mods in the future. like hotend adjustment and fan for cooling print.

thingiverse

free

Tevo Tarantula fanDuct by hafidz

...nd.

bullduct 06 have large gap on the 30 mm fan intake

sorry if you print older version and can't cutoff the 30 mm fan intake

thingiverse

free

BLtouch mount for DBot CoreXY by robohead456

...djust the spacing between the nozzle and the bed, tighten the bolts. this forces the washer to deform the printed piece slightly.

thingiverse

free

Hotend Bracket for E3D Volcano and BLTouch (to suit Geeetech printers & Clones) by Celcius1

...y laid out to print in the center of the bed, in abs. and with the correct print settings.

have fun with the new hot end bracket

thingiverse

free

BLTouch mount for Satsana Duct by giahuy2201

... my satsana duct, so i designed this extension to mount my bltouch.

i used a spare m3 bolt from the stock fan shroud to mount it.

thingiverse

free

Sapphire Plus E3D Volcano hotend upgrade kit by auroratechchannel

...part cooling fans)

m3*8mm x2 (bltouch adjustable height plate)

m3 hex nuts x6

aurora tech channelhttp://youtube.com/c/auroratech

thingiverse

free

BLTouch mount for Anycubic i3 Ultrabase by hamop

...e bltouch. i printed mine in abs as it's quite near to the hotend.

on my printer, z offset it around -2.3 mm with this mount.

thingiverse

free

40mm E3Dv6 Clone Intake by alieneila

...sed by the air intake doesn't go towards the hot bed.

am using an anet a8 with an e3dv6 clone hotend and the stock 40mm fan.

Fanduct

thingiverse

free

jgmaker magic fanduct

...jgmaker magic fanduct

thingiverse

jgmaker magic fanduct

thingiverse

free

Ultimaker fanduct by Gijs

...ultimaker fanduct by gijs

thingiverse

replacement fanduct for ultimaker stock fan.

thingiverse

free

50mm Fanduct by NitroXpress

...50mm fanduct by nitroxpress

thingiverse

fanduct for 50mm fan.

85mm long

print without support.

thingiverse

free

Minimalist Fanduct

...esigned this new fanduct to be more minimalist.

also i'm using this fanguard:https://www.thingiverse.com/thing:1691426

thanks

thingiverse

free

BigBooster FanDuct by PHROZENOne

...bigbooster fanduct by phrozenone

thingiverse

big booster fanduct for 35x35 radial part fans and 40x40 hotendfan

thingiverse

free

Fanduct for chimera by StikkaDesign

...thingiverse

a simply fanduct for chimera (configuration with the rotating heating blocks - resistance and thermistor in lateral)

thingiverse

free

Geeetech A10 Fanduct by stefan177gr

...geeetech a10 fanduct by stefan177gr

thingiverse

fanduct for geeetech a10

thingiverse

free

Tevo Tarantula FanDuct by hkgary_g

...tevo tarantula fanduct by hkgary_g

thingiverse

fanduct for tevo tarantula

thingiverse

free

Mendel90 40mm Fanduct by sivar2311

...mendel90 40mm fanduct by sivar2311

thingiverse

40mm fanduct for mendel90.

thingiverse

free

Artillery Genius Hotend Fanduct

...artillery genius hotend fanduct

thingiverse

it is a fanduct for the artillery genius.

Junior

3ddd

$1

Scandia Junior

...scandia junior

3ddd

scandia , junior

scandia junior

design_connected

$13

Scandia Junior

...scandia junior

designconnected

fjordfiesta.furniture scandia junior computer generated 3d model. designed by brattrud, hans.

3ddd

$1

ARRI 150 Junior

... junior

высокополигональная модель источника света arri 150 junior, студийное освещение.

3ddd

free

Leander / Junior bed

... дания

кровать junior bed, leander (дания)

размеры, мм: 1500х700х495http://www.leander.com/produkter/junior-bed

turbosquid

$12

Deathwing (Junior)

...3d model deathwing (junior) for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1259098)

3d_export

free

disney junior cartoon text

...disney junior cartoon text

3dexport

maya model disney junior cartoon text

turbosquid

$30

Belle Epoque Junior

...royalty free 3d model belle epoque junior for download as skp on turbosquid: 3d models for games, architecture, videos. (1475562)

3ddd

free

Alfa Romeo GT 1300 Junior

... gt , junior , машина

alfa romeo gt 1300 junior

turbosquid

$20

Junior with skateboard 0795

...h skateboard 0795 for download as max, fbx, wrl, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1709242)

turbosquid

$16

Leander Junior Bed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Delta

design_connected

$16

Delta

...delta

designconnected

arflex international spa delta computer generated 3d model. designed by koivisto, eero.

design_connected

$16

Delta

...delta

designconnected

lj lamps delta computer generated 3d model. designed by janowski-lenhart, sasha.

design_connected

$13

Delta

...delta

designconnected

emu group delta armchairs computer generated 3d model. designed by marin chiaramonte .

3ddd

$1

Delta Light

...delta light

3ddd

delta light , you-turn reo 3033

точечний светильник delta light

3ddd

$1

Blanco / delta

...blanco / delta

3ddd

blanco , мойка

мойка blanco delta со смесителем

3ddd

$1

Delta Light Spot

...delta light spot

3ddd

delta light

светильник фирмы delta light

3ddd

free

Bianchi Delta LVMDLT200100

...i delta lvmdlt200100

3ddd

bianchi delta , смеситель

смеситель bianchi delta lvmdlt200100

design_connected

free

Delta 190

...delta 190

designconnected

free 3d model of delta 190 by zanotta designed by progetti, emaf.

design_connected

$27

Delta 211

...delta 211

designconnected

zanotta delta 211 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Delta 234

...delta 234

designconnected

zanotta delta 234 computer generated 3d model. designed by progetti, emaf.

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Designs

3ddd

$1

LINE DESIGN (Doors Design)

...line design (doors design)

3ddd

дверь

modern doors design - line design concept

turbosquid

$5

designer

...alty free 3d model designer for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1422665)

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

кресло ver design

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

диван ver design

3ddd

$1

Bagno design

...bagno design

3ddd

bagno design , унитаз

санитария bagno design

3ddd

free

VER DESIGN

...ver design

3ddd

ver design , стеллаж

полка ver design

3ddd

$1

VER DESIGN

...ver design , лежак , шезлонг

шезлонг ver design

3d_export

free

designer

..., trees and much more. the model has 3 types of parts: - 4 cells - 6 cells - 8 cells the *.max file contains 5 colored materials.

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

3d_export

$7

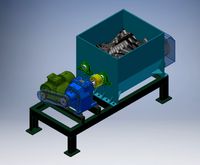

Crusher design

...crusher design

3dexport

crusher design