Thingiverse

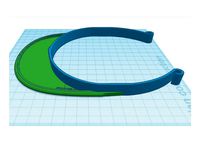

Face Shield Lite + easy mount+pins by FOR_MAKERSPACE

by Thingiverse

Last crawled date: 4 years, 2 months ago

This is a modification of our first model (https://www.thingiverse.com/thing:4238829). We made it and tested it together with FAB LAB Bucuresti.

Now it can be used both with non-perforated thin sheets (<0,3 mm), using the gap between frames, and with thick perforated sheets (>0,3mm) using the pins.

You can find the DXF sheets for the frontal, perforated and non-perforated. They are ready to be cut by laser or CNC.

PRINT PARAMETERS FOR a 0,4 mm Nozzle diameter:

It is just a reference based on the original Coronavirus Makers settings (Spain) and our own tests, as each printer (and slicer software) has its own parameters to ensure optimal prints.

-Layer height: 0.28mm

-Fill: 50%

-Fill type: Grid

-Upper layers: 3

-Lower layers: 3

-Shell: 4

-Flow (extrusion multiplier): 80% Important to ensure the thin gap keeping the plastic sheet!!! UPDATE some printers and some old materials need a bigger flow. Please make some tests. The exterior frame should move, but the whole thing has to be solid!

-No supports needed

-Printing speed: tested in 3 different models with good result

PRUSA MK3S Creality CR10 I3 MENDEL 2016

General 80 mm/s 60 mm/s 50 mm/s

Perimeters : 80 mm/s 60 mm/s 45 mm/s

Small perimeters: 80 mm/s 60 mm/s 45 mm/s

External perimeters: 80 mm/s 60 mm/s 45 mm/s

Fill: 80 mm/s 60 mm/s 50 mm/s

Solid fill: 80 mm/s 60 mm/s 50 mm/s

Top solid fill: 80 mm/s 60 mm/s 50 mm/s

Bridges: No bridges in our remix

Fill: 80 mm/s 60 mm/s 50 mm/s

Travel: 180 mm/s 80 mm/s 80 mm/s

Please print a test and ensure everything is ok before going further

With a 0,80 flow, there are some chances of under-extrusion. It can lead to poor layer adhesion, especially in the frontal thin walls, ruining the functionality of the piece.

If it is your case, there are some fine tunings in the slicer software that can be made to fix the problem.

Parameters related to the extrusion width and to the behavior on thin walls will solve the issue. The idea is to avoid gaps in thin walls.

We would be pleased to help you get optimal results.

If you arrived here from Romania following our social media call, first of all, thank you. Just get in contact with us. If you cannot reach us please leave a comment and we will answer asap.

Makers unite against coronavirus, let's shield our amazing healthcare personnel!

Now it can be used both with non-perforated thin sheets (<0,3 mm), using the gap between frames, and with thick perforated sheets (>0,3mm) using the pins.

You can find the DXF sheets for the frontal, perforated and non-perforated. They are ready to be cut by laser or CNC.

PRINT PARAMETERS FOR a 0,4 mm Nozzle diameter:

It is just a reference based on the original Coronavirus Makers settings (Spain) and our own tests, as each printer (and slicer software) has its own parameters to ensure optimal prints.

-Layer height: 0.28mm

-Fill: 50%

-Fill type: Grid

-Upper layers: 3

-Lower layers: 3

-Shell: 4

-Flow (extrusion multiplier): 80% Important to ensure the thin gap keeping the plastic sheet!!! UPDATE some printers and some old materials need a bigger flow. Please make some tests. The exterior frame should move, but the whole thing has to be solid!

-No supports needed

-Printing speed: tested in 3 different models with good result

PRUSA MK3S Creality CR10 I3 MENDEL 2016

General 80 mm/s 60 mm/s 50 mm/s

Perimeters : 80 mm/s 60 mm/s 45 mm/s

Small perimeters: 80 mm/s 60 mm/s 45 mm/s

External perimeters: 80 mm/s 60 mm/s 45 mm/s

Fill: 80 mm/s 60 mm/s 50 mm/s

Solid fill: 80 mm/s 60 mm/s 50 mm/s

Top solid fill: 80 mm/s 60 mm/s 50 mm/s

Bridges: No bridges in our remix

Fill: 80 mm/s 60 mm/s 50 mm/s

Travel: 180 mm/s 80 mm/s 80 mm/s

Please print a test and ensure everything is ok before going further

With a 0,80 flow, there are some chances of under-extrusion. It can lead to poor layer adhesion, especially in the frontal thin walls, ruining the functionality of the piece.

If it is your case, there are some fine tunings in the slicer software that can be made to fix the problem.

Parameters related to the extrusion width and to the behavior on thin walls will solve the issue. The idea is to avoid gaps in thin walls.

We would be pleased to help you get optimal results.

If you arrived here from Romania following our social media call, first of all, thank you. Just get in contact with us. If you cannot reach us please leave a comment and we will answer asap.

Makers unite against coronavirus, let's shield our amazing healthcare personnel!

Similar models

thingiverse

free

#RESISTANCECOVID RC4 - covid coronavirus Prusa Protective Face Shield - RC1 RC2 RC3 RC3.1 - NO ELASTIC - NO HOLE - !!!41min!!! TO PRINT 145x145x5 MODEL by TESLA3DTORE

...dges: no bridges in our remix

support: no support in our remix

gap fill: 40 mm/s 40 mm/s 40 mm/s

travel: 180 mm/s 80 mm/s 80 mm/s

thingiverse

free

CR-6 SE Handle / Hot Bed Handle by Fox1387

...al thin wall type: allow single extrusion fill

allowed perimeter overlap: 100% (section advancedd)

print-speed: 45 mm/s / 60 mm/s

thingiverse

free

Kleiderstange by Daraff

...es

no

complete individual objects

no

enable ooze prevention

no

keep fan on

no

retract on layer change

no

wipe while retracting

no

thingiverse

free

Pleating Fork 1/2" Pleats, rounded, tapered, poker, ruler by tlmelk

...250 mm/s

top solid infill: 100 mm/s

gap fill: 0 mm/s (disable)

setting adopted from maker's muse:https://youtu.be/3kw9snk4lkc

thingiverse

free

Retrofit Kits for 3M Respirators -- common surgical masks can be used as filters in 3M 6000/7500 series respirators. by HiddenOne

...ottom solid layers: 3

under advanced tab -- layer modifications

start printing at height: 3.6mm

stop printing at height: disabled

thingiverse

free

MK3 Extrusion and X axis ringing test by UltiMike

...st layer 200 other layers 195

bed: first layer 50 other layers 50

retraction:

length: 2mm

all other settings untouched

thingiverse

free

extrusion multiplier test

... mm .(as well as the width of the nozzle)

setup : 1 wall perimeter

top solid layers 0

buttom solid layer 3

infill 0

thingiverse

free

Mountain landscape by HappySubMarine

...g parameters:

first layer height - 0,27 mm

layer height - 0,2 mm

fill density - 100%

print speed - 60 mm/s

travel speed - 80 mm/s

thingiverse

free

Eiffla tower by HappySubMarine

...g parameters:

first layer height - 0,27 mm

layer height - 0,2 mm

fill density - 100%

print speed - 60 mm/s

travel speed - 80 mm/s

thingiverse

free

D&D castle of ravenloft complete tile set by botero5

...fill gaps checked

solid infill every 0

fill angle 45

solid infill threshold area 70

only retract with crossing perimeters checked

Makerspace

thingiverse

free

Milwaukee Makerspace by raster

...milwaukee makerspace by raster

thingiverse

a line rendition of the milwaukee makerspace logo.

thingiverse

free

Milwaukee Makerspace by raster

...milwaukee makerspace by raster

thingiverse

a stippled rendition of the milwaukee makerspace logo.

thingiverse

free

Portachiavi Makerspace by MattewScongiu

...portachiavi makerspace by mattewscongiu

thingiverse

portachiavi laboratorio makerspace itis einstein roma

thingiverse

free

Lulea Makerspace by juntti99

...lulea makerspace by juntti99

thingiverse

was bored one day and thought does our makerspace have a 3d logo yet.

thingiverse

free

MAKERSPACE by MakerHelle

...e: rockwell extra bold, width 65% and 490 high

k: p-something (see pic), width 100% and 490 high and 330 wide

cut in 4 mm plywood

thingiverse

free

Makerspace Starter Kit by DesignMakeTeach

... facebook.com/designmaketeach. i love to talk with teachers, designers and makers about 3d printing, stem and learning by making.

thingiverse

free

Coventry Makerspace Keyring by DD28

...y makerspace keyring by dd28

thingiverse

first attempt at using openscad to create a keyring design for the coventry makerspace.

thingiverse

free

Beijing Makerspace Badge by AzureViolin

...g makerspace badge by azureviolin

thingiverse

3d printed version of beijing makerspace badge, with a flashing led in the middle.

thingiverse

free

Makerspace Urbana Logo by DocJames

...rspace urbana logo by docjames

thingiverse

the logo for the urbana, illinois, usa makerspace rendered in 3d.

made with openscad.

thingiverse

free

PORTACHIAVI MAKERSPACE V3 V4 by MattewScongiu

...portachiavi makerspace v3 v4 by mattewscongiu

thingiverse

portachiavi makerspace corretto

Lite

design_connected

$11

Lite

...lite

designconnected

sphaus lite coffee tables computer generated 3d model. designed by eero saarinen.

3ddd

$1

Foscarini_Giga-Lite

... giga-lite , лампы , light

foscarini_giga-lite

turbosquid

free

LegendarySwords - Lite

...odel legendaryswords - lite for download as dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559781)

turbosquid

$85

DS Lite

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jet Lite

... model jet lite for download as 3ds, obj, fbx, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1476173)

turbosquid

$1

Mod-Lite

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

lite on.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$13

Multi-Lite Pendant

...multi-lite pendant

designconnected

gubi multi-lite pendant computer generated 3d model. designed by weisdorf, louis .

turbosquid

$120

Cartoon Pack Lite

...

royalty free 3d model cartoon pack lite for download as fbx on turbosquid: 3d models for games, architecture, videos. (1255320)

turbosquid

$100

HUAWEI P3 Lite

...id

royalty free 3d model huawei p30 lite for download as c4d on turbosquid: 3d models for games, architecture, videos. (1515805)

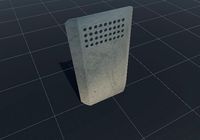

Shield

3d_export

$5

shield

...shield

3dexport

shield

3d_export

$5

Shield

...shield

3dexport

shield and a spear

3d_ocean

$6

Shield

...shield

3docean

game shield low polygon mei evil shild old shield shield

2048 texture obj,fbx,blend game ready.

3d_export

$5

Shield

...shield

3dexport

a shield that hasn't been made of materials will be available to everyone

3d_ocean

$4

Round Shield

...round shield

3docean

ancient battle fantasy knight medieval shield shields warrior

nice model of round shield.

3d_export

free

metal shield

...metal shield

3dexport

russian metal shield - anti-riot shield.

3d_export

$5

shield

...shield

3dexport

old shield, damaged and covered in mold. every file have a zip folder in with textures.

turbosquid

free

Shield

...shield

turbosquid

free 3d model shield for download as c4d on turbosquid: 3d models for games, architecture, videos. (1164800)

3d_export

$5

fire shield

...fire shield

3dexport

fire shield

turbosquid

$10

SHIELD

...

turbosquid

royalty free 3d model shield for download as obj on turbosquid: 3d models for games, architecture, videos. (1273553)

Pins

3d_export

$5

Pin

...pin

3dexport

very god pin

3d_ocean

$1

Bowling pins

...e inside of cinema 4d. there are 3 files included : pin.c4d : pins array.c4d : pin.obj pins array is the bowling pins set up i...

3d_ocean

$5

Pins

...v-ray studio render setting ready close-ups camera support polys: low: 6.314 high: 1.681.922 (with turbosmooth modifier) *incl...

turbosquid

$4

pin

...osquid

royalty free 3d model pin for download as 3dm and max on turbosquid: 3d models for games, architecture, videos. (1669685)

3d_ocean

$15

Map Pins

...map pins

3docean

factory kremlin map moscow oil oil-derrick pin pins red russia soviet soviet union star

some stylized map pins.

turbosquid

$9

Pins

...lty free 3d model pins for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1506195)

turbosquid

$7

Pin

...alty free 3d model pin for download as dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1609891)

turbosquid

$35

Pins

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Pin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Pin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Face

turbosquid

$100

face a face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Face To Face Swing

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Almerich Face to Face

... гибкостью материала, прозрачностью и тактом, чтобы создавать игры со светом и тенью.

размеры: 48 x 48 x 155 см

полигоны: 39 376

design_connected

$11

Face

...face

designconnected

montis face chairs computer generated 3d model. designed by gerard van den berg.

turbosquid

$15

Face

...ce

turbosquid

royalty free 3d model face for download as mud on turbosquid: 3d models for games, architecture, videos. (1178369)

turbosquid

$6

Face

...ce

turbosquid

royalty free 3d model face for download as max on turbosquid: 3d models for games, architecture, videos. (1409756)

turbosquid

$1

Face

...uid

royalty free 3d model face for download as obj and blend on turbosquid: 3d models for games, architecture, videos. (1288500)

turbosquid

$150

Face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Face

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Easy

design_connected

$16

Easy

...easy

designconnected

sollos easy computer generated 3d model. designed by almeida, jader.

design_connected

$20

Easy

...easy

designconnected

established & sons easy armchairs computer generated 3d model. designed by ed carpenter.

3d_ocean

$1

Easy Button

... it is accurate in close-ups. you can drop this model right into any setting. the textures are included as well as links to do...

design_connected

$16

Easy Armchair

...easy armchair

designconnected

easy armchair computer generated 3d model. designed by jeanneret, pierre.

3ddd

$1

Pouf EASY

... easy

3ds max 2010.v-ray 2.40.03.file formats fbx,obj. pouf desiree 2014 easy. dimensions 100x100x45 cm.

design_connected

$18

Easy Armchair

...easy armchair

designconnected

fsm easy armchair computer generated 3d model. designed by hartmann, markus.

design_connected

$16

Easy Rider

...easy rider

designconnected

bulo easy rider computer generated 3d model. designed by venlet, danny.

design_connected

$16

Easy Chair

...easy chair

designconnected

magis easy chair computer generated 3d model. designed by seymour, jerszy.

design_connected

$11

Easy Footstool

...easy footstool

designconnected

fsm easy footstool computer generated 3d model. designed by hartmann, markus.

design_connected

$18

Doda - Easy

...doda - easy

designconnected

molteni & c doda - easy computer generated 3d model. designed by laviani, ferruccio.

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)