GrabCAD

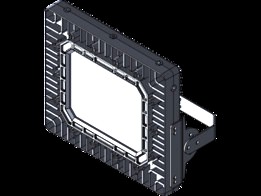

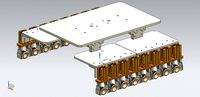

Explosion Proof 150 Watt Low Bay LED Light Fixture - 140° Spread - Paint Booth Approved - C2D1

by GrabCAD

Last crawled date: 1 year, 11 months ago

http://www.larsonelectronics.com/p-106223-explosion-proof-150-watt-low-bay-led-light-fixture-140-spread-paint-booth-approved-c2d1.aspx

The Larson Electronics EPLC2-HB-150LED-RT-140DB Explosion Proof Low Bay light fixture provides operators with a powerful and energy efficient alternative to traditional hazardous location luminaries. Cree LED technology and compact design makes this lamp an excellent replacement upgrade option for bulky and high maintenance cost older incandescent, metal halide and high pressure sodium lights.

This Class 1 Division 2, Class 2 Division 1 & 2 explosion proof low bay LED light fixture provides 17,500 of high quality light while drawing only 150 watts. The copper free aluminum alloy body is powder coated for added durability and an attractive aesthetic appearance. Special heat dissipating design in conjunction with LED technology helps this fixture to achieve an excellent 60,000 hour rated lifespan with 80% lumen retention. Light weight and a low profile make this unit an attractive alternative to larger and heavier older fixtures and requires less hardware to install.

LED Benefits: Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation and/or transportation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current is applied, providing instant illumination with no warm up or cool down time before re-striking. Because there is no warm up period, this light can be cycled on and off with no reduction in lamp life.

LED lights run at significantly cooler temperatures than traditional metal halide and high pressure sodium lights and contain no harmful gases, vapors, or mercury, making them both safer and more energy efficient. No extra energy is wasted in cooling enclosed work areas due to external heat emissions from bulb type lights, and the operator risks associated with traditional lighting methods, such as accidental burns and exposure to hazardous substances contained in the glass bulbs, are eliminated. In addition, LEDs are also safer for the environment as they are 100% recyclable, which eliminates the need for costly special disposal services required with traditional gas burning and arc type lamps.

LED Drivers: Even in LED fixtures, heat is the single largest factor in premature light failure and color shifting. As a result, many manufacturers reduce the output of their LEDs in order to reduce the amount of heat produced. Rather than lower light output or quality, Larson Electronics addresses this problem with the addition of electronic LED drivers. These internal drivers provide the ability to automatically monitor and adjust input current to maintain the correct LED voltage levels regardless of input levels across a specific range. This not only reduces the energy dissipation, effectively lowering the operating temperature of the fixture, but also prevents AC over-voltage and short circuit loading making this fixture virtually maintenance free. Because the electronic drivers allow the EPLC2-HB-150LED-RT-140DB to run at a cooler internal temperature and regulates the electrical current, energy efficiency and LED service hours are maximized while at the same time reducing operating costs and downtime incurred from the frequent servicing intervals required with other hotter running lights.

The explosion proof LED light fixture features multiple LED drivers which helps to increase the operational life of the fixture. With traditional LED lights, in the event an LED array or driver fails, the entire fixture no longer illuminates. With the EPLC2-HB-150LED-RT-140DB series of explosion proof lamps from Larson Electronics, each LED fixture contains twelve individual LED boards configured in a series of banks. Each bank contains two LED on a single board with an individual driver. In the event of a driver failure, only one bank of LEDs will be effected while the other banks will continue to operate. In the event that of an LED failure, the mating LED will continue to operate.

Beam Angles: When used as a fixed mount fixture, the varying beam angles need to be mounted at certain heights in order to achieve the greatest coverage and efficiency in both high bay and low bay lighting situations. The 60° beam should be mounted in high bay fixtures over 25' in height and 25' away from objects if used as a wall mounted light. The 125° beam is ideal for low bay fixtures in a height range of 15-25 feet and the same distance away from objects when the wall mounting option is employed. The 140° beam is best used as a low bay fixture in areas with a ceiling height of 15' or less or for illuminating objects up to 15' away when wall mounted.

This explosion proof LED high bay produces a total of 17,500 lumens with a color temperature of 5000K standard and a color rendering index of 75 which produces colors and details much more accurately than high pressure sodium or mercury vapor luminaries. We also offer a 3000K warm white and 4000K natural white color temperature options (longer lead times may apply for non-standard temperatures). This lamp uses Cree LED units that have been chosen for their high lumen per watt ratio and extreme longevity. These Cree LEDs generate a robust 116.67 lumens per watt effective lumen output and have a 80% lumen retention at 60,000 hours, giving them better efficiency and operational life than traditional light sources.

Field Serviceability: This explosion proof LED light fixture is field serviceable. All major internal components can be purchased from Larson Electronics and installed by a licensed electrician with basic tools. With most explosion proof fixtures, the fixture must be returned to the manufacturer for repair work, which presents downtime and long turn around times for repair work. Larson Electronics addresses this issue with the EPLC2-HB-150LED-RT-140DB series with field serviceability, allowing operators to perform service work without having to return the fixture to the manufacturer in the event of damage or failure.

Voltage: This light is universal voltage capable and can be operated with 100-277V AC, 50/60 Hz without modifications to the fixture, and a low voltage version of this LED fixture that operates on AC/DC voltages from 11-25 volts for rigs and vision systems. 18-48V AC/DC voltages are available for network systems and marine vessels. We also offer an additional 347-480V high voltage and 0-10V dimmable versions of this explosion proof LED light fixture.

Mounting: The EPLC2-HB-150LED-RT-140DB offers several mounting options including ceiling mounting, pendant mounting, and wall mounting. Ceiling and wall applications are mounted using the adjustable swivel mount bracket found on the rear of the unit. Pendant applications are mounted from the ceiling and are suspended by rigid pipe via the 3/4" NPT hub on the back of the explosion proof fixture. Wiring is fed through rigid pipe to the junction box and tied in to the fixture’s lead wires, completing the electrical connection.

This explosion proof LED light fixture is paint spray booth listed, IP67 rated, dust-proof, and protected against high pressure jets and temporary submersion. The cast aluminum body and LED lamp give this light excellent durability and resistance to vibration and impacts. The housing is specially designed to dissipate heat which increases the efficiency and lifespan of the LEDs and electronics.

Suggested Applications: The EPL-HB-2X150LED-RT is approved for use within environments where flammable or combustible gases, vapors, dusts, fibers, and flying exist or stand the potential to exist, and is ideal for a wide variety of applications.

Applications include but not limited to aircraft maintenance, alcohol processing, aerospace, chemical manufacturing, coke processing, cold storage, compressed natural gas (CNG) facilities, cranes, cryogenics, distilleries, food processing (with food grade gasketed polycarbonate lens: EPL-HB-150LED-RT-188), fuel storage, gas processing plants, grain processing, laboratories, liquefied natural gas (LNG) facilities, liquid propane gas (LPG), manufacturing, marine vessels, methane production, mining, offshore, oil drilling rigs, oil refineries, paint spray booths, paper processing, petrochemical, pharmaceuticals, power plants, production refineries, sand blast cabinets, sewage and septic tanks, shipyards, solvent and cleaning areas, storage facilities, tank farms, tankers, textile, washdown areas, waste treatment plants, and woodworking. Click here to read the NEC description for explosion proof and hazardous locations.

The Larson Electronics EPLC2-HB-150LED-RT-140DB Explosion Proof Low Bay light fixture provides operators with a powerful and energy efficient alternative to traditional hazardous location luminaries. Cree LED technology and compact design makes this lamp an excellent replacement upgrade option for bulky and high maintenance cost older incandescent, metal halide and high pressure sodium lights.

This Class 1 Division 2, Class 2 Division 1 & 2 explosion proof low bay LED light fixture provides 17,500 of high quality light while drawing only 150 watts. The copper free aluminum alloy body is powder coated for added durability and an attractive aesthetic appearance. Special heat dissipating design in conjunction with LED technology helps this fixture to achieve an excellent 60,000 hour rated lifespan with 80% lumen retention. Light weight and a low profile make this unit an attractive alternative to larger and heavier older fixtures and requires less hardware to install.

LED Benefits: Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation and/or transportation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current is applied, providing instant illumination with no warm up or cool down time before re-striking. Because there is no warm up period, this light can be cycled on and off with no reduction in lamp life.

LED lights run at significantly cooler temperatures than traditional metal halide and high pressure sodium lights and contain no harmful gases, vapors, or mercury, making them both safer and more energy efficient. No extra energy is wasted in cooling enclosed work areas due to external heat emissions from bulb type lights, and the operator risks associated with traditional lighting methods, such as accidental burns and exposure to hazardous substances contained in the glass bulbs, are eliminated. In addition, LEDs are also safer for the environment as they are 100% recyclable, which eliminates the need for costly special disposal services required with traditional gas burning and arc type lamps.

LED Drivers: Even in LED fixtures, heat is the single largest factor in premature light failure and color shifting. As a result, many manufacturers reduce the output of their LEDs in order to reduce the amount of heat produced. Rather than lower light output or quality, Larson Electronics addresses this problem with the addition of electronic LED drivers. These internal drivers provide the ability to automatically monitor and adjust input current to maintain the correct LED voltage levels regardless of input levels across a specific range. This not only reduces the energy dissipation, effectively lowering the operating temperature of the fixture, but also prevents AC over-voltage and short circuit loading making this fixture virtually maintenance free. Because the electronic drivers allow the EPLC2-HB-150LED-RT-140DB to run at a cooler internal temperature and regulates the electrical current, energy efficiency and LED service hours are maximized while at the same time reducing operating costs and downtime incurred from the frequent servicing intervals required with other hotter running lights.

The explosion proof LED light fixture features multiple LED drivers which helps to increase the operational life of the fixture. With traditional LED lights, in the event an LED array or driver fails, the entire fixture no longer illuminates. With the EPLC2-HB-150LED-RT-140DB series of explosion proof lamps from Larson Electronics, each LED fixture contains twelve individual LED boards configured in a series of banks. Each bank contains two LED on a single board with an individual driver. In the event of a driver failure, only one bank of LEDs will be effected while the other banks will continue to operate. In the event that of an LED failure, the mating LED will continue to operate.

Beam Angles: When used as a fixed mount fixture, the varying beam angles need to be mounted at certain heights in order to achieve the greatest coverage and efficiency in both high bay and low bay lighting situations. The 60° beam should be mounted in high bay fixtures over 25' in height and 25' away from objects if used as a wall mounted light. The 125° beam is ideal for low bay fixtures in a height range of 15-25 feet and the same distance away from objects when the wall mounting option is employed. The 140° beam is best used as a low bay fixture in areas with a ceiling height of 15' or less or for illuminating objects up to 15' away when wall mounted.

This explosion proof LED high bay produces a total of 17,500 lumens with a color temperature of 5000K standard and a color rendering index of 75 which produces colors and details much more accurately than high pressure sodium or mercury vapor luminaries. We also offer a 3000K warm white and 4000K natural white color temperature options (longer lead times may apply for non-standard temperatures). This lamp uses Cree LED units that have been chosen for their high lumen per watt ratio and extreme longevity. These Cree LEDs generate a robust 116.67 lumens per watt effective lumen output and have a 80% lumen retention at 60,000 hours, giving them better efficiency and operational life than traditional light sources.

Field Serviceability: This explosion proof LED light fixture is field serviceable. All major internal components can be purchased from Larson Electronics and installed by a licensed electrician with basic tools. With most explosion proof fixtures, the fixture must be returned to the manufacturer for repair work, which presents downtime and long turn around times for repair work. Larson Electronics addresses this issue with the EPLC2-HB-150LED-RT-140DB series with field serviceability, allowing operators to perform service work without having to return the fixture to the manufacturer in the event of damage or failure.

Voltage: This light is universal voltage capable and can be operated with 100-277V AC, 50/60 Hz without modifications to the fixture, and a low voltage version of this LED fixture that operates on AC/DC voltages from 11-25 volts for rigs and vision systems. 18-48V AC/DC voltages are available for network systems and marine vessels. We also offer an additional 347-480V high voltage and 0-10V dimmable versions of this explosion proof LED light fixture.

Mounting: The EPLC2-HB-150LED-RT-140DB offers several mounting options including ceiling mounting, pendant mounting, and wall mounting. Ceiling and wall applications are mounted using the adjustable swivel mount bracket found on the rear of the unit. Pendant applications are mounted from the ceiling and are suspended by rigid pipe via the 3/4" NPT hub on the back of the explosion proof fixture. Wiring is fed through rigid pipe to the junction box and tied in to the fixture’s lead wires, completing the electrical connection.

This explosion proof LED light fixture is paint spray booth listed, IP67 rated, dust-proof, and protected against high pressure jets and temporary submersion. The cast aluminum body and LED lamp give this light excellent durability and resistance to vibration and impacts. The housing is specially designed to dissipate heat which increases the efficiency and lifespan of the LEDs and electronics.

Suggested Applications: The EPL-HB-2X150LED-RT is approved for use within environments where flammable or combustible gases, vapors, dusts, fibers, and flying exist or stand the potential to exist, and is ideal for a wide variety of applications.

Applications include but not limited to aircraft maintenance, alcohol processing, aerospace, chemical manufacturing, coke processing, cold storage, compressed natural gas (CNG) facilities, cranes, cryogenics, distilleries, food processing (with food grade gasketed polycarbonate lens: EPL-HB-150LED-RT-188), fuel storage, gas processing plants, grain processing, laboratories, liquefied natural gas (LNG) facilities, liquid propane gas (LPG), manufacturing, marine vessels, methane production, mining, offshore, oil drilling rigs, oil refineries, paint spray booths, paper processing, petrochemical, pharmaceuticals, power plants, production refineries, sand blast cabinets, sewage and septic tanks, shipyards, solvent and cleaning areas, storage facilities, tank farms, tankers, textile, washdown areas, waste treatment plants, and woodworking. Click here to read the NEC description for explosion proof and hazardous locations.

Similar models

grabcad

free

Explosion Proof 150 Watt Low Bay LED Light Fixture - 140° Spread - Paint Booth Approved - C1D1

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

Class II Division 1 Explosion Proof 100 Watt High Bay LED Light Fixture 11,667 Lumens - CID2 / CIID1

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

150W Explosion Proof High Bay LED Colored Light Fixture - 17500 Lumens - C1D1 - Paint Spray Booth

... message sales@larsonelectronics.com for more information about our custom options tailored to meet your specific industry needs.

grabcad

free

150W Explosion Proof High Bay LED Light Fixture - 21000 Lumens - C1D1 - Paint Spray Booth Approved - 180° Beam Angle

...eas, waste treatment plants, and woodworking. click here to read the nec description for explosion proof and hazardous locations.

grabcad

free

150W Explosion Proof Food Safe LED Light Fixture - C1D1/C2D1 - 17500 Lumens - No Exposed Glass

...eas, waste treatment plants, and woodworking. click here to read the nec description for explosion proof and hazardous locations.

grabcad

free

C1D1 Explosion Proof 150 Watt High Bay LED Light Fixture-140°-Paint Booth Approved -150' w/ EXP Plug

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

C1D1 Explosion Proof 150 Watt High Bay LED Light Fixture-140°-Paint Booth Approved -250' w/ EXP Plug

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

C1D1 Explosion Proof 150 Watt High Bay LED Light Fixture-Paint Booth Approved-140°-200' w/ EXP Plug

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

150W Explosion Proof High Bay LED Colored Light Fixture - 21000 Lumens - C1D1 - Paint Spray Booth

...bration/impact resistant.

13. significantly cooler operation.

14. less frequent outages, higher output improves workplace safety.

grabcad

free

C1D1 Explosion Proof 100 Watt Low Bay LED Light Fixture - 140° Spread - Paint Spray Booth Approved

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

C2D1

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

5000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

Explosion Proof Control Station - C1D1/C2D1 - Local/Off/Auto 3-Pos Switch - 10k Ohm Potentiometer

...int spray booths, food manufacturing buildings, agricultural sites, grain storage centers, small motors, manual control and more.

grabcad

free

Explosion Proof SPST Three Phase Starter Switch - Copper Free Aluminum - 30 Amp Rated - C1D1 C2D1

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

Hazardous Location Exit Sign - C1D2 - C2D1&2 - IP65 - 120V/277VAC - Green or Red Exit Sign

...rants making identification and location of exits in emergency situations easier than with typical self illuminated exit markers.

grabcad

free

Explosion Proof Red Crane Warning Laser- C1D1-2 - C2D1-2 - Surface Mount - 12-24V DC - Aluminum

...nal strips, completing the electrical connection.

applications: crane safety, crane measurements, crane warning system and more.

Approved

3d_export

$30

Stamp 3D Model

...stamp invoice wooden handle office supply tool ink stamper approved documents letter form paper stamp 3d model tartino 27989...

cg_studio

$30

Stamp3d model

...rubber stamp invoice wooden handle supply tool ink stamper approved documents letter form paper .3ds .c4d .dxf .obj -...

3d_ocean

$12

Pumpkin Package

... stability and has earned the aethereal studios game ready stamp of approval. the autumn pumpkin package is optimized for both...

3ddd

$1

FREDERICIA FURNITURE 3Seats sofa No.1

...ard fabrics according to current price list. customer specified fabrics (com) upon factory approval.

dimensions in cm

206х86х83

3d_ocean

$9

Catwalk for structures

...for structures, heavy duty, aisc 360 and can/csa 16 approved used in mine plants and construction infrastructure, scale 1:1,...

3ddd

$1

FREDERICIA FURNITURE 2Seats sofa No.1

...rd fabrics according to current price list. customer specified fabrics (com) upon factory approval.

dimensions in cm

143x86x 83

3d_ocean

$8

Adidas Conext15 Official match ball

...adidas conext15 official match ball 3docean adidas approved ball brazuca conext conext15 field fifa football goal match...

3d_ocean

$8

Adidas Finale 2014/2015 Champions League Ball

...adidas finale 2014/2015 champions league ball 3docean adidas approved ball champions fifa finale football goal league net score...

3d_ocean

$8

Adidas Finale Berlin 2015

...adidas finale berlin 2015 3docean adidas approved ball berlin champions fifa final finale football goal league...

3d_ocean

$8

Puma evoPower 1 Statement and Statement 15

...puma evopower 1 statement and statement 15 3docean approved ball evo evopower fifa football goal kick official power...

Spread

turbosquid

$20

Chocolate Spread

...d

royalty free 3d model chocolate spread for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492105)

turbosquid

$19

Speculoos Spread

...d

royalty free 3d model speculoos spread for download as max on turbosquid: 3d models for games, architecture, videos. (1535687)

turbosquid

$10

Spread eagle

...squid

royalty free 3d model spread eagle for download as ige on turbosquid: 3d models for games, architecture, videos. (1338670)

turbosquid

$3

Volunteers spread mulch

...olunteers spread mulch for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1505993)

turbosquid

$24

Benecol Buttery Spread 400g

...free 3d model benecol buttery spread 400g for download as max on turbosquid: 3d models for games, architecture, videos. (1334871)

turbosquid

$8

Pernigotti chocolate spread jar

...late spread jar for download as blend, obj, dae, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1688319)

turbosquid

$7

Lindt chocolate spread jar

...late spread jar for download as blend, dae, obj, stl, and fbx on turbosquid: 3d models for games, architecture, videos. (1623582)

turbosquid

free

Nutella Chocolate Hazelnut Spread

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Tartare Cheese Spread Collection 150g

...del tartare cheese spread collection 150g for download as max on turbosquid: 3d models for games, architecture, videos. (1344808)

turbosquid

$24

Cadbury Milk Chocolate Spread 400g

... model cadbury milk chocolate spread 400g for download as max on turbosquid: 3d models for games, architecture, videos. (1389383)

Watt

3ddd

$1

Watt & Veke

...watt & veke

3ddd

watt & veke

настольная лампа messina фабрики watt & veke.

3ddd

$1

Watt & veke / Soomkai

...

watt & veke , ротанг

стильная люстра из ротанга soomkai фабрики watt&veke.;

3ddd

free

ROLLE Watt&Veke

...rolle , watt&veke

подвесной светильник rolle watt&veke; из осенней коллекции

turbosquid

$35

We Watt Kiosk

...yalty free 3d model we watt kiosk for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1461926)

3ddd

$1

Luceplan / OTTO Watt

...условия для любых задач, отдыха или работы. пожалуй, идеальный спутник вашего стола.

дополнительные форматы: max(2010), fbx, 3ds.

3d_export

free

1300 watt subwoofer for cars

...1300 watt subwoofer for cars

3dexport

the model is made to take up space in the house or in the car. power 1300 watts.

3ddd

free

Watt&Veke Spring

...авесной светильник от watt & veke spring, подойдет как для детских, так и для строгих интерьеров, особенно в стилистике лофт.

3d_export

$5

30 watts of power 3D Model

...port

30 watts power 3d model factory electric electrical energy high poly

30 watts of power 3d model karenmodeling 84649 3dexport

3ddd

$1

Watt&Veke Table Lamp

...ble lamp

3ddd

watt&veke

производитель watt&veke;

абажур - vivianne19 h16 ∅19 ∅14

опора для абажура - henning h30 ∅12

3d_export

$5

Substation 110 watts power 3D Model

...odel factory electric electrical energy high poly substation 110

substation 110 watts power 3d model karenmodeling 84650 3dexport

Proof

turbosquid

$6

bullet proof jacket

...el bullet proof jacket for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1193147)

turbosquid

$1

Sound Proofing Foam

... sound proofing foam for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1289027)

turbosquid

$25

Flame proof fibricks_lit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$149

Bullet Proof Vest with molle attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$40

chevrolet nova ss 70 death proof

...chevrolet nova ss 70 death proof

3dexport

3d_export

$9

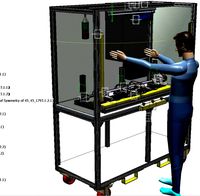

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

turbosquid

$29

Nikon Coolpix AW110 rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Armoured fighting vehicles armoured vehicles with explosion-proof wheels

...ured vehicles with explosion-proof wheels for download as max on turbosquid: 3d models for games, architecture, videos. (1629664)

turbosquid

$27

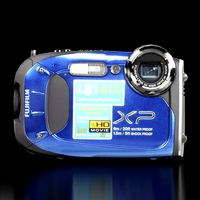

Fujifilm FinePix XP60 Blue rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$23

Panasonic Lumix DMC-TS5 rugged and proof digital gamera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Explosion

3d_export

$6

explosion

...explosion

3dexport

3 d of explosion

3d_export

$10

explosion

...explosion

3dexport

3d model of explosion for 3d printing

turbosquid

$5

Explosion

...rbosquid

royalty free 3d model explosion for download as max on turbosquid: 3d models for games, architecture, videos. (1202603)

3d_export

$10

Explosion

...explosion

3dexport

turbosquid

$14

Explosion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Explosive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Explosive Barrel

...explosive barrel 3docean barrel decoration explosion explosive industrial low low poly metal object old poly...

3ddd

free

KOLARZ Serie Explosion

... serie explosion , австрия

kolarz serie explosion 0109.118.5.kot. врай. текстуры.

3d_export

$5

atomic bomb explosion

...atomic bomb explosion

3dexport

atomic bomb explosion

turbosquid

$1

explosives pack

...squid

royalty free 3d model explosives pack for download as on turbosquid: 3d models for games, architecture, videos. (1316376)

140°

turbosquid

$50

An-140

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Cove 140

...cove 140

designconnected

paola lenti cove 140 computer generated 3d model. designed by rota, francesco.

turbosquid

free

Table 140

...id

free 3d model table 140 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1503818)

3ddd

$1

Тема 140

...тема 140

3ddd

ванна

ванна тема140

turbosquid

$12

Chair 140

...d model chair 140 for download as max, max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1578671)

turbosquid

$10

Lamp 140

...3d model lamp 140 for download as max, max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1592328)

turbosquid

$9

Office 140

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

evermotion

$7

railing 140 am79

...key sculptures am79 railing 140

highly detailed architecture railing with all textures and materials.. evermotion 3d models shop.

evermotion

$120

Archmodels vol. 140

...ectural visualizations. this collection comes with high quality lamps with all textures and materials. evermotion 3d models shop.

design_connected

$20

Cestone armchair 140

... armchair 140

designconnected

flexform cestone armchair 140 armchairs computer generated 3d model. designed by antonio citterio.

Bay

3ddd

$1

Bay

...bay

3ddd

calligaris

стул bay итальянской фабрики сalligaris /max2011,fbx,obj,mat/

3ddd

$1

MDF / BAY

...mdf / bay

3ddd

bay , mdf italia

диван "bay"

*turbosmooth присутствует

turbosquid

$8

Bay

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

BAY XL

... giulio marelli

giulio marelli italia. bay xl.

диван, дизайн studio crgm в тканевом исполнении.

длина: 2.55

design_connected

$18

Bai Armchair

...bai armchair

designconnected

ondarreta bai armchair computer generated 3d model. designed by lizaso, ander.

3ddd

$1

Kichler Hayman Bay

...kichler hayman bay

3ddd

kichler , hayman bay

люстра kichler lighting 43256daw hayman bay

design_connected

$13

Bai Chandelier

...bai chandelier

designconnected

parachilna bai chandelier computer generated 3d model. designed by neri&hu.

3ddd

$1

Lamp poters bay

...lamp poters bay

3ddd

eichholtz

eichholtz, lamp poters bay

turbosquid

$32

Shuttle Bay

...ty free 3d model shuttle bay for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1475258)

turbosquid

$20

Iris Bay

...free 3d model iris bay for download as 3ds, c4d, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1367781)

Booth

3d_export

$10

Booth Devassa

...booth devassa

3dexport

booth 10x10

3d_export

$10

Booth VENEZA

...booth veneza

3dexport

booth 12x10

3d_export

$10

Booth MSD

...booth msd

3dexport

booth 8.00x6.00

3d_export

$10

Booth Oncoclincas

...booth oncoclincas

3dexport

booth 14.00x11.00

3d_export

$10

Booth SOLINFTEC

...booth solinftec

3dexport

booth 11.00x5.00

3d_export

$7

Booth Janssen

...booth janssen

3dexport

booth 6.00x6.00

3d_export

$7

Booth Astellas

...booth astellas

3dexport

booth 6.00x6.00

3d_export

$7

Booth Galvani

...booth galvani

3dexport

booth 4.00x4.50

3d_export

$5

exhibition booth

...exhibition booth

3dexport

exhibition booth

3d_export

$5

Booth Camil

...booth camil

3dexport

booth 6x3

Fixture

turbosquid

$5

Fixture

...turbosquid

royalty free 3d model fixture for download as max on turbosquid: 3d models for games, architecture, videos. (1160462)

turbosquid

$39

FIXTURE

...id

royalty free 3d model fixture for download as ige and obj on turbosquid: 3d models for games, architecture, videos. (1332983)

turbosquid

$2

Fixture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

fixture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

fixture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

ROBOT FIXTURE

...fixture

3dexport

it is a robot fixture. it is used to pick the insert from the table and place that insert into the mold cavity.

turbosquid

free

lighting fixtures

...odel lighting fixtures for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1428616)

3d_ocean

$2

Light Fixture 02

...reat for any game enviroment. the light fixture has texture with both lid bulb, and unlid bulb. low poly (238 polygons – 245 v...

turbosquid

$29

bathroom fixtures

...odel bathroom fixtures for download as 3ds, max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1180328)

turbosquid

$20

Wall Fixture

... 3d model wall fixture for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1270353)

150

3ddd

$1

МООН 150

...моон 150

3ddd

moon

модель 150

3d_export

$5

f 150

...f 150

3dexport

f 150 formats max 3ds obj stl

3ddd

free

Тема 150

... акватика , ванна , угловая

ванна тема 150

design_connected

$11

Bolero 150

...bolero 150

designconnected

bolero 150 computer generated 3d model. designed by lazzeroni, roberto.

turbosquid

$25

Earrings 150

...alty free 3d model earrings 150 for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1203665)

turbosquid

$25

Ring 150

...royalty free 3d model ring 150 for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1203661)

turbosquid

$15

Cornice 150

...y free 3d model cornice 150 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1537239)

turbosquid

$15

Curtain 150

...e 3d model curtain 150 for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1707882)

turbosquid

$15

TZ-150

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Table 150

...d model table 150 for download as max, max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1592365)

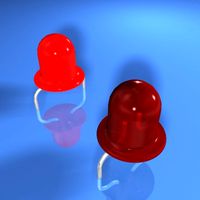

Led

3d_export

$5

led

...led

3dexport

the led is cut with all the parts.

3ddd

$1

Monacor / PARL56DMX / LED-320RGBW / LED-345RGBW / LED-300RGB

... прожектор

http://www.monacor.dk/

parl56dmx

led-320rgbw

led-345rgbw

led-300rgb

turbosquid

$10

LED

...led

turbosquid

free 3d model led for download as blend on turbosquid: 3d models for games, architecture, videos. (1691856)

3d_export

$5

led lamp

...led lamp

3dexport

led lamp, brightness animation

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

современный торшер

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

настольный лампа

turbosquid

$19

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Led

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Paint

archibase_planet

free

Paints

...paints

archibase planet

paints paint

paints n241211 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Paint

...paint

archibase planet

jar of paint paint can

paint - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

paint

...paint

3ddd

paint

archibase_planet

free

Paint

...paint

archibase planet

paint

paint - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Painting

...painting

3ddd

картина

painting in double wooden frame decorated antique

3ddd

$1

The collection of paintings

...

картина , фото

collection of modern and contemporary paintings.

contemporary paintings.

turbosquid

$29

painting

...free 3d model painting for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1383201)

turbosquid

$1

Painting

...ee 3d model painting for download as 3ds, obj, md3, and blend on turbosquid: 3d models for games, architecture, videos. (1207611)

turbosquid

free

Painting

... 3d model painting for download as ma, 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1219609)

3ddd

$1

PAINTINGS

...paintings

3ddd

панно

размеры:

1170х900

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...