GrabCAD

Ender3 V2

by GrabCAD

Last crawled date: 1 year, 10 months ago

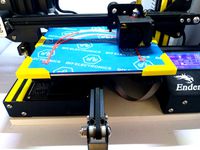

Many custom designed parts for the Ender3 V2 that make an already great 3D printer even better

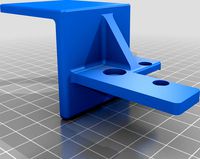

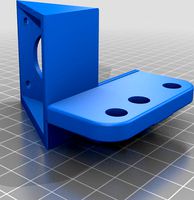

I designed a new direct drive mount that utilizes the stock, or an after-market extruder mechanism. This plate is also made to fit an 12mm Linear rail (MGN12C) for the X-Axis. This very small piece of Bowden tubing line up perfectly to create a super short filament path to the hot-end. I used MIC6 Tooling plate that was 3/8" of an inch thick and faced it down to the thickness I wanted it to be. I have been using 2 of these plates on both of my Ender3 V2's for several months and have had zero issues. As a matter of fact, I also own a MicroSwiss Direct-drive plate system for the stock Ender3-V2 using the stock V-Wheels and the design I made works as good if not better than that particular unit. The only difference being that they made their own tension/arm system that is integrated into their design and I didn't. I wanted this to be easily machined by those guys with a smaller CNC machine that can mill small thinner pieces of aluminum stock without issue. You will have to create your own toolpaths obviously, but the CAD files are all there and you can just open it up in your CAM software and create your toolpaths and get machining. I added a couple pictures of the plate and with a stock Ender3 hot-end and stepper motor. Obviously the extruder bracket would attach on top of this plate using M3 screws to attach the extruder stepper from behind. So, in order, extruder bracket, direct drive plate, and then the extruder stepper motor. If you have any questions feel free to send me a message or drop a comment and I'll get back to you as soon as I can.

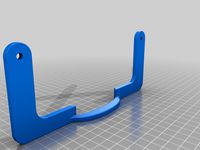

The rest of the parts in Bright Green I designed to be add-ons to the Ender3-V2. The extra drawers on the sides, the 4040 extrusion drawers (there are some like this on Thingiverse however, mine are deeper and print in 2 pieces (the drawer and knob) whereas others print in 3 pieces making it a real pain to assemble if you have even a slight elephants foot on the initial layer. So, I designed it to be all one piece and used a massive fillet in the inside corners to keep the bridging to a minimum across the rear of the drawer (which is the very top as it is orientated on the print bed) to enable this to be a single piece instead of two.

As for the Motherboard and Raspberry Pi enclosures these were a culmination of me sick of looking for something that used a downdraft fan to blow cool air across the boards

I designed a new direct drive mount that utilizes the stock, or an after-market extruder mechanism. This plate is also made to fit an 12mm Linear rail (MGN12C) for the X-Axis. This very small piece of Bowden tubing line up perfectly to create a super short filament path to the hot-end. I used MIC6 Tooling plate that was 3/8" of an inch thick and faced it down to the thickness I wanted it to be. I have been using 2 of these plates on both of my Ender3 V2's for several months and have had zero issues. As a matter of fact, I also own a MicroSwiss Direct-drive plate system for the stock Ender3-V2 using the stock V-Wheels and the design I made works as good if not better than that particular unit. The only difference being that they made their own tension/arm system that is integrated into their design and I didn't. I wanted this to be easily machined by those guys with a smaller CNC machine that can mill small thinner pieces of aluminum stock without issue. You will have to create your own toolpaths obviously, but the CAD files are all there and you can just open it up in your CAM software and create your toolpaths and get machining. I added a couple pictures of the plate and with a stock Ender3 hot-end and stepper motor. Obviously the extruder bracket would attach on top of this plate using M3 screws to attach the extruder stepper from behind. So, in order, extruder bracket, direct drive plate, and then the extruder stepper motor. If you have any questions feel free to send me a message or drop a comment and I'll get back to you as soon as I can.

The rest of the parts in Bright Green I designed to be add-ons to the Ender3-V2. The extra drawers on the sides, the 4040 extrusion drawers (there are some like this on Thingiverse however, mine are deeper and print in 2 pieces (the drawer and knob) whereas others print in 3 pieces making it a real pain to assemble if you have even a slight elephants foot on the initial layer. So, I designed it to be all one piece and used a massive fillet in the inside corners to keep the bridging to a minimum across the rear of the drawer (which is the very top as it is orientated on the print bed) to enable this to be a single piece instead of two.

As for the Motherboard and Raspberry Pi enclosures these were a culmination of me sick of looking for something that used a downdraft fan to blow cool air across the boards

Similar models

thingiverse

free

Titan Extruder Direct drive plate for Ender3. by meo_udon

...titan extruder direct drive plate for ender3. by meo_udon

thingiverse

titan extruder direct drive plate for ender3.

thingiverse

free

Direct Drive Extruder Mod for Ender3 by madwrench

...rain the hot-end wiring across the front.

edit: i re-uploaded the correct file, without the goofy embossing and crap. mea culpa.

thingiverse

free

Ender 3 V2 Direct Drive Stock Extruder Mod by bgyen

...iverse.com/thing:4666359 it might or might not work with other fan ducts; it will depend on how the duct is mounted on the plate.

thingiverse

free

E3V2 Satsana direct drive bracket tested by Darky82

...drive bracket for satsana with red metal extruder and stock hotend

print standing on the angled face where the stepper motor sits

thingiverse

free

Direct Drive Extruder 1.75mm V1.0 by SarwarKhan

...as well as to have an extruder as 1 piece (fan mount, hotend etc)

please feel free to modify and comment so we all can benefit.

thingiverse

free

Ender3 Direct Drive Mount with support for BL Touch and Dual Gear Extruder by furconc

... the stock plastic extruder or an upgraded metal single-gear extruder.

no extra hardware should be needed to install this part.

thingiverse

free

DMD - CR10s Pro V2 Direct drive bracket by _Ymir_

...thing:4814295) and my bracket is a perfect fit with it.

you can use the stock one. just use some washers/spacers to fill the gap

thingiverse

free

BMG V6 Direct Drive mount for HeroMe Gen 5 (Stock Creality Gantry) by edddeduck

...ng position for a bl touch and fan mounts. i recommend the light weight 5015 fans but you can pick your own they all should work.

thingiverse

free

CR-10 Direct Drive by s_gutz

...xis limit switch. this is necessary due to the added thickness of the direct drive plate so it can make contact with the switch.

thingiverse

free

Ender 3 Printermods MDD Bracket and spacers by ddwilli

...e

hot end spacers provided for thicknesses of 2.5 - 5.5mm. you can resize the hot-end spacer in cura if other thickness required

Ender3

3d_export

free

ender 3 3d print bed clips

...ender 3 3d print bed clips 3dexport ender3 3d print, print bed clips, glass bed clips, i...

3d_export

free

danish lunch

...with 3d printer made in thindercad and printed on ender3 max,<br>i used petg filament and have painted with vajjejo...

thingiverse

free

Ender3 pro

...ender3 pro

thingiverse

a plastic cover for the ender3 pro power supply, 100% fit.

note: fits only on the ender3 pro.

thingiverse

free

Guide filament ENDER3

...guide filament ender3

thingiverse

guide filament pour ender3

thingiverse

free

Ender3 Display Knob

...ender3 display knob

thingiverse

rotary encoder knob for ender3

thingiverse

free

Poignée ender3

...poignée ender3

thingiverse

bon print

thingiverse

free

Support Buses Ender3 / Nozzles holder Ender3

...support buses ender3 / nozzles holder ender3

thingiverse

un support de buses directement sur votre ender 3

thingiverse

free

Scrapper holder for Ender3 by clem3109

...scrapper holder for ender3 by clem3109

thingiverse

scrapper holder for ender3

thingiverse

free

ender3 filament guide by robotic_arm

...ender3 filament guide by robotic_arm

thingiverse

ender3 filament guide

thingiverse

free

Ender3, Ender3 pro reel holder with ballracer by nesan

...ender3, ender3 pro reel holder with ballracer by nesan

thingiverse

ender 3 ball racers need raft support on bed plate only.

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)