Thingiverse

Ender 3 Z Axis Adjustment by Weird_Stealth

by Thingiverse

Last crawled date: 4 years, 8 months ago

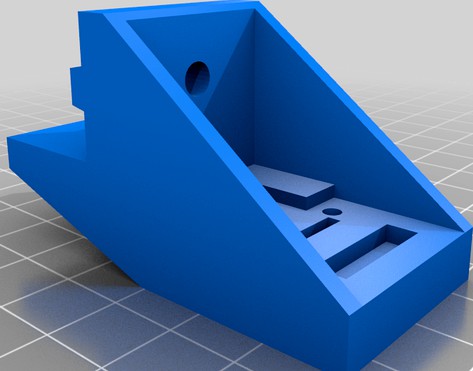

I recently printed someone's Z axis adjustment parts for the Ender 3, and noticed some issues I had with it, so I design my own. My design has some nice features, like the X axis cover uses 2 of the original screws to hold it in place, and the mount for the Z axis adjustment bolt uses the other two screws. Hopefully it should make installing the parts easier.

The following is required to be picked up from your local hardware store:

-M4 hex cap screw that are at least 40mm long.

-A spring just big enough the M4 screw can fit inside and move freely up and down.

-A M4 T-slot nut

-M3x20 Hex Flat Head Cap Screw (for the knob)

The design I printed used the hex cap end of the screw with disc to adjust the Z axis height, but I noticed that I sometimes bump the damn thing throwing off my adjustment. So I designed mine to have the screw flipped, the thread end will be what hits the sensor, and the adjustment knob far away from nozzle and any chances of being bumped.

I have two versions you can print, v1 which doesn't have that big ring at the top and you don't have to use the knob and shaft. V2 has a big ring at the top for the knob and shaft for tool-less adjustment.

All holes that are required to hold a thread are 0.15 smaller than the screws they require, all holes not required to hold a thread are 0.15 bigger than the screws they require. if you don't have a thread tap, then I suggest getting at least a M4 thread tap, you'll need it for the adjustment screw. The M3 screws that hold the sensor switches will cut their own threads.

I also left a nice big blank spot so you can put logos there or what have you. That way you can give your printer some character!

Edits:

Edit #1: I increased the size for the hex shaft for the adjustment shaft and decreased the part of the shaft that goes into the knob end. I'll be printing a test print in the morning to check it's sizing.

If anyone printing these parts run into any issues I haven't already addressed and fixed, please let me know. I am human and a scatter brain so I'm bound to make mistakes or over look something.

Edit #2: Ran into an issue with the Z Axis Adjustment Mount V2 mount, I forgot to account for the sensor when adding the ring at the top, so when I tested the printed part, it blocked the sensor from being touched. So I fixed the issue, shaved off some of the right side of it so the sensor can be triggered, and did a better job at hiding the sensor. The new part is now labeled V2-1 so I can keep track of the edits on my end. I also noticed that I forgot to give the Z axis sensor enough space in it's mount, so I widened the mount and gave it more space, also gave the plug more room, I didn't bother on rounding any edges on V2 of the sensor mount.

The following is required to be picked up from your local hardware store:

-M4 hex cap screw that are at least 40mm long.

-A spring just big enough the M4 screw can fit inside and move freely up and down.

-A M4 T-slot nut

-M3x20 Hex Flat Head Cap Screw (for the knob)

The design I printed used the hex cap end of the screw with disc to adjust the Z axis height, but I noticed that I sometimes bump the damn thing throwing off my adjustment. So I designed mine to have the screw flipped, the thread end will be what hits the sensor, and the adjustment knob far away from nozzle and any chances of being bumped.

I have two versions you can print, v1 which doesn't have that big ring at the top and you don't have to use the knob and shaft. V2 has a big ring at the top for the knob and shaft for tool-less adjustment.

All holes that are required to hold a thread are 0.15 smaller than the screws they require, all holes not required to hold a thread are 0.15 bigger than the screws they require. if you don't have a thread tap, then I suggest getting at least a M4 thread tap, you'll need it for the adjustment screw. The M3 screws that hold the sensor switches will cut their own threads.

I also left a nice big blank spot so you can put logos there or what have you. That way you can give your printer some character!

Edits:

Edit #1: I increased the size for the hex shaft for the adjustment shaft and decreased the part of the shaft that goes into the knob end. I'll be printing a test print in the morning to check it's sizing.

If anyone printing these parts run into any issues I haven't already addressed and fixed, please let me know. I am human and a scatter brain so I'm bound to make mistakes or over look something.

Edit #2: Ran into an issue with the Z Axis Adjustment Mount V2 mount, I forgot to account for the sensor when adding the ring at the top, so when I tested the printed part, it blocked the sensor from being touched. So I fixed the issue, shaved off some of the right side of it so the sensor can be triggered, and did a better job at hiding the sensor. The new part is now labeled V2-1 so I can keep track of the edits on my end. I also noticed that I forgot to give the Z axis sensor enough space in it's mount, so I widened the mount and gave it more space, also gave the plug more room, I didn't bother on rounding any edges on V2 of the sensor mount.