Thingiverse

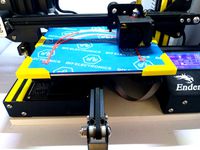

Ender 3 CR20 Belt clearance upgrade by Propeller3D

by Thingiverse

Last crawled date: 3 years, 2 months ago

This is a modification that lowers the belts on the x and y axis so they are running inside the extrusions on the motor side. This is a quick fix and not the ultimate solution. Hopefully this will spark some ideas to others that can improve on it and maybe make a better solution.

I have a CR20 but this should also fit the Ender 3 and maybe other creality printers.

By default the belts are not quite parrallel with the axis which will make them rub against the extrusions and also create some other problems. This is a bad design by creality and I haven't seen this flaw on other printers.

Mathematically speaking the belt will not be long enough when the trolleys are close to the edges which will make the weakest point bend/flex a little which is probably the motor brackets (they are pretty weak). The belts are pretty unstretchable. Having the brackets bend/flex will cause the belts to want to travel from side to side on the pulleys.

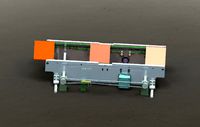

This is a clip on that pushes the belt down into the extrusion. You will need to remove the aluminium bed and y axis trolley to fit it. The x axis can be mounted without removing the x axis trolley if you loosen or remove the left upper wheel nyloc nut. The belt holds the clip in place. Pull on the belt and if the clip wants to move out a little when you pull leave it there since it will want to stabilise into that position anyway.

Make sure that the clip and belt is centered inside the extrusion, there is sideways adjustability. The belt may chafe a little where it goes through the extrusion because it is the same dimension as the hole in the extrusion, this should fix it self after a while when the rubber wears off a little.

The size of the hole where the belt goes into the clip on the x axis is not quite aligned, this is done to fasten it better.

The idler pulleys can be adjusted down a bit, since they are bigger they will not be a problem. I drilled out some bigger holes for the screws on the x axis idler bracket to allow more adjustment of the position.

I have a CR20 but this should also fit the Ender 3 and maybe other creality printers.

By default the belts are not quite parrallel with the axis which will make them rub against the extrusions and also create some other problems. This is a bad design by creality and I haven't seen this flaw on other printers.

Mathematically speaking the belt will not be long enough when the trolleys are close to the edges which will make the weakest point bend/flex a little which is probably the motor brackets (they are pretty weak). The belts are pretty unstretchable. Having the brackets bend/flex will cause the belts to want to travel from side to side on the pulleys.

This is a clip on that pushes the belt down into the extrusion. You will need to remove the aluminium bed and y axis trolley to fit it. The x axis can be mounted without removing the x axis trolley if you loosen or remove the left upper wheel nyloc nut. The belt holds the clip in place. Pull on the belt and if the clip wants to move out a little when you pull leave it there since it will want to stabilise into that position anyway.

Make sure that the clip and belt is centered inside the extrusion, there is sideways adjustability. The belt may chafe a little where it goes through the extrusion because it is the same dimension as the hole in the extrusion, this should fix it self after a while when the rubber wears off a little.

The size of the hole where the belt goes into the clip on the x axis is not quite aligned, this is done to fasten it better.

The idler pulleys can be adjusted down a bit, since they are bigger they will not be a problem. I drilled out some bigger holes for the screws on the x axis idler bracket to allow more adjustment of the position.

Similar models

thingiverse

free

Ender 3 X Axis PS3 Eye Camera Mount by repens

... on the idler pulley are not long enough, but my ender 3 came with two extra bolts which are longer and worked perfect for this.

thingiverse

free

Adimlab Gantry-S Y Tensioner

... m4 nylock nut to attach the idler to the pulley assembly

2x, m4 x 10 and the original v slot nuts to mount to the 4020 extrusion

thingiverse

free

Hadron (ORD Bot) X and Y Idler Pulley Brackets by flurin

....stl uploaded *.

update jan 21, 2013:

idlerpulleybracketv2.stl uploaded.

update, jan 27, 2013:

added misumispacer for the x-axis.

thingiverse

free

Creality/Ender 3 belt shim for X carriage

...a shim for the right side so i uploaded a mirror part too.

no supports needed, print in the orientation as they are in the files.

thingiverse

free

Geeetech I3 Y axis idler pulley by mbridak

...geeetech i3 y axis idler pulley by mbridak

thingiverse

idler pulley for y axis. prevents belt from rubbing on metal bracket.

thingiverse

free

X AXIS COVER

...n the x axis motor. design to make the adjustment of the pulley faster and easier.

probably fit on the other creality 3d printer.

thingiverse

free

Ender 3 Y Axis Idler reinforced by starfox64

...rough the male bracket and keep it firmly in place. one of the pictures shows me screwing that longer screw in with an allen key.

thingiverse

free

Ender 3 x-axis belt tensioner gap fill by liberotak

...e and bends a little due to pressure applied. thus, i had to use this in order to prevent wobbling and bending.

share your makes

thingiverse

free

Creality CR-10 S4 Y Axis Belt/Idler Cover by hondazcrxsi

...ingiverse

pressure fit cover for y axis belt/idler. to install, slide on from the rear to the front of the y axis idler bracket.

thingiverse

free

Ender 3 Pro X-Axis Adjustment Spacer by tamashi

...cut it to the size you need.

the big version can make it easier to melt the ring together after attaching it to the pulley wheel.

Cr20

thingiverse

free

CR20 PRO Feet Damper

...cr20 pro feet damper

thingiverse

this is feet damper for creality cr20 or cr20 pro

thingiverse

free

CR20 / CR20 PRO LCD COVER

... the cover with my logo, print one of the many other cover or just customize one to put you personnal name or information wanted.

thingiverse

free

Z Limit Switch Holder CR20 CR10 Ender 3

... bl touch. when i wanted to make it manual level without the bl touch i needed to design a limit switch base to hold it in place.

thingiverse

free

Hotend Chain Mount CR20 by Batmanbroom

...mixed this and made the cable chain bracket bigger to support 20.5mm chain and moved the bracket further out for my direct drive.

thingiverse

free

CR20 SKR/MKS GEN Board adaptor by doughy2002

...it.

the fans are for cooling of the tmc drivers, been using this for nearly 2 years (today is 07.04.2021) thought id upload it,

thingiverse

free

USB C and micro SD card mount for CR20/CR20 Pro by ssrix

...crew hole in the case and the old usb port hole. hot glue it all in place and screw it back up and it looks like nothing changed.

thingiverse

free

Creality CR20 glass bed clips by gutbuket

... by gutbuket

thingiverse

remixed to suit a creatliy glass bed. smaller gap and printed in abs. so far hold the bed very tightly.

thingiverse

free

Bed Bracket Creality CR20s pro Cable management by JSW72

...oles with a 4mm drill to fit , and replaced the back corner case screw with a longer onehttps://www.thingiverse.com/thing:2920060

thingiverse

free

AA, AAA & CR20 battery box by The_Lord_of_the_Things

... battery holder for various popular formats.

holds up to 6 aa batteries, 6 aaa batteries and 3 cr2032 batteries at the same time.

thingiverse

free

E3D Hemera + Noctua 40mm + BLTouch for Ender 3 / CR20-Pro

...octua 40mm + bltouch for ender 3 / cr20-pro

thingiverse

print with petg or better with abs!!

bltouch offset: x: -56,8 | y: +0

Clearance

turbosquid

$1

Clearance Sign

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$15

HDRI - Clearance

...res & lowres version) and a .ldr file of the image (as .jpeg). the environment is a 360° panorama in horizontal and holds ...

3d_export

$10

k-mf series planetary reducer

...is from 3 to 1000 to 3, low back clearance 8-15 arc minutes for the whole series of single...

3d_export

$5

puzzle cube

...held and moved in a specific direction to separate. clearance between the parts is around .3mm allowing for smooth...

3ddd

$1

Restoration Hardware Belgian Track Arm Upholstered chair

...32"h - luxe: 40"w x 43"d x 34"h - clearance needed for delivery:...

3ddd

$1

FULHAM LEATHER SOFAS

...x 30'h luxe depth: 96'w x 47'd x 30'h clearance needed for delivery:...

3d_export

$15

gaz-aa

...dimensions: 2450mm x 1870mm wheelbase: 3340mm , rear axis clearance 200mm clutch: single disk, dry mechanical brakes tyres: 6.50-20...

3d_export

$20

Tower Crane - Revit Family

...cast foundation<br>cabin options:<br>- side cabin<br>- suspended cabin<br>analytic visualization options:<br>- clearance zone<br>- maximum load 3d graph<br>parametric dimensions:<br>- jib length<br>- counter...

3d_export

$200

german motorcycle r 75 ww2

...mm 1,730 height, mm 1,000 wheelbase, mm 1,444 ground clearance mm 150 seat height 780 * weight, kg 420...

3d_export

$200

german motorcycle r 75 schwarz grau ww2

...mm 1,730 height, mm 1,000 wheelbase, mm 1,444 ground clearance mm 150 seat height 780 * weight, kg 420...

Upgrade

turbosquid

$15

Upgraded Glock

...e 3d model upgraded glock for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1185950)

3ddd

$1

Calligaris / UPGRADE

...calligaris / upgrade

3ddd

calligaris

c материалом

3d_export

free

cz upgrade

...cz upgrade

3dexport

https://www.buymeacoffee.com/mestrezen3d https://linktr.ee/mestrezen3

turbosquid

$80

Custer Tank upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Domestos 1 upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Upgraded tea cup

...upgraded tea cup

3dexport

a cup with an unusual design and a unique shape for a more enjoyable tea experience

3d_export

$8

dixy outlander classic style upgraded poplar wood lounge chair

...utlander classic style upgraded poplar wood lounge chair

3dexport

dixy outlander classic style upgraded poplar wood lounge chair

turbosquid

free

AK-12 + Upgrades low-poly 3D model

...ow-poly 3d model for download as fbx, blend, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1501145)

evermotion

$700

Upgrade from V-ray 1.5 to 3.5 for 3ds max

...here is no need to purchase a new dongle - your current dongles will be reprogrammed to carry v-ray 3. evermotion 3d models shop.

evermotion

$300

Upgrade from V-Ray 2.0 to V-ray 3.5 for 3ds Max

... interface (gui) for editing settings on one machine and one render node for rendering on one machine. evermotion 3d models shop.

Ender

3ddd

$1

Enders / Elegance

...enders / elegance

3ddd

обогреватель

уличный газовый обогреватель enders elegance

высота: 2200 мм

3d_export

free

ender 3 frame cavity covers

... of the creality ender 3 - makes it look a bit more attractive it just slides into the open channels of the aluminium framework

turbosquid

$1

pen support for ender 3

...y free 3d model pen support for ender 3 for download as blend on turbosquid: 3d models for games, architecture, videos. (1611282)

3d_ocean

$9

Ender Dragon Minecraft

...ojang obj poly videogames

ender dragon minecraft created with cinema 4d r15 formats included: max 2013 – fbx 2012 – c4d r15 – obj

3d_export

free

Creality ender enclosure webcam mount

...e creality enclosure. sure is better than a tripod. change it up if it helps. i printed pla with 50% infill on my dd ender 3 pro.

3d_export

free

ender 3 enclosure corners

...er corners and 4 upper corners, using 25mmx25mm angled aluminium pieces that gets covered on inside of the frame with plexiglass

3d_export

free

ender 3 3d print bed clips

...ed + normal aluminium bed frame of the creality ender 3 = 6mm (b) these clips are designed for glass plate + aluminium bed = 4mm

3d_export

$5

GRUMPY CAT

...grumpy cat 3dexport grumpy cat to print in ender ...

3d_export

$5

Logs fire

...with one multi material for corona and vray r ender. albedo, normal, uvmap, roughness format jpg 4096x4096 models:...

3d_export

$42

excavator

...is the original size. 0.12 mm printing surface creality ender5 ...

Belt

turbosquid

$9

Belt conveyor belt

...t conveyor belt for download as 3ds, ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1226546)

3d_export

$6

belt

...d then comes off and fastens at the front of the seat. version: 2015 units: millimetres x-form: yes polys: 120 950 verts: 163 944

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

3ddd

$1

column belt

...column belt

3ddd

колонна

column belt

turbosquid

$5

Belt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Leather Belt

...ather belt is created in 3dsmax 2011 and rendered with vray 1.5 and it has all the texture included with the multiple obj format.

3d_ocean

$5

Belt Ring

...belt ring

3docean

belt jewelry ring

belt ring 3d model. total weight 3.5 gram & 1.1 stone size. 3dm and obj file format.

design_connected

$11

Belt Square

...belt square

designconnected

meridiani belt square computer generated 3d model. designed by parisio, andrea.

design_connected

$11

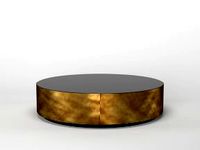

Belt Round

...belt round

designconnected

meridiani belt round computer generated 3d model. designed by parisio, andrea.

3

turbosquid

$10

Mountain Bike 3 -3 of 3

...model mountain bike 3 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438752)

turbosquid

$6

Rock 3-3

...urbosquid

royalty free 3d model rock 3-3 for download as obj on turbosquid: 3d models for games, architecture, videos. (1628065)

turbosquid

$29

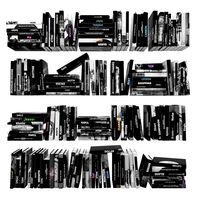

Books 150 pieces 3-3-3

...books 150 pieces 3-3-3 for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1384033)

turbosquid

$3

Genesis 3 Clothing 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3ddd

$1

Розетка 3

...розетка 3

3ddd

розетка

розетка 3

turbosquid

$50

is-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Mountain Bike 3 -2 of 3

...model mountain bike 3 (#2 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438750)

turbosquid

$10

Mountain Bike 1 -3 of 3

...model mountain bike 1 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438743)

3d_export

$5

3 CATS

...3 cats

3dexport

3 cats pen holder