Thingiverse

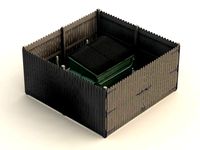

Enclosure CR10 V2

by Thingiverse

Last crawled date: 4 years, 3 months ago

This is an enclosure made by myself to prevent against fire, cold temperature, dust etc.

It's based on a IKEA BROR Black Shelving metal unit 85x55x190 cm with 4 Shelf in pine plywood.

Adding:

3 gyplat boards (one in back, 2 on right side).

1 polystyrene mirror 2mm on the right side

2 mirror from Ikea in the back.

1 polystyrere clear 3mm for the front and left door.

1 support on the top for filament + Fire detector

1 Car Insulation Material in 5mm for bottom and in 10mm for the top of the cage (still waiting shipment)

Some piece of EPDM roof for 3Dprinter support anti vibration or to use as spacer.

Front doors are equal measure with 90degree of opening

Left side doors are divided where the filament is passing through the 3d printer with 120degree of opening (even if you see 135 on the stl).

You will need to do some hole in the wood (2,3,10 & 20 mm diameter).

Also Dremel is needed to cut some parts of the polystyrere clear to adapt perfectly the weight of the hinge.

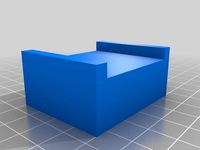

You can choose between simple version of 3dprinter support or with the anti-vibration. Check file 3Dprinter_support or 3Dprinter_anti-vibration.

Issues found during the build:

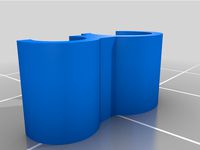

Depending of the weight, you will need choose between hinge_panels_upper_PinBase or hinge_panels_upper_PinBaseV2. I use Pinbase for the front and PinbaseV2 for the sidepanel. This was the most difficult part of the assembling (need some adjustment or leveling).

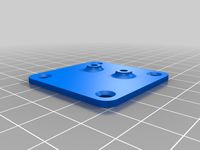

The hole of 20mm is used for passing cable to the power supply with the power_cable_hole.stl. I recommend to not glue this one as the issue is with the Bed connector which is bit more than 20mm. If you not glue, you can force a bit and this will be ok.

It's based on a IKEA BROR Black Shelving metal unit 85x55x190 cm with 4 Shelf in pine plywood.

Adding:

3 gyplat boards (one in back, 2 on right side).

1 polystyrene mirror 2mm on the right side

2 mirror from Ikea in the back.

1 polystyrere clear 3mm for the front and left door.

1 support on the top for filament + Fire detector

1 Car Insulation Material in 5mm for bottom and in 10mm for the top of the cage (still waiting shipment)

Some piece of EPDM roof for 3Dprinter support anti vibration or to use as spacer.

Front doors are equal measure with 90degree of opening

Left side doors are divided where the filament is passing through the 3d printer with 120degree of opening (even if you see 135 on the stl).

You will need to do some hole in the wood (2,3,10 & 20 mm diameter).

Also Dremel is needed to cut some parts of the polystyrere clear to adapt perfectly the weight of the hinge.

You can choose between simple version of 3dprinter support or with the anti-vibration. Check file 3Dprinter_support or 3Dprinter_anti-vibration.

Issues found during the build:

Depending of the weight, you will need choose between hinge_panels_upper_PinBase or hinge_panels_upper_PinBaseV2. I use Pinbase for the front and PinbaseV2 for the sidepanel. This was the most difficult part of the assembling (need some adjustment or leveling).

The hole of 20mm is used for passing cable to the power supply with the power_cable_hole.stl. I recommend to not glue this one as the issue is with the Bed connector which is bit more than 20mm. If you not glue, you can force a bit and this will be ok.

Similar models

thingiverse

free

Rear view mirror anti-vibration cushion by AaronTheCrafter

...nd the top of the rear view mirror. no vibration at all now. the stl and the solidworks files are attached for the added cushion.

thingiverse

free

118B Front suspension arm by duke24

...here are the files. if you need the right side, just mirror the left side ;)

update: v2 is a bit stronger then the first release.

thingiverse

free

Ikea Lack - Filament Guide

...ikea lack - filament guide

thingiverse

filament guide for ikea lack enclosure. use a 1/2in drill bit.

thingiverse

free

Ikea Lack Enclosure Leg Bracing by ElmoC

... to help align the legs of the table above it.

you will need to mirror the hinge version in your slicer to get one for each side.

thingiverse

free

Ikea Lack filament guide 2 sided

...you will get not only the .stl files. the .f3d and .stp files are also in the download.

(this is my first thing here btw.)

enjoy.

3dwarehouse

free

Unishower Arc Front Left Hand Enclosure

... arc front left hand enclosure

3dwarehouse

curved front enclosure with side panel on left hand side #bathroom #enclosure #shower

thingiverse

free

Filament guide for IKEA IVAR / 18mm Panels by Mafiatorte

...ikea stuva enclosure, just made it a bit smaller to fit to my ikea ivar shelf. you will need a 25mm drill / holecutter to fit it.

thingiverse

free

Anti-vibration feet for aluminium profile 20mm by HARRAEL

...anti-vibration feet for aluminium profile 20mm by harrael

thingiverse

anti-vibration feet for aluminium profile 20mm.

cg_trader

$15

Shoe sole for the blind

...ibrate, and if it's on the right side right one will vibrate. if in the front then the vibration motor in front will vibrate.

thingiverse

free

Left Tray Ender 3 by Pascal0815

...e better one, without the ender 3 lettering. if you like the dragon on the plate print it with 60% scale and glue it on the top.

Cr10

3d_export

$21

Hall tree and Clothing Rack CR10

... real object. 3. lights and cameras are included in the scenes renders using vray * renders are made in 3ds max 2018 using vray 5

thingiverse

free

Clips for Ender 3, CR10, CR10S

.... maybe others, but only been tested with these.

these clips makes a tight fit, so that the cable and bowden tube stays in place.

thingiverse

free

X-axis endstop offset for cr10 cr10s Ender 3

...x-axis endstop offset for cr10 cr10s ender 3

thingiverse

x-axis endstop offset for cr10 cr10s ender 3

thingiverse

free

Filament Sensor CR10

...or cr10

thingiverse

remix of the sensor with fixation in order to face directly the extruder and ptfe tube

cr10, cr10s ender3...

thingiverse

free

Fan V4 CR10/CR10S Ender3 Versione 4 by creativesolutions-lab

...fan v4 cr10/cr10s ender3 versione 4 by creativesolutions-lab

thingiverse

fan v4 cr10/cr10s versione 4

thingiverse

free

CR10 Feet by Leighton417

...cr10 feet by leighton417

thingiverse

this is a cr10 feet for people who have short table width.

thingiverse

free

Dremel Attachment for CR10, Ender 3, Cr10s by Conn22_43

...verse

a bracket to hold a dremel onto any ender 3, cr10 bracket. i printed it in petg, but it can be made in any rigid material.

thingiverse

free

CR10S-Plus Hotend by scorpio_man30ro

...cr10s-plus hotend by scorpio_man30ro

thingiverse

cr10s-plus hotend

thingiverse

free

Leveling knob CR10 by JMJacques

...leveling knob cr10 by jmjacques

thingiverse

leveling knob cr10

thingiverse

free

Soporte Superior sensor filamento CR10 v2 - CR10 v3 by Guimir

...3 by guimir

thingiverse

soporte sensor de filamento guia superiror tipo cr10 v3 para convertir la cr10 v2 en extrusión directa.

Enclosure

3d_export

free

electrical enclosure

...l enclosure where electrical devices like (relays, contactors, busbars ) are kept in order to protect from hazardous environment.

turbosquid

$100

GPU Enclosure

...yalty free 3d model gpu enclosure for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1381061)

3d_export

$5

Electrical Enclosure

...ed. also has tower lights attaced on the top.<br>file format that are available:<br>.step<br>.obj<br>.stl

archive3d

free

Enclosure 3D Model

...closure 3d model

archive3d

shower enclosure-acquarius- 3d model for interior 3d visualization.

archive3d

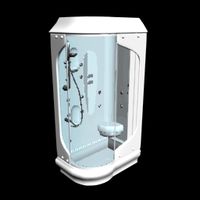

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-omega- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-vega - 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-zenith - 3d model for interior 3d visualization.

turbosquid

$20

shower enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Dumpster Enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

3d printer enclosure

... model 3d printer enclosure for download as ipt, skp, and fbx on turbosquid: 3d models for games, architecture, videos. (1634310)

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)