Thingiverse

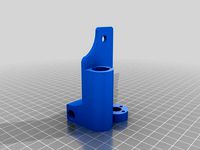

Emphacy's Minimal Leadscrew Upgrade

by Thingiverse

Last crawled date: 4 years, 2 months ago

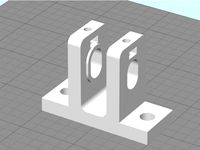

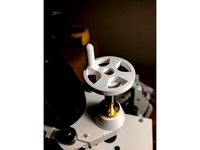

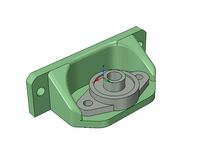

This is a remix of the original Hobsie's Parametric Leadscrew Upgrade designed to prevent bending of the Z rods. You can preview and download the source at https://a360.co/2HHakJK

Changes

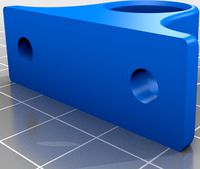

Improved the idler design so the tension is placed onto the X rods instead of the Z rods. This also allows you to slide out the X rods without disassembling the entire Z axis.

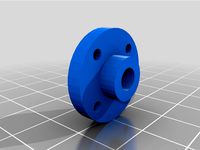

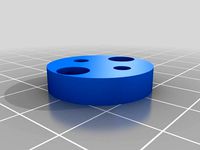

Redesigned the idler so it's on the outside of the axis (more room for carriage on the inside). There are two versions for pulleys with 3mm/5mm bore bearings.

Reduced the number of holes for the Trapezoidal nuts as only two are required.

Replaced the Z endstop bolt hole (not needed for probes) with a modular hole instead.

Parameters

There is a parameter in the Fusion design which changes the distance between the rod and leadscrew. The default is 17mm which is appropriate for the Prusa i3 (all versions) and the P3Steel. If you own a P3Steel XL you'll want to change this to 18mm. The STLs are at 17mm.

Components

4x LM8UU or Igus RJUM-02-08

2x M3 Self Locking Nuts

2x M3 Standard Nuts

2x M3 Bolts (recommend 20mm)

Questions

Q: Can I use anti-backlash nuts with the leadscrews?

A: No. They will not fit and you don't need them anyway. Earth has 1G gravity.

Q: How do I add a Z endstop bolt?

A: Design and print a mount for the bolt and screw it into the modular hole at the bottom of the motor side.

Q: How do I tighten the Idler / Tensioner?

A: Turn the bolts counter-clockwise. You may need to add some force to stop the pushers rotating at first but once there is enough tension they'll stop rotating.

Changes

Improved the idler design so the tension is placed onto the X rods instead of the Z rods. This also allows you to slide out the X rods without disassembling the entire Z axis.

Redesigned the idler so it's on the outside of the axis (more room for carriage on the inside). There are two versions for pulleys with 3mm/5mm bore bearings.

Reduced the number of holes for the Trapezoidal nuts as only two are required.

Replaced the Z endstop bolt hole (not needed for probes) with a modular hole instead.

Parameters

There is a parameter in the Fusion design which changes the distance between the rod and leadscrew. The default is 17mm which is appropriate for the Prusa i3 (all versions) and the P3Steel. If you own a P3Steel XL you'll want to change this to 18mm. The STLs are at 17mm.

Components

4x LM8UU or Igus RJUM-02-08

2x M3 Self Locking Nuts

2x M3 Standard Nuts

2x M3 Bolts (recommend 20mm)

Questions

Q: Can I use anti-backlash nuts with the leadscrews?

A: No. They will not fit and you don't need them anyway. Earth has 1G gravity.

Q: How do I add a Z endstop bolt?

A: Design and print a mount for the bolt and screw it into the modular hole at the bottom of the motor side.

Q: How do I tighten the Idler / Tensioner?

A: Turn the bolts counter-clockwise. You may need to add some force to stop the pushers rotating at first but once there is enough tension they'll stop rotating.

Similar models

thingiverse

free

Aurora A3 Y-Axis Tension Adjustment Idler Mount (whew!) by DaHai8

...er bolt giving you 4.5mm of play.

i just basically stretched the stock y-axis idler mount and added holes for the bolts and nuts.

thingiverse

free

adjustable z axis endstop mount for prusa p3steel by ksevin

...rt of toolson's z endstop trigger at: https://www.thingiverse.com/thing:1036871

you need a bolt m3x25, two nuts and a spring.

thingiverse

free

Ender 3 Belt Driven Dual Z-Axis by wjohnsaunders

...ting hardware.

replace the stock leadscrew on the left side with the longer leadscrew.

todo - continue with install instructions.

thingiverse

free

Z axis Leadscrew to leadscrew coupler (8mm to 5mm) with 0.14mm clearence

...adscrew to leadscrew coupler (8mm to 5mm) with 0.14mm clearence

thingiverse

extra parts required:

2x m3 nuts

2x m3 screws (8mm+)

thingiverse

free

prusa i3 X endstop for leadscrew by Benn25

...ly...

leadscrew nut diameter : 10.2mm

lm8uu linear bearings diameter : 15mm

use a m5 screw for the tensioner and a 625zz bearing.

thingiverse

free

Prusa i3 x-belt tensionner upgrade by ffleurey

...nut in the middle is the original one from the prusa i3 idler holder. the bolt holding the idler holder in the x end is removed.

thingiverse

free

Prusa Steel X axis with tensioner and 8mm leadscrew support by fedewolfie

...ner and a m5 screw and nut for the toothed idler, i use a cheap aliexpress toothed idler with a m5 bore.

prints without supports.

thingiverse

free

Anet A8 M3 X Belt Tensioner by viktor3d

...esigns:

-captive m3 nut for the idler bolt (orange circle)

-internal spacers between the idler and the walls (light blue circles)

thingiverse

free

anet a8 front brace Y axis by nclsdf

...ll need 2x m8 nuts, 2x m8 washers 2x m3 nuts 2x m3 bolts 30mm long.

back brace version : http://www.thingiverse.com/thing:1844389

thingiverse

free

X axis end clamp by bunjatec

...ll need to print :

1x end clamp

2x end clamp fixings

the clamp then holds the ends of the x stage rods and stops them poking out.

Emphacy

thingiverse

free

PowerFlower Geared Extruder by Emphacy

...0mm/s

e jerk: 5.0

e accelleration: 1000mm/s

i will be releasing a mount for a filament cleaner and gear guard in the near future.

thingiverse

free

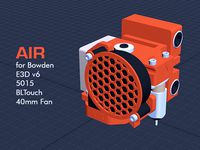

Bowden X-Carriage Mount for E3D v6 with 40mm Fan and BLTouch by Emphacy

... the noctua nf a4x10 flx as the cooling fan.

bltouch position (from nozzle): x = +36mm y = 0mm. z = +2mm - z will not be perfect.

thingiverse

free

Hobsie's Parametric Leadscrew Upgrade by Hobsie

...off by 1mm in the z axis (thanks to @emphacy for pointing that out!). don't worry if you've already...

Leadscrew

thingiverse

free

Leadscrew Support by The_Custom_Side

...w support for 8mm leadscrew.

printed in 0.25mm petg

requires bearing (16mm od, 8mm id).

no supports, no rafts, 20% gyroid infill.

thingiverse

free

Hook for M8 Leadscrew

...hook for m8 leadscrew

thingiverse

hook which holds on m8 leadscrew without pressure on the screw

thingiverse

free

X Idler Leadscrew by GOO2014

...x idler leadscrew by goo2014

thingiverse

x idler leadscrew

thingiverse

free

10mm Leadscrew Knob by carboncopy101

...10mm leadscrew knob by carboncopy101

thingiverse

this is a knob for a 10mm leadscrew for manual turning. enjoy.

thingiverse

free

nut for m5 leadscrew by mbzn

...nut for m5 leadscrew by mbzn

thingiverse

created to use as a nut for m5 threaded bar in place of a leadscrew

thingiverse

free

8mm Leadscrew Crank by dakahler

...igned for the cyclone pcb, but can be used on any 8mm leadscrew.

the captive nut for the set screw is designed to be heat-staked.

thingiverse

free

Z leadscrew support for KFL08 by bajmar

...z leadscrew support for kfl08 by bajmar

thingiverse

z leadscrew support for kfl08

thingiverse

free

X-Axis Leadscrew Idler by brisinger

...x-axis leadscrew idler by brisinger

thingiverse

x-axis leadscrew idler

thingiverse

free

Leadscrew Adapter by PhoenixZip

...rew, and it does not fit our lorei printers.

this adapter allows use of holes that are 16mm apart to our (roughly) 11.85mm holes.

thingiverse

free

Trintcore z-axis modified leadscrew by grubeludouche

... modified leadscrew by grubeludouche

thingiverse

this is a mod to fit a t8 pitch leadscrew, replacing the original m8 leadscrew.

Upgrade

turbosquid

$15

Upgraded Glock

...e 3d model upgraded glock for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1185950)

3ddd

$1

Calligaris / UPGRADE

...calligaris / upgrade

3ddd

calligaris

c материалом

3d_export

free

cz upgrade

...cz upgrade

3dexport

https://www.buymeacoffee.com/mestrezen3d https://linktr.ee/mestrezen3

turbosquid

$80

Custer Tank upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Domestos 1 upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Upgraded tea cup

...upgraded tea cup

3dexport

a cup with an unusual design and a unique shape for a more enjoyable tea experience

3d_export

$8

dixy outlander classic style upgraded poplar wood lounge chair

...utlander classic style upgraded poplar wood lounge chair

3dexport

dixy outlander classic style upgraded poplar wood lounge chair

turbosquid

free

AK-12 + Upgrades low-poly 3D model

...ow-poly 3d model for download as fbx, blend, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1501145)

evermotion

$700

Upgrade from V-ray 1.5 to 3.5 for 3ds max

...here is no need to purchase a new dongle - your current dongles will be reprogrammed to carry v-ray 3. evermotion 3d models shop.

evermotion

$300

Upgrade from V-Ray 2.0 to V-ray 3.5 for 3ds Max

... interface (gui) for editing settings on one machine and one render node for rendering on one machine. evermotion 3d models shop.

Minimal

3d_export

$10

minimalism armchair

...minimalism armchair

3dexport

minimalism armchair

turbosquid

$40

Minimal Table

...quid

royalty free 3d model minimal table for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1242982)

turbosquid

$26

Minimal house

...id

royalty free 3d model minimal house for download as blend on turbosquid: 3d models for games, architecture, videos. (1641136)

3d_export

$10

Minimal space

...minimal space

3dexport

https://www.dock4all.com/

3ddd

$1

minimal table

...minimal table

3ddd

журнальный

st

3ddd

$1

minimal dining table

...minimal dining table

3ddd

обеденный

modern minimal dining table

turbosquid

$7

Minimalism chair

...e 3d model minimalism chair for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1480621)

turbosquid

$25

minimal sofa

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Minimal Soft

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$16

Minimal basin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.