Thingiverse

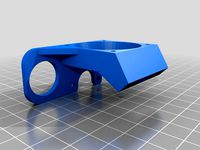

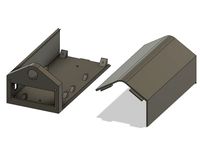

eMAKER Huxley E3D V6 Lite Hot End Mount by gdeemer86

by Thingiverse

Last crawled date: 3 years, 4 months ago

Comments

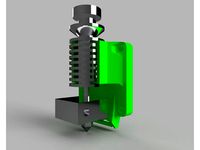

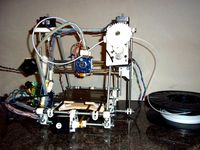

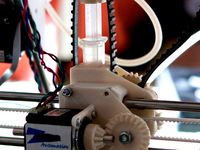

This is one of the first versions of the E3D mount for my Huxley. I took a 4 year hiatus from printing letting my Hux collect dust. We needed to prototype a few things for a different project, and were having major issues with the original hot end. We opted to buy the brand named E3D v6 Lite Print head because of the great reviews. This mount was created as a first draft. We plan to develop the mount as issues arise (and I'm sure they will). Please keep that in mind if you plan to use it or remix. This part is under heavy development.

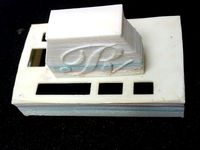

We used as much of the original Hux X mount as possible. We re-used the mount screws ,but did have to purchase a few bolts to hold the mount bracket together. The one from the pictures was printed in PLA, but ABS may be a better solution because of the proximity of the first two fins (that get ~35C-40C when printing with ABS.)

The E3D V6 Lite comes with a significantly larger PTFE tube as the original eMAKER Huxley. We have also created a remixed version of the rays-jones bowden extruder that includes a spot to mount the new fitting from E3D.http://www.thingiverse.com/thing:1365834

A word of advice after configuring Slic3r for the new hot end:

We had the 2011 model with the .5 nozzle so a lot of slic3r settings changed when we moved to the .4. Slow the the first layer WAY down. We were getting bubbling (and still are to some extent).

Our first theory was the airflow of the hot end fan impacting the cooling in unintended spots. E3D recommends leaving the back side of the fins open for airflow, but this was not an option because of the form factor of the Hux.(check the comments there is a solution for this issue in development by another maker) After testing, we realized that the fist layer was printing way to fast. We changed the print speed to 30% for the first layer increased the width of the first layer to 125%.

Revision History

Revision .93 Initial Development model. We would like to address the following issues

-unintended fan air flow out of the bottom of the hot end

-vents to allow lateral airflow

-delete screw holes on the small piece

-mount a 3m ptfe sheet on the bottom of the fan to protect against heating from the heater block

Please comment on issues if you think of something we would love feedback

This is one of the first versions of the E3D mount for my Huxley. I took a 4 year hiatus from printing letting my Hux collect dust. We needed to prototype a few things for a different project, and were having major issues with the original hot end. We opted to buy the brand named E3D v6 Lite Print head because of the great reviews. This mount was created as a first draft. We plan to develop the mount as issues arise (and I'm sure they will). Please keep that in mind if you plan to use it or remix. This part is under heavy development.

We used as much of the original Hux X mount as possible. We re-used the mount screws ,but did have to purchase a few bolts to hold the mount bracket together. The one from the pictures was printed in PLA, but ABS may be a better solution because of the proximity of the first two fins (that get ~35C-40C when printing with ABS.)

The E3D V6 Lite comes with a significantly larger PTFE tube as the original eMAKER Huxley. We have also created a remixed version of the rays-jones bowden extruder that includes a spot to mount the new fitting from E3D.http://www.thingiverse.com/thing:1365834

A word of advice after configuring Slic3r for the new hot end:

We had the 2011 model with the .5 nozzle so a lot of slic3r settings changed when we moved to the .4. Slow the the first layer WAY down. We were getting bubbling (and still are to some extent).

Our first theory was the airflow of the hot end fan impacting the cooling in unintended spots. E3D recommends leaving the back side of the fins open for airflow, but this was not an option because of the form factor of the Hux.(check the comments there is a solution for this issue in development by another maker) After testing, we realized that the fist layer was printing way to fast. We changed the print speed to 30% for the first layer increased the width of the first layer to 125%.

Revision History

Revision .93 Initial Development model. We would like to address the following issues

-unintended fan air flow out of the bottom of the hot end

-vents to allow lateral airflow

-delete screw holes on the small piece

-mount a 3m ptfe sheet on the bottom of the fan to protect against heating from the heater block

Please comment on issues if you think of something we would love feedback

Similar models

thingiverse

free

Huxley E3D V6 Hot End Mount with Airflow Fix by henriksod

...ems with airflow, making my hot-end cooling too inefficient for proper functionality.

made in inventor 2016, .ipt files attached.

thingiverse

free

E3Dv6 hot end with layer fan and zprobe mount by Aguante0

...dv6 hot end with layer fan and zprobe mount by aguante0

thingiverse

fan layer and proximity sensor m18 mount for e3d v6 hot end.

thingiverse

free

eMAKER Huxley Remixed Bowden Extruder for use with E3D V6 by gdeemer86

...lopment) for a complete solution for the emaker huxley e3d upgrade. https://www.thingiverse.com/thing:1350748

print with support

thingiverse

free

Folger Tech Kossel with E3D V6 Hot End - Part Cooling Fan Duct by Scotty-G

...ted out of abs in vertical orientation (.2mm orientation & 1mm thick walls) so supports did not fill air pathway inside duct.

thingiverse

free

Small Blower Fan Mount for v6 E3D Hotend by Steampunq

...e the 30mm fan mount with a small blower fan mount because i have had such bad luck with 30mm fans. this fits the e3d v6 hot end.

thingiverse

free

RepRapPro Huxley E3D mount by mcbig

...reprappro huxley e3d mount by mcbig

thingiverse

e3d hot end for huxley reprappro with fun.

thingiverse

free

40mm Fan Duct - Chinese E3D v6 Hot end by xvsideswipe

...40mm fan duct - chinese e3d v6 hot end by xvsideswipe

thingiverse

40mm fan duct for the chinese e3d v6 hot end

thingiverse

free

Low profile Rostock Max layer fan (E3D V6) by _jamesm

...(http://www.thingiverse.com/thing:137140). the normal layer fan will sit just a bit too low when using the 'tall' mount.

thingiverse

free

Delta E3D V6 Radial / Blower Fan Mount 120° by zsoltm

...and after a few test print it works well on my highly customised 3ku k3000 based delta.

the 120° heatsink mount is from ariuskooo

thingiverse

free

E3D-v6 Fan Duct Mashup for Orion / Rostock Max Mount by briankb

...

this is a mashup between the provided seemecnc orion peek fan duct and the fan mount that was included with the e3d-v6 hot end.

Gdeemer86

thingiverse

free

Huxley E3D V6 Hot End Mount with Airflow Fix by henriksod

...by henriksod thingiverse this is a modified version of gdeemer86#39;s emaker huxley e3d v6 lite hot end mount. this...

thingiverse

free

eMAKER Huxley Remixed Bowden Extruder for use with E3D V6 by gdeemer86

...lopment) for a complete solution for the emaker huxley e3d upgrade. https://www.thingiverse.com/thing:1350748

print with support

Emaker

thingiverse

free

eMaker Huxley Higher Z by burtyb

...ey higher z by burtyb

thingiverse

mod on the emaker huxley to achieve a z height of ~150mm (mine previously only managed ~95mm).

thingiverse

free

Emaker Huxley electronics enclosure by Weldingrod1

...d to work with the emaker huxley electronics. it clears the sd card and accomodates the connector orientation used on the huxley

thingiverse

free

eMAKER Filament spool holder by emaker_io

...ger prints.

the included .scad files are based on erik debruin's standing frame vertex, http://www.thingiverse.com/thing:2200

thingiverse

free

Hallebarde by EMake

...esigned on fusion 360

4 pieces to glue

i printed it on a creality cr-10

layer : 0.15mm

speed : 70mm/s

material : pla

no supports

thingiverse

free

eMAKER Huxley by emaker_io

... aluminium, nichrome heated bed

single board arduino motherboard

design files can be found here: https://github.com/emaker/huxley

thingiverse

free

Arduino scooter box by EMake

...x by emake

thingiverse

this is a box to fix on a diy electric scooter based on arduino uno.

tuto on https://makeitwithconrad.fr/

thingiverse

free

Fixation ruban LED by EMake

...fixation ruban led by emake

thingiverse

petite pièce pour fixer un ruban led avec vis ou clous

thingiverse

free

Greatests Mavic Pro 3D Prints by EMake

...greatests mavic pro 3d prints by emake

thingiverse

greatests mavic pro 3d prints

thingiverse

free

eMaker Huxley Y-axis belt tensioner by joo

...oner to fit the emaker huxley.

hole pitch 16mm and belt-clamp for t2.5 timing belts.

it should also work on the reprappro huxley

thingiverse

free

Thermometer fixation box by EMake

...ll box to fix a thermometer on a wall with two screws

resolution: 0.15 mm

printing time: 1h20

infill: 17%

designed on 123d design

Huxley

thingiverse

free

Reprap Huxley Tray Build by ridingg

...reprap huxley tray build by ridingg

thingiverse

reprap huxley parts all ready to print on a huxley sized print bed!

thingiverse

free

Simple spool holder Huxley by plexer

...simple spool holder huxley by plexer

thingiverse

modified for huxley

thingiverse

free

Huxley printable frog by 3DAndy

...huxley printable frog by 3dandy

thingiverse

printable one-piece y-axis-frog for huxley-printers.

thingiverse

free

Huxley Frame Stabilizer by MaxTex

...huxley frame stabilizer by maxtex

thingiverse

nice frame stabilizer for my huxley:

m6 rods 7cm

m6 nuts

thingiverse

free

Huxley Paste Extruder by mattroberts

...er by mattroberts

thingiverse

a complete redesign of richrap's paste extruder. this design will work on a reprappro huxley.

thingiverse

free

Emaker Huxley electronics enclosure by Weldingrod1

...d to work with the emaker huxley electronics. it clears the sd card and accomodates the connector orientation used on the huxley

thingiverse

free

Adjustable z-stop for Huxley by Inquisitor

...adjustable z-stop for huxley by inquisitor

thingiverse

an adjustable z-stop for a reorap huxley

3d_sky

$8

Baker, HUXLEY SOFA No. 6605S

...baker, huxley sofa no. 6605s

3dsky

baker huxley

dimensions width: 89 inches depth: 40 inches height: 35 inches

thingiverse

free

Huxley Glass Clip. by zMath

...huxley glass clip. by zmath

thingiverse

clip to hold plate of glass on huxley print bed.

i use 4. printed in abs.

thingiverse

free

Huxley MiniExtruder holder by 3DAndy

...y

thingiverse

simple holder for the miniextruder to the huxley frame. fits also to the original reprappro extruder (new design).

Lite

design_connected

$11

Lite

...lite

designconnected

sphaus lite coffee tables computer generated 3d model. designed by eero saarinen.

3ddd

$1

Foscarini_Giga-Lite

... giga-lite , лампы , light

foscarini_giga-lite

turbosquid

free

LegendarySwords - Lite

...odel legendaryswords - lite for download as dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559781)

turbosquid

$85

DS Lite

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jet Lite

... model jet lite for download as 3ds, obj, fbx, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1476173)

turbosquid

$1

Mod-Lite

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

lite on.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$13

Multi-Lite Pendant

...multi-lite pendant

designconnected

gubi multi-lite pendant computer generated 3d model. designed by weisdorf, louis .

turbosquid

$120

Cartoon Pack Lite

...

royalty free 3d model cartoon pack lite for download as fbx on turbosquid: 3d models for games, architecture, videos. (1255320)

turbosquid

$100

HUAWEI P3 Lite

...id

royalty free 3d model huawei p30 lite for download as c4d on turbosquid: 3d models for games, architecture, videos. (1515805)

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

Hot

turbosquid

$1

HOT

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

$9

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

free

hot chili

...hot chili

3dexport

hot chili<br>for fruits and getegables collection

3d_export

$5

hot air balloon

...hot air balloon

3dexport

hot air balloon

3d_export

free

Hot dog shop

...hot dog shop

3dexport

hot dog shop

turbosquid

$90

hot venue

...rbosquid

royalty free 3d model hot venue for download as fbx on turbosquid: 3d models for games, architecture, videos. (1336949)

turbosquid

$20

Hot Rod

...

turbosquid

royalty free 3d model hot rod for download as ma on turbosquid: 3d models for games, architecture, videos. (1351690)

turbosquid

$14

Hot Pepper

...bosquid

royalty free 3d model hot pepper for download as obj on turbosquid: 3d models for games, architecture, videos. (1611643)

turbosquid

$1

Hot dog

...turbosquid

royalty free 3d model hot dog for download as max on turbosquid: 3d models for games, architecture, videos. (1450961)

End

archibase_planet

free

Cigarettes end

...d

archibase planet

cigarettes end cigarette stub cigar-butt

cigarette-end - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

turbosquid

$10

End Table

...rbosquid

royalty free 3d model end table for download as max on turbosquid: 3d models for games, architecture, videos. (1570610)

turbosquid

$5

End Table

...urbosquid

royalty free 3d model end table for download as ma on turbosquid: 3d models for games, architecture, videos. (1622809)

turbosquid

$3

End Table

...rbosquid

royalty free 3d model end table for download as fbx on turbosquid: 3d models for games, architecture, videos. (1315115)

3d_export

$5

rope end ring

...rope end ring

3dexport

rope end ring

turbosquid

$2

End Tables

...

royalty free 3d model end tables for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1706896)

turbosquid

$14

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1403051)

turbosquid

$12

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1574707)

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)