Thingiverse

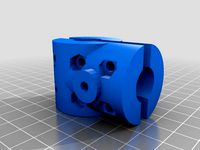

Electric Knuckle Coupler for Garden Railway G scale by dagnall53

by Thingiverse

Last crawled date: 3 years ago

Edit Oct 2017: after a lot of revisions, I have a much better design with a Moving Knuckle now working:https://www.thingiverse.com/thing:2553019

This has significant advantage that the servo is not actively holding the knuckle closed.

I have also updated the main knuckle coupling geometry so that the 'other' couplings are now all single piece. Unfortunately the revised geometry of the coupling means that it is not fully compatible with this original hook design.

Edit 30 May 2017 .. Getting a bit fustrated with this design.. Since changing to push capable knuckles, I have realised that the servo is underpowered. It is not strong enough to actually open the couplings and release.. I am still working on the concept, but please do not think this design is 'proven' ..

EDIT 28 Feb 2017: Modified the knuckle to be "push capable", in line with my revised push capable knuckle coupler. http://www.thingiverse.com/thing:1989545

Use the new "Push capable" knuckle and tang STL's in place of the old ones.

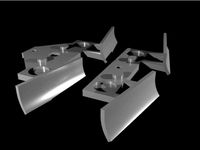

This is the electric version of my LGB remix of Raby's Knuckle Coupling.

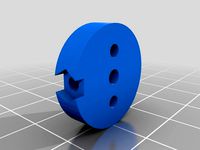

It uses a slightly modified version of the knuckle and tang, which have a small detent added to make the knuckle actively open when the servo drives back a wire armature.

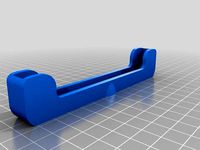

The Armature is the most difficult part to make and is quite critical to the operation. I made mine of 1mm spring steel wire, which was difficult to bend precisely. I designed a small jig to make bending easier, and photos of how it was intended to be used are included.

Once bent, the key thing is to fit it, and check that it moves smoothly. It shoud be fitted to the "lowest" of the three holes on the servo arm, and the top of the servo arm will need to be cut off so it has enough room to move.

All parts will need some filing for smooth operation. The Motor Clap parts need to be glued (use acetone) to the Main Body. There is also a small knuckle part that needs to be glued to the bottom of the knuckle.

Assemble the tang first into the main housing, and then slide in the knuckle.

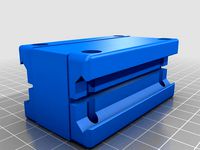

The assembly can then be fitted to the loco. The front coupling on the LGB Stainz has a deeper "front plate", and if you do not want to modify your model, you will have to use the "Stainz Front" variants of the motor clamp, Bottom housing and Main housing". This version has an extra cut out that allows it to fit, but you will have to do some filing to make sure the Tang and Knuckle can move freely.

Once you have the Armature nice and square (note: this is difficult) then fit it to the servo.

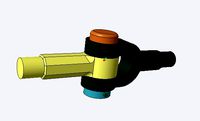

The servo then slides into the bottom housing, and the "front tabs" on the servo pcb should just be retained under some notches in the housing. The "back" of the servo, where the wires are, will sit down into a small recess. Bend the servo wires under the housing, and put some sticky tape on the. This will (should!) allow you to hold the box without the servo falling out.

Fit the main housing to the Loco, making sure that the knuckle and tang can move freely.

Then fit the "bottom housing", making sure that the Armature slides cleanly through the slots and is correctly engaged with the springs on the Tang and Knuckle. It is helpful at this stage if the servo is connected to a servo tester so you can check for free movement and operation.

Finally fit the two 1.7mm by 10mm screws and you should be finished.

https://youtu.be/sStIJU6A8bE

This has significant advantage that the servo is not actively holding the knuckle closed.

I have also updated the main knuckle coupling geometry so that the 'other' couplings are now all single piece. Unfortunately the revised geometry of the coupling means that it is not fully compatible with this original hook design.

Edit 30 May 2017 .. Getting a bit fustrated with this design.. Since changing to push capable knuckles, I have realised that the servo is underpowered. It is not strong enough to actually open the couplings and release.. I am still working on the concept, but please do not think this design is 'proven' ..

EDIT 28 Feb 2017: Modified the knuckle to be "push capable", in line with my revised push capable knuckle coupler. http://www.thingiverse.com/thing:1989545

Use the new "Push capable" knuckle and tang STL's in place of the old ones.

This is the electric version of my LGB remix of Raby's Knuckle Coupling.

It uses a slightly modified version of the knuckle and tang, which have a small detent added to make the knuckle actively open when the servo drives back a wire armature.

The Armature is the most difficult part to make and is quite critical to the operation. I made mine of 1mm spring steel wire, which was difficult to bend precisely. I designed a small jig to make bending easier, and photos of how it was intended to be used are included.

Once bent, the key thing is to fit it, and check that it moves smoothly. It shoud be fitted to the "lowest" of the three holes on the servo arm, and the top of the servo arm will need to be cut off so it has enough room to move.

All parts will need some filing for smooth operation. The Motor Clap parts need to be glued (use acetone) to the Main Body. There is also a small knuckle part that needs to be glued to the bottom of the knuckle.

Assemble the tang first into the main housing, and then slide in the knuckle.

The assembly can then be fitted to the loco. The front coupling on the LGB Stainz has a deeper "front plate", and if you do not want to modify your model, you will have to use the "Stainz Front" variants of the motor clamp, Bottom housing and Main housing". This version has an extra cut out that allows it to fit, but you will have to do some filing to make sure the Tang and Knuckle can move freely.

Once you have the Armature nice and square (note: this is difficult) then fit it to the servo.

The servo then slides into the bottom housing, and the "front tabs" on the servo pcb should just be retained under some notches in the housing. The "back" of the servo, where the wires are, will sit down into a small recess. Bend the servo wires under the housing, and put some sticky tape on the. This will (should!) allow you to hold the box without the servo falling out.

Fit the main housing to the Loco, making sure that the knuckle and tang can move freely.

Then fit the "bottom housing", making sure that the Armature slides cleanly through the slots and is correctly engaged with the springs on the Tang and Knuckle. It is helpful at this stage if the servo is connected to a servo tester so you can check for free movement and operation.

Finally fit the two 1.7mm by 10mm screws and you should be finished.

https://youtu.be/sStIJU6A8bE

Similar models

grabcad

free

LGB Knuckle Couplings

...k with different lgb bodies to avoid having to cut the coach/wagon /loco bodywork. i use the middle one for my 3d printed wagons.

thingiverse

free

Knuckle Coupler for LGB by dagnall53

...push them down firmly in the housings. it has similar "push" performance to the two part version and they...

grabcad

free

Servo operated Knuckle Coupling

...quire less filing, and the main coupling has been moved 1.2mm laterally to make for better alignment when coupling on the track.

thingiverse

free

Servo Operated Knuckle Coupling by dagnall53

...b housings. these are here: https://www.thingiverse.com/thing:1989545

chose the housing that works best for your truck/coach etc.

thingiverse

free

Revised G Scale LGB Servo Coupling by dagnall53

...ted to the loco. the photos on my older design (https://www.thingiverse.com/thing:398423) show the assembly process quite nicely.

grabcad

free

Revised Hook and Loop decoupler for LGB

...ve moved to my knuckle coupling .

i provide this file for anyone who can improve the design!. please let me know if you succeed!

thingiverse

free

Hudson Tipper railway truck. (new hubs) by dagnall53

...ginal versions.

may 2015 i have added stefan's hubs to the files.(see http://www.thingiverse.com/make:125279) thanks stefan!.

thingiverse

free

LGB Stainz spare parts by illust

...are parts for the lgb stainz locomotive. the handle next to the door comes with a special version with support for a sla printer.

thingiverse

free

Axial SCX10 Front Servo Bumper (Shortened Remix)

...rward to make room for my front mounted motor.

i have not printed this yet but will update when i do to confirm fit and function.

thingiverse

free

SG90 Servo Case by renzema

...m for drilling.

there are channels in the case and bottom for the servo wire.

fit for the servo into the base is by friction only

Dagnall53

thingiverse

free

5SCased tripod mount by dagnall53

...53

thingiverse

just a remix, slightly larger housing to take a cased 5s

included the 123d file so its easier to remix next time!

thingiverse

free

Walker Type Nautical Log by dagnall53

...lacement. designed to give approximately 20,000 pulses per nautical mile.

must be calibrated by user before any navigational use!

thingiverse

free

Catalac 8m Catamaran Cruiser Boat by dagnall53

...rawn originally in softfx, but the stl is unfortunately not printable as it is.

feel free to adapt to improve and make printable.

thingiverse

free

Points Servo Drive (Train track) by dagnall53

... spring mechanism allows the trains to push past "closed" points without derailing.

video: http://youtu.be/xdbzoc0kwsc

thingiverse

free

Man with CAP 1:32 scale by dagnall53

...n guard for a 1:32 scale railway.

supports to help print were made in meshmixer, so it should print "without supports".

thingiverse

free

Ticket Office and WHS Kiosk by dagnall53

...ches) and two servo drives to drive points at the station. the code is available here https://github.com/dagnall53/espwifirocnet

thingiverse

free

Dimension test for coach side part of couplings by dagnall53

...://www.thingiverse.com/thing:1000218

but has not been built or tested and would need some tidying up to work as a coach coupling.

thingiverse

free

G scale Re-Railer by dagnall53

... the re-railer bottom surface.

i have attached the 123d file so you can modify the design if your railway does not use lgb locos.

thingiverse

free

Magnetic electrical connector for LGB Carriages and Trains by dagnall53

...ave used this to couple power from the engine to light the carriages without having to have track brushes on the carriage wheels.

thingiverse

free

G scale arch by dagnall53

...id not get all the "bricks" perfectly, but it looks good when painted with sandstone type paints. feel free to modify!

Knuckle

3d_export

$20

Knuckles

...knuckles

3dexport

knuckles

3ddd

$1

Сlassic Knuckles

...s

3ddd

sonic , knuckles , sega

сlassic knuckles

3d_export

$5

iron knuckle

...iron knuckle

3dexport

a classic iron knuckle.

3d_export

$5

knuckle joint

...knuckle joint

3dexport

this is a 3d model of knuckle joint

3d_export

$5

Knuckle Joint

...knuckle joint

3dexport

industry use knuckle joint

turbosquid

$19

Knuckle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$2

Knuckle dusters

...pplied. it comes in obj/blend/dae/fbx formats, all of which are ready to import and render. check out my other cool stuff. enjoy!

turbosquid

$10

Knuckle-Knife

...id

royalty free 3d model knuckle-knife for download as blend on turbosquid: 3d models for games, architecture, videos. (1177912)

turbosquid

$1

Brass Knuckles

...uid

royalty free 3d model brass knuckles for download as fbx on turbosquid: 3d models for games, architecture, videos. (1484405)

turbosquid

$1

brass knuckles

...ty free 3d model brass knuckles for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1474385)

Coupler

turbosquid

$5

Jet ski coupler

...ee 3d model jet ski coupler for download as 3ds, 3dm, and stl on turbosquid: 3d models for games, architecture, videos. (1190218)

3d_export

$25

Scaffold 3D Model

...scaffolding modular aluminium ladder work platform building painting tube coupler construction max game low poly detailed uv scaffold 3d...

cg_studio

$29

Scaffold3d model

...scaffolding modular aluminium ladder work platform building painting tube coupler construction max game low poly detailed uv .obj .max...

3d_ocean

$25

PC Case

...3d audio blu-ray button card case cd computer conector coupler detailed dvd dvi electronics fan hd hdmi internet microphone...

3d_export

$199

AS15 - Mini Skid Steer - Loader Bucket

...arm<br>loader bucket<br>main body - a<br>main body - b<br>plastic parts<br>quick couplerlt;br>rear tire - left<br>rear tire - right<br>rear wheel - left<br>rear...

thingiverse

free

coupler by Curiositie

...coupler by curiositie

thingiverse

picatinny coupler

thingiverse

free

coupler by ratpog

...coupler by ratpog

thingiverse

coupler-comment for dimensions

thingiverse

free

Coupler by alexander111

...coupler by alexander111

thingiverse

two sided heavy duty coupler

thingiverse

free

Coupler by RoboticArts

...coupler by roboticarts

thingiverse

coupler of the robot made by robotic arts.

3dfindit

free

Coupler

...coupler

3dfind.it

catalog: abb installation products

Railway

archibase_planet

free

Railway

...tact wire railroad contact wire railway line

railway contact wire n210814 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$9

railway stations

...railway stations

3dexport

railway stations<br>сollection of four railway stations.

turbosquid

$10

Railway

...yalty free 3d model railway for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1283992)

turbosquid

$29

railway

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

railway tank

...railway tank

3dexport

low-poly railway tank model

3d_export

$65

railway

...railway

3dexport

simple rendering of the scene file

3d_export

$65

railway

...railway

3dexport

simple rendering of the scene file

3d_export

$65

railway

...railway

3dexport

simple rendering of the scene file

3d_export

$65

railway

...railway

3dexport

simple rendering of the scene file

3d_export

$65

railway

...railway

3dexport

simple rendering of the scene file

G

3ddd

free

G. Moscatelli

...алка

вешалка 25 / 26 / 27коллекция: belle heleneбренд: g. moscatelliстрана: италияразмеры: высота - 190 / 195; диаметр - 50 / 60.

3ddd

$1

G Plan Vintage

...g plan vintage

3ddd

винтаж , g plan

g plan vintage armchair

turbosquid

free

G protein

...otein

turbosquid

free 3d model g protein for download as c4d on turbosquid: 3d models for games, architecture, videos. (1309660)

turbosquid

$14

Fence G

...turbosquid

royalty free 3d model fence g for download as fbx on turbosquid: 3d models for games, architecture, videos. (1310122)

turbosquid

$7

G for Gun

...rbosquid

royalty free 3d model g for gun for download as max on turbosquid: 3d models for games, architecture, videos. (1685215)

turbosquid

$5

G Ring

...

turbosquid

royalty free 3d model g ring for download as stl on turbosquid: 3d models for games, architecture, videos. (1285079)

turbosquid

$5

Letter G

...urbosquid

royalty free 3d model letter g for download as max on turbosquid: 3d models for games, architecture, videos. (1408463)

turbosquid

$5

Letter g

...urbosquid

royalty free 3d model letter g for download as max on turbosquid: 3d models for games, architecture, videos. (1408408)

3ddd

$1

Infiniti / G-Chair

...infiniti / g-chair

3ddd

infiniti

www.infinitidesign.it/ita/g-chair.php

3ddd

$1

кресло G-68

...кресло g-68

3ddd

кресло

кресло руководителя g-68

Electric

3d_export

$5

Electric pole

...electric pole

3dexport

electric pole for street, electricity line

3ddd

$1

electric mixer

...electric mixer

3ddd

electric mixer , миксер

electric mixer

3ddd

$1

electrical installation

...electrical installation

3ddd

electrical installation , розетка

electrical installation

turbosquid

$19

The electric water heater electric

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Electrical Outlet electric splitter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$20

Electric Guitar

...electric guitar

3docean

electric electric guitar guitar music music instrument

model of a electric guitar created in maya.

3d_ocean

$12

Electric Shaver

...electric shaver

3docean

electric electric shaver hair removal personal care shaver shaving

electric shaver created in 3ds max.

3ddd

$1

electrical switch

...h

3ddd

electrical , розетка

electrical switch from bticino company

series livinglight

3d_export

$7

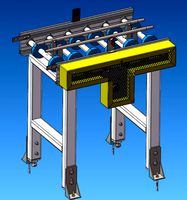

Electric Conveyor

...electric conveyor

3dexport

electric conveyor

3d_export

$5

electric drums

...electric drums

3dexport

electric drums

Garden

3d_export

$18

garden-garden-tree 60

...garden-tree 60<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

3d_export

$18

garden-garden-tree 41

...garden-tree 41<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

3d_export

$18

garden-garden-tree 58

...garden-tree 58<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

3d_export

$18

garden-garden-tree 59

...garden-tree 59<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

3d_export

$18

garden-garden-tree 56

...garden-tree 56<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

3d_export

$18

garden-garden-tree 57

...garden-tree 57<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

turbosquid

$1

garden

...

turbosquid

royalty free 3d model garden for download as max on turbosquid: 3d models for games, architecture, videos. (1167978)

3d_export

$6

roof garden furniture seating and garden set

...roof garden furniture seating and garden set

3dexport

roof garden furniture seating and garden set

3d_export

$25

garden swing

...garden swing

3dexport

garden swing

3d_export

$12

Modern garden

...modern garden

3dexport

modern garden

Scale

turbosquid

$20

Weight scale or Bathroom Scale

...ght scale or bathroom scale for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1664576)

turbosquid

$19

Scale

...e

turbosquid

royalty free 3d model scale for download as fbx on turbosquid: 3d models for games, architecture, videos. (1411722)

turbosquid

$5

Scales

...s

turbosquid

royalty free 3d model scales for download as ma on turbosquid: 3d models for games, architecture, videos. (1393439)

turbosquid

$40

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$17

Scales

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

of scales

...s have a flat point of support. the samples are rendered in the standard cinema 4d renderer. enjoy your use and creative success.

3d_export

$5

scale knob

...scale knob

3dexport

scale knob

3d_export

$20

cartoon weight scale or bathroom scale

...cartoon weight scale or bathroom scale

3dexport

texture size:512px number of texture:1 texture format: png